Anchor rod transloading set

A unit and bolt technology, which is used in mining equipment, earth-moving drilling, underground transportation, etc., can solve the problem of not being able to adapt to the use of small-section tunnels in mines, and achieve the goal of shortening tunnel formation time, increasing support speed, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

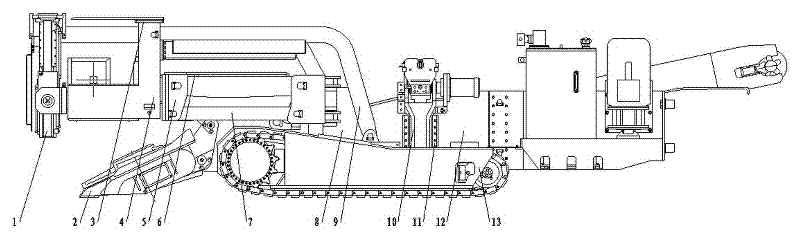

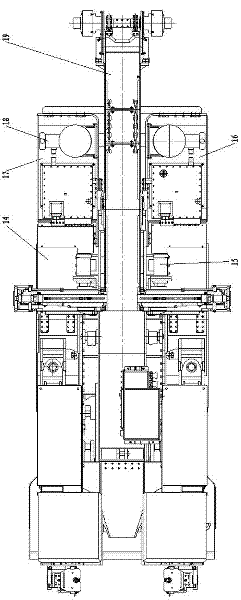

[0030] The present invention is mainly divided into 10 parts according to structure and function, which are respectively: chassis, reloading mechanism, conveyor, front anchor protection, lifting platform, rear anchor protection, pumping station, electrical system, hydraulic system, temporary support, etc. Its main technical parameters are shown in the table below:

[0031] .

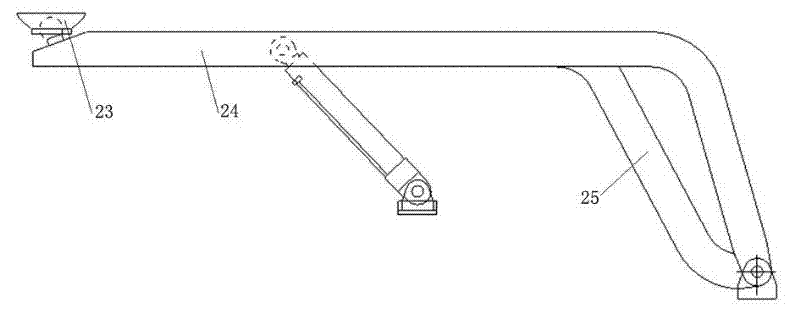

[0032] Specifically: the chassis includes the main frame, the left track frame, the right track frame and the tail frame. The tops of the left track frame and the right track frame are respectively equipped with lifting mechanisms. The workbench that can be fixed relative to it, the front part of the workbench is connected to the front anchor guard, and the two outer sides of the rear part of the main frame are respectively installed with rear anchor guards that can slide up and down relative to it and can be fixed relative to it. A temporary support that can rotate and be fixed relative to the left t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com