Patents

Literature

32results about How to "Increase support speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

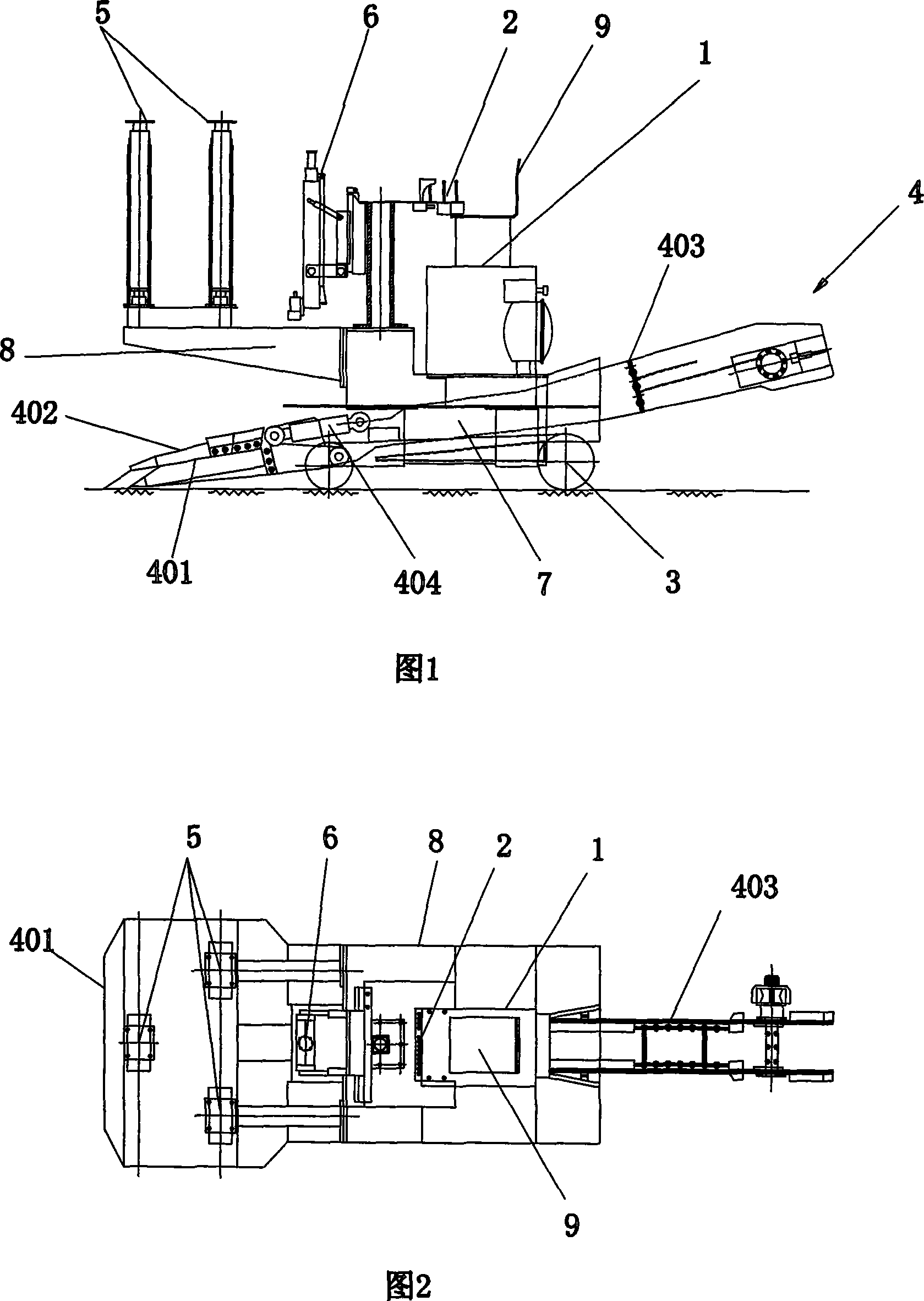

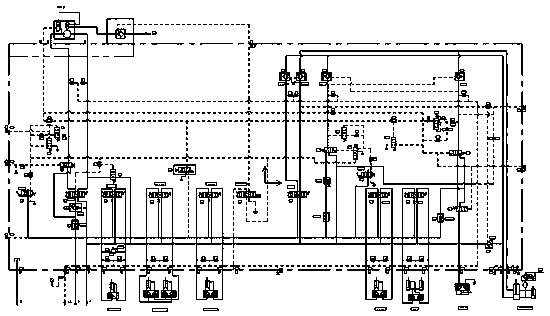

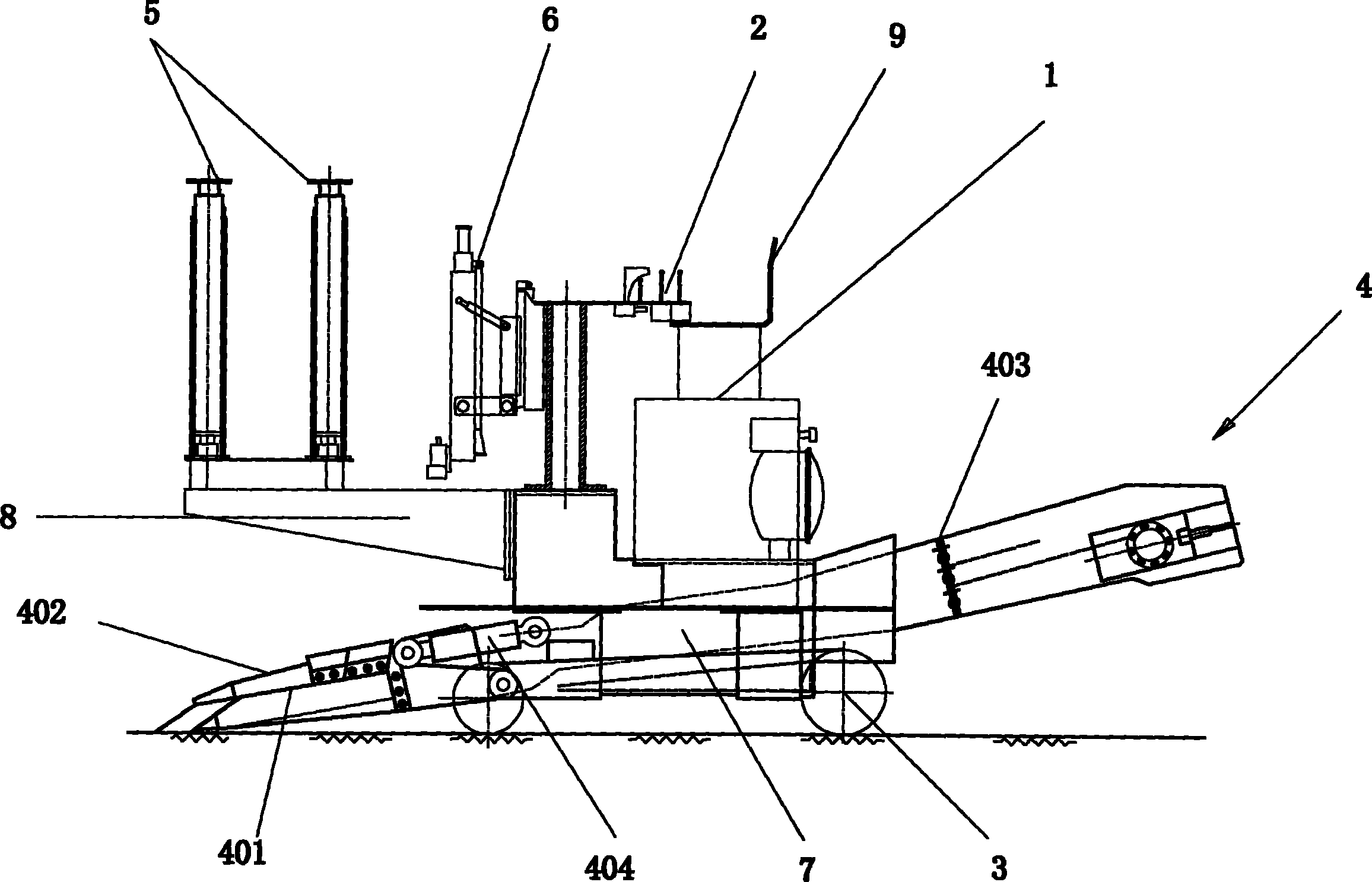

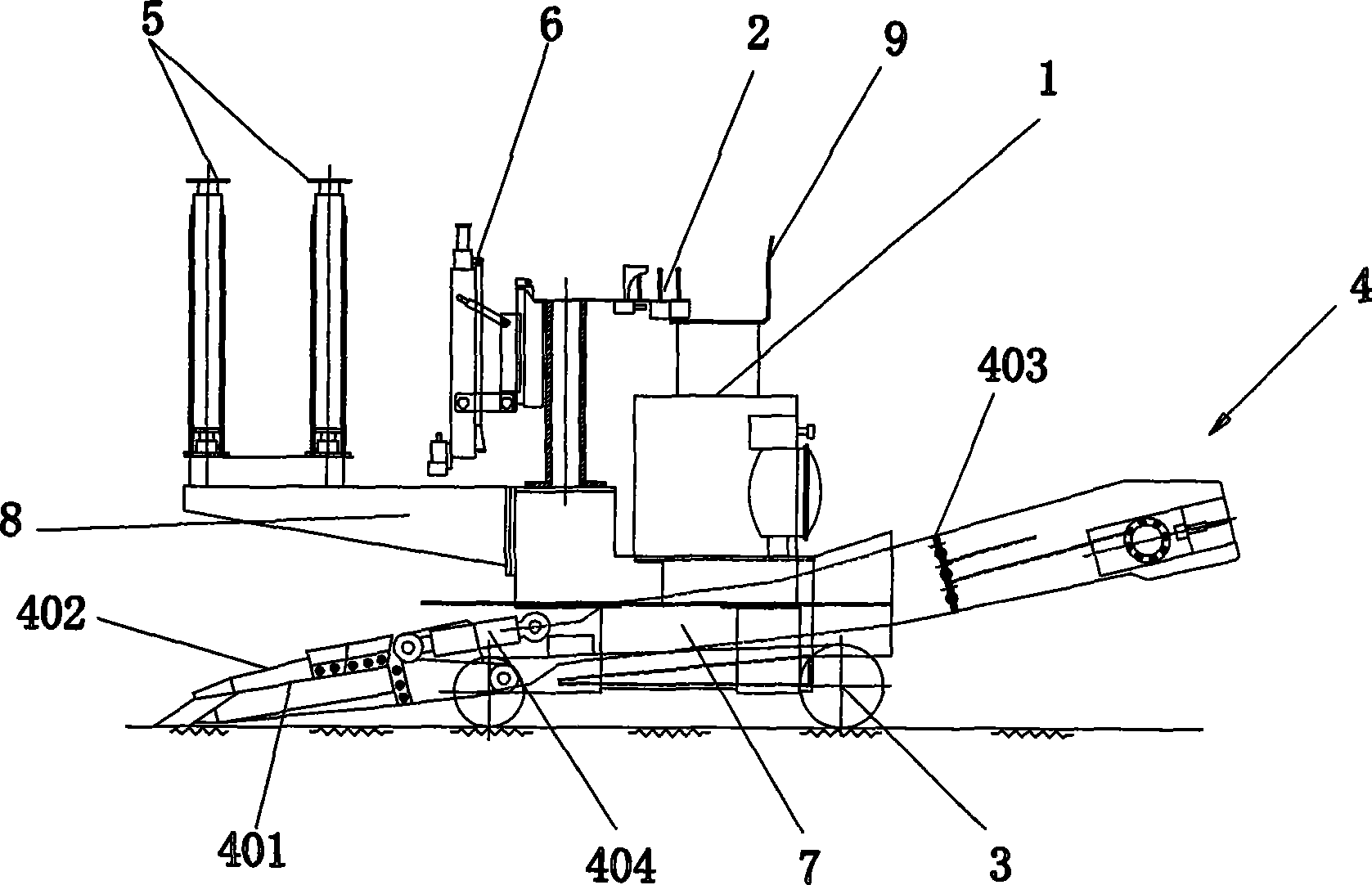

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

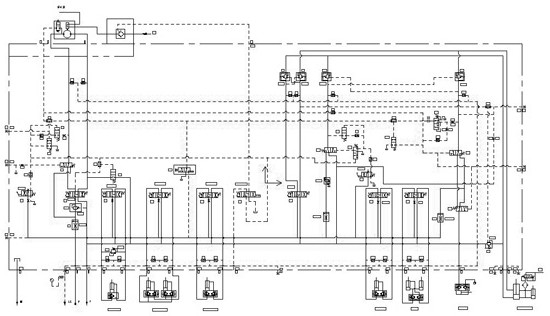

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

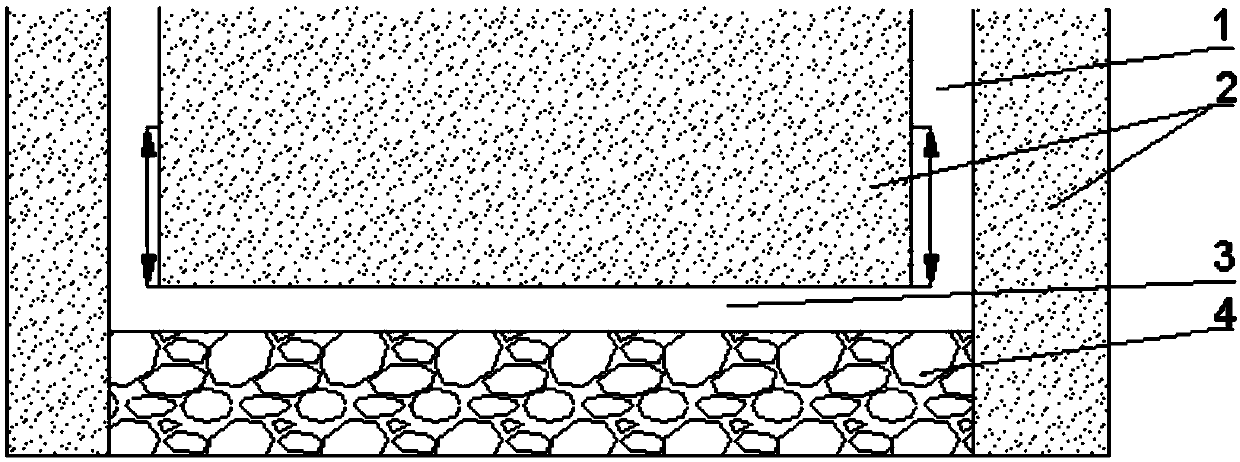

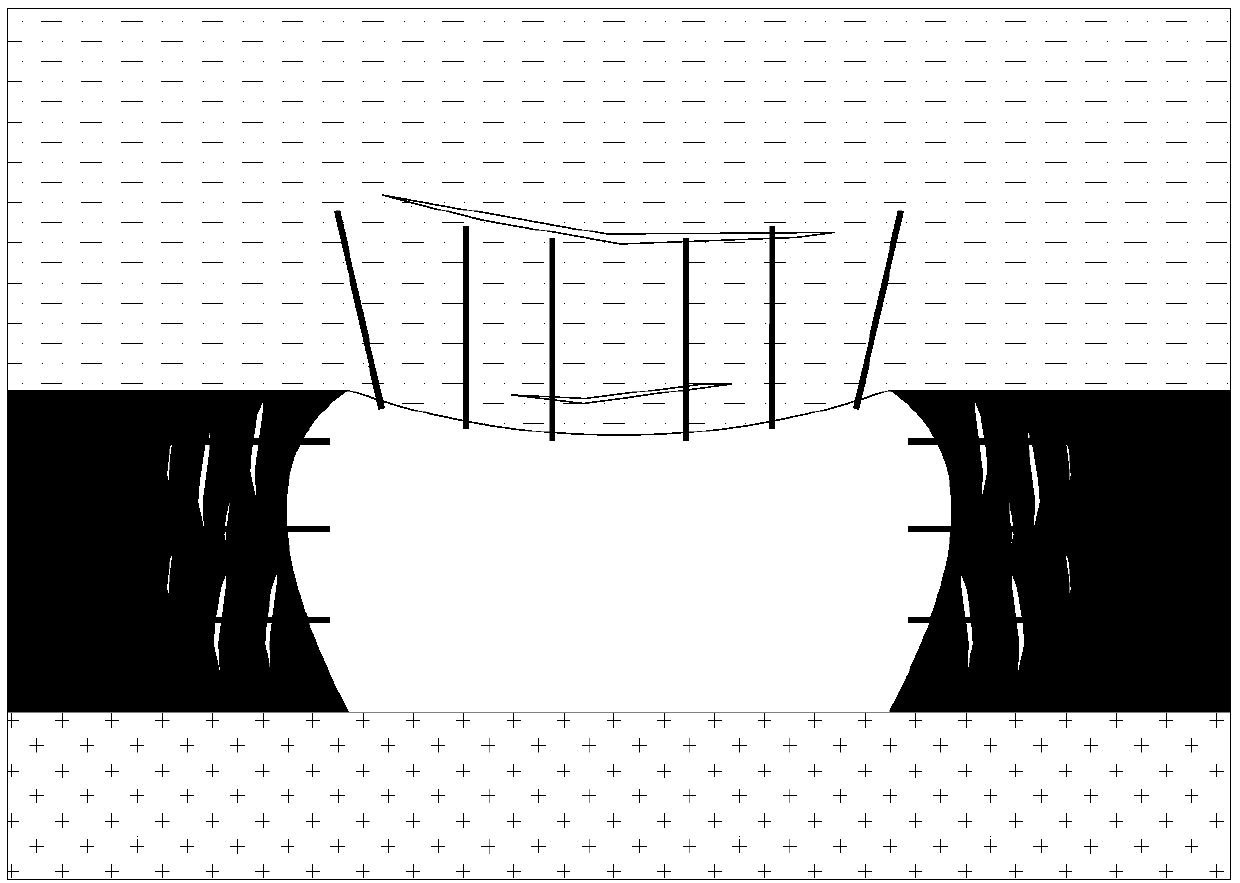

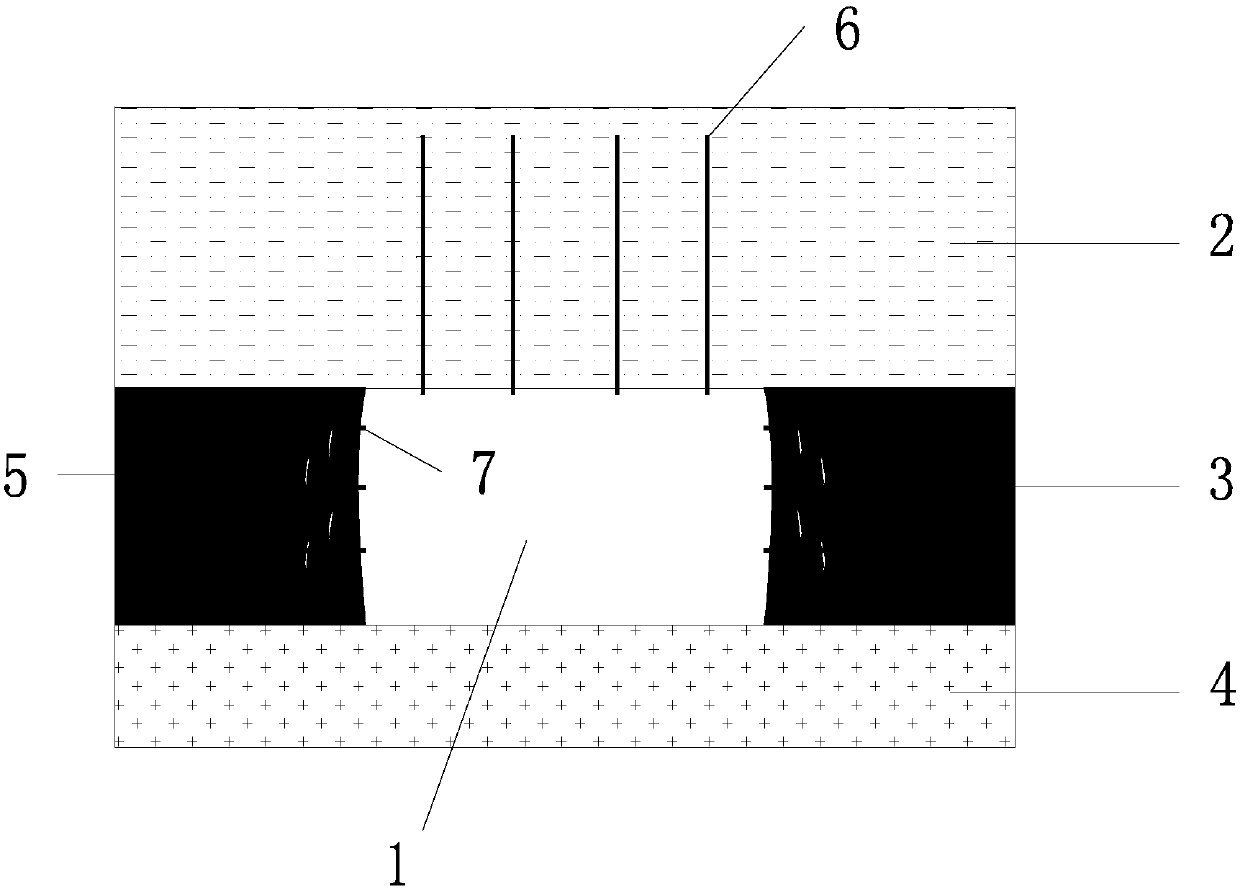

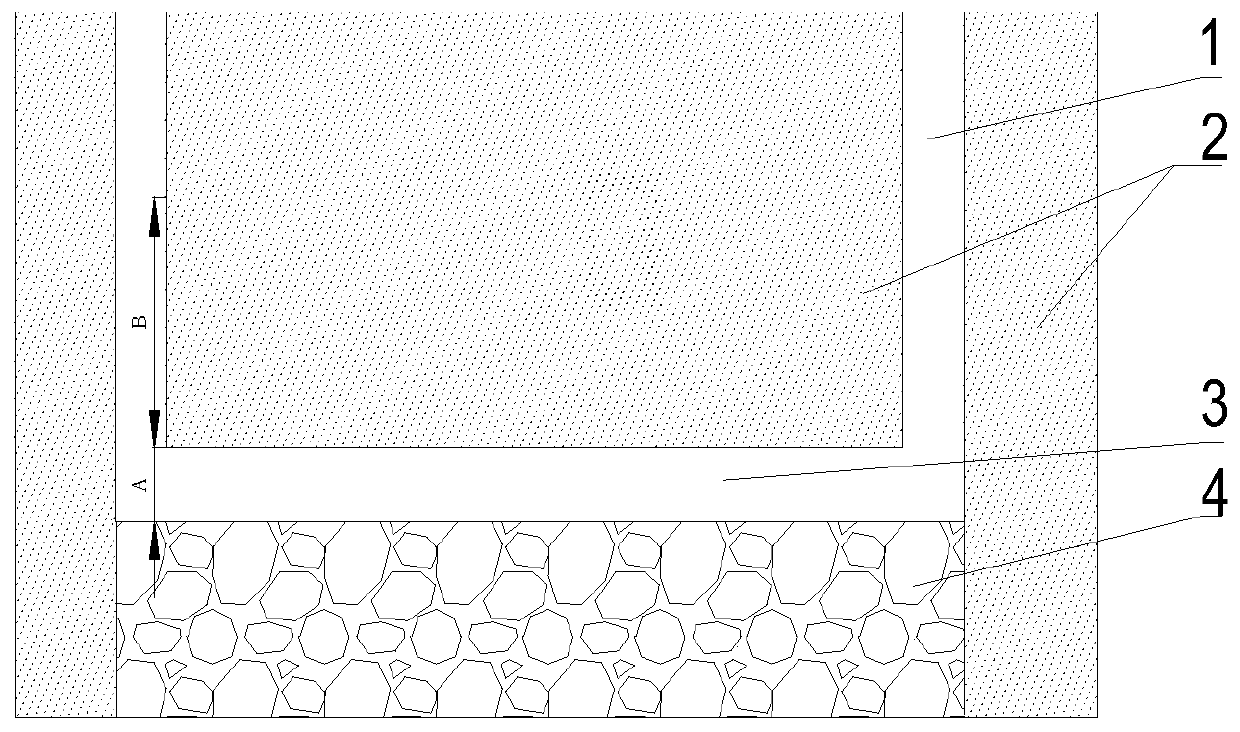

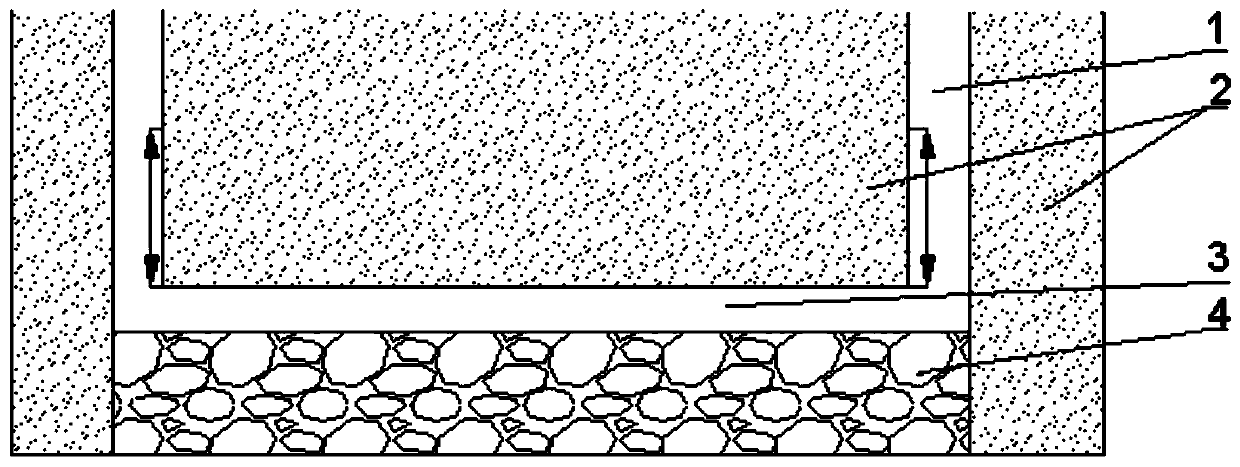

Grouting anchor cable advanced supporting method

ActiveCN109681248AIncrease support speedEasy to operateUnderground chambersTunnel liningCoal miningDistribution law

The invention relates to a grouting anchor cable advanced supporting method, belongs to the field of advanced supporting and aims at solving the problems of insufficient supporting strength and slow supporting speed in the prior art and roof breakage and large worker labor intensity caused by repeated supporting. The advanced supporting method disclosed by the invention comprises the following steps: step 1, determining a mining roadway (1) to be supported on a current working face (3); step 2, determining an advanced supporting distance L according to the advanced supporting pressure distribution law and the engineering geological condition of the mining roadway (1); step 3, adding grouting anchor cable advanced supporting to a roof of the mining roadway (1) to form a roof supporting structure. In a coal mining process, the working face (3) is propelled forwards, the grouting anchor cable advanced supporting is simultaneously and continuously added in the propelling direction, and theadvanced supporting distance is maintained in a safe range. The grouting anchor cable advanced supporting method disclosed by the invention can ensure safe mining and simultaneously improve supporting strength and supporting efficiency and reduce worker labor intensity.

Owner:CHINA UNIV OF MINING & TECH +2

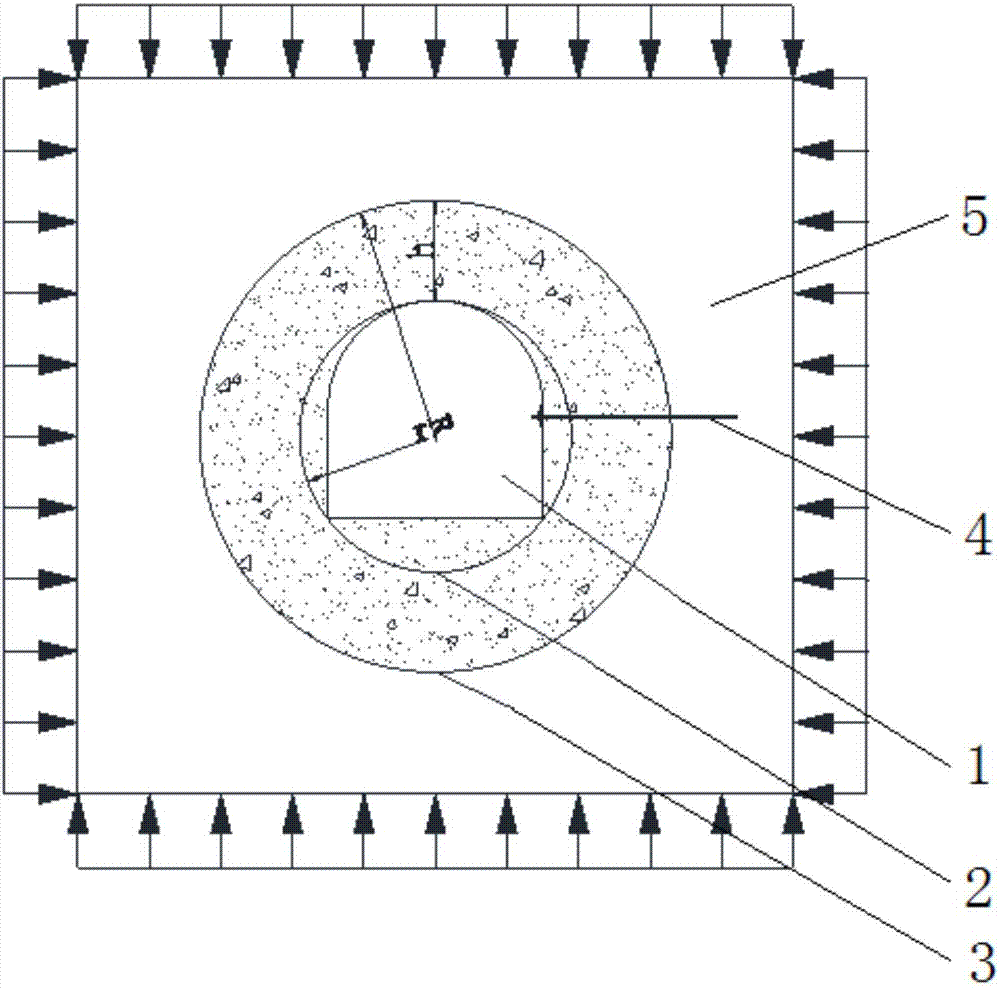

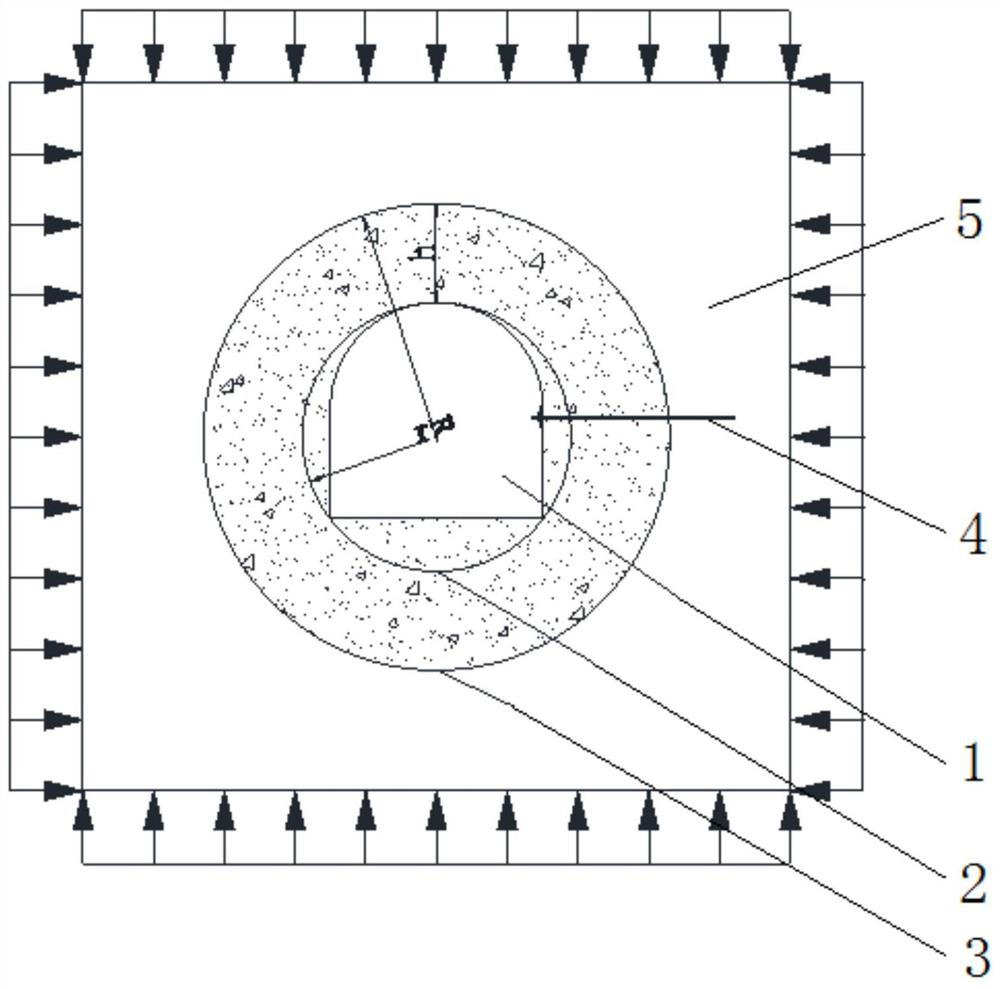

Length determining method for anchor rod for roadway supporting

ActiveCN107133381AControl deformationMeet the requirements of high productivity and high efficiencyGeometric CADSpecial data processing applicationsEngineeringMine safety

The invention discloses a length determining method for an anchor rod for roadway supporting. The length determining method includes the steps that according to the shape of a cross section of a roadway, a circumcircle of a contour line of the roadway is made; then an expansion concentric circle of the circumcircle is made according to the development depth of a surrounding-rock plastic zone, and parameters of the reasonable length of the anchor rod are obtained in the mode that the distance from the surface of the roadway to the expansion concentric circle of the plastic zone, the length that the anchor rod is anchored into hard-and-stable surrounding rock and the exposed length of the anchor rod are superposed. According to the length determining method, the process that the reasonable length of the anchor rod is determined is simple, operation is convenient, the accuracy is high, materials of a rod body of the anchor rod are saved, waste is avoided, the construction speed of drilling is increased, the labor strength of workers is reduced, the surrounding-rock control efficiency of the anchor rod is improved, and the favorable condition is provided for mine safety production.

Owner:CHINA UNIV OF MINING & TECH

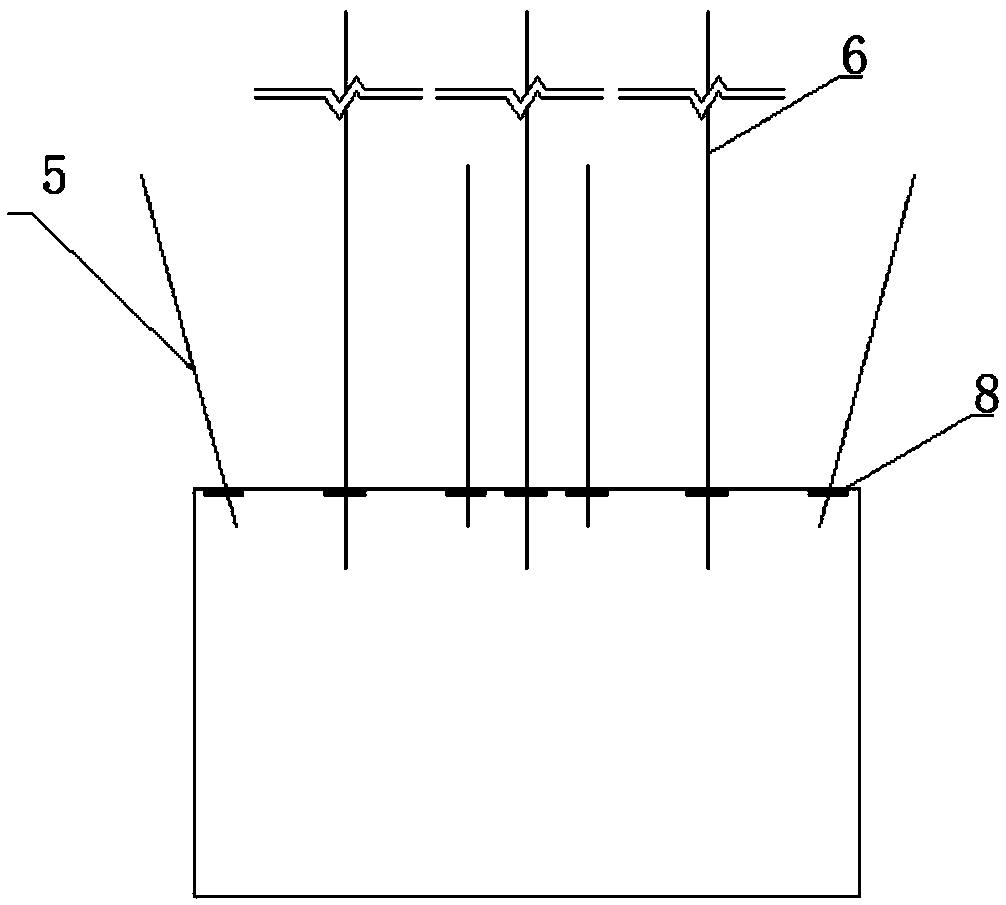

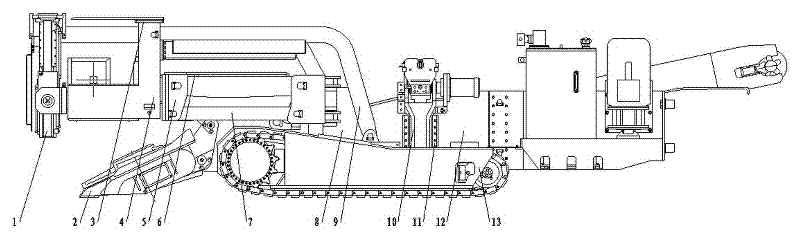

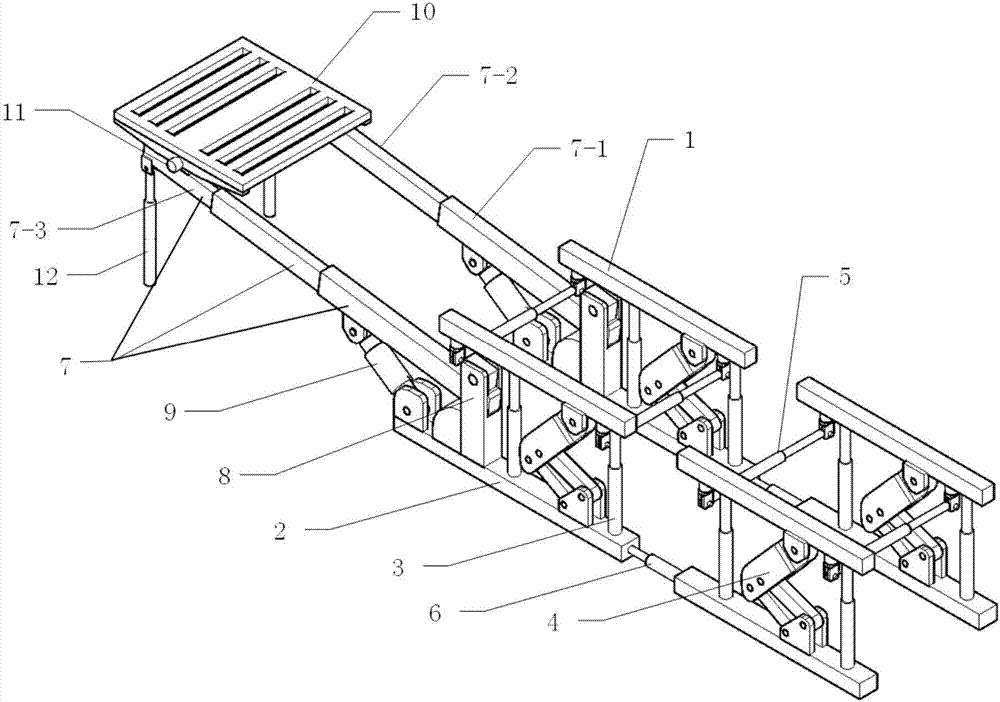

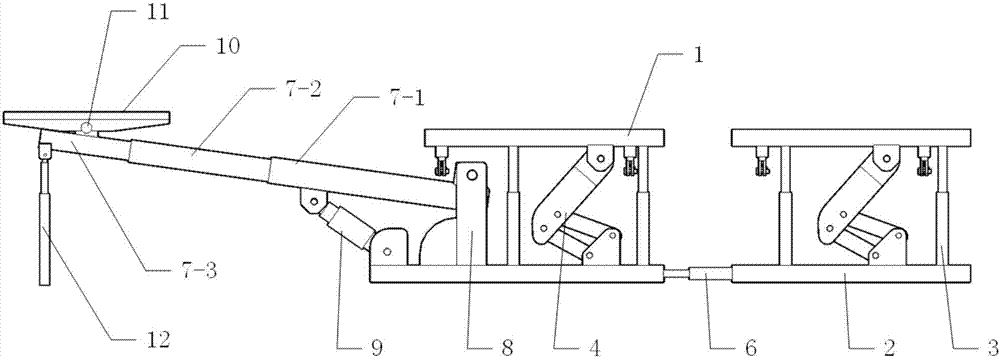

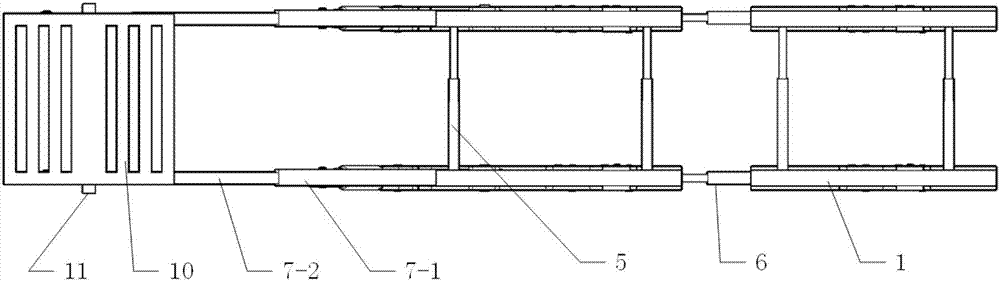

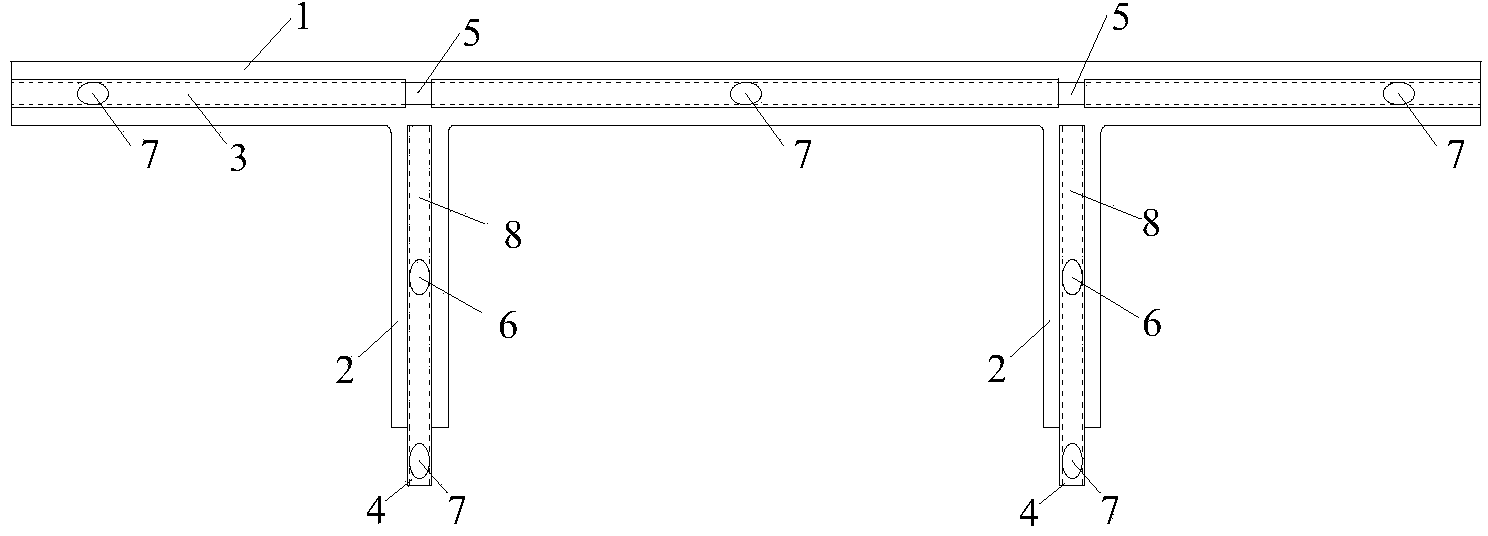

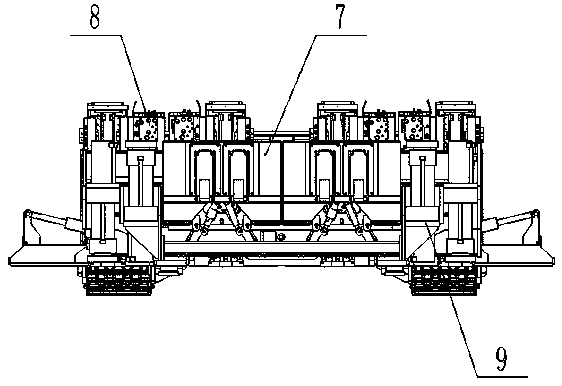

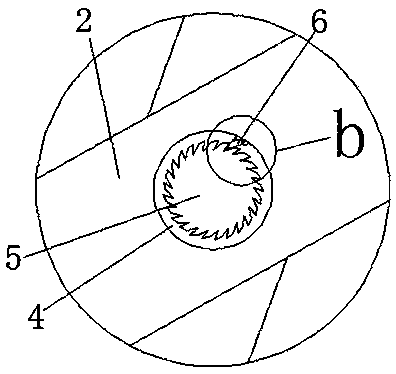

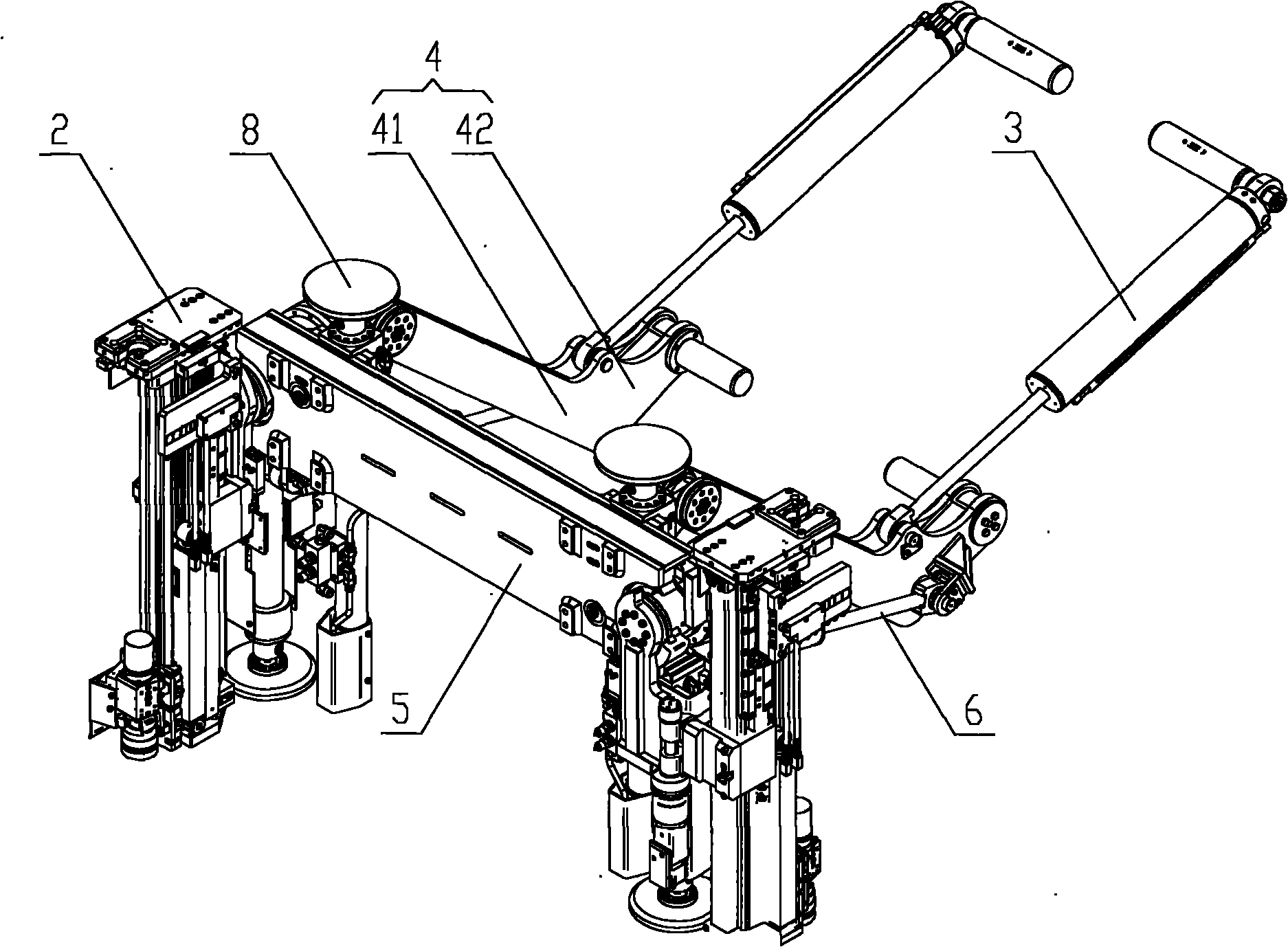

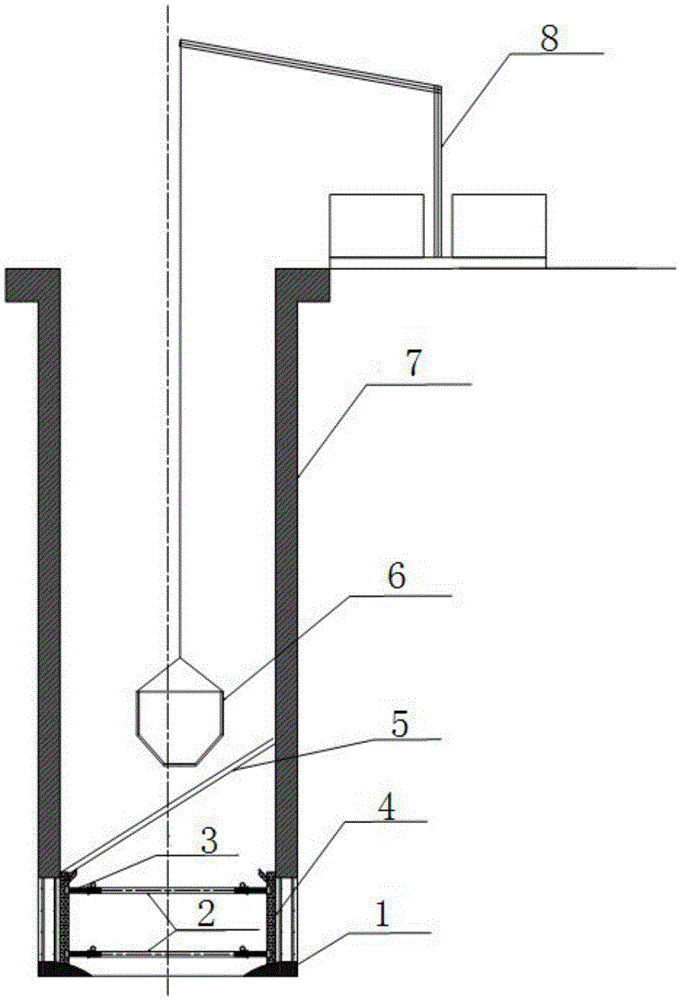

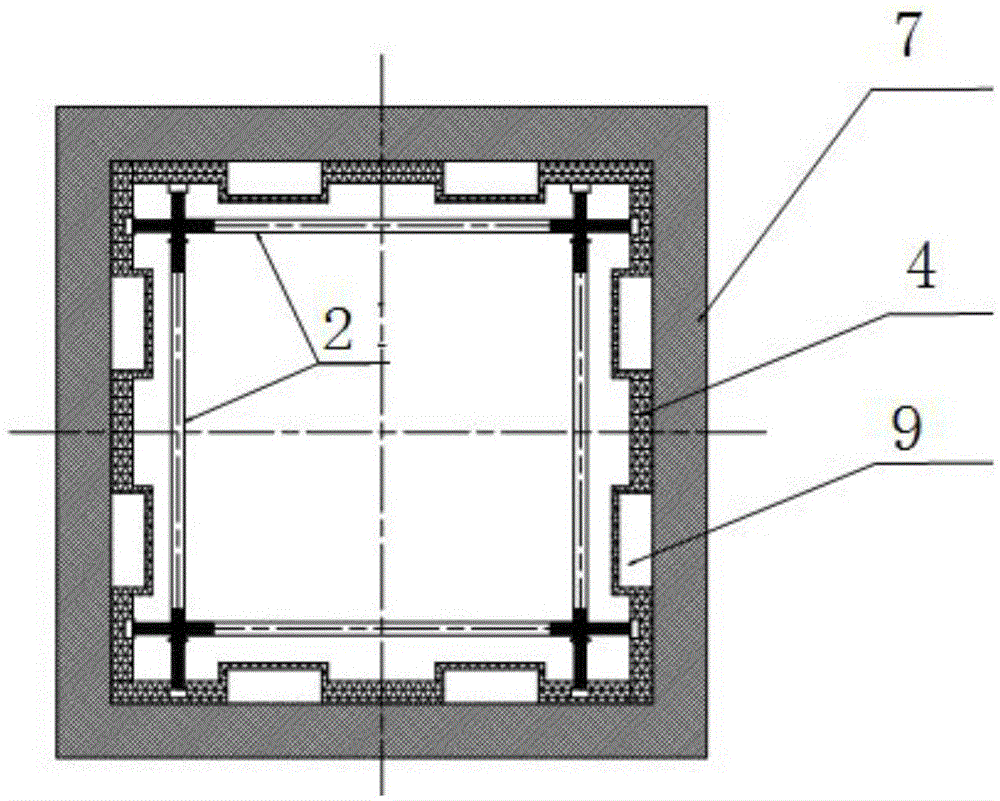

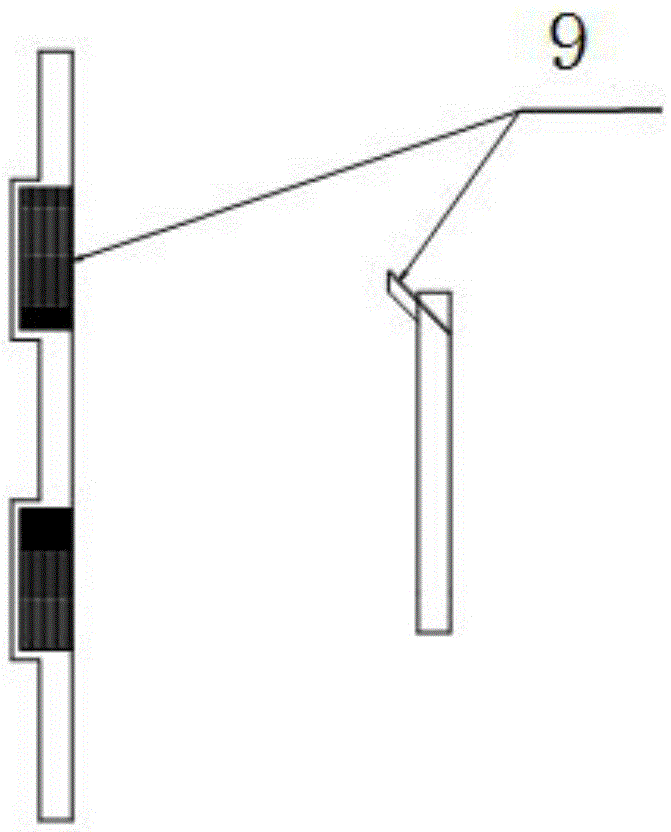

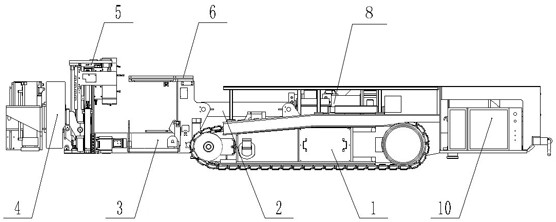

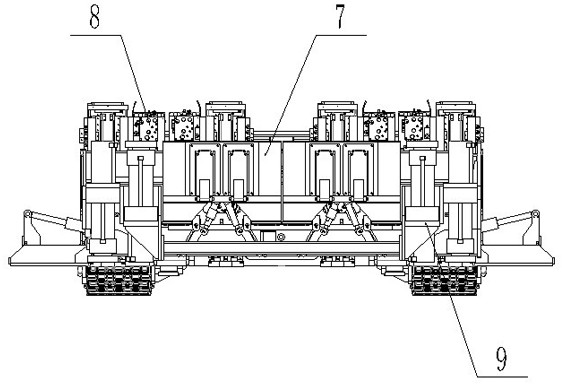

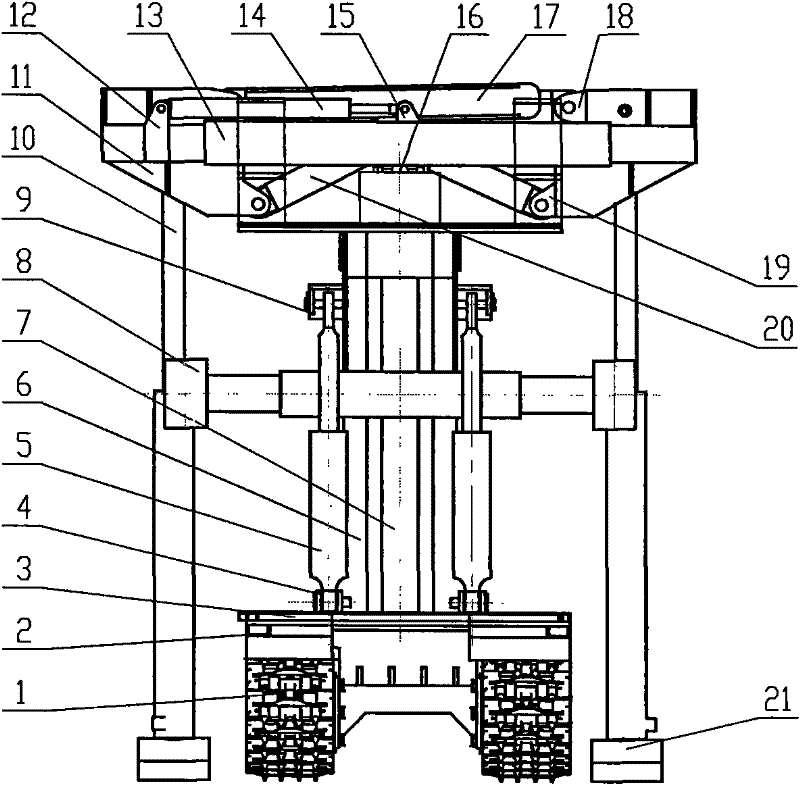

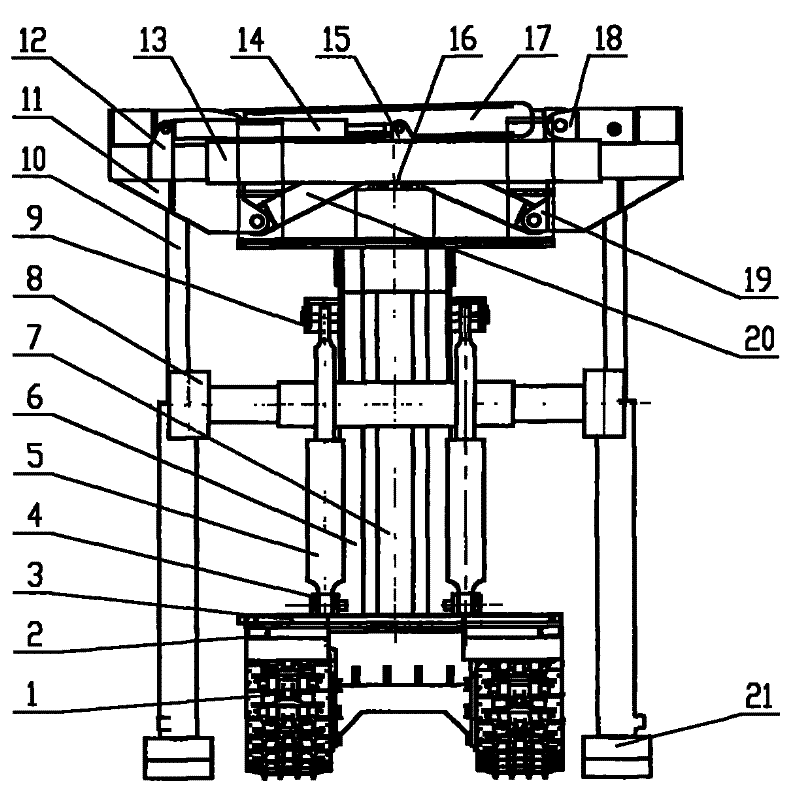

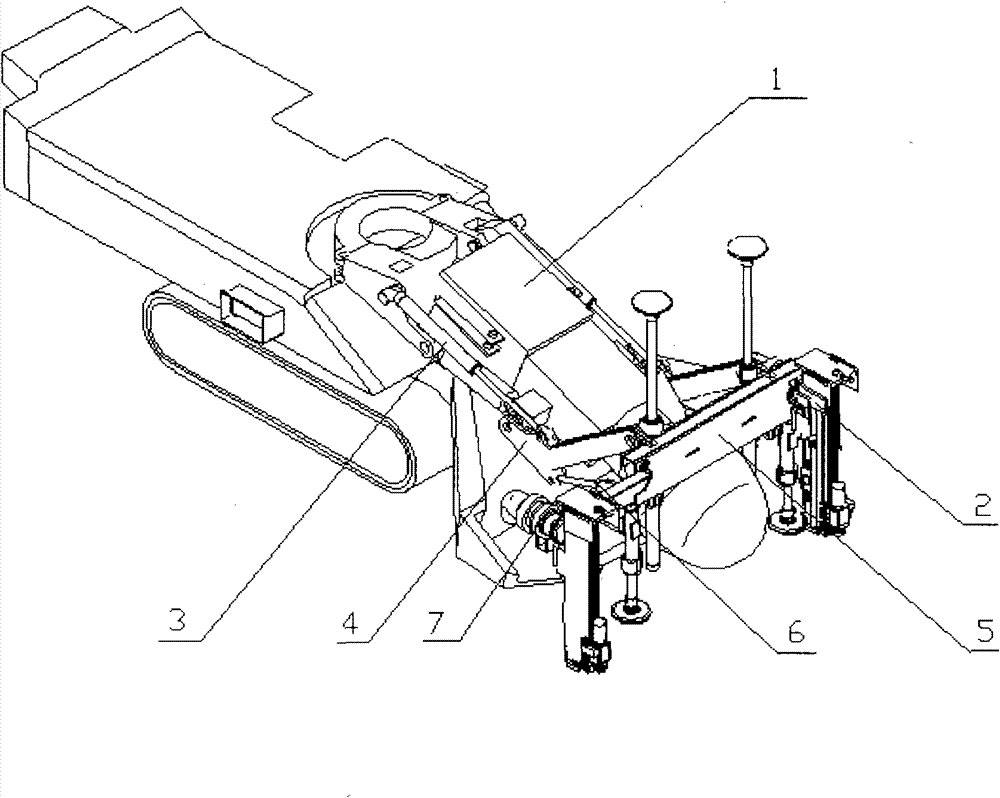

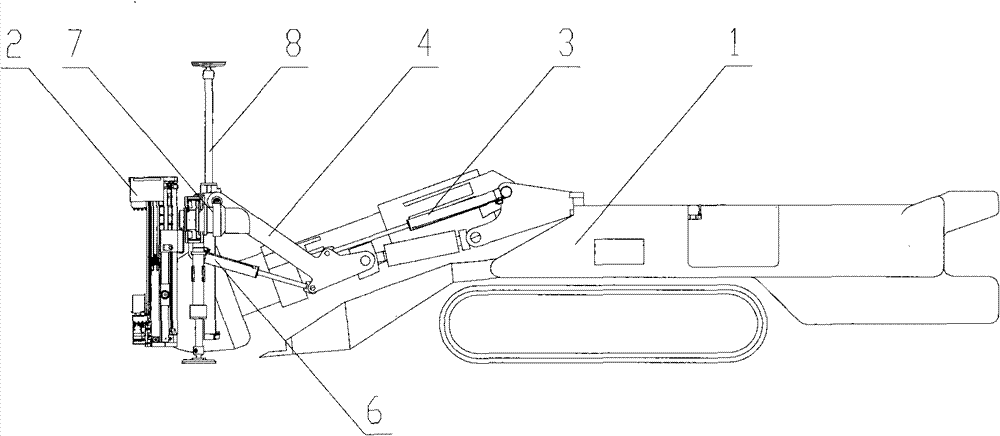

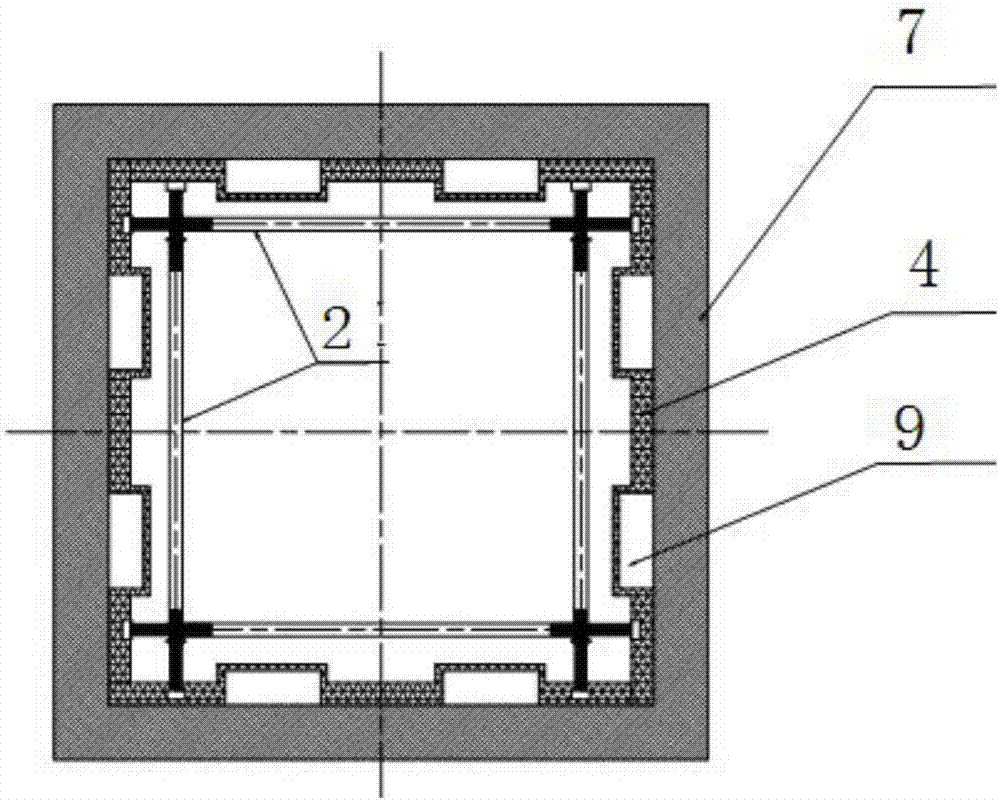

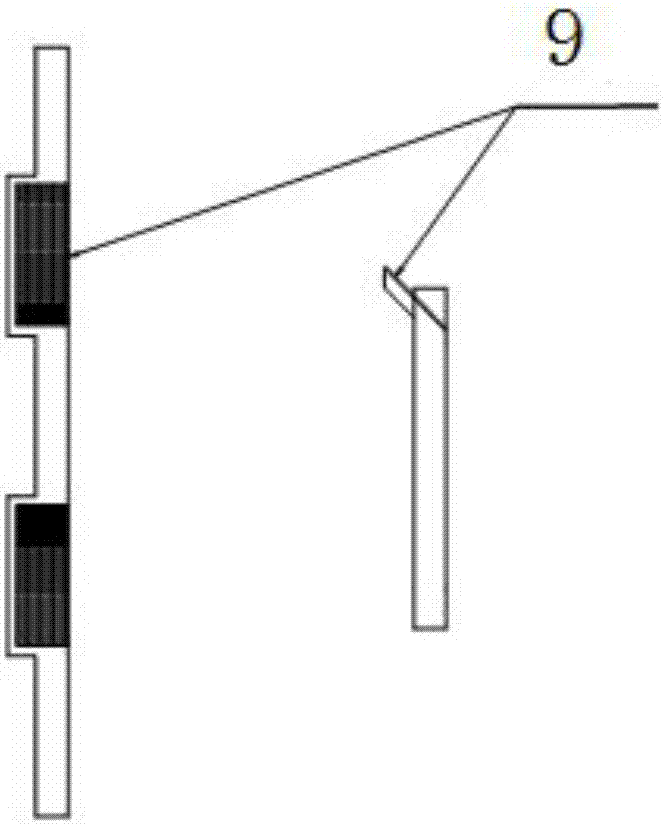

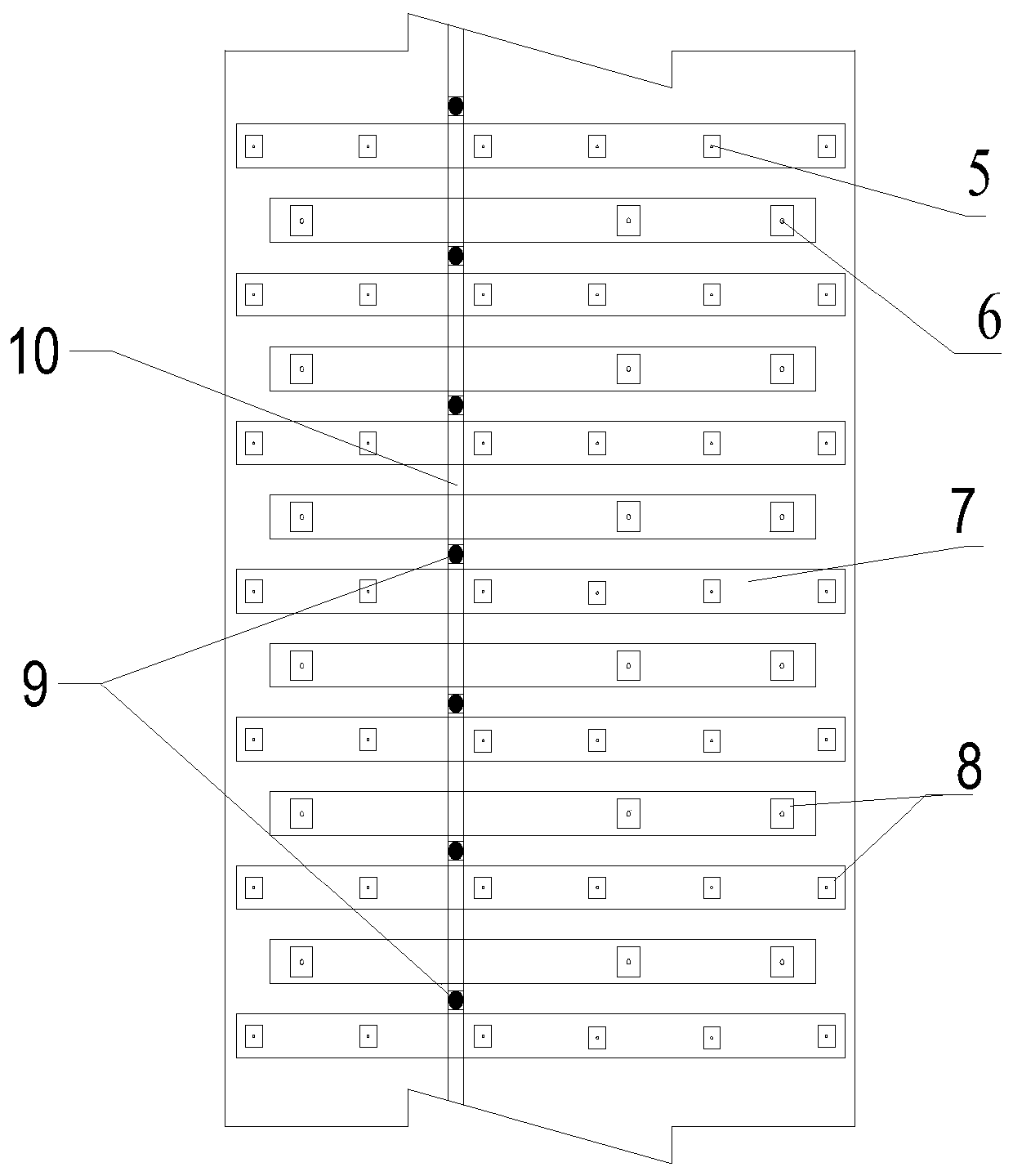

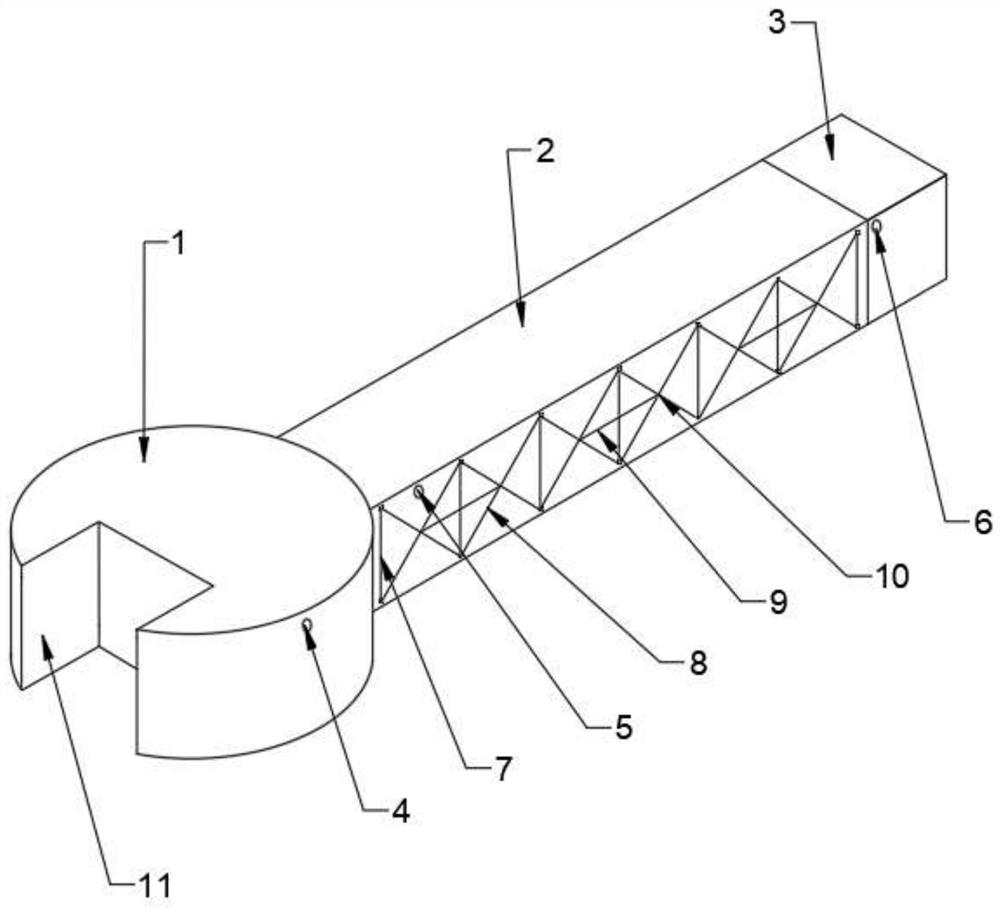

Anchor rod transloading set

ActiveCN102536312ATimely transportImprove delivery capacityMine roof supportsUnderground transportEngineeringTransfer mechanism

The invention belongs to the technical field of underground equipment in a coal mine and particularly relates to an anchor rod transloading set which solves the problem that existing underground equipment in the coal mine cannot be suitable for mines with small section roadways and mines with coal beds in poor geological conditions. The anchor rod transloading set comprises a chassis, a transloading mechanism and a scraper conveyer. The bottom disc is provided with the transfer mechanism and comprises a main frame, a left crawler frame, a right crawler frame and a tail frame. Lifting mechanisms are respectively arranged at the top parts of the left crawler frame and the right crawler frame. The top parts of the lifting mechanisms are connected with a worktable, and the front part of the worktable is connected with a front anchor protector. A rear anchor protector is arranged at the rear part of the main frame. Temporary supports are further hinged on the left crawler frame and the right crawler frame. The invention has the beneficial effects that the anchor rod transloading set can be used for mines with small section roadways and mines with coal beds in poor geological conditions, the complete machine is arranged compactly, the structure is reasonable, the anchor protector part has high degree of automation and fast support speed, and the anchor rod transfer set has large loading capacity, strong climbing ability and can protect and transfer at the same time.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

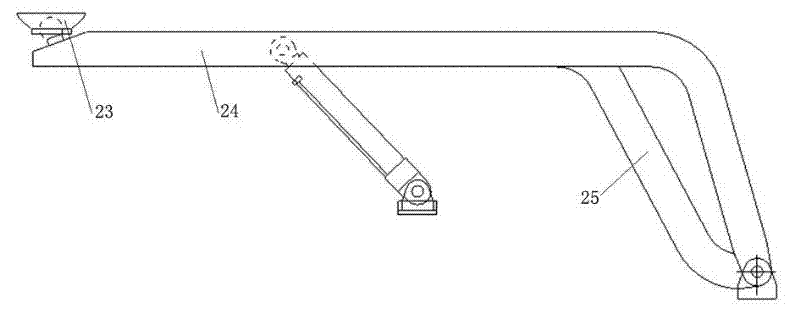

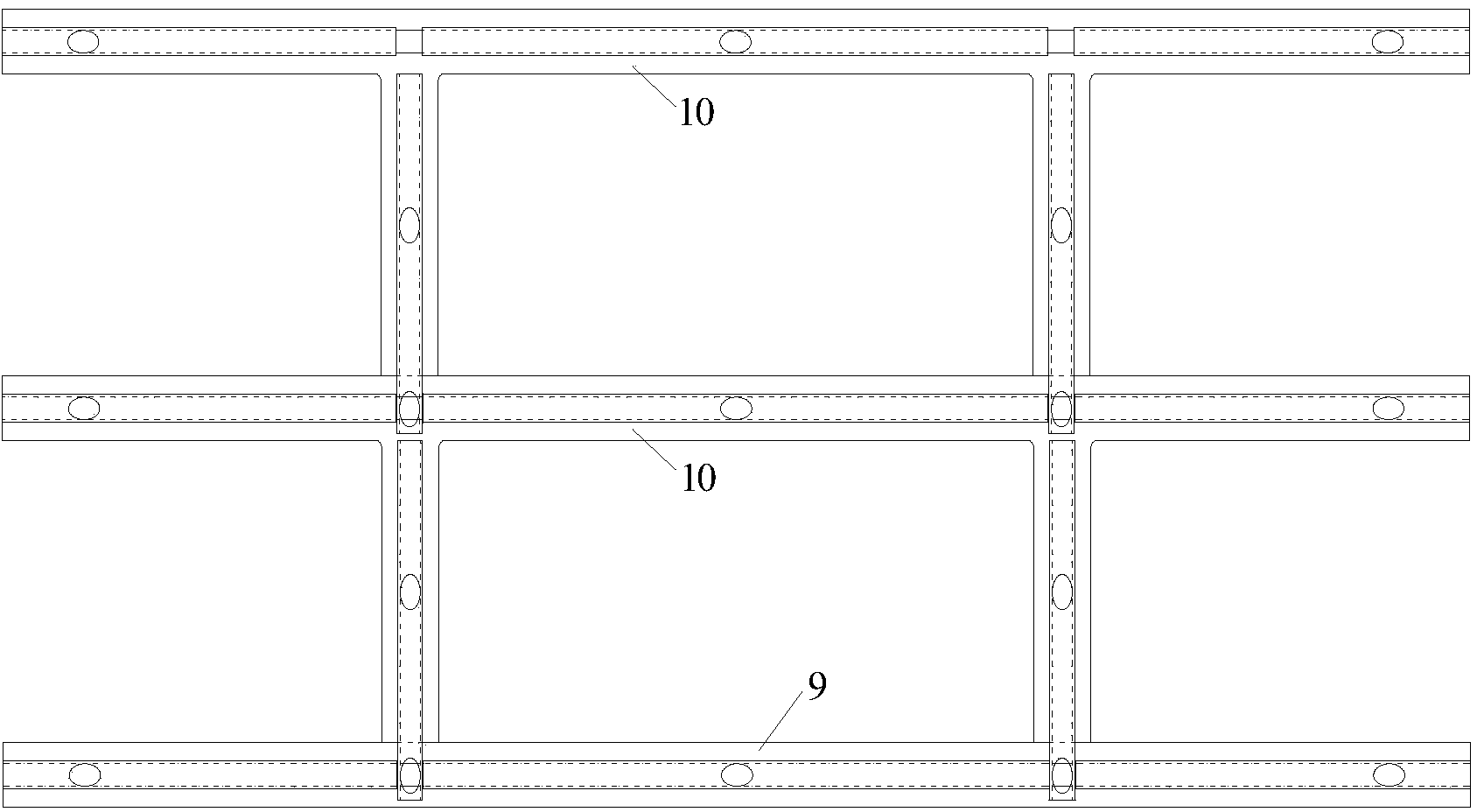

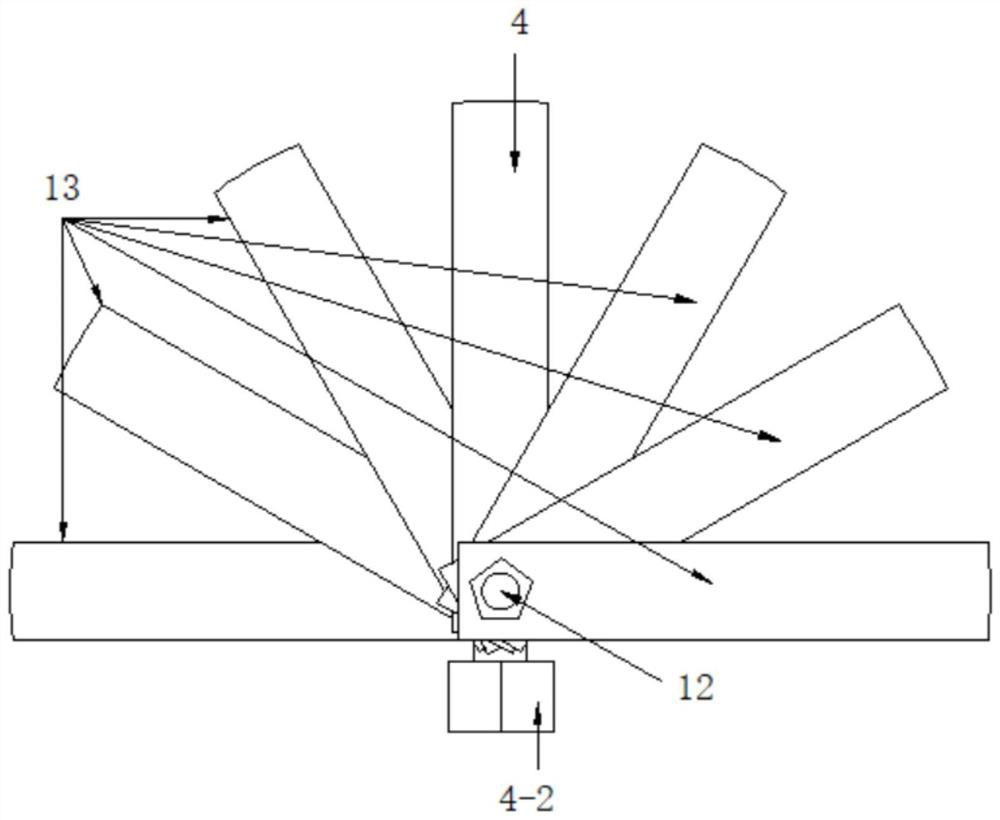

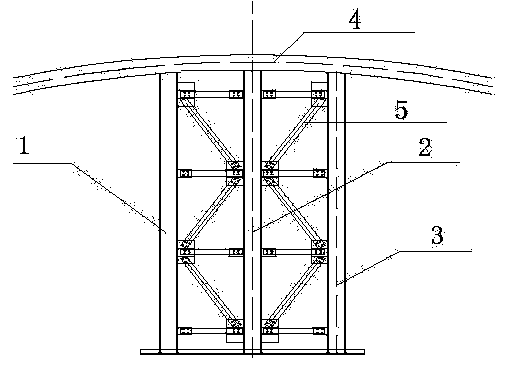

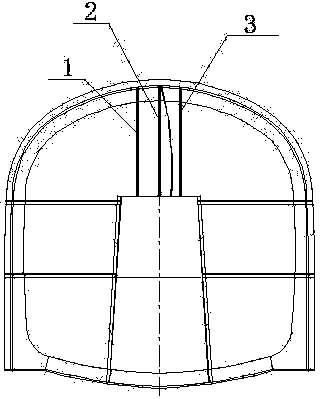

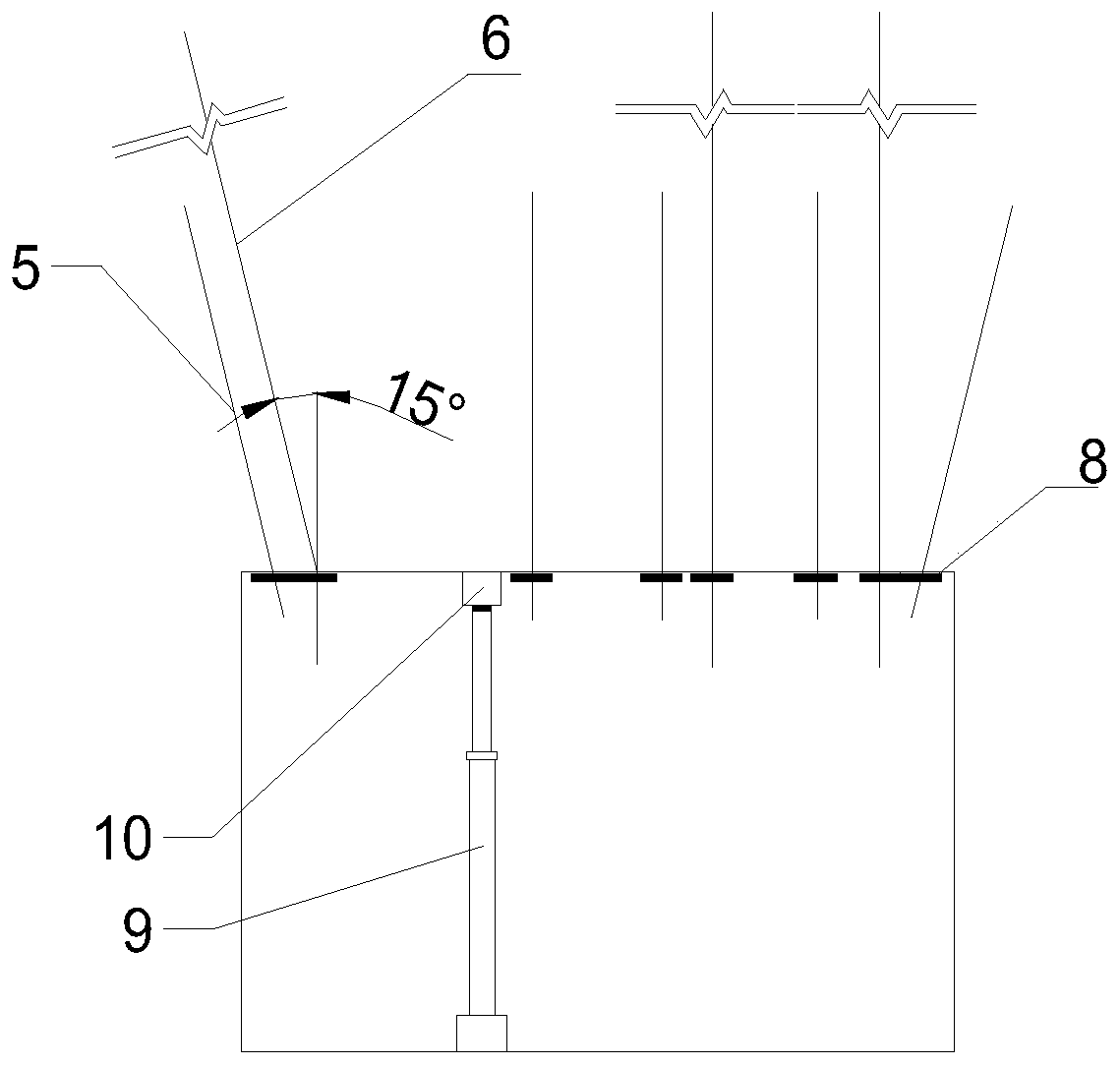

Roadway drivage advanced telescopic cantilever support device and construction method thereof

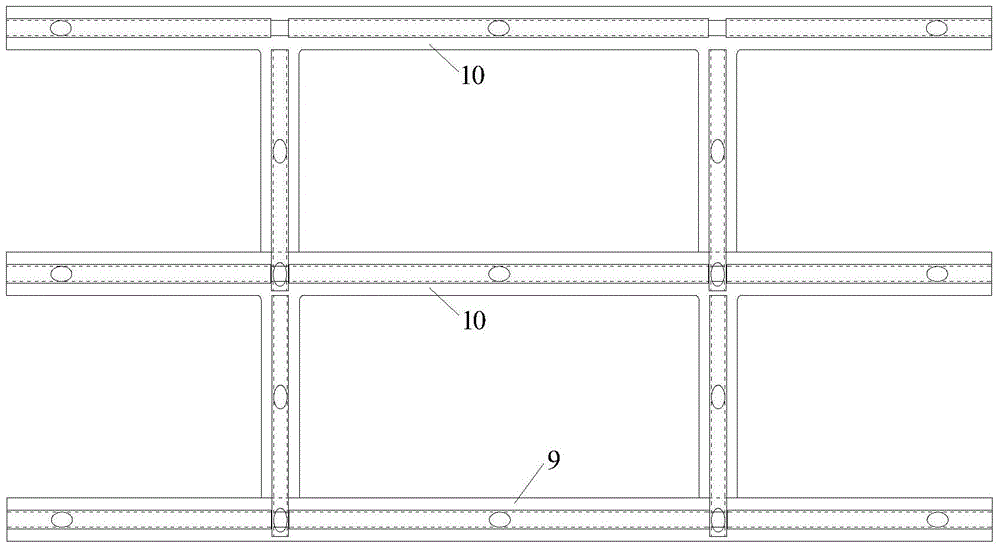

PendingCN107178384ADoes not affect the normal excavation processRealize parallel operationMine roof supportsAnchoring boltsControl systemArchitectural engineering

The invention discloses a roadway drivage advanced telescopic cantilever support device and a construction method thereof. The roadway drivage advanced telescopic cantilever support device comprises an electro hydraulic control system, a pump station, a crossheading support, a telescopic arm and a top-support grid plate; the crossheading support is formed by connecting four section support units in two rows and two columns through a horizontal oil cylinder and a longitudinal oil cylinder, and each support unit is composed of a top beam, a base, a stand column and a four-bar linkage; and the front portions of the bases of the support units in the front row are connected with one end of the telescopic arm, and the other end of the telescopic is connected with the top-support grid plate and an advanced suspended stand column. As the driving of the roadway drivage machine, the telescopic arm extends to support the top. According to the roadway drivage advanced telescopic cantilever support device, a wide range of temporary support for roadway drivage is provided, the support strength is high, anchor bolts and anchor ropes in multi rows can construct parallel, the technological requirement of one-drivage multi-anchoring is met, the staff operate under the full support condition, the safety is high, the roadway driving cost is reduced, and the construction speed is increased over 70%; and the device is suitable for the fields of coal mines, metallurgy mines, underground construction, tunnel construction and the like.

Owner:中煤能源研究院有限责任公司

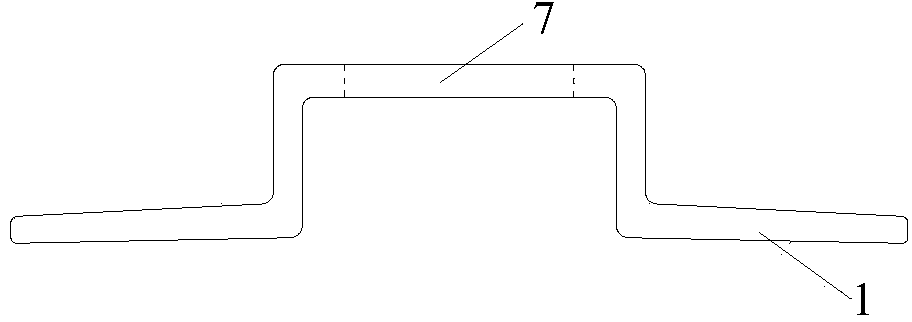

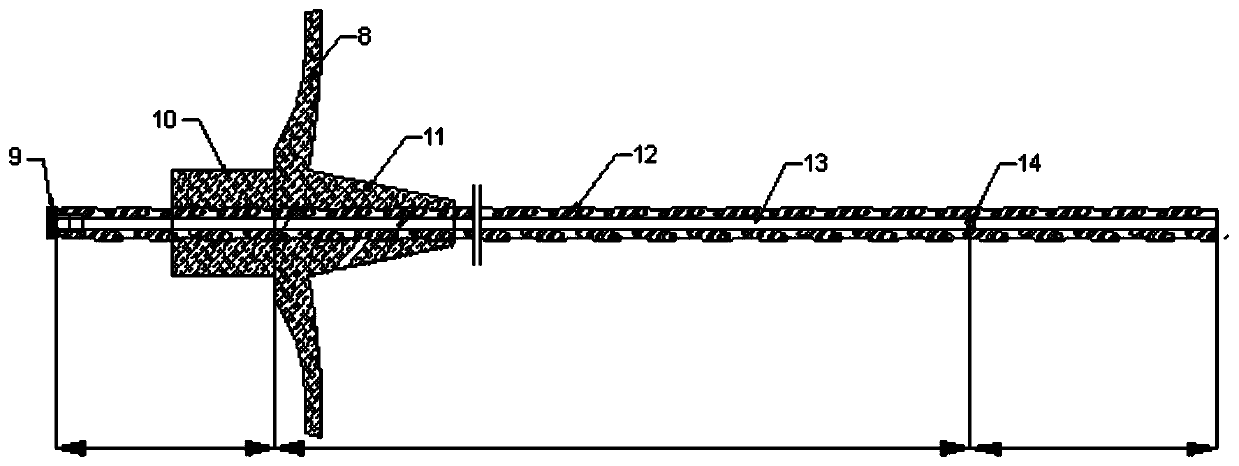

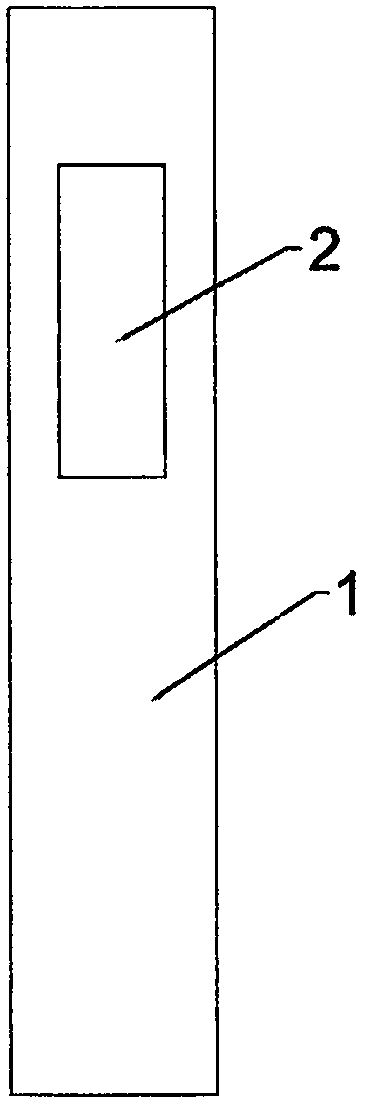

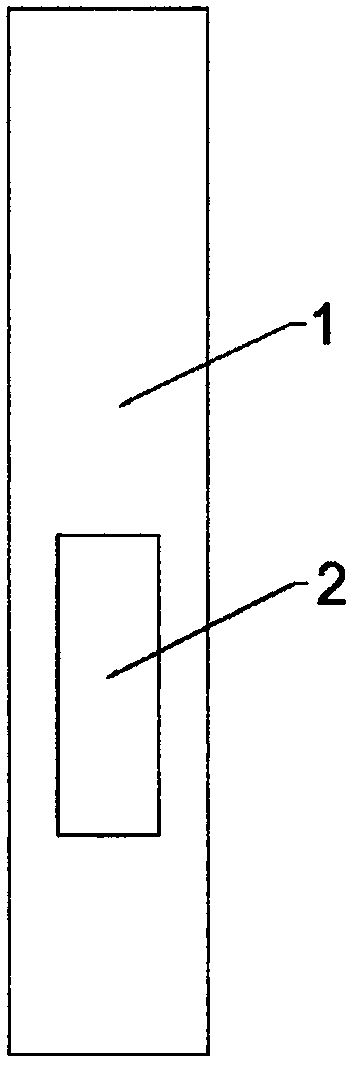

Mining anchoring steel belt and roadway top plate anchor rod supporting method

InactiveCN103883340AReduce labor intensityImprove mechanical propertiesAnchoring boltsTransverse grooveStructural engineering

The invention relates to a mining anchoring steel belt and roadway top plate anchor rod supporting method. Mining anchoring steel belts include a transverse steel belt and two longitudinal steel belts, one ends of the longitudinal steel belts are connected with the transverse steel belt, the transverse steel belt and the longitudinal steel belts are integrally formed, a transverse groove is formed on the transverse steel belt, a longitudinal groove is formed on each longitudinal steel belt, a protruding outwards-extending structure is formed at a free end of each longitudinal steel belt, a lapping structure used for being matched with an outwards-extending structure of another mining anchoring steel belt is formed on the transverse steel belt, an anchor rope limiting hole is arranged in each longitudinal groove, and an anchor rod limiting hole is arranged on each outwards-extending structure. Due to adoption of the above technical scheme, temporary supporting effect similar to that of a forepoling bar can be realized; conventional forepoling bar temporary supporting is replaced, so that labor intensity of workers is lowered, and supporting speed is increased.

Owner:SHANDONG UNIV OF SCI & TECH

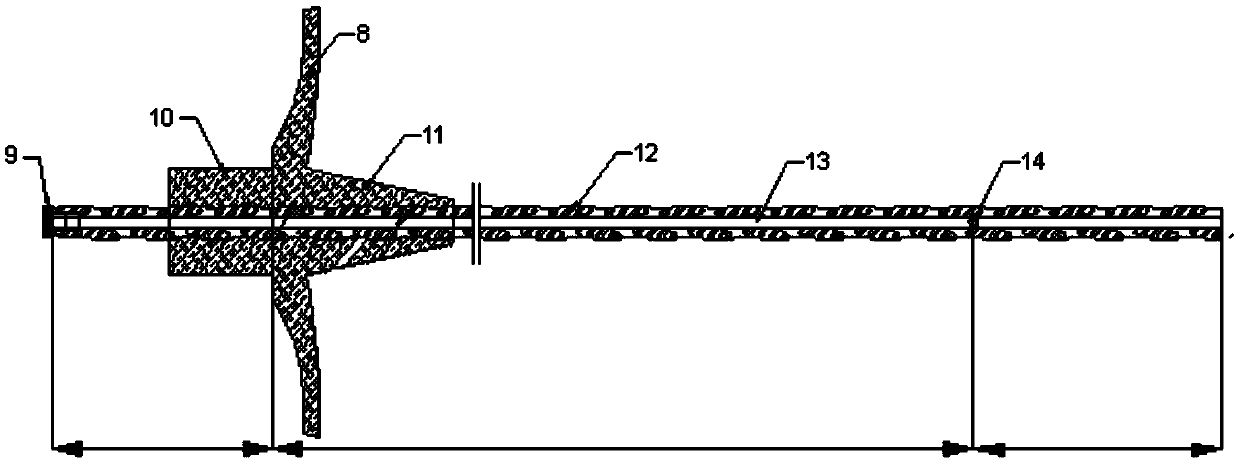

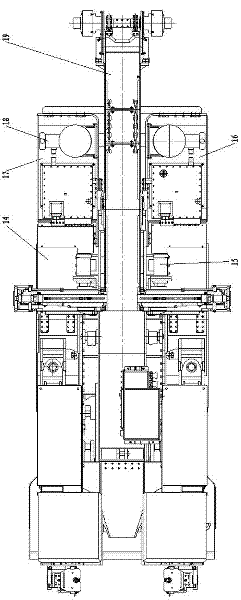

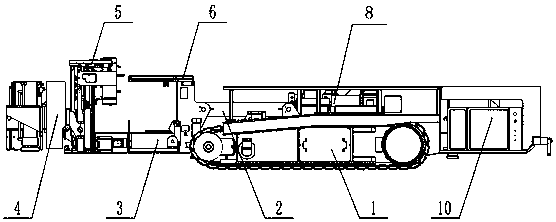

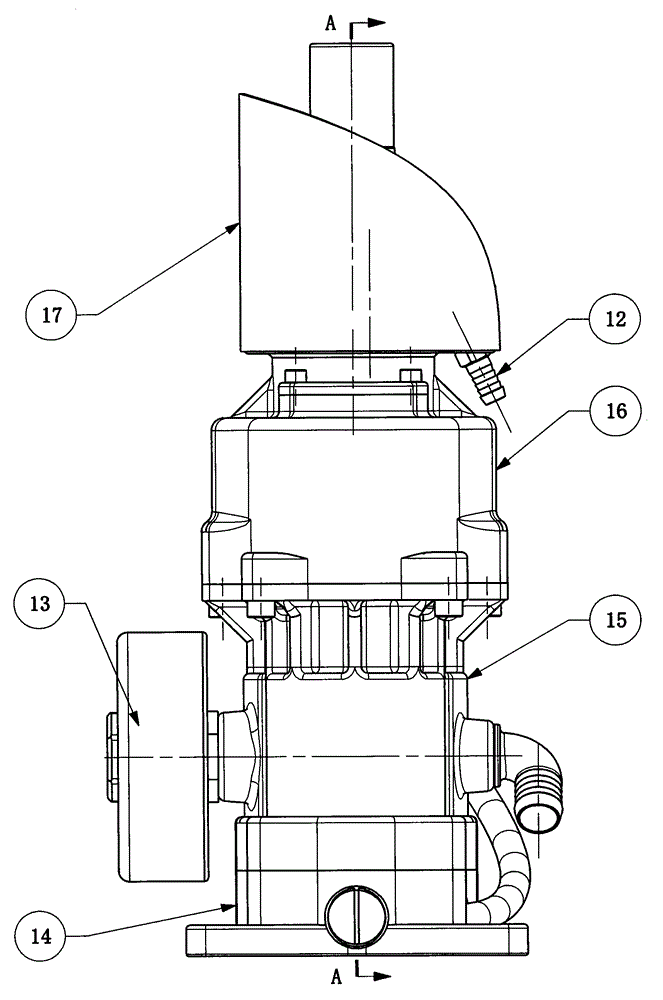

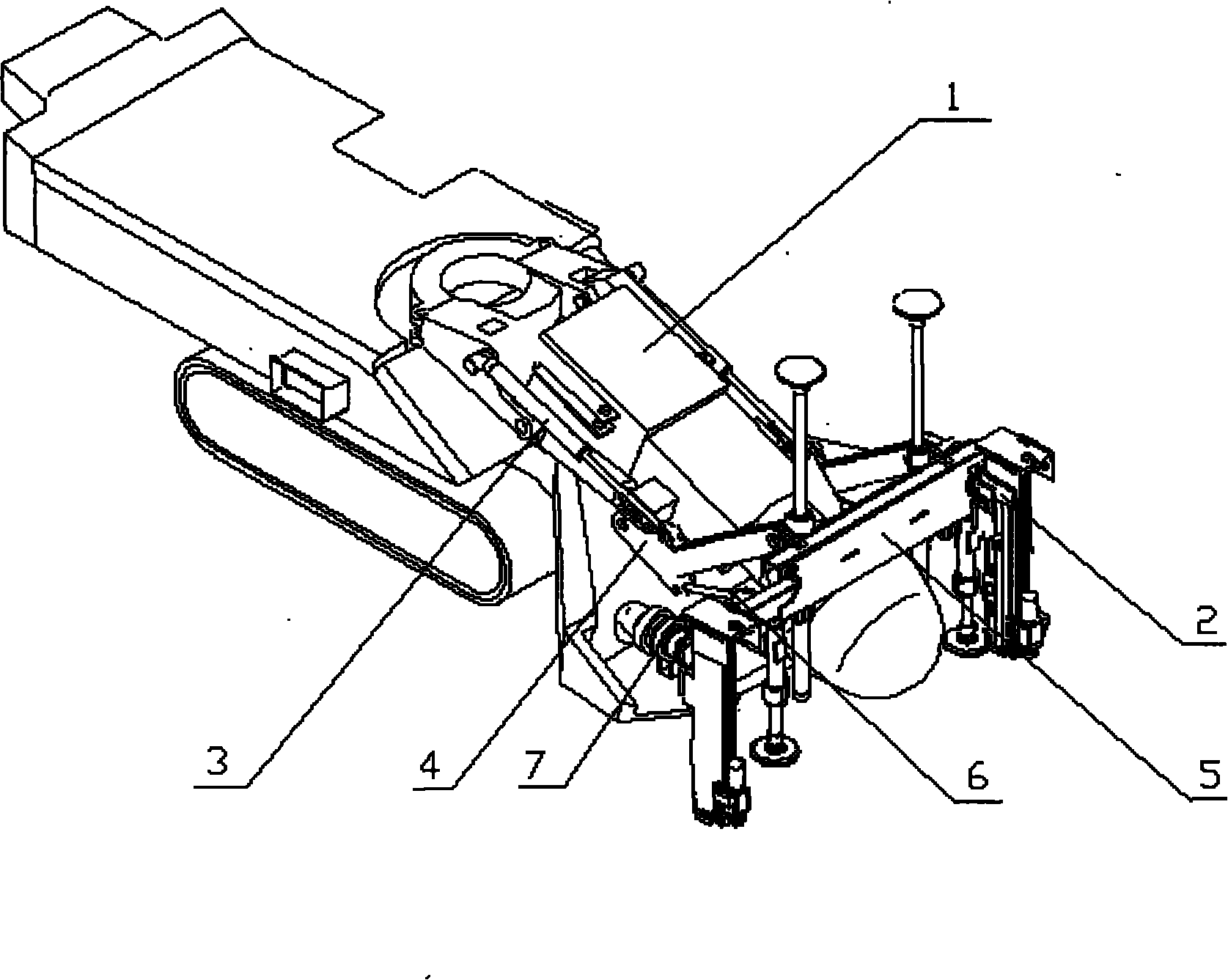

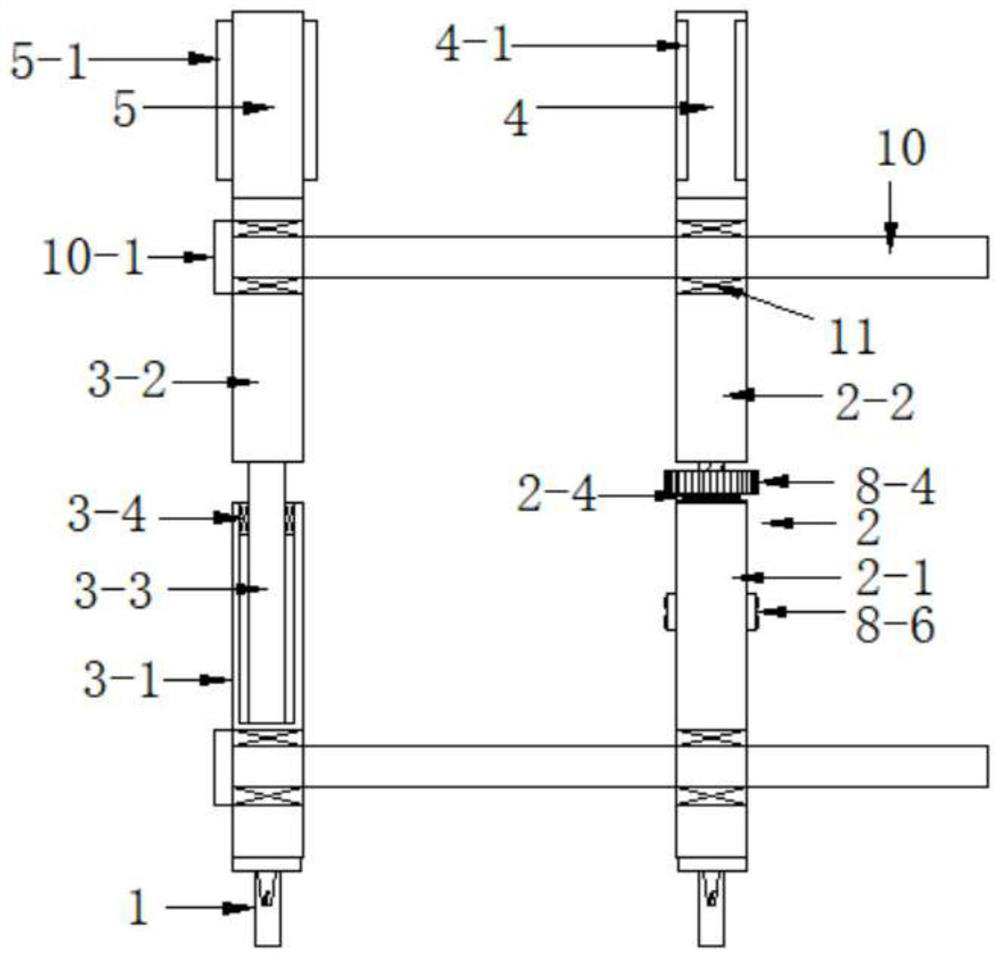

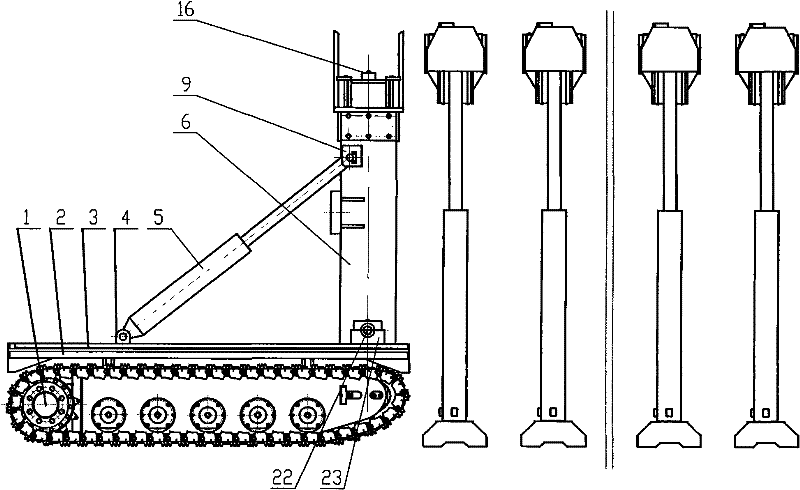

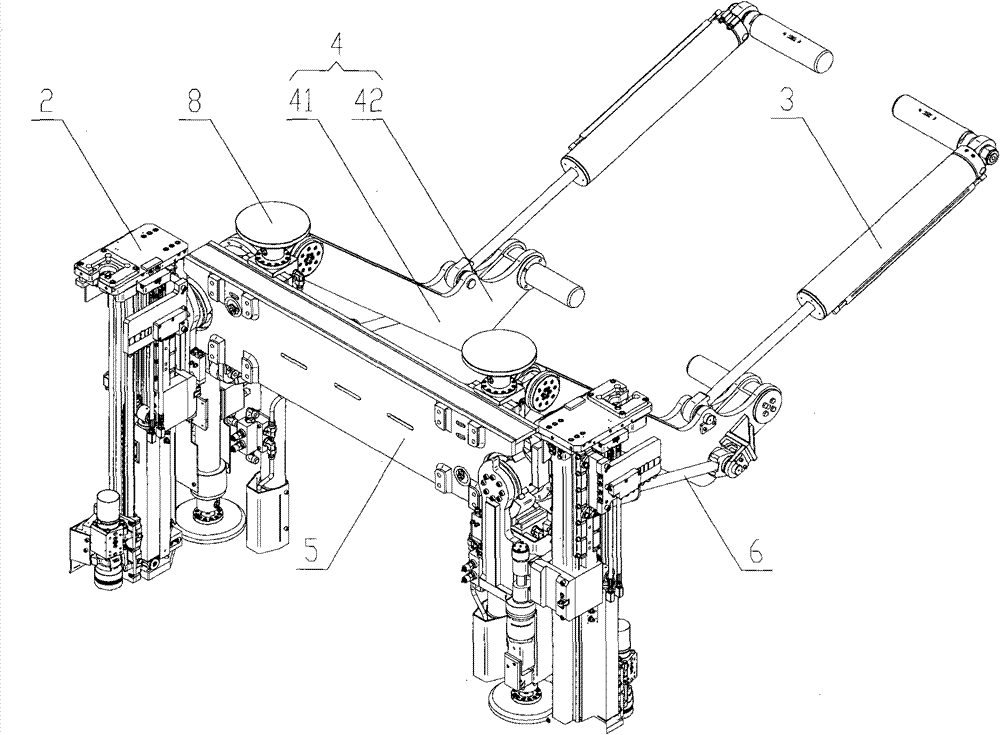

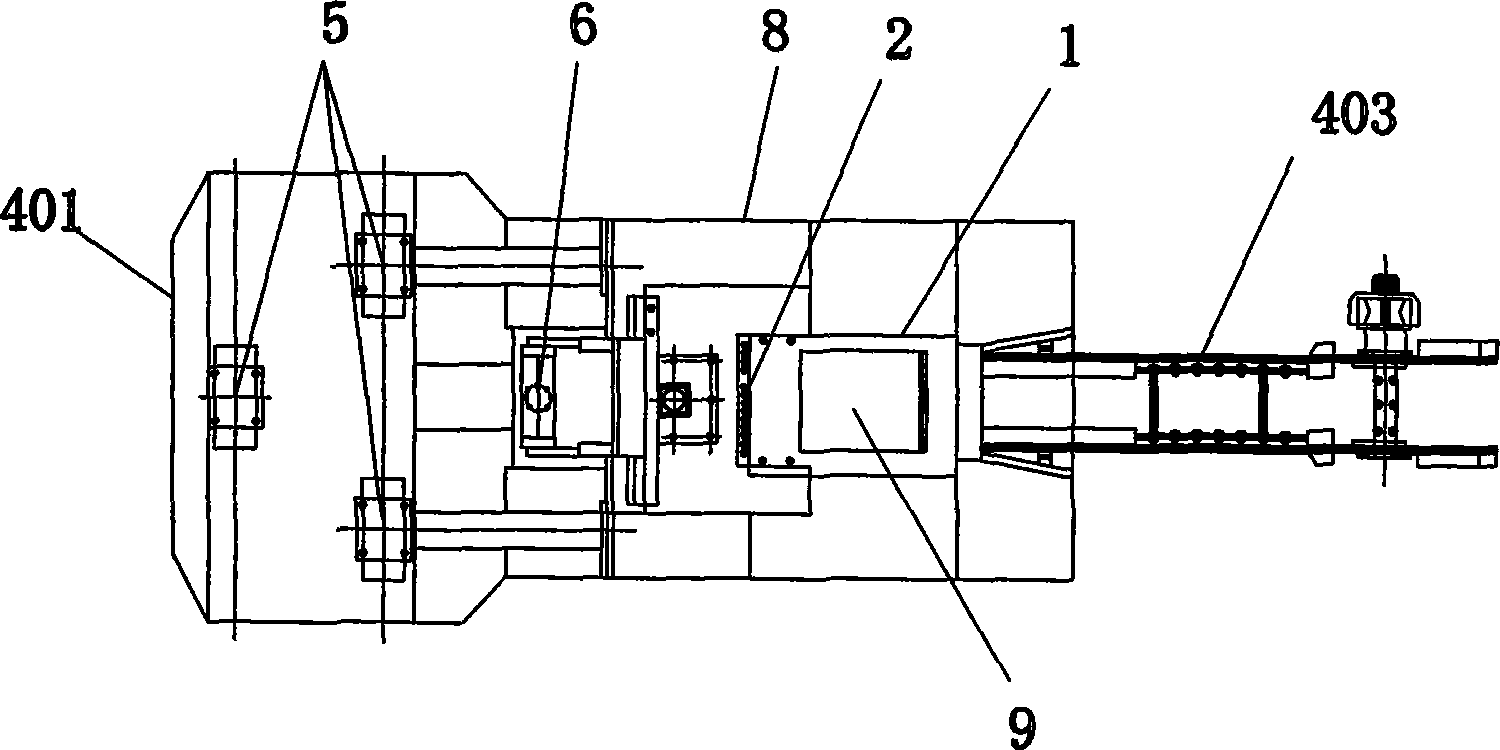

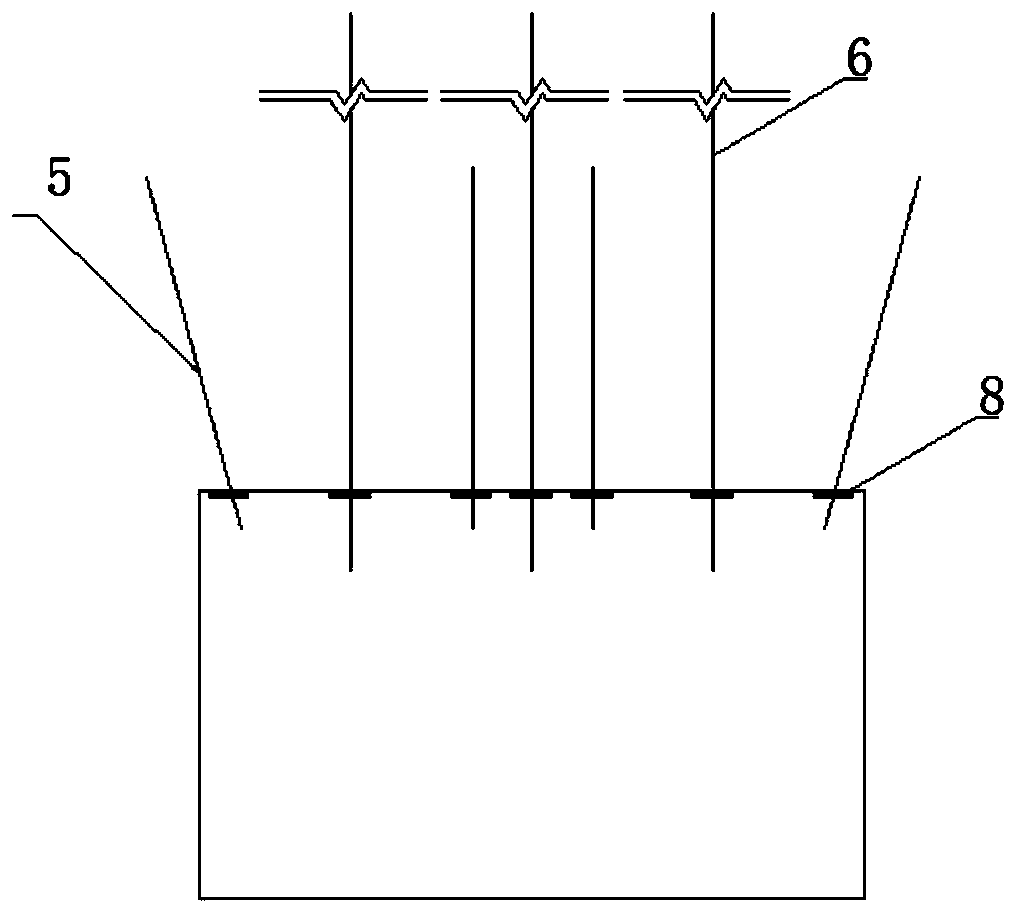

Crawler-type thin seam anchor rod drill rig

ActiveCN110374498AIncrease support speedIncrease the speed of excavationConstructionsDerricks/mastsDrillMechanism based

The invention relates to mine exploration equipment and provides a crawler-type thin seam anchor rod drill rig. The crawler-type thin seam anchor rod drill rig comprises a workbench and a crawler-typetravelling mechanism base disc, wherein the base disc is connected with the workbench by an arranged lifting mechanism, the base disc enters a middle part of one side of a thin seam and is sunken toform a counter groove, a fixed lug seat is arranged in the counter groove and is used for being hinged with the lifting mechanism, one end of the lifting mechanism is hinged with the fixed lug seat, the other end of the lifting mechanism is hinged with the workbench and is pushed by a hydraulic mechanism in the lifting mechanism so as to ascend and descend in a rotation way, the lifting mechanismis sunk into the counter groove when descending to the lowest part so that the height of the drill rig is 1.1-1.5 meters. By the crawler-type thin seam anchor rod drill rig, the problems of mine resource exploration of the thin seam and application of mine resource in coal mine transportation of a vertical shaft are solved, and the mine resource exploration efficiency and safety of the thin seam is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

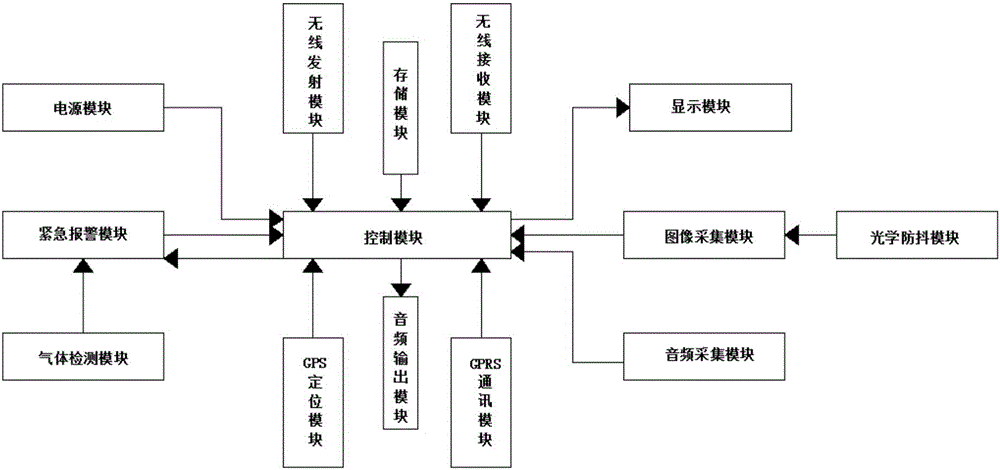

Digital two way radio with automatic GPS (Global Positioning System)

InactiveCN106100679AVersatileEasy to useTelevision system detailsColor television detailsComputer hardwareWireless transmission

The invention relates to the technical field of two way radios, and specifically discloses a digital two way radio with an automatic GPS (Global Positioning System). The digital two way radio with the automatic GPS comprises a power module, a gas detection module, an image collection module and an audio collection module. The output end of the power module is electrically connected with the input end of a control module; the output end of the gas detection module is in signal connection with the input end an emergency alarm module; the output end of the image collection module is in signal connection with the input end of the control module; and a GPS positioning module, a GPRS communication module, a wireless transmission module and a wireless reception module are in signal connection with the control module. The digital two way radio with the automatic GPS provides precise position information and transmits the precise position information to partners around through the wireless transmission module, so that supporting partners can find the supporting site accurately and rapidly, the supporting speed among the police officers is increased, and image and audio information can be collected clearly.

Owner:泉州欧讯电子有限公司

Coal roadway roof reinforcing and upper protecting anchor rod supporting method based on top plate stability

InactiveCN108035752ARow spacing increasedIncrease the speed of excavationMaterial strength using tensile/compressive forcesEarth material testingRock coreEngineering

A coal roadway roof reinforcing and upper protecting anchor rod supporting method based on top plate stability is suitable for the field of roadway supporting. A roadway top plate is divided into different areas, rock core information of each area is analyzed, and therefore the rock integrity of each area of the top plate is obtained; the testing result of each area is analyzed, the mass index ofrock in each area of the top plate is judged, when the rock mass index is larger than a preset value, a plurality of anchor rods or anchor ropes are evenly and perpendicularly distributed in the areaof the top plate to conduct simplex reinforcing supporting, and a plurality of anchor rods are evenly and perpendicularly distributed within corresponding ranges of coal uppers on the two sides. The anchor rod supporting array pitch is greatly increased, supporting time is saved, and the advance rate is remarkably increased; due to the increase of strength and length of the anchor rods of the topplate and the increase of the pretightening force of the anchor rods, an anchoring rock beam of a sufficient thickness is formed by the top plate, and therefore the overall roadway stability is improved; meanwhile, the peak pressure positions of the uppers are transferred to be close to the coal wall side, and the deformation of the coal uppers can be controlled through the low-strength short anchor rods.

Owner:CHINA UNIV OF MINING & TECH

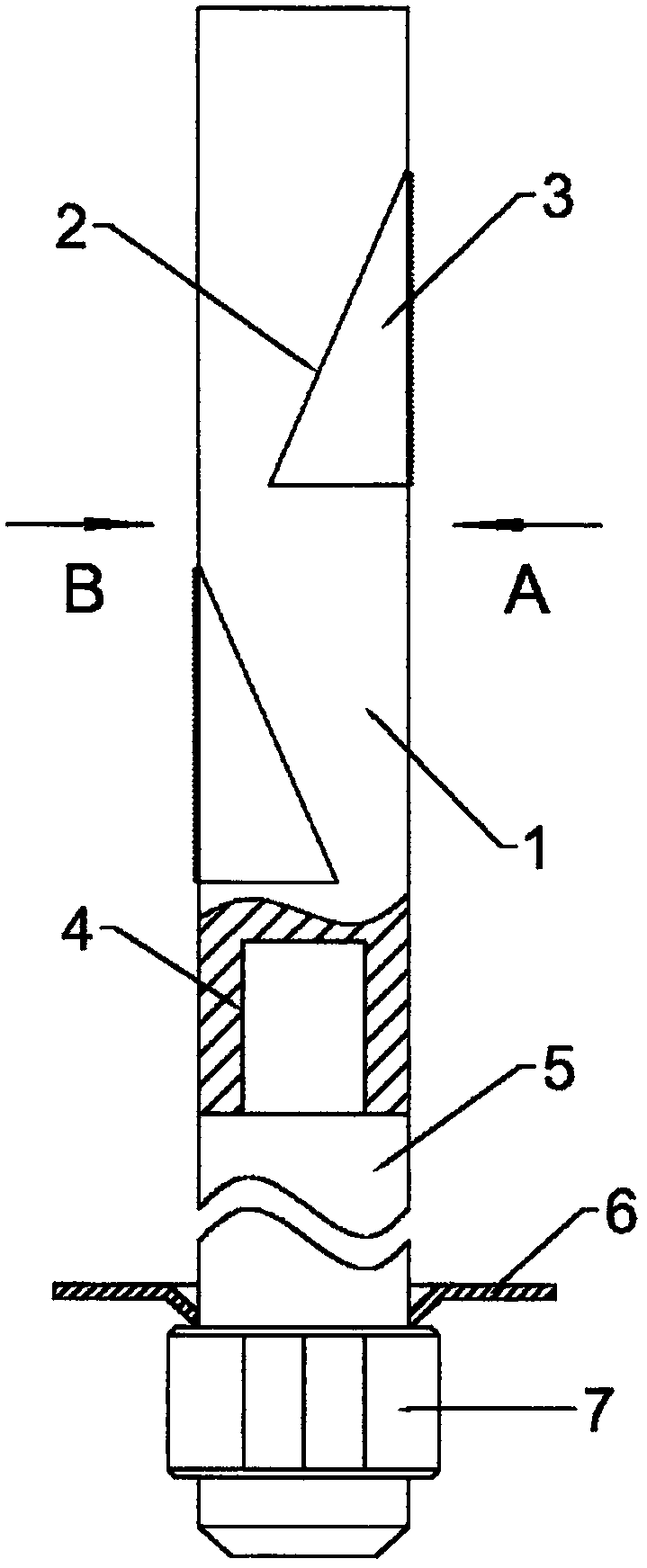

Rotary Impact Pneumatic Roof Bolter Drilling Rig

ActiveCN103015890BIncrease support speedLow gas consumptionDrilling drivesAnchoring boltsEngineeringMechanical engineering

The invention relates to a rotary impact type pneumatic roofbolter. The roofbolter is a drilling tool in a coal mine roadway bolt supporting work. Currently, in the coal mine roadway bolt supporting work, the most common roofbolter is the rotary type pneumatic roofbolter; the current rotary type pneumatic roofbolter only can support a roadway with a hardness f of less than 10 because of uncertainty of the coal mine roadway environment. In order to support the roadway with the hardness f of more than 10, a pneumatic impact structure is integrated into the current rotary type pneumatic roofbolter; and the new rotary impact type pneumatic roofbolter not only can support the tougher roadway, but also can increase a support speed.

Owner:孙旭

Movable supporting frame for roast duck production

InactiveCN111328841AIncrease productivityAvoid wasteBaking ovenSpecial goods bakingRatchetRoast duck

The invention provides a movable supporting frame for roast duck production. The movable supporting frame for roast duck production comprises two supporting rods which are connected by a pin shaft ina rotatable manner, wherein a rod head is in dismountable connection to an end part of each of the two supporting rods; a round groove is formed in the supporting rod located on the front side, a ratchet wheel limited in the round groove is connected to the front end of the pin shaft, and a ratchet pawl fitted with the ratchet wheel is disposed on the groove wall of the round groove; a regular polygonal groove is formed in the supporting rod located on the rear side, a round plate limited in the regular polygonal groove is connected to the rear end of the pin shaft, and a taper hole is formedin the round plate; and a regular polygonal limiting plate fitted with the regular polygonal groove is also disposed, and an insertion connecting rod which can be inserted into the taper hole is disposed on the regular polygonal limiting plate. The movable supporting frame has the beneficial effects of accelerating formation of supporting inside a duck, boosting increase of production efficiency,avoiding generation of rejects and greatly improving appearance of roast ducks.

Owner:湖南润香源食品股份有限公司

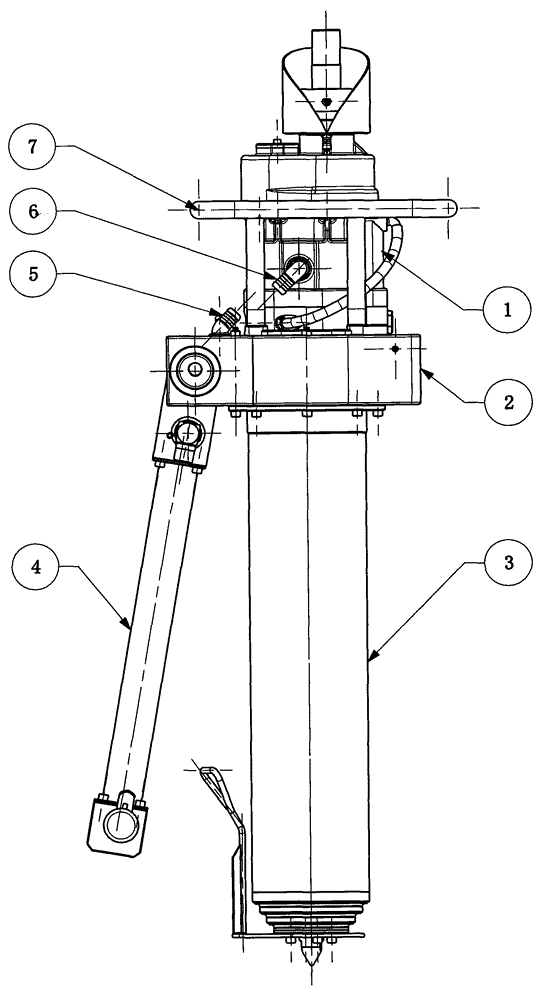

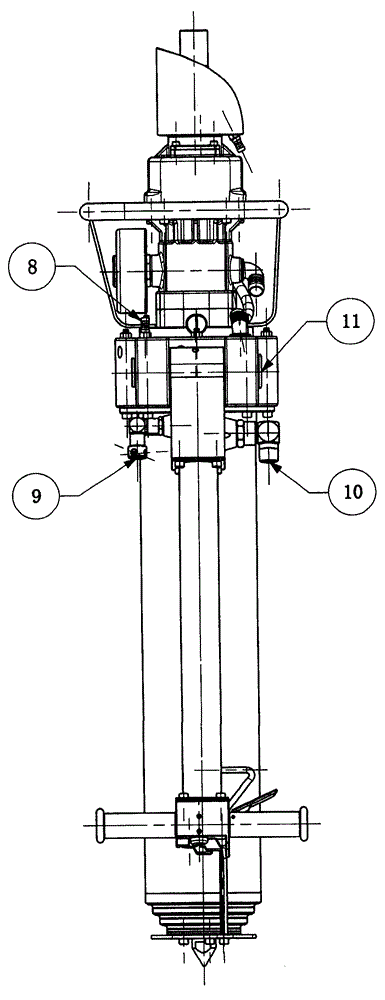

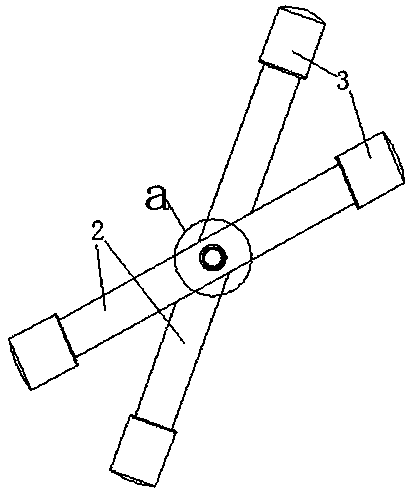

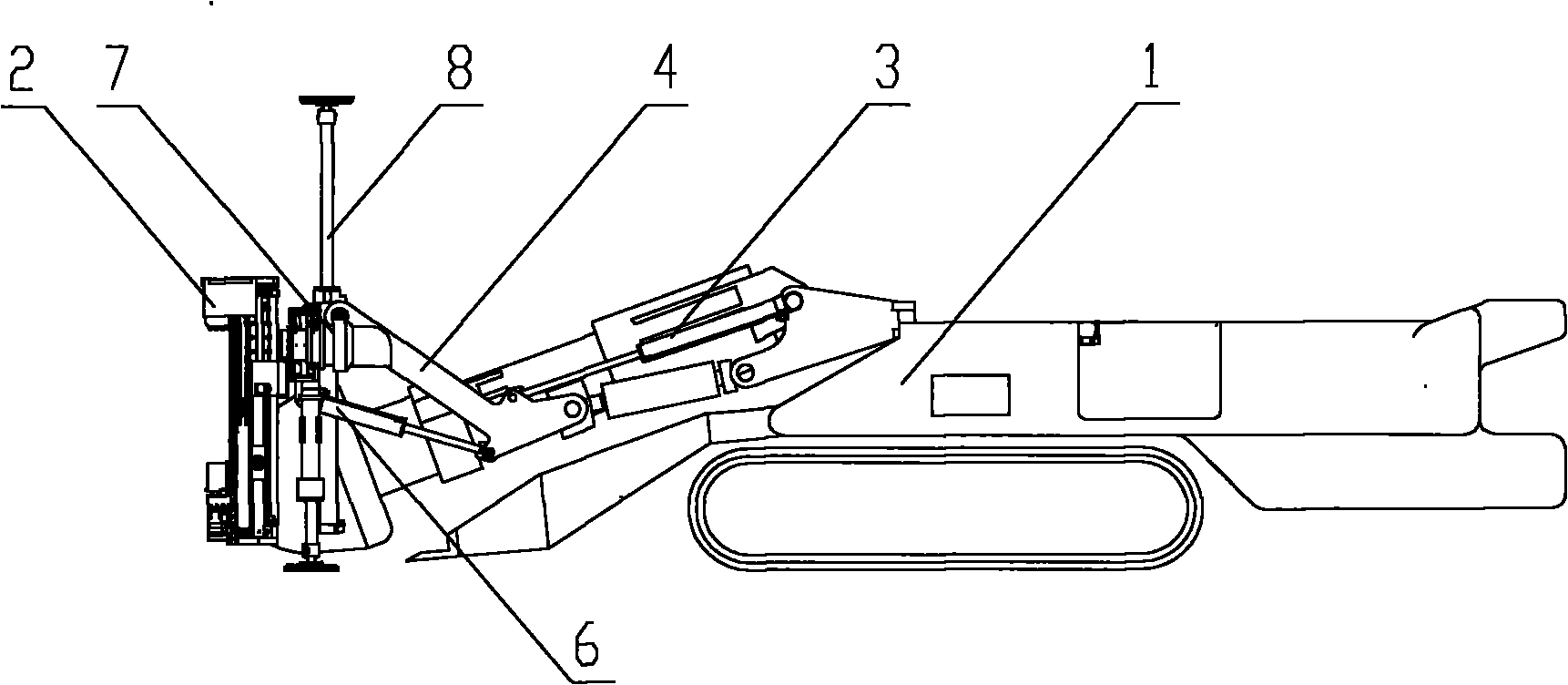

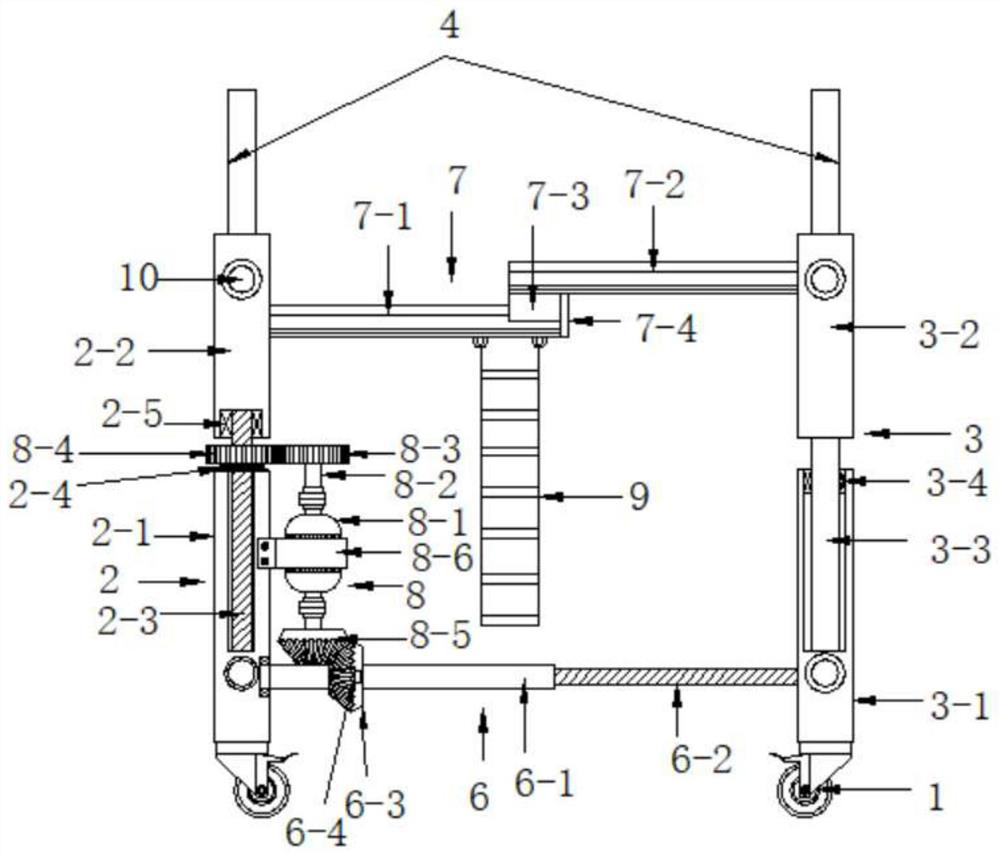

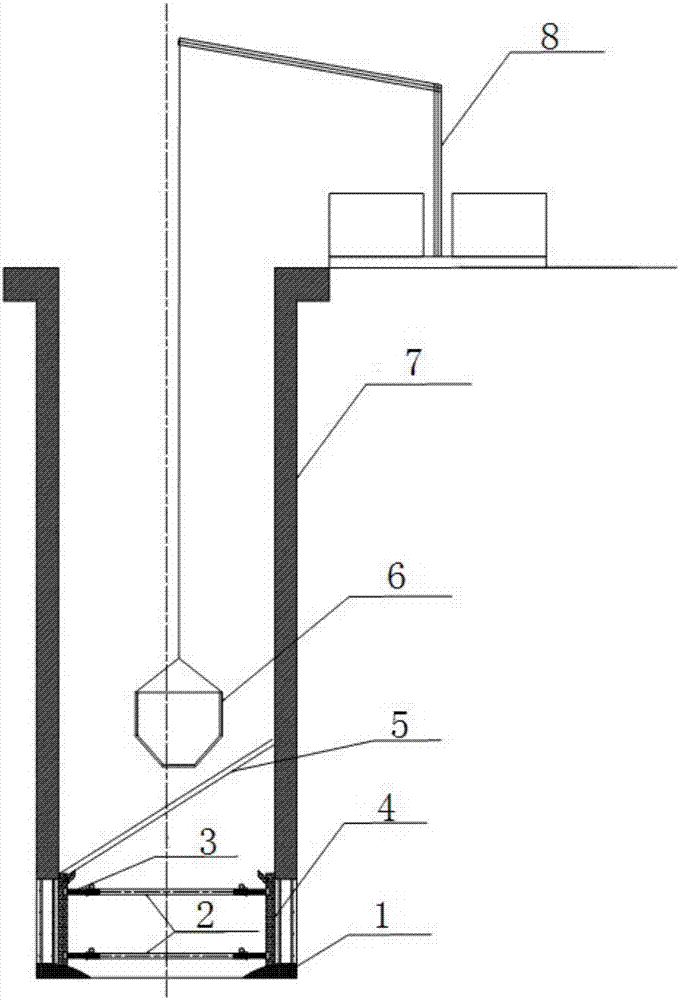

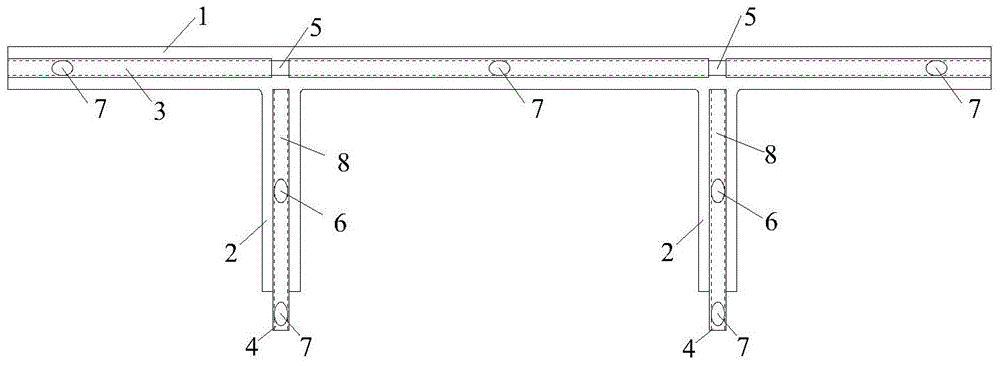

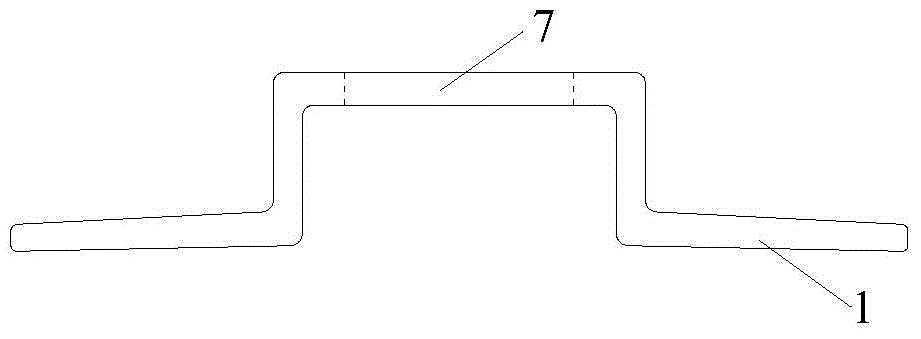

Development machine

The invention discloses a development machine, comprising a development machine body (1) as well as a supporting device (2) and a driving device (3) for driving the supporting device (2) to move; wherein the supporting device (2) is arranged at the front part of the development machine body (1), and the supporting device (2) can be in supported position under the action of the driving device (3). The development machine provided by the invention can widen application range thereof while ensuring use cost to be low, and meanwhile the time required by supporting is reduced, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

Protective bracket with net profile structure for subway tunnel construction

The invention relates to the technical field of tunnel construction, in particular to a protective bracket with a net profile structure for subway tunnel construction. A universal wheel positioned atthe lower part of a main supporting rod is fixed at the lower end of a main fixed rod; a supporting rod screw is movably inserted in the main fixed rod; the upper end of the supporting rod screw is inserted in a main bearing; the main bearing is embedded in the lower end of a main movable rod; the portion, at the upper end of the main fixed rod, of the supporting rod screw is sleeved with a drivengear in a drive mechanism; threads meshing with the supporting rod screw are arranged on the inner ring surface of the driven gear; and the lower ring surface of the driven gear is fixed on the upperring surface of a plane thrust ball bearing; and the lower ring surface of the plane thrust ball bearing is fixed at the upper end of the main fixed rod. The supporting range of the bracket can be adjusted according to the size of a net profile frame, so that the bracket has high adjustability and wider application range.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Construction method for quickly pouring anti-slide pile protection wall concrete

ActiveCN105544561AEliminate hidden dangers of retaining wall qualityThe construction process is safe and reliableExcavationsEngineeringRebar

The invention provides a construction method for quickly pouring anti-slide pile protection wall concrete. After a previous section of poured protection wall concrete has a certain strength, a sand cushion layer is cleared, all sand cushions are collected together for standby application, and anti-slide pile excavation is continued; after the pouring height of one section of a protection wall is reached, protection wall steel bars are welded and bound under the poured protection wall; a sand bottom moldboard is laid to the position 3 centimeters above the bottom of a protection wall side moldboard, and the width of the sand bottom moldboard is 30 centimeters or above larger than that of the protection wall side moldboard; the optimized and improved protection wall side moldboard in which concrete feeding holes are pre-formed is erected, after the side moldboard is erected, the bottom of the side moldboard is embedded deep into 3 centimeters in a sand layer to prevent grout runout, the portion 5 centimeters above the top of the side moldboard is closely attached to the face of the previous section of the protection wall, and the protection wall moldboard is reinforced through steel pipes and adjustable lead screws. A concrete lifting bucket is lifted through a small lifting winch, the concrete can be directly poured into the moldboards through a simple movable concrete sliding groove, the concrete pouring speed is high, and the labor intensity of workers is reduced. Through the steps, quick construction of the anti-slide pile sand bottom moldboards is achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

A crawler type thin coal seam bolter

ActiveCN110374498BIncrease support speedIncrease the speed of excavationConstructionsDerricks/mastsMining engineeringRock bolt

The invention relates to mine exploration equipment and provides a crawler-type thin seam anchor rod drill rig. The crawler-type thin seam anchor rod drill rig comprises a workbench and a crawler-typetravelling mechanism base disc, wherein the base disc is connected with the workbench by an arranged lifting mechanism, the base disc enters a middle part of one side of a thin seam and is sunken toform a counter groove, a fixed lug seat is arranged in the counter groove and is used for being hinged with the lifting mechanism, one end of the lifting mechanism is hinged with the fixed lug seat, the other end of the lifting mechanism is hinged with the workbench and is pushed by a hydraulic mechanism in the lifting mechanism so as to ascend and descend in a rotation way, the lifting mechanismis sunk into the counter groove when descending to the lowest part so that the height of the drill rig is 1.1-1.5 meters. By the crawler-type thin seam anchor rod drill rig, the problems of mine resource exploration of the thin seam and application of mine resource in coal mine transportation of a vertical shaft are solved, and the mine resource exploration efficiency and safety of the thin seam is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Anchor cable drilling machine for mining

InactiveCN107503777AImprove securityEasy to processDerricks/mastsAnchoring boltsDrilling machinesSafety coefficient

The present invention relates to a mine mining equipment, in particular to a cable-anchor drilling rig for mining, which comprises a main body of a cable-anchor drilling rig, a main body of a cable-anchor drilling rig, a telescopic rod and an anchor rod connected in sequence, and the bottom of the main body of a cable-anchor drilling rig is sequentially arranged from left to right There are a booster, a slideway plate and a gradient gauge, the main body of the cable anchor drilling rig is placed on the slideway plate, the slideway plate is connected with a support, a storage box is arranged on the support, and the bottom of the support is connected with wheels. The invention has the advantages of simple processing, convenient operation, firmness and durability, and low cost, greatly improves the support speed and support quality, improves the safety factor of construction personnel, and creates conditions for realizing rapid and comprehensive mechanized excavation.

Owner:SHANDONG HUALIAN MINING

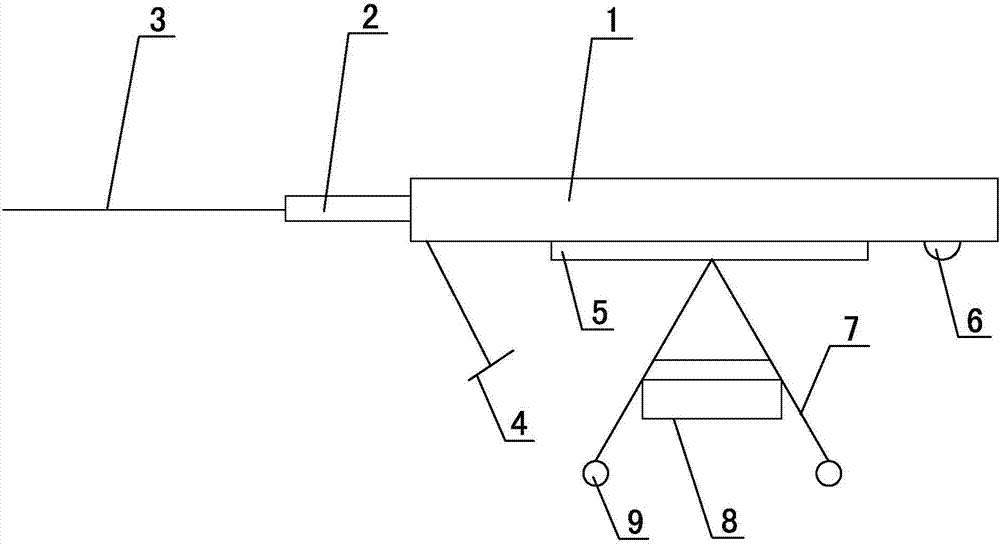

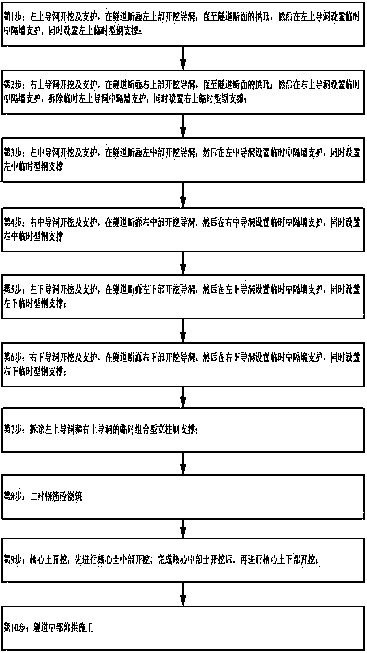

Excavation Method of Combined Section Steel Temporary Support for Extra Large Section Tunnel

InactiveCN102704939BImprove securityIncrease support speedTunnelsProtective coversReinforced concreteRapid construction

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

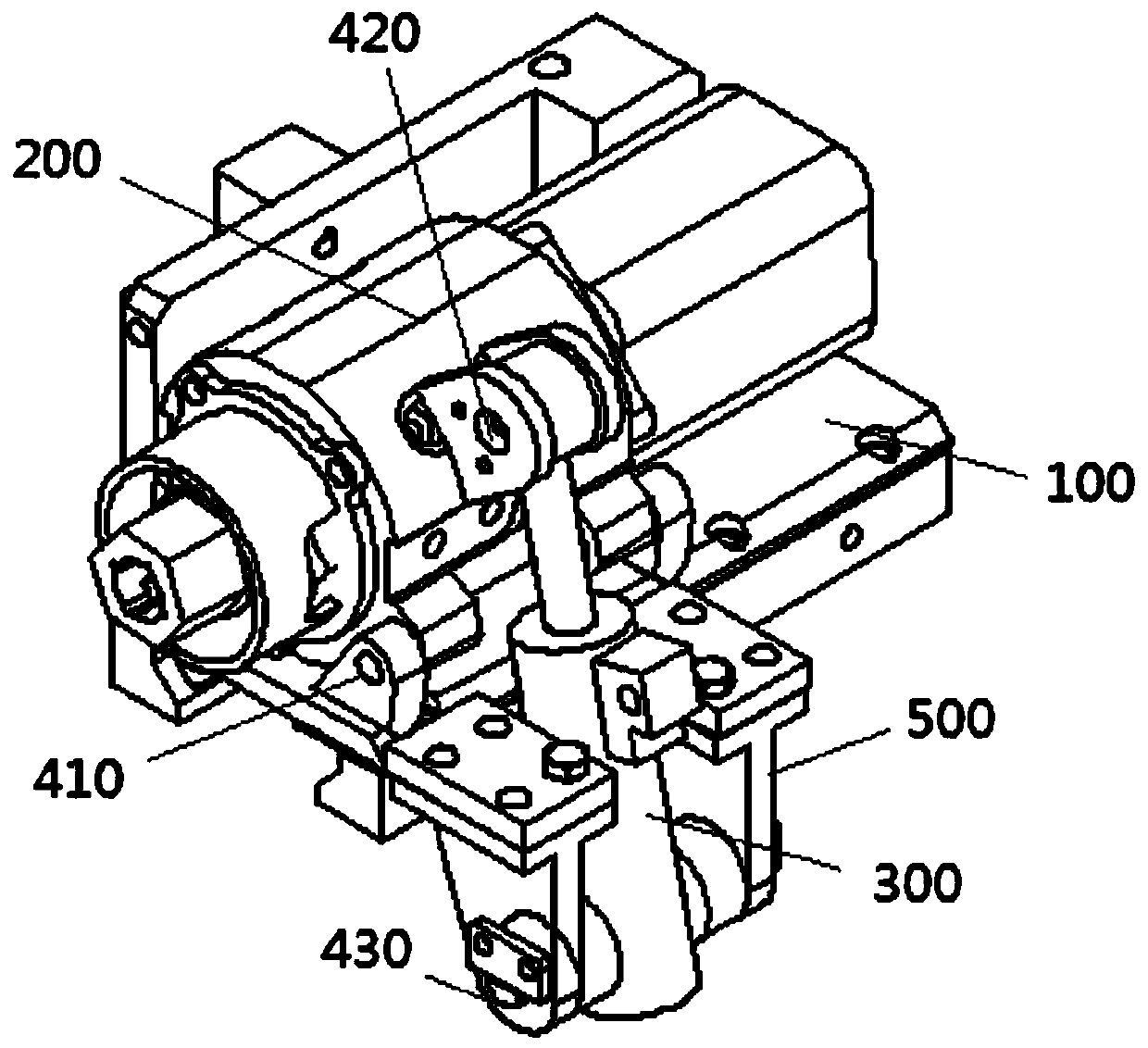

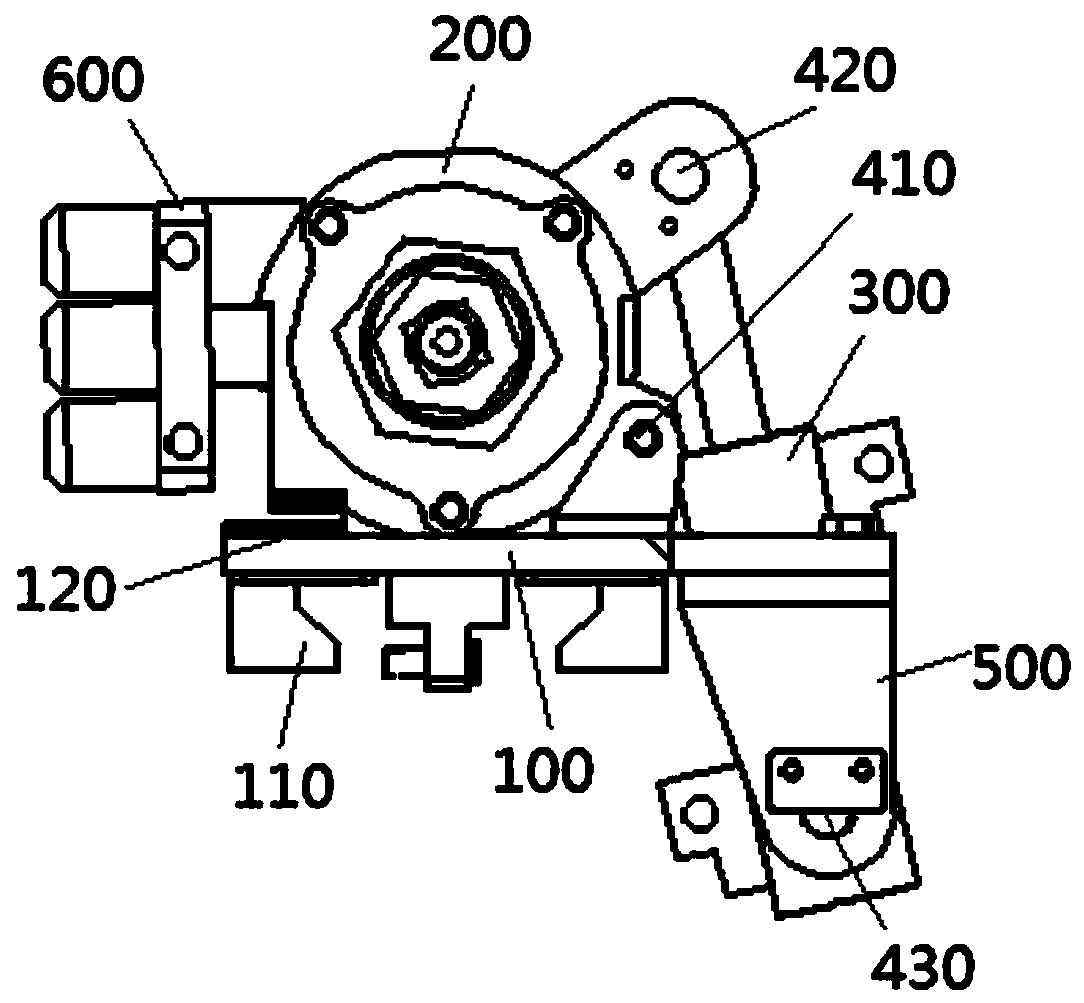

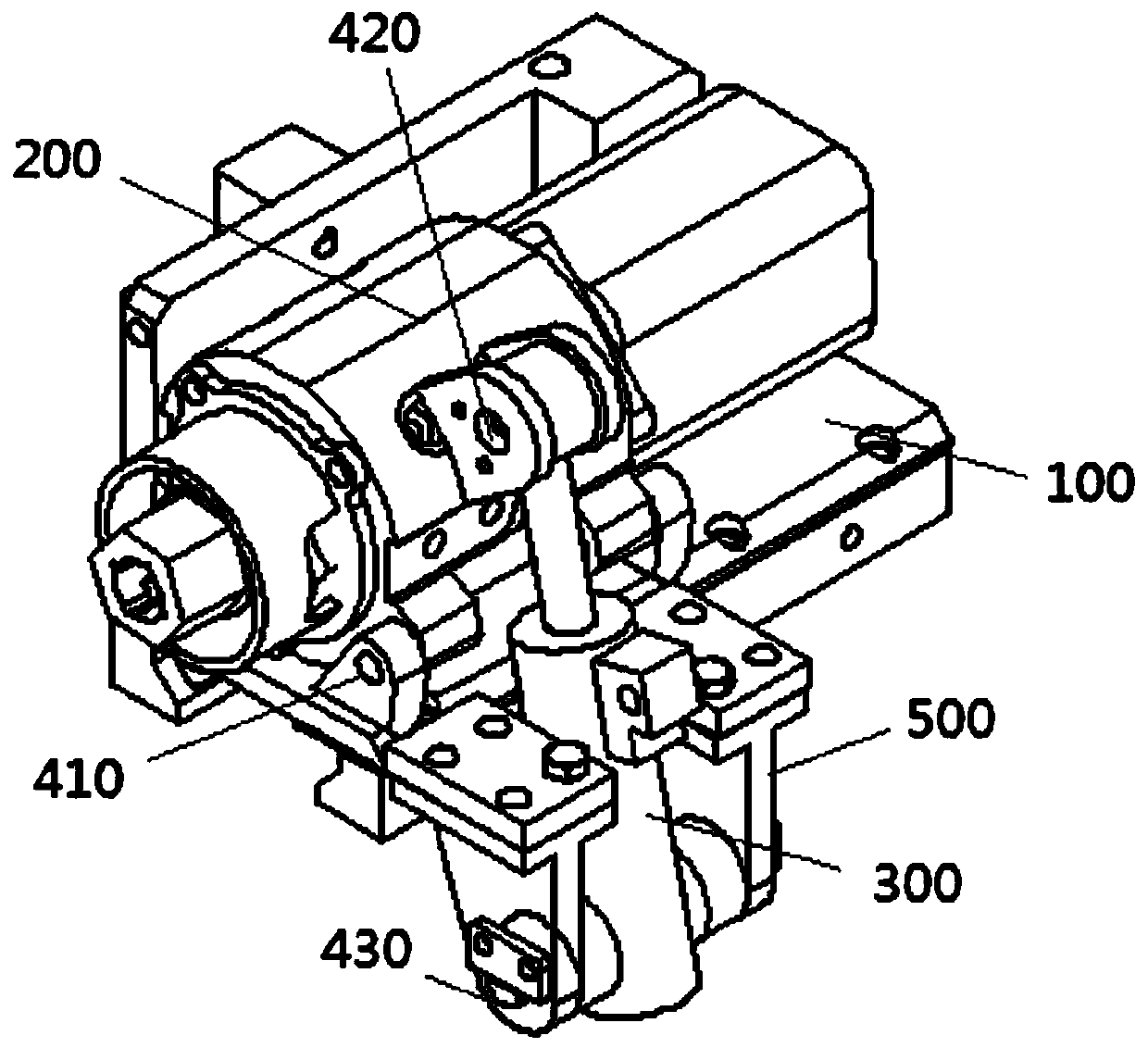

Reversible drilling box for roof bolter

PendingCN110700868AIncrease support speedSolve the replacement problemConstructionsDerricks/mastsRock boltDrill

The invention discloses a reversible drilling box for a roof bolter. The reversible drilling box comprises a fixed seat arranged on a roof bolter sliding rail, a drilling box body capable of being reversed relative to the fixed seat, and a reversing oil cylinder for pushing the drilling box body to be reversed, wherein the drilling box body is connected with the fixed seat through a first hinge shaft; one end of the reversing oil cylinder is connected with the drilling box body through a second hinge shaft; the other end of the reversing oil cylinder is connected with the fixed seat through athird hinge shaft; and the drilling box body is driven by the reversing oil cylinder to be reversed left and right around the first hinge shaft. According to the roof bolter, the problem of replacinga drill rod and an anchor rod when the anchor rod is constructed in a small roadway is solved, when the anchor rod is constructed through the roof bolter, the roof bolter does not need to be moved when the anchor rod is inserted, the problem that the replacing efficiency of the drill rod and the anchor rod is low is solved, the anchor rod is inserted more conveniently, the anchoring efficiency isimproved, the secondary eye finding time is shortened, and the anchor rod supporting speed is increased.

Owner:YANKUANG GRP CO LTD +1

Self-circulation type advanced hydraulic support

InactiveCN101644162BImprove securityIncrease support speedMine roof supportsEngineeringUltimate tensile strength

The invention relates to an advanced support device of a coal mine fully mechanized mining working surface lane, in particular to a self-circulation type advanced hydraulic support. The self-circulation type advanced hydraulic support consists of a walking part, a frame part and a plurality of support parts, wherein, the frame part is arranged on the walking part and can be telescopic and supportthe support parts for walking, and a plurality of support parts are supported in the lane; when the self-circulation type advanced hydraulic support needs to be moved forward, the manual handling is unnecessary, only the support parts need to be contracted for being supported on the frame part, the walking part advances and then the support parts are well supported. The self-circulation type advanced hydraulic support can improve the safety of a support environment of the fully mechanized mining working surface ventilation lane, reduce the labor intensity of miners, improve the support speed of a fully mechanized mining working surface and accelerate coal production.

Owner:SHANXI DONGHUA MACHINERY

Development machine

The invention discloses a development machine, comprising a development machine body (1) as well as a supporting device (2) and a driving device (3) for driving the supporting device (2) to move; wherein the supporting device (2) is arranged at the front part of the development machine body (1), and the supporting device (2) can be in supported position under the action of the driving device (3).The development machine provided by the invention can widen application range thereof while ensuring use cost to be low, and meanwhile the time required by supporting is reduced, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

Construction Method of Rapid Casting Concrete for Anti-sliding Pile Retaining Wall

The invention provides a construction method for quickly pouring anti-slide pile protection wall concrete. After a previous section of poured protection wall concrete has a certain strength, a sand cushion layer is cleared, all sand cushions are collected together for standby application, and anti-slide pile excavation is continued; after the pouring height of one section of a protection wall is reached, protection wall steel bars are welded and bound under the poured protection wall; a sand bottom moldboard is laid to the position 3 centimeters above the bottom of a protection wall side moldboard, and the width of the sand bottom moldboard is 30 centimeters or above larger than that of the protection wall side moldboard; the optimized and improved protection wall side moldboard in which concrete feeding holes are pre-formed is erected, after the side moldboard is erected, the bottom of the side moldboard is embedded deep into 3 centimeters in a sand layer to prevent grout runout, the portion 5 centimeters above the top of the side moldboard is closely attached to the face of the previous section of the protection wall, and the protection wall moldboard is reinforced through steel pipes and adjustable lead screws. A concrete lifting bucket is lifted through a small lifting winch, the concrete can be directly poured into the moldboards through a simple movable concrete sliding groove, the concrete pouring speed is high, and the labor intensity of workers is reduced. Through the steps, quick construction of the anti-slide pile sand bottom moldboards is achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

A Mixed Advance Support Method for Mining Roadway with Small Section

ActiveCN110529144BExpand the effective carrying rangeImprove integrityUnderground chambersTunnel liningStructural engineeringStoping

The invention relates to a small-section mining roadway mixing type advanced support method and belongs to the technical field of mining roadway supports. The method solves the problems that an existing support method is low in support efficiency, large in labor intensity of workers, high in cost, low in mining efficiency, insufficient in effective construction space and low in operation safety and reliability. The support method comprises the steps that 1, a mining roadway to be supported is determined; 2, a grouting anchor cable and an individual hydraulic prop mixing type advanced support are additionally installed on a top plate of the mining roadway, and a top plate support structure is formed; and 3, in the coal mining process, while the mining working face is propelled forwards, thegrouting anchor cable is additionally installed in the propelling direction constantly, an individual hydraulic prop and a hinge top beam of the working face end are pushed towards the front end of the advanced support constantly, and thus the distance of the advanced support is kept within the safe range. According to the method, the support efficiency and the mining efficiency are improved, thelabor intensity of the workers and the support cost are reduced, the support strength is higher, the support effect is better, and safe and efficiency production is achieved.

Owner:CHINA UNIV OF MINING & TECH

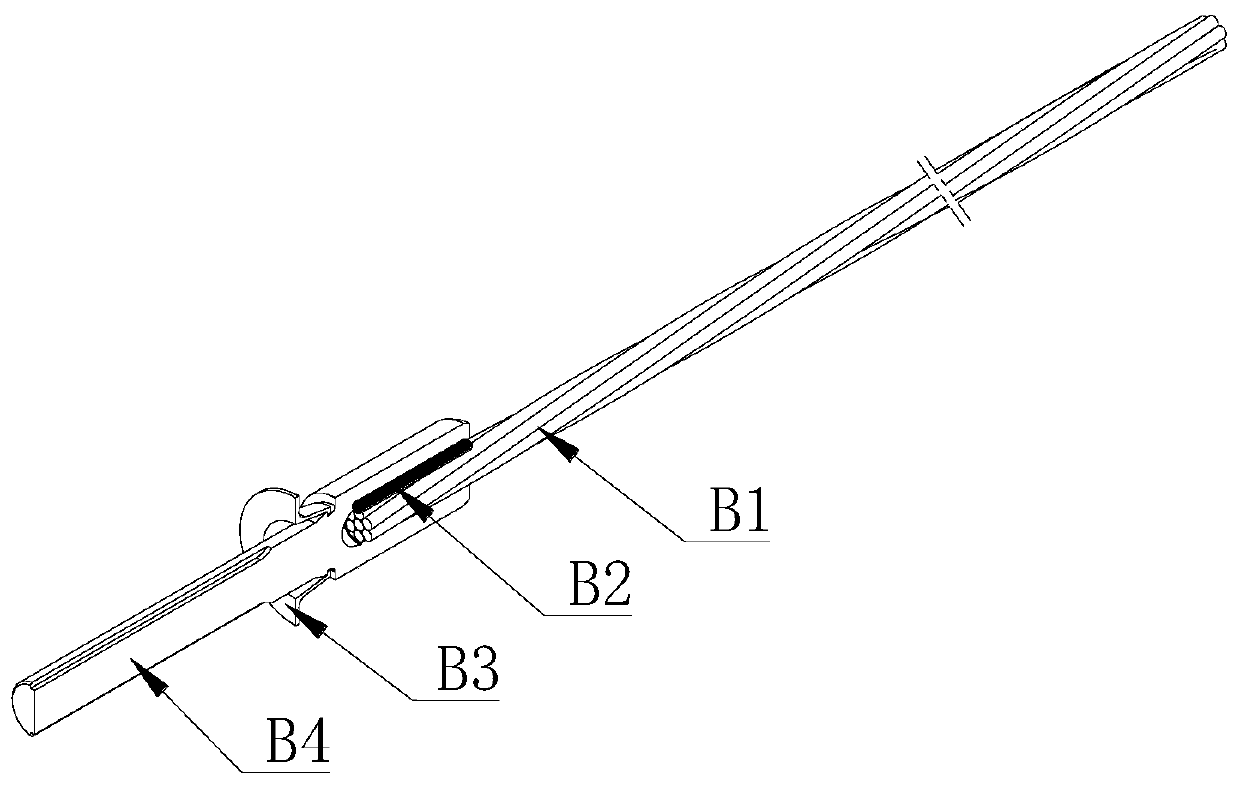

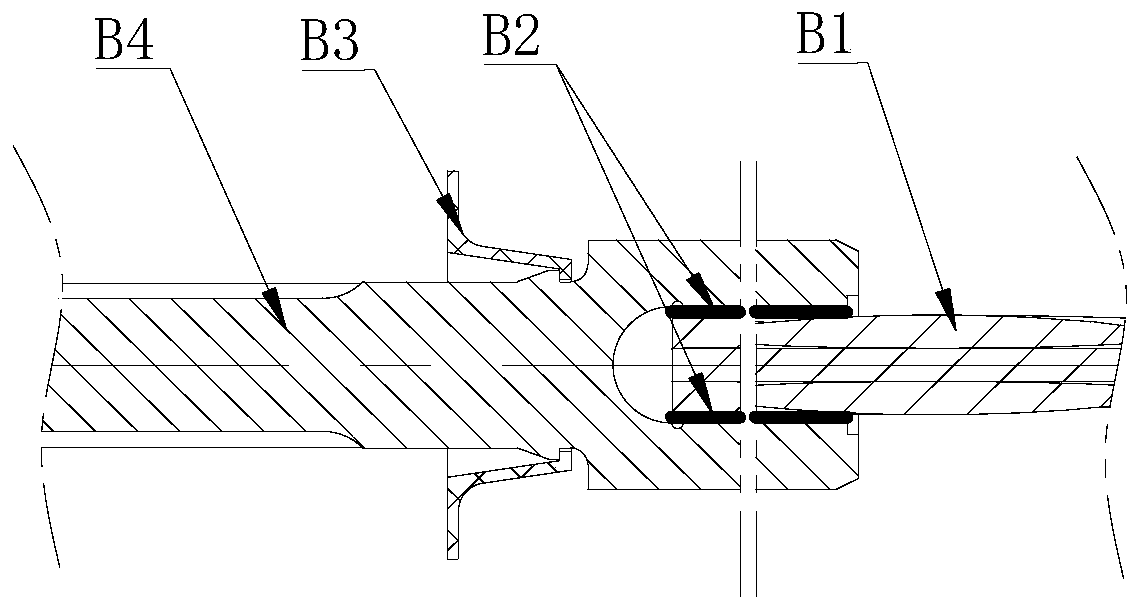

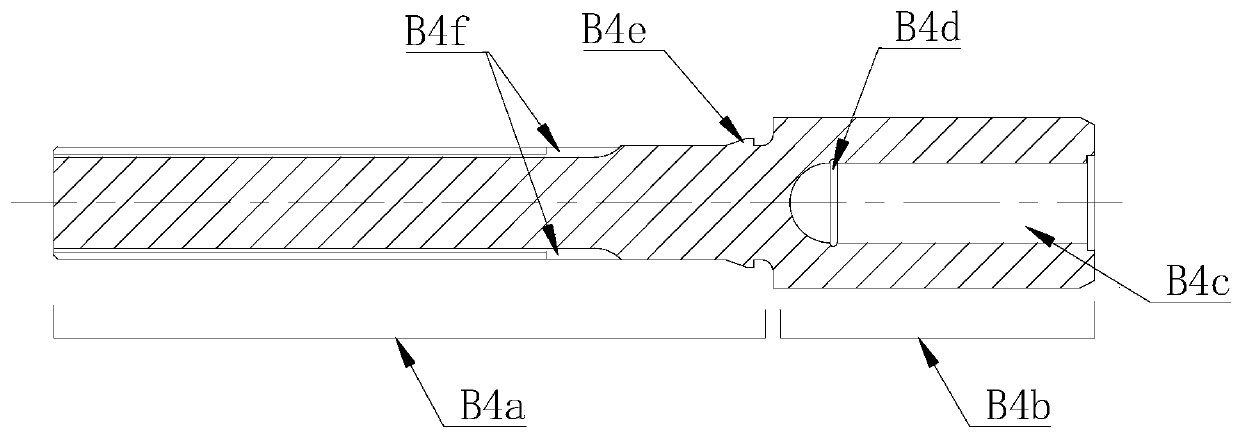

A construction method of a flexible anchor rod

ActiveCN109488355BSolve the problem that the length is limited by the height of the roadwayMeet the requirements of the complex environment on siteAnchoring boltsDetentEngineering

Owner:CHINA UNIV OF MINING & TECH

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086BIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading andconveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

A Method for Determining the Length of Anchor Rod for Roadway Support

ActiveCN107133381BControl deformationMeet the requirements of high productivity and high efficiencyGeometric CADSpecial data processing applicationsArchitectural engineeringRock bolt

The invention discloses a length determining method for an anchor rod for roadway supporting. The length determining method includes the steps that according to the shape of a cross section of a roadway, a circumcircle of a contour line of the roadway is made; then an expansion concentric circle of the circumcircle is made according to the development depth of a surrounding-rock plastic zone, and parameters of the reasonable length of the anchor rod are obtained in the mode that the distance from the surface of the roadway to the expansion concentric circle of the plastic zone, the length that the anchor rod is anchored into hard-and-stable surrounding rock and the exposed length of the anchor rod are superposed. According to the length determining method, the process that the reasonable length of the anchor rod is determined is simple, operation is convenient, the accuracy is high, materials of a rod body of the anchor rod are saved, waste is avoided, the construction speed of drilling is increased, the labor strength of workers is reduced, the surrounding-rock control efficiency of the anchor rod is improved, and the favorable condition is provided for mine safety production.

Owner:CHINA UNIV OF MINING & TECH

A kind of advance support method of grouting anchor cable

ActiveCN109681248BImprove work efficiencyDefects affecting strengthUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention relates to a grouting anchor cable advanced supporting method, belongs to the field of advanced supporting and aims at solving the problems of insufficient supporting strength and slow supporting speed in the prior art and roof breakage and large worker labor intensity caused by repeated supporting. The advanced supporting method disclosed by the invention comprises the following steps: step 1, determining a mining roadway (1) to be supported on a current working face (3); step 2, determining an advanced supporting distance L according to the advanced supporting pressure distribution law and the engineering geological condition of the mining roadway (1); step 3, adding grouting anchor cable advanced supporting to a roof of the mining roadway (1) to form a roof supporting structure. In a coal mining process, the working face (3) is propelled forwards, the grouting anchor cable advanced supporting is simultaneously and continuously added in the propelling direction, and theadvanced supporting distance is maintained in a safe range. The grouting anchor cable advanced supporting method disclosed by the invention can ensure safe mining and simultaneously improve supporting strength and supporting efficiency and reduce worker labor intensity.

Owner:CHINA UNIV OF MINING & TECH +2

Telescopic flexible die for gob-side entry retaining

InactiveCN112983514AEasy to pourImprove efficiencyProps/chocksConstruction engineeringStructural engineering

The invention provides a telescopic flexible die for gob-side entry retaining. The telescopic flexible die comprises three flexible die units including a flexible die A, a flexible die B and a flexible die C, wherein the flexible die A, the flexible die B and the flexible die C are integrally connected, a grouting hole A, a grouting hole B and a grouting hole C are respectively formed in the side walls of the flexible die A, the flexible die B and the flexible die C, a groove is formed in one side of the flexible die A, and the groove is matched with the flexible die C. The telescopic flexible die has the advantages of convenience in pouring and high use efficiency, an adopted telescopic flexible formwork can extend and retract as required, pouring materials are poured into the flexible formwork, the flexible formwork support speed is increased, the limitation of flexible formwork support on the stoping speed is relieved, material leakage is prevented, and the construction requirement is met.

Owner:韩佳峰

Mine-used anchoring steel belt and roadway roof bolt support method

InactiveCN103883340BReduce labor intensityImprove mechanical propertiesAnchoring boltsTransverse grooveRock bolt

The invention relates to a mining anchoring steel belt and roadway top plate anchor rod supporting method. Mining anchoring steel belts include a transverse steel belt and two longitudinal steel belts, one ends of the longitudinal steel belts are connected with the transverse steel belt, the transverse steel belt and the longitudinal steel belts are integrally formed, a transverse groove is formed on the transverse steel belt, a longitudinal groove is formed on each longitudinal steel belt, a protruding outwards-extending structure is formed at a free end of each longitudinal steel belt, a lapping structure used for being matched with an outwards-extending structure of another mining anchoring steel belt is formed on the transverse steel belt, an anchor rope limiting hole is arranged in each longitudinal groove, and an anchor rod limiting hole is arranged on each outwards-extending structure. Due to adoption of the above technical scheme, temporary supporting effect similar to that of a forepoling bar can be realized; conventional forepoling bar temporary supporting is replaced, so that labor intensity of workers is lowered, and supporting speed is increased.

Owner:SHANDONG UNIV OF SCI & TECH

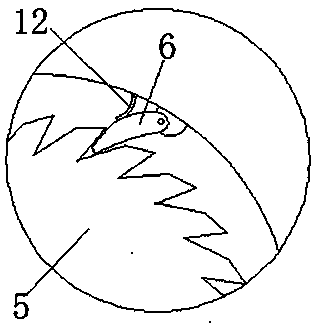

Multi-point inverted-oblique-type self-locking anchor bolt

The invention relates to the technical field of coal mine tunnel support equipment, in particular to a multi-point inverted-oblique-type self-locking anchor bolt. The multi-point inverted-oblique-typeself-locking anchor bolt comprises a multi-point inverted-oblique-type self-locking device, an anchor bolt body, a supporting plate and a nut, wherein the multi-point inverted-oblique-type self-locking device comprises a cylinder; oblique sliding grooves with the dimension of 18 mm * 18 mm * 80 mm are separately formed at two sides of the cylinder; oblique sliding arrows matching the oblique sliding grooves are arranged in the oblique sliding grooves; the outer surfaces of the oblique sliding grooves are inverted serrated; a thread groove with an opening facing downward is formed at the lowerpart of the cylinder; two ends of the anchor bolt body are both provided with threads; the upper end of the anchor bolt body is in threaded connection with the thread groove; and the lower end of theanchor bolt body is in threaded connection with the nut. The multi-point inverted-oblique-type self-locking anchor bolt has the advantages of simplifying the operation, greatly accelerating the speedof bolt support, recycling the anchor bolt body, the supporting plate and the nut for use, and greatly saving the cost. The multi-point inverted-oblique-type self-locking anchor bolt meets the environmental protection requirements with no pollution in the production and using process, and can provide guarantee for the safety of tunnels.

Owner:山西金宝泰能源科技有限公司

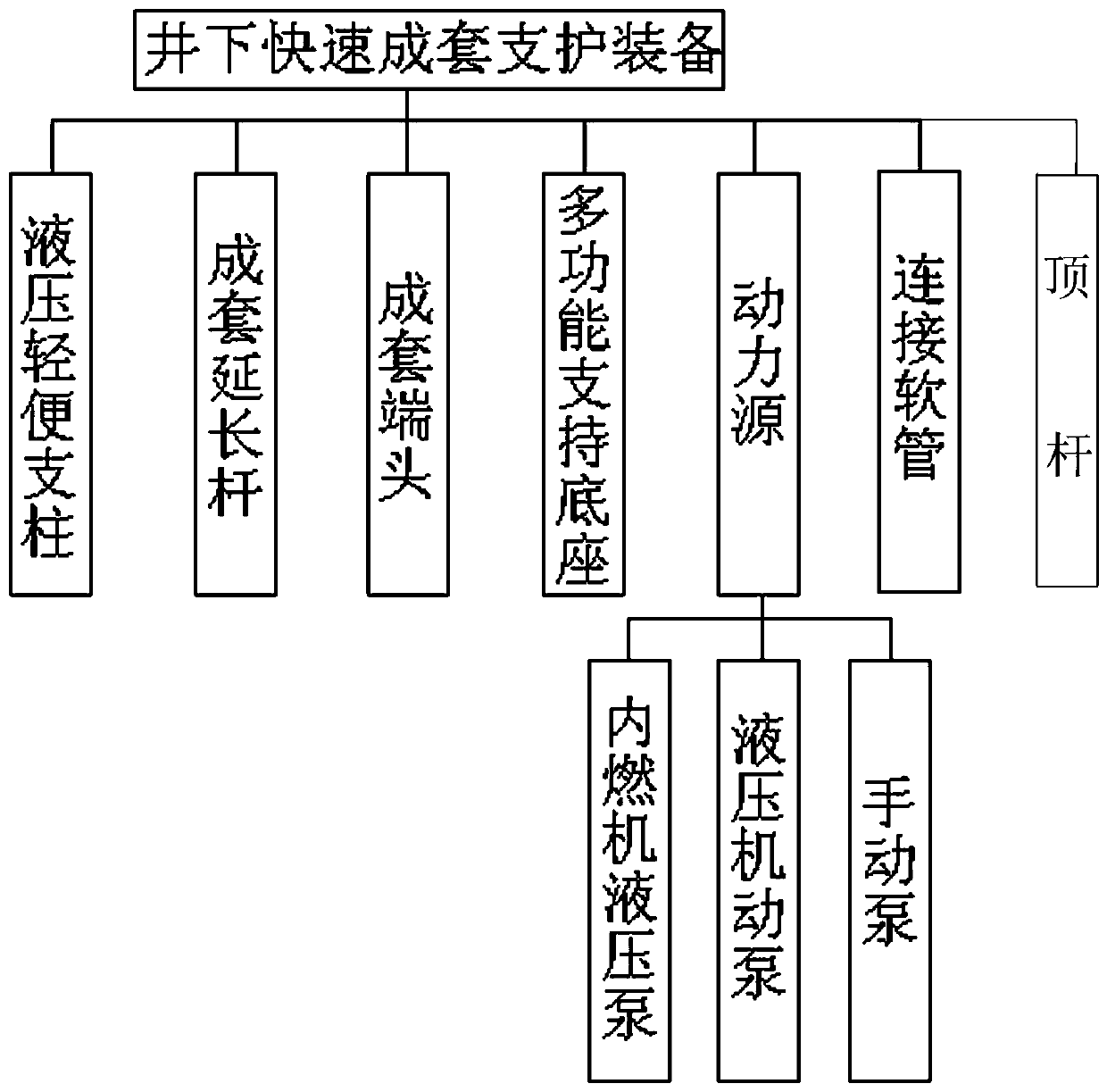

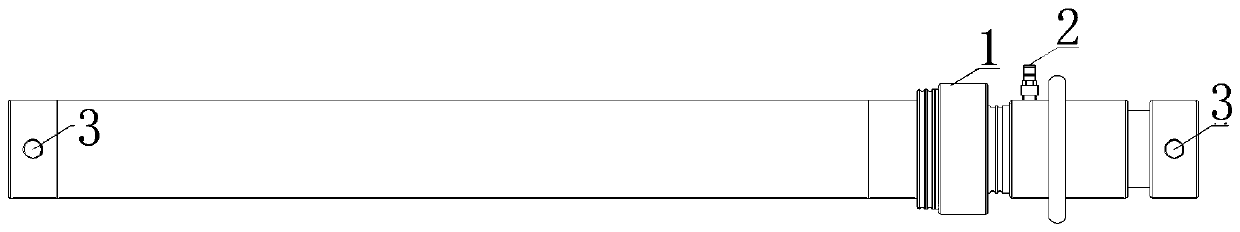

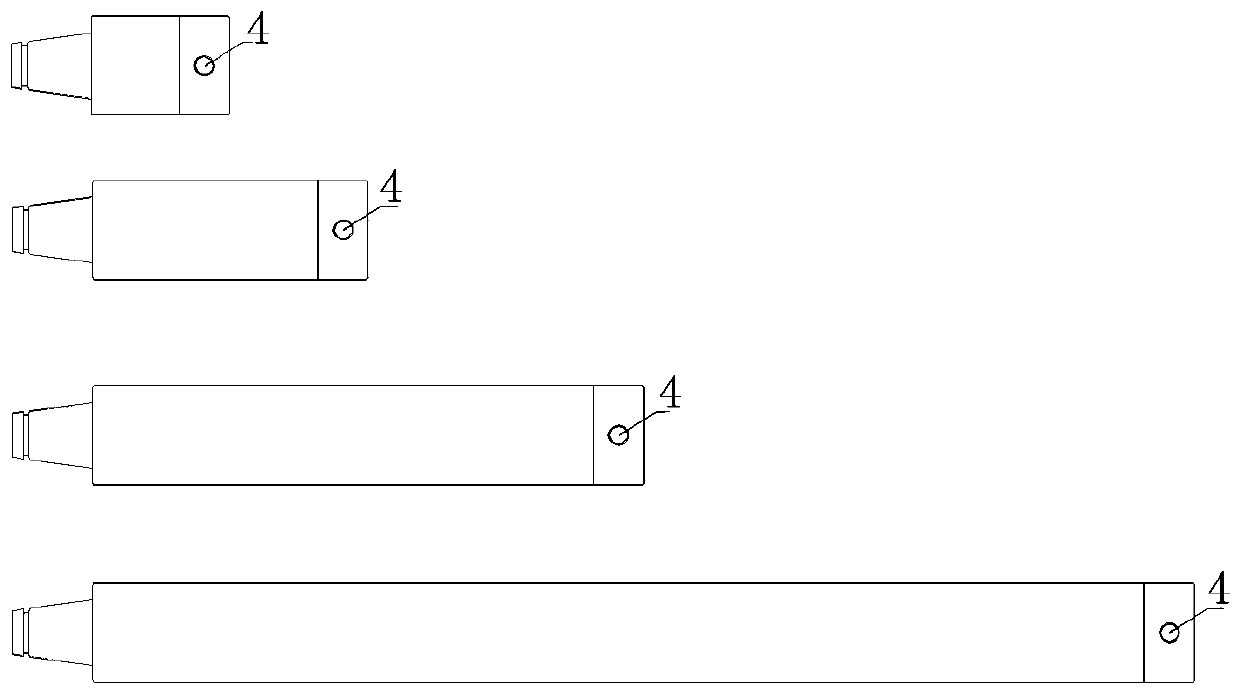

Downhole fast complete set of support equipment

ActiveCN105507942BAvoid concatenation usingImprove stabilityProps/chocksSafety equipmentsWorkloadFactor of safety

Owner:DATONG COAL MINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com