Protective bracket with net profile structure for subway tunnel construction

A technology for protective brackets and mesh profiles, which is applied to mine roof brackets, mining equipment, and earth-moving drilling and mining, etc., can solve problems such as being unfavorable for tunnel construction and poor adjustability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

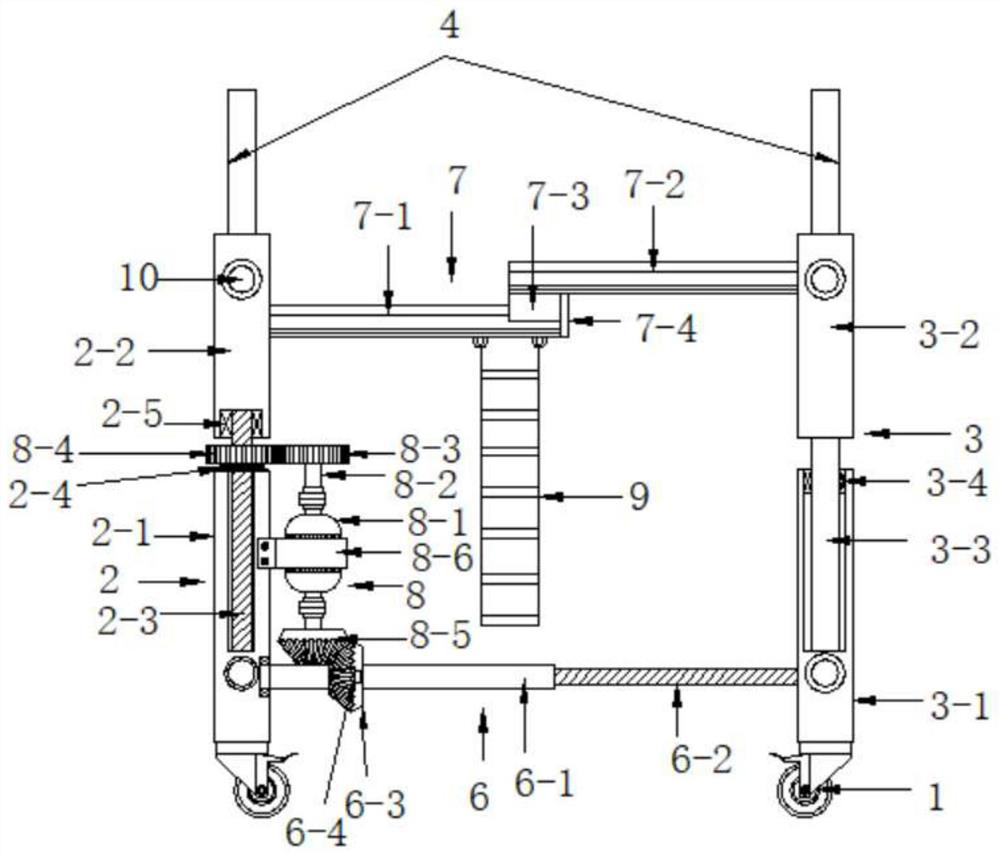

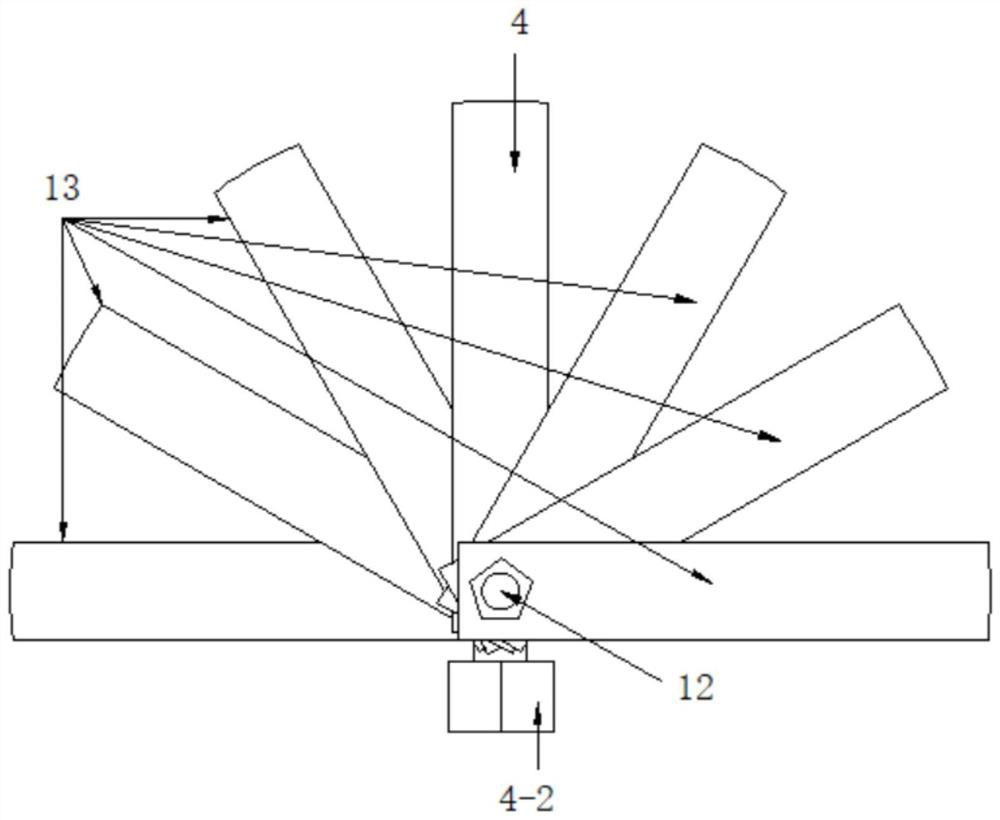

[0027] Such as Figure 1-Figure 3 As shown, this specific embodiment adopts the following technical scheme: it includes universal wheel 1, main strut 2, auxiliary strut 3, No. 1 support top 4, No. 2 support top 5, stretching mechanism 6, guide rail group 7 , driving mechanism 8, soft ladder 9, horizontal guide shaft 10, horizontal guide bearing 11, pin shaft 12 and auxiliary support top 13;

[0028] Above-mentioned main strut 2 is made of main fixed rod 2-1, active rod 2-2, strut screw rod 2-3, plane thrust ball bearing 2-4 and main bearing 2-5; The steering wheel 1 is fixed on the lower end of the main fixed rod 2-1 by screw connection; the main fixed rod 2-1 is movably inserted with a strut screw rod 2-3, and the upper end of the strut screw rod 2-3 is inserted into the main bearing 2-5, the main bearing 2-5 is embedded and welded and fixed in the lower end of the active rod 2-2, and the strut screw rod 2-3 located at the upper end of the main fixed rod 2-1 is sleeved with ...

specific Embodiment approach 2

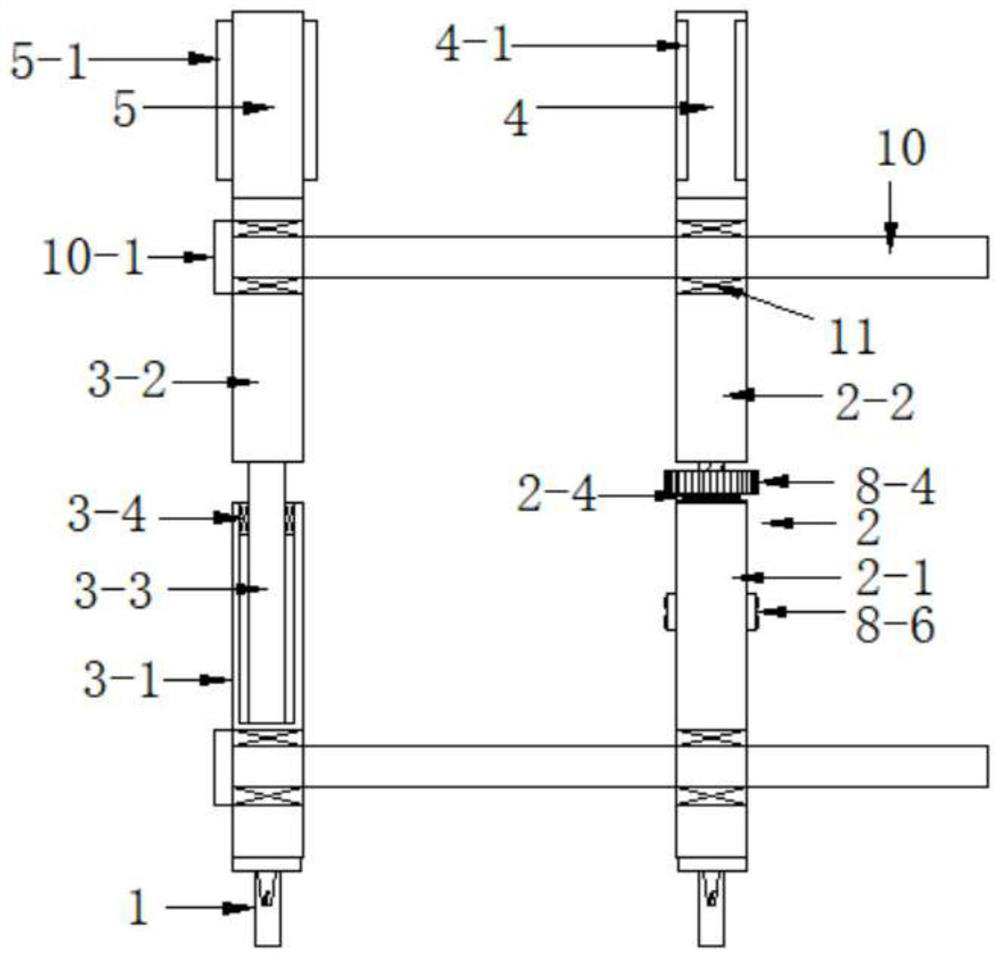

[0043] see Figure 4 The difference between this specific embodiment and the specific embodiment one is that: the opposite two vertical surfaces of the No. 1 support top 4 are provided with docking grooves 4-1, and the opposite two The vertical surface is integrally formed with a butt edge 5-1 that is inserted in cooperation with the butt groove 4-1, and the rest of the structure is the same as that of the specific embodiment one. Two auxiliary struts 3 are sleeved on the horizontal guide shaft 10, and are located on the front and rear sides of the main strut 2. The No. 2 support top 5 at the upper end of the two auxiliary struts 3 utilizes the butt joint edge 5-1 to connect with the main strut. 2. The insertion and fit of the docking groove 4-1 in the No. 1 support top 4 at the upper end is connected as a whole, and two horizontal guide shafts 10 in the auxiliary strut 3 connected with the main strut 2 are also sleeved on the front and rear. Auxiliary strut 3, the No. 2 supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com