Telescopic flexible die for gob-side entry retaining

A telescopic and soft-form technology, which is applied in the direction of mining equipment, earthwork drilling, pillars/brackets, etc., can solve the problem of reduced quality of gob-side entry in the working face, difficulty in ensuring the quality of flexible-form support, and the existence of gob-side entry Potential safety hazards and other issues, to achieve the effect of increasing speed, preventing material leakage, and meeting construction needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

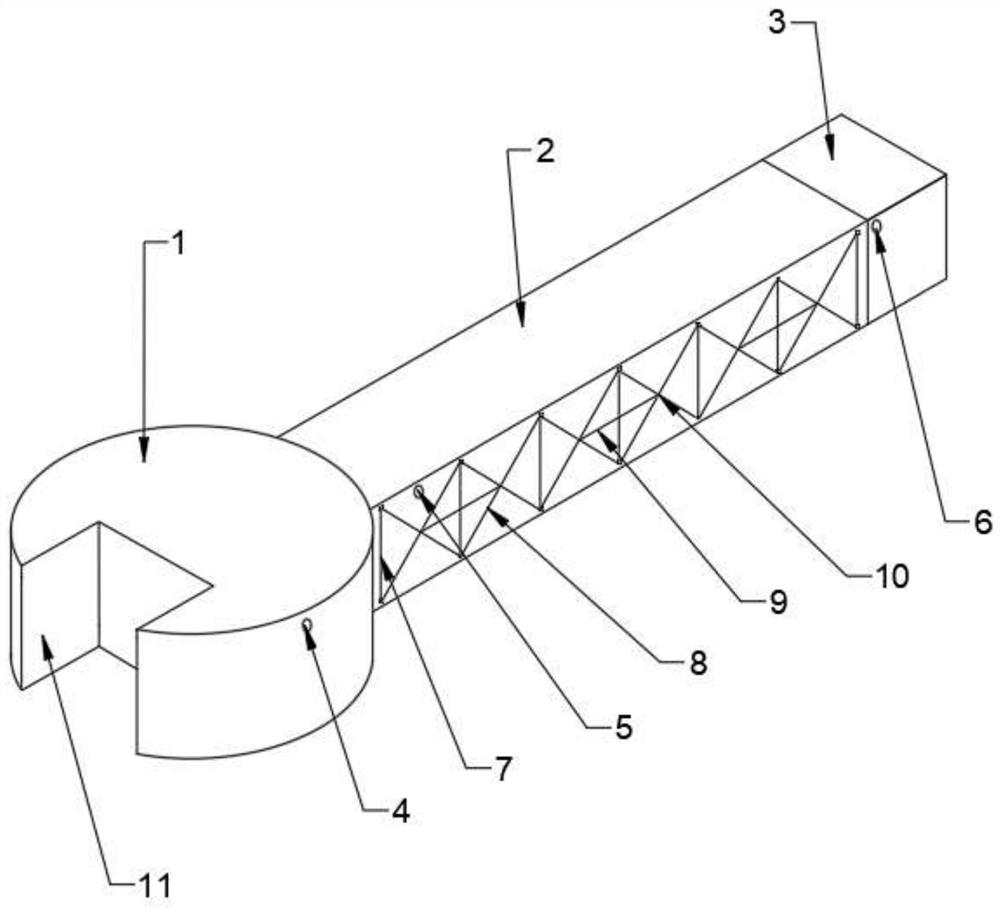

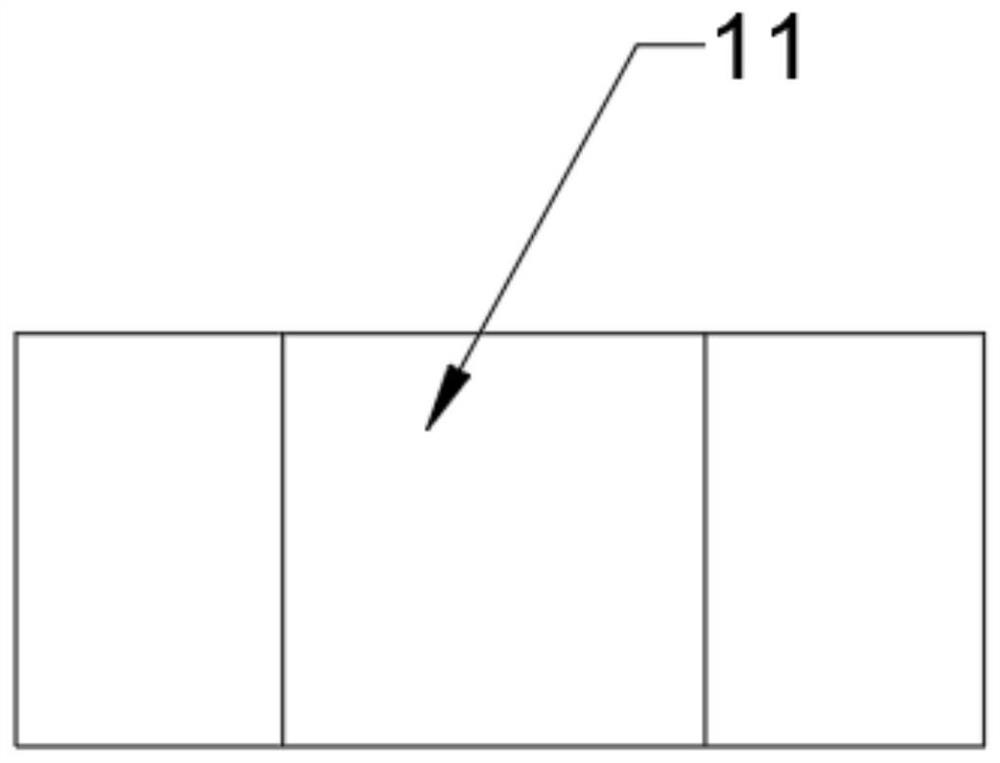

[0016] Embodiment 1: as Figure 1-3 The telescopic flexible mold for gob-side entry shown is composed of three flexible mold units, namely flexible mold A1, flexible mold B2 and flexible mold C3, the flexible mold A1, flexible mold B2 and flexible mold C3 The flexible mold A1, the flexible mold B2 and the flexible mold C3 are integrally connected, and the side walls of the flexible mold A1, the flexible mold B2 and the flexible mold C3 are respectively provided with a grouting hole A4, a grouting hole B5 and a grouting hole C6, and one side of the flexible mold A1 is opened with a Groove 11, said groove 11 is compatible with flexible mold C3.

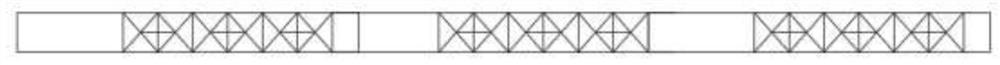

[0017] The flexible mold B2 is a strip-shaped rectangular structure, and both sides of the flexible mold B2 are equidistantly provided with vertical telescopic rods 7 along its length direction, and two adjacent vertical telescopic rods 7 are connected with "X" ladders Beam 8.

[0018] The center of the "X" of the ladder beam 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com