A crawler type thin coal seam bolter

A technology of bolt drilling rig and thin coal seam, which is applied in the directions of bolt installation, earthwork drilling, drilling equipment, etc., can solve the technical problems of thin coal seam mining, narrow application range of coal plow, and production efficiency of blasting mining. Low problems, to achieve the effect of improving mining efficiency and safety, increasing the scope of use, and increasing the speed of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

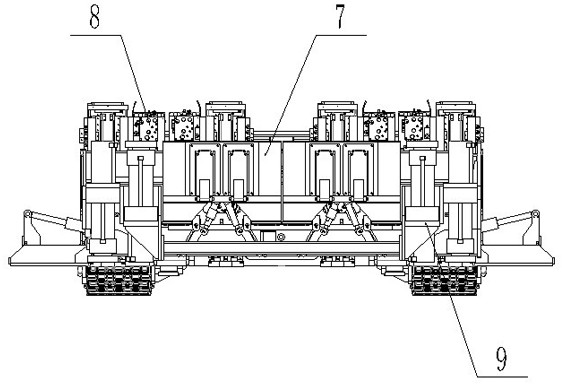

[0052] This embodiment is a crawler-type thin coal seam bolter, which includes a workbench 3 and a chassis 1 of a crawler-type traveling mechanism. The chassis 1 is connected to the workbench 3 through a lifting mechanism 2 provided, and the chassis 1 enters The middle part of one side of the roadway in the thin coal seam is sunken downward to form a sinker, and a fixed ear seat for hinged lifting mechanism 2 is arranged in the sinker.

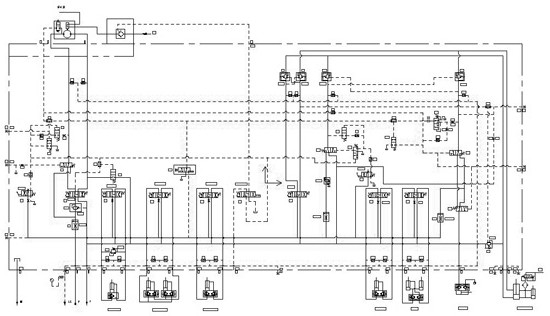

[0053] One end of the lifting mechanism 2 is hinged to the fixed ear seat, and the other end is hinged to the workbench 3, and is driven by the hydraulic mechanism inside the lifting mechanism 2 to lift in a rotating manner; when the lifting mechanism 2 falls to the lowest position, it sinks into the The height of the drilling rig is 1.1-1.5m in the sinking tank; an anchor drilling system 5 is provided on the workbench 3, and the anchor drilling system 5 and the lifting mechanism are provided by the hydraulic system 8 arranged on the chassis 1....

Embodiment 2

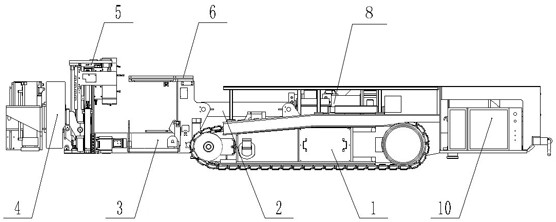

[0064] Such as Figure 1-2 As shown, the main components of a crawler-type thin coal seam bolter rig in this embodiment consist of a chassis 1, a lifting mechanism 2, a workbench 3, a slide rail 4, an anchor drilling system 5, a ceiling assembly 6, a dust removal system 7, and a hydraulic system. 8. Temporary support 9 and electrical system 10 are formed.

[0065] The body height of the whole machine is 1.3 meters, and the minimum support height is 1.4 meters; among them, the chassis 1 is the main part of the whole machine, and the lifting mechanism 2 is arranged in front of the chassis 1, and the workbench can be lifted up and down by the lifting cylinder of the workbench; the lifting mechanism 2 A workbench 3 is arranged ahead, and a ceiling assembly 6 is arranged on the workbench, both of which play the role of protecting operators.

[0066] The slide rail 4 is connected with the workbench 3 through bolts, and provides the installation base and the swing mechanism for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com