A kind of advance support method of grouting anchor cable

A technology of grouting anchor cable and advanced support, which is applied in the installation of bolts, earthwork drilling, shaft equipment, etc. The effect of avoiding damage to the roadway roof, reducing the labor intensity of workers and improving the speed of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

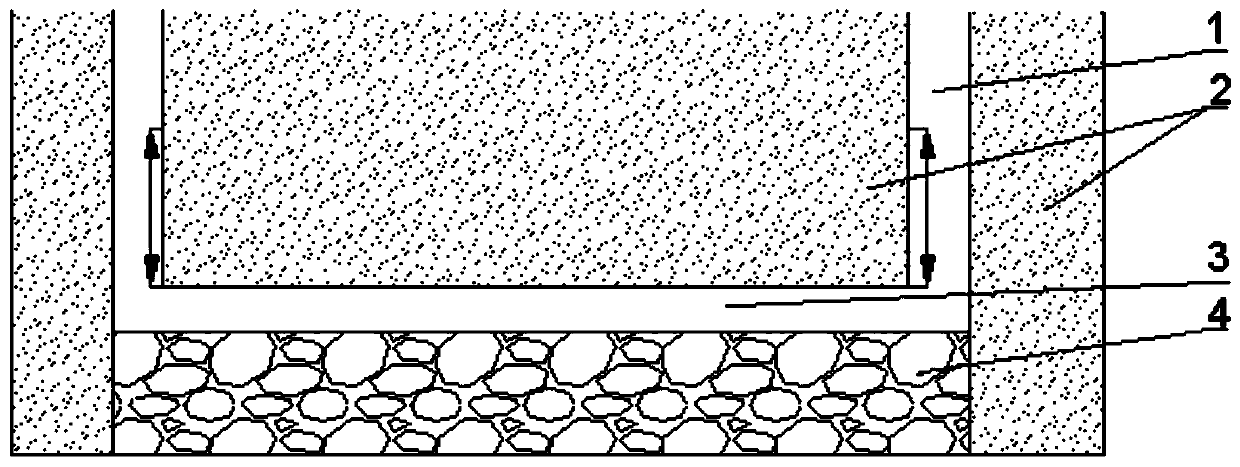

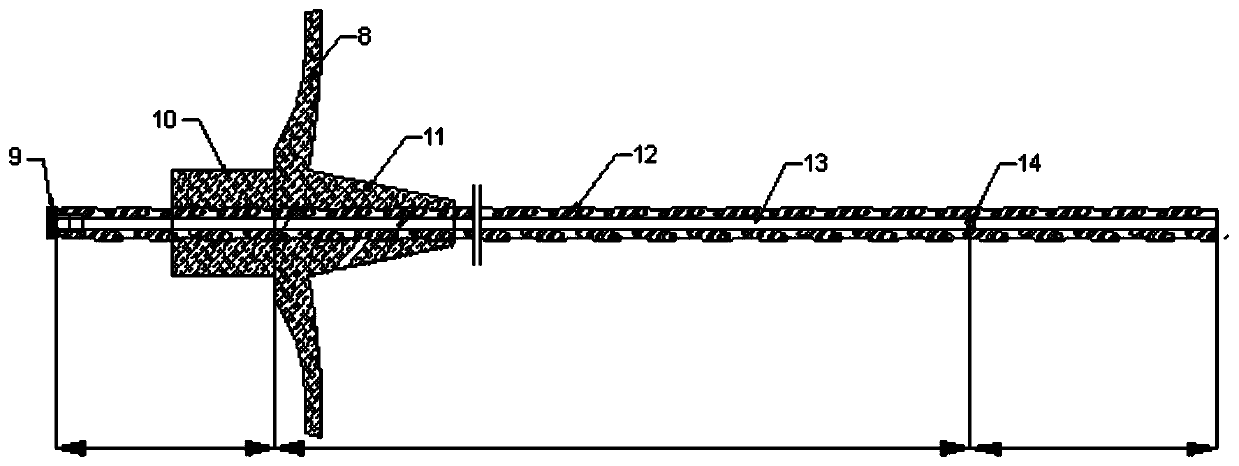

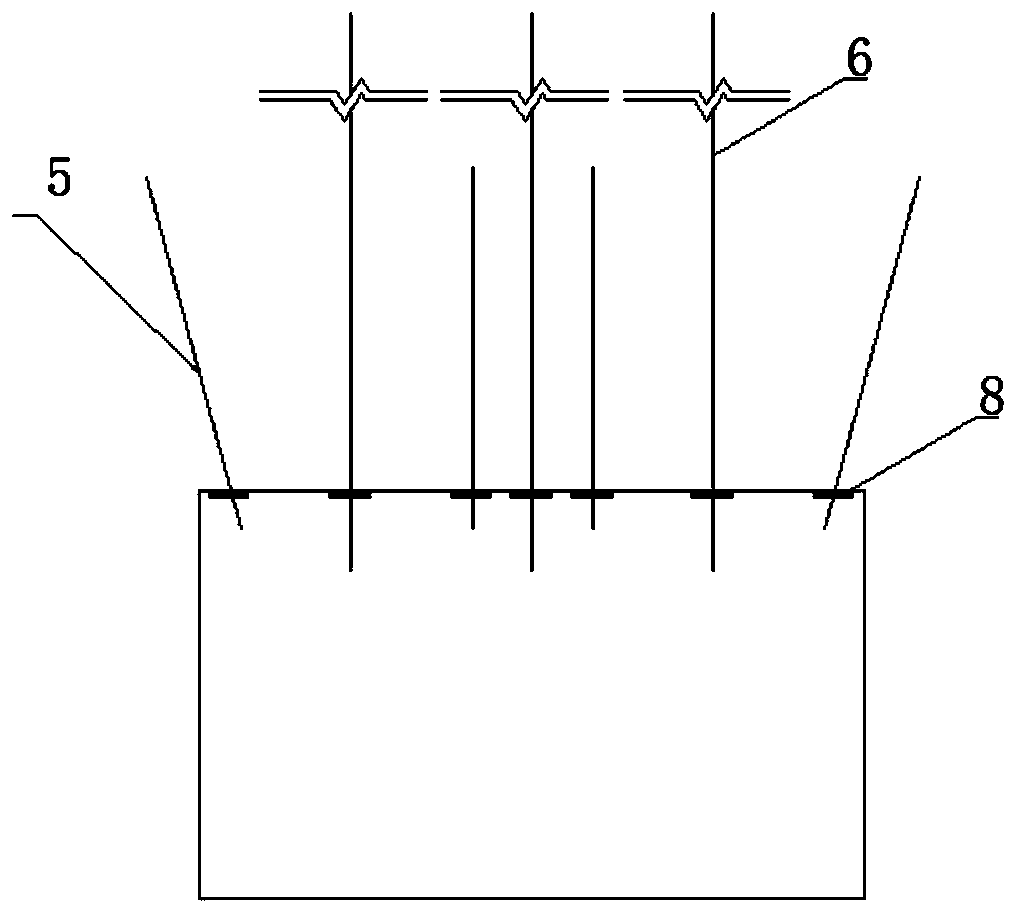

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0031] A specific embodiment of the present invention discloses a method for advance support of grouting anchor cables, comprising the following steps:

[0032] In step 1, the mining roadway 1 to be supported is determined on the current mining face 3 . The determination of the mining roadway 1 is based on the geological conditions and engineering production conditions, and the mining roadway 1 that meets the above conditions is selected for advance support.

[0033] Step 2: Select single or multiple recovery roadways 1; determine the advance support distance L according to the advance suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com