Mine-used anchoring steel belt and roadway roof bolt support method

A technology of bolt support and roadway roof, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of inconvenient erection of permanent support, affect the speed of roadway excavation, and inconvenient operation for workers, and achieve enhanced mechanical properties , Improve support speed and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

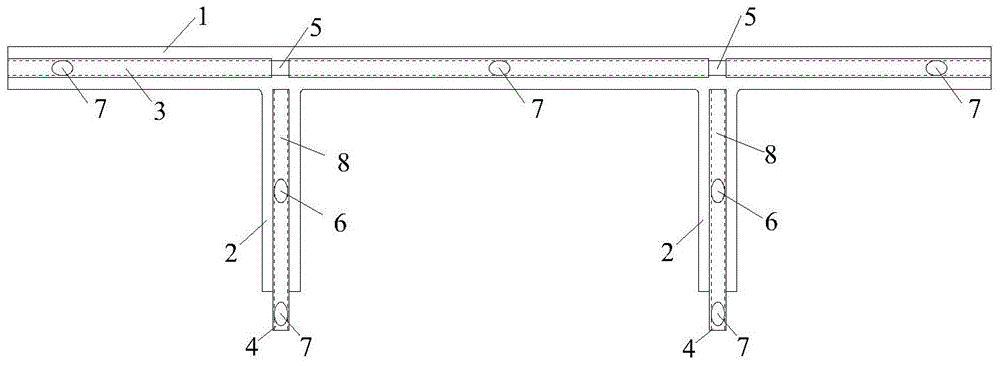

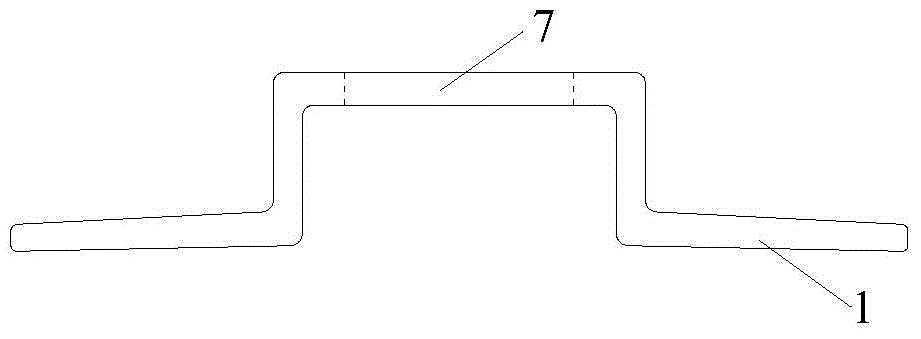

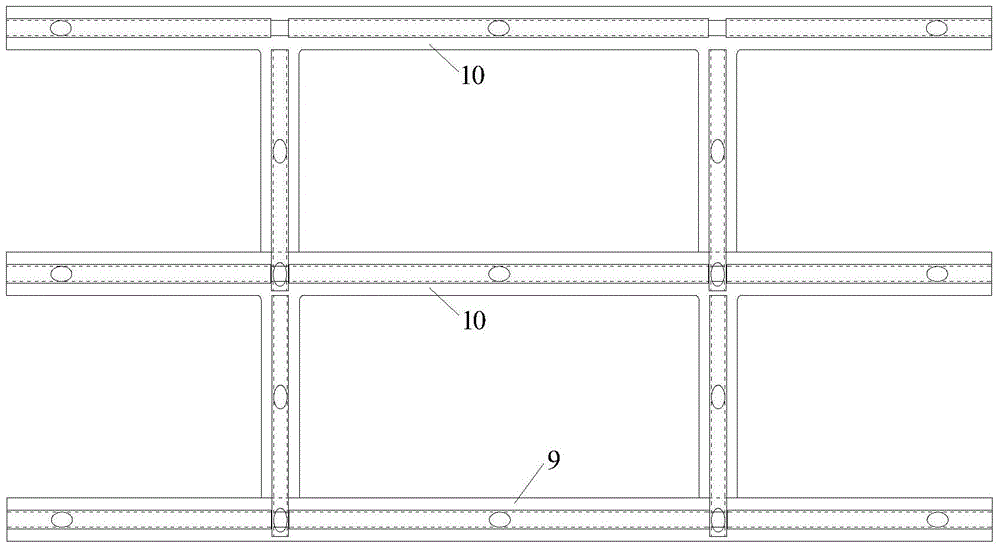

[0022] Please refer to figure 1 and 2 , the present invention provides a mine anchoring steel strip, comprising a transverse steel strip 1 and two longitudinal steel strips 2, wherein one end of the two longitudinal steel strips 2 is connected to the transverse steel strip 1, and the transverse steel strip 1 is connected to the Two longitudinal steel strips 2 are integrally formed; the transverse steel strip 1 is formed with a transverse groove 3, and the longitudinal steel strip 2 is formed with a longitudinal groove 8; the free end of the longitudinal steel strip 2 is formed with a protruding overhanging structure 4, and the transverse The steel belt 1 is formed with an overlapping structure 5 for matching with the overhanging structure of another mine anchoring steel belt; the longitudinal groove 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com