Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

A bolt support and mechanical technology is applied in the field of comprehensive mechanized tunneling operation methods and devices, which can solve the problems of low mine production capacity and mine safety factor, inability to achieve advanced support, and low recovery rate of coal resources, etc. Top time, light weight, good explosion-proof performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

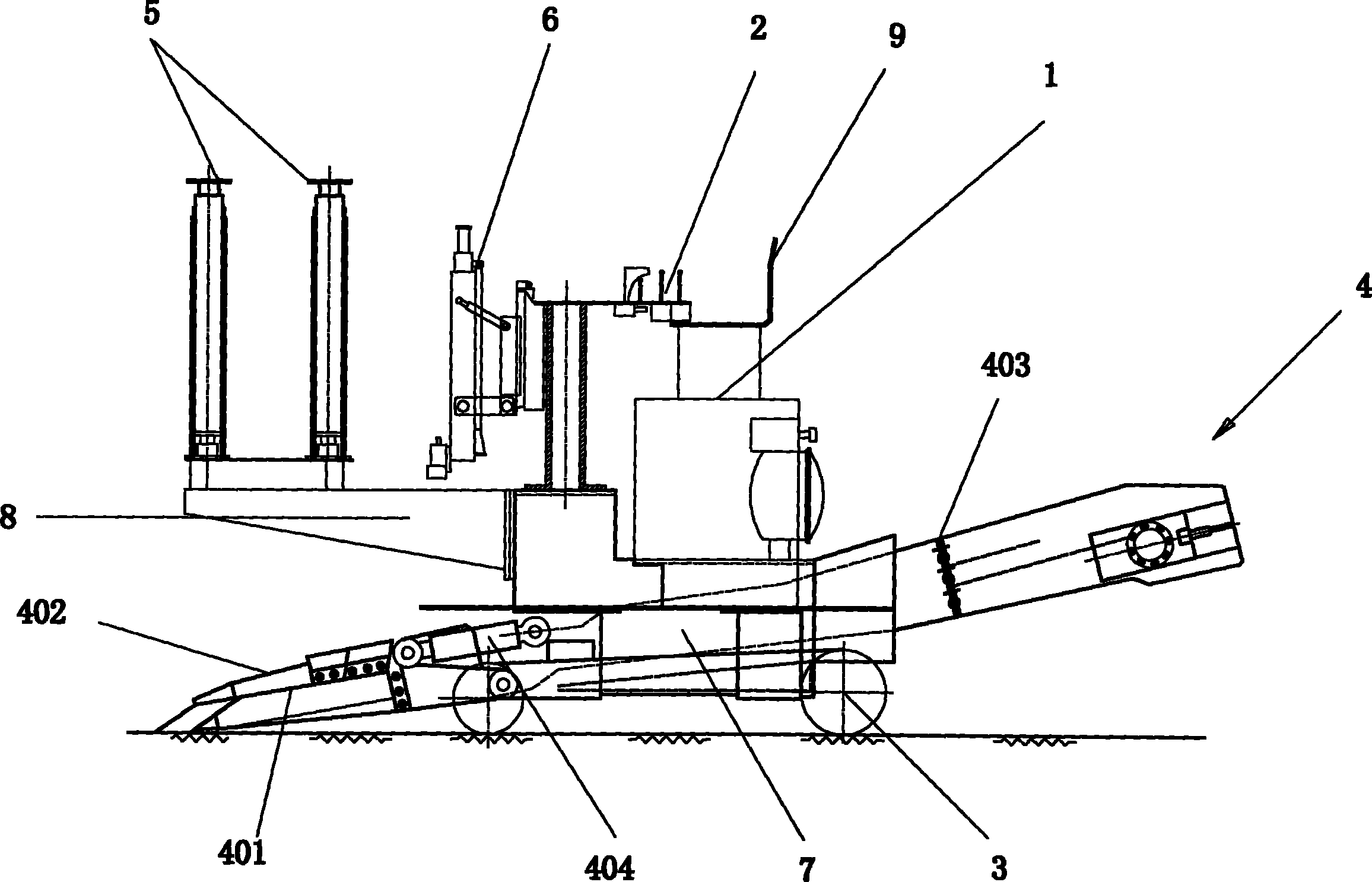

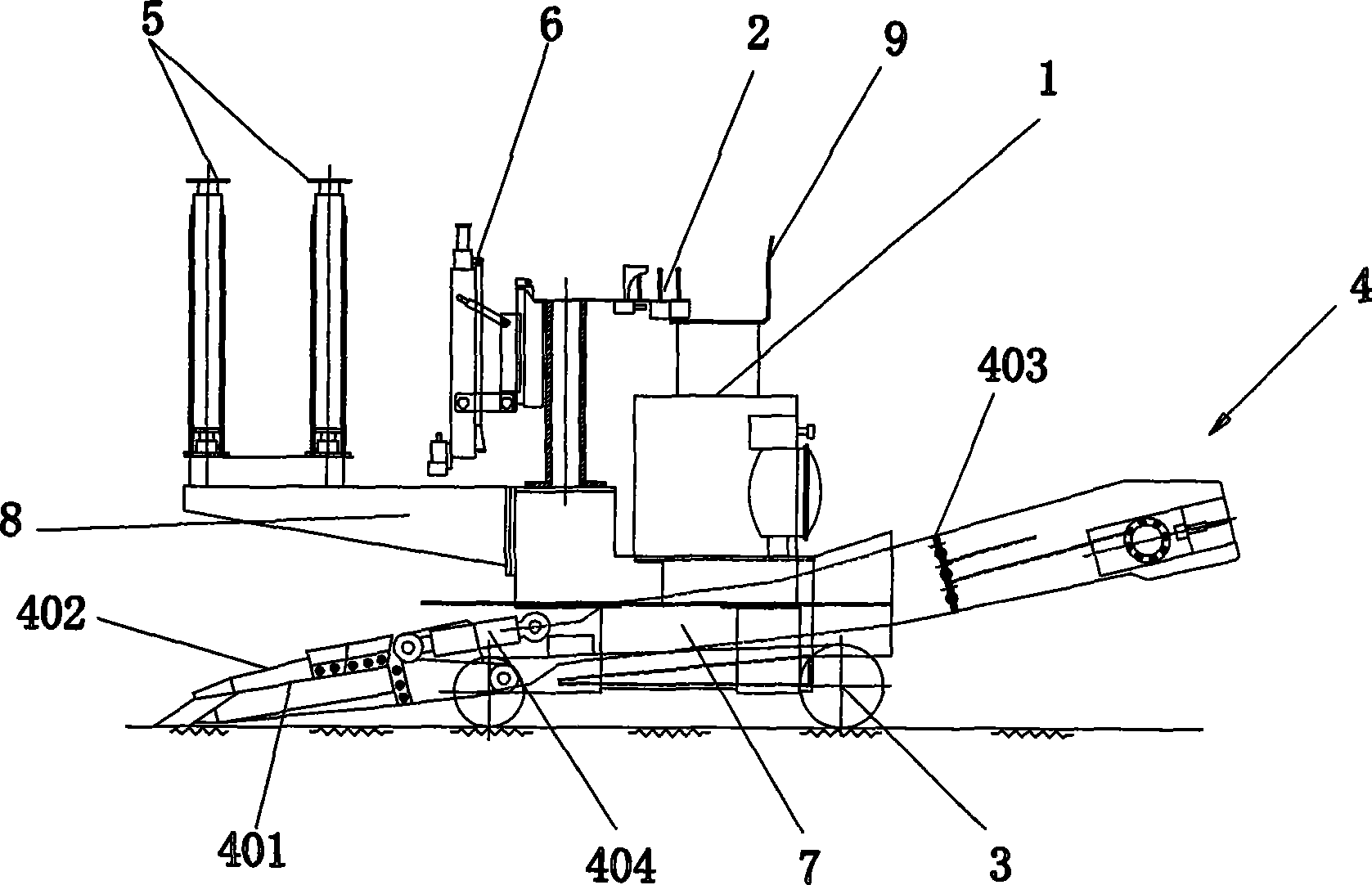

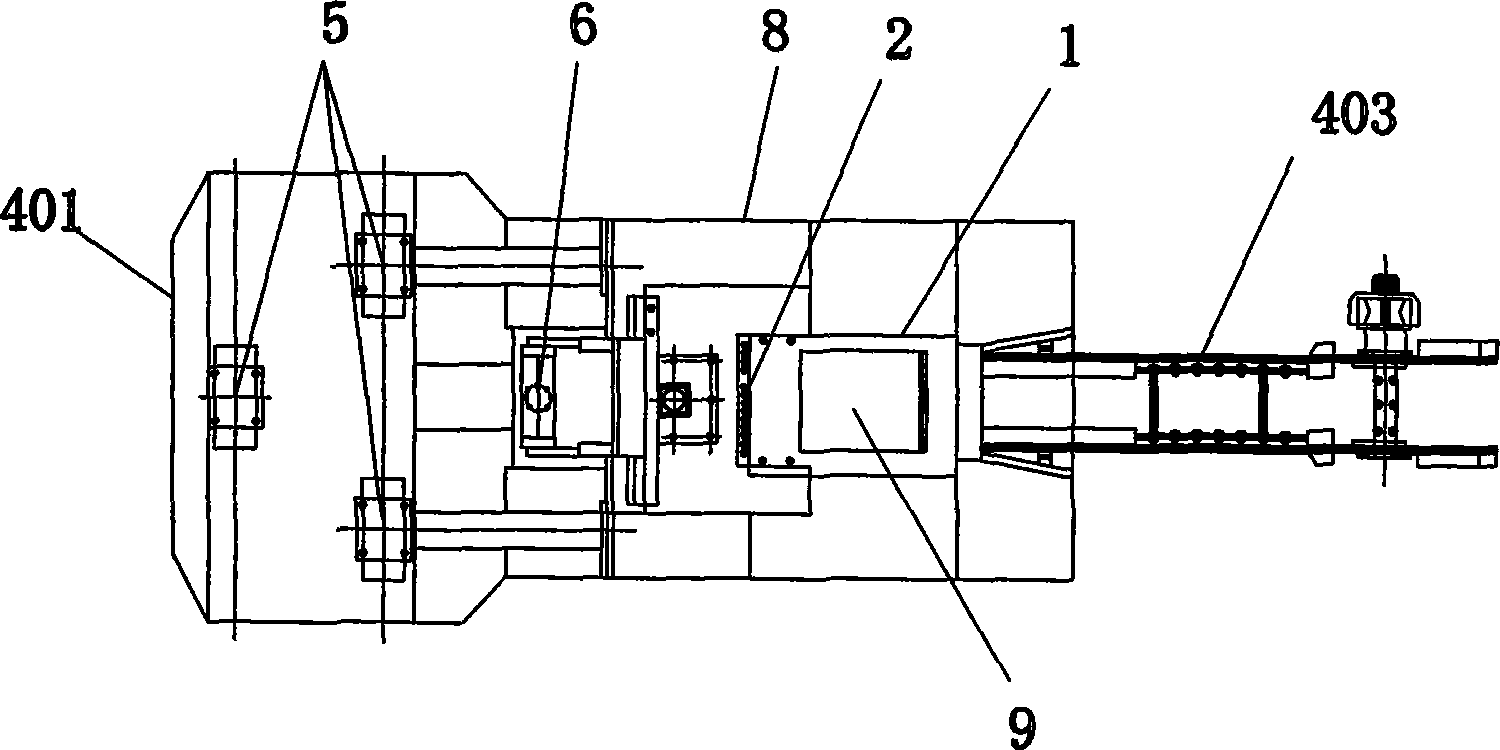

[0040] As shown in Fig. 1 and Fig. 2, it is a mechanical integration device for coal loading, coal transportation and bolt support after blasting and falling coal. It includes hydraulic system and oil tank, etc. 1, hydraulic control console 2, crawler walking part 3, coal transportation part 4, support part 5, hydraulic bolter 6; coal transportation part consists of shovel plate 401 and airborne rake claw 402 is composed of two parts, and the coal transportation is carried out by the scraper conveyor 403 at the rear part of the shovel plate. A platform 8 is fixed and installed on the underframe beam 7 of the crawler walking part, and a coal transportation part is fixed between the underframe beam and the platform. The front is adjusted to be in contact with the ground by the oil cylinder 404 of the coal transportation part, and the scraper conveyor for coal transportation is in the middle and rear of the underframe beam. The support part is three hydraulic props distributed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com