Coal roadway roof reinforcing and upper protecting anchor rod supporting method based on top plate stability

A technology of stability and support for bolts, which is applied in the application of stable tension/pressure to test the strength of materials, installation of bolts, and earth-moving drilling, etc. It can improve the sensitivity and improve the stability of the problems such as the large proportion of the tunneling time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

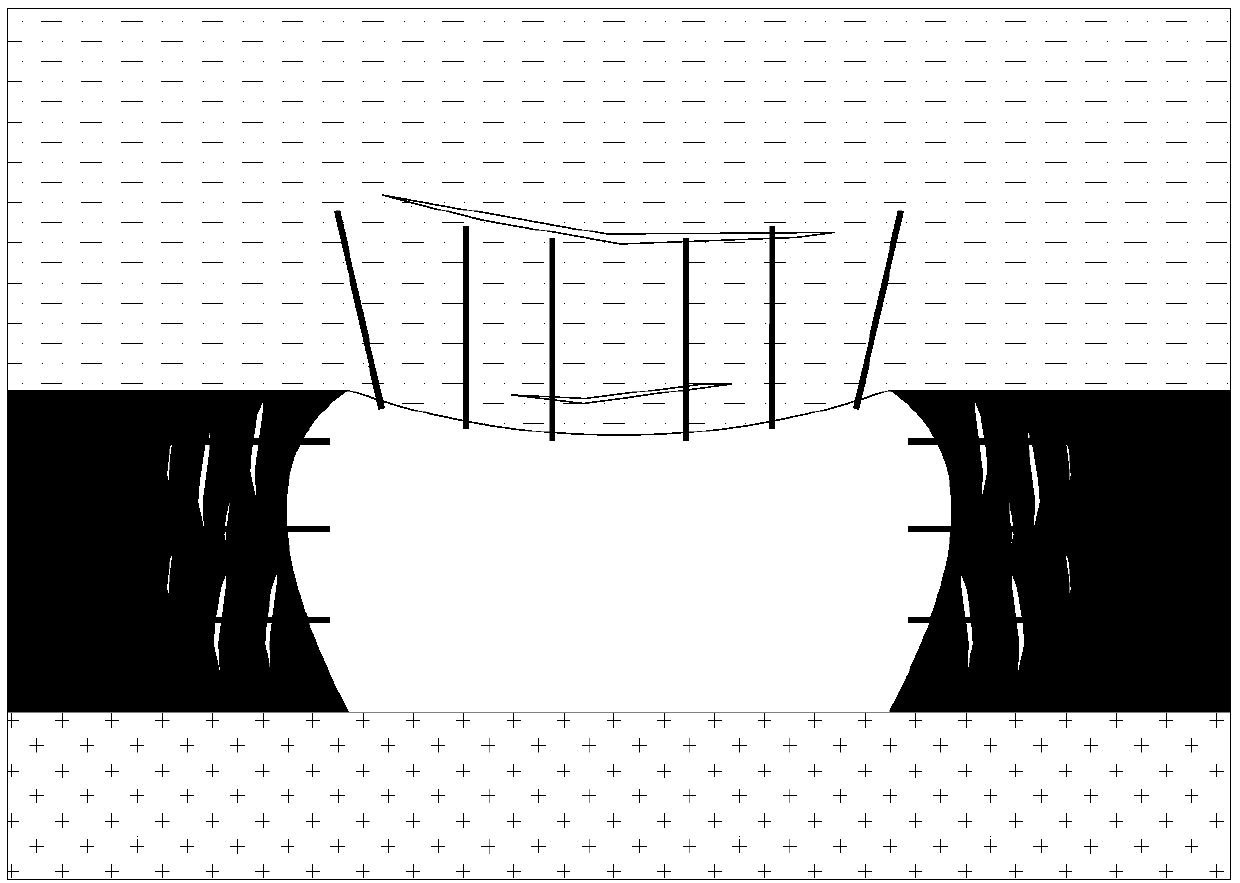

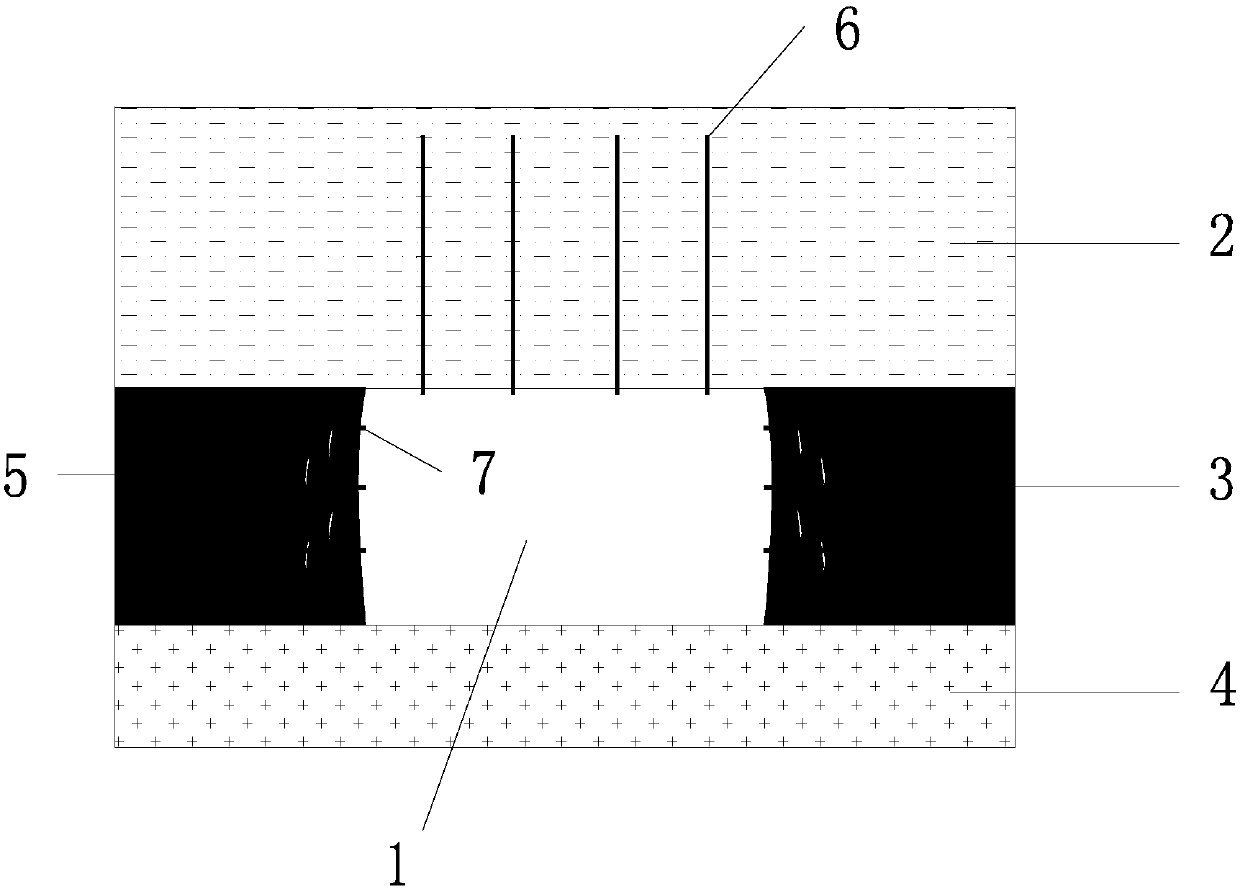

[0024] Below in conjunction with accompanying drawing, the present invention is further explained:

[0025] Such as figure 1 and figure 2 As shown, the step of a kind of coal roadway strong top protection side bolt support method of the present invention is: the coal roadway roof 2 is divided into different regions, and the staff drills the rock cores of each region roof 2 on the bottom plate 4, and analyzes each region The core information of the roof 2, so as to obtain the integrity of the rock mass of the roof 2 in each area;

[0026] If the core integrity of the detected area exceeds the preset value, it is judged that the rock formation in this area is a relatively complete rock formation or a complete rock formation, and a uniaxial compressive test is performed on the core in this area. By analyzing the test results of each area, it is determined that each area of the roof 2 Rock mass quality index, when the obtained regional rock mass quality index is greater than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com