A flat glass furnace

A flat glass and kiln technology, applied in the direction of feeding trough, etc., can solve the problem that single-line forming cannot match large-tonnage kilns, and achieve the effect of increasing glass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

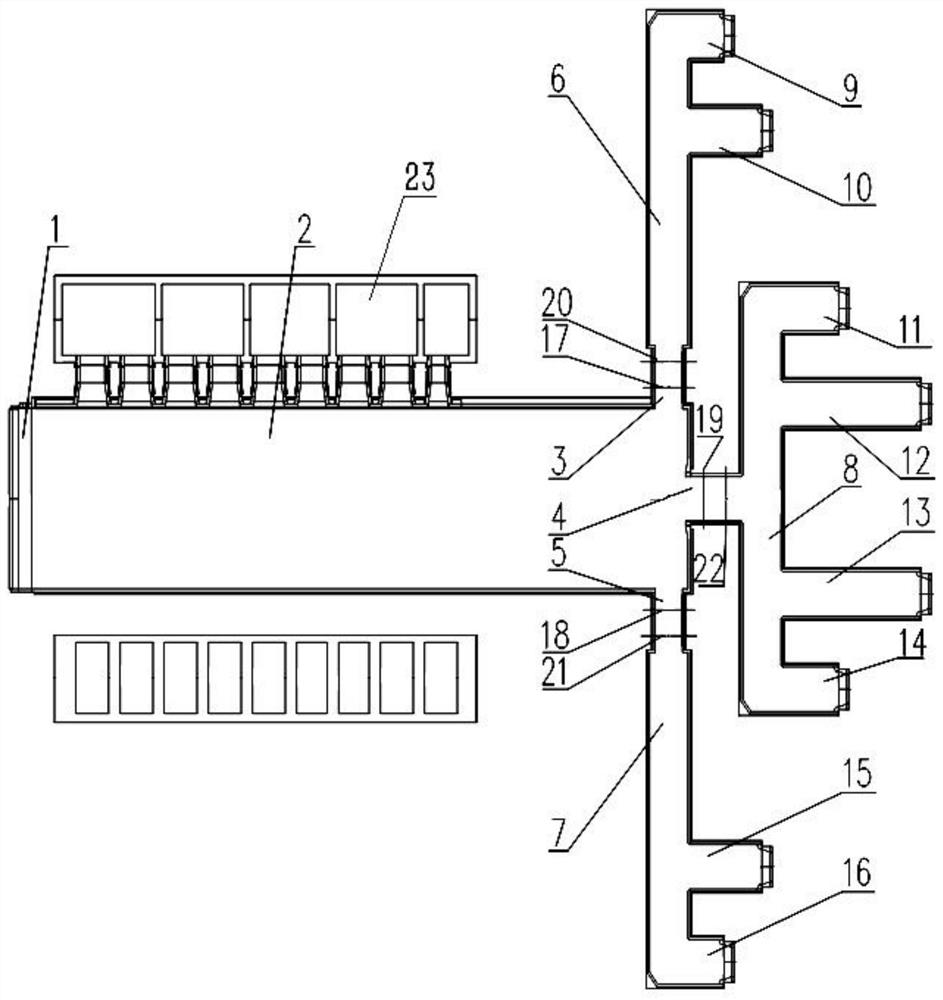

[0045] Such as figure 1 As shown, the present invention provides a flat glass furnace, comprising: a melting part 2, one end of the melting part 2 is provided with a feeding port 1; Connected at one end, the conveying passage includes a plurality of main passages, each of which corresponds to one neck, and all the main passages are arranged in parallel and perpendicular to the center line of the melting part 2; all the main passages Each passage is provided with at least one branch passage perpendicular to it, and the adjacent branch passages are arranged in parallel with a certain distance.

[0046] After the material to be processed is melted into molten glass in the melting part, it enters the main passage. Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com