Slide block control system of hydraulic machine

A hydraulic control system and control system technology, applied in the field of hydraulic presses, can solve problems such as inaccurate calculation and large errors, and achieve the effects of accurate calculation of return speed, low noise and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

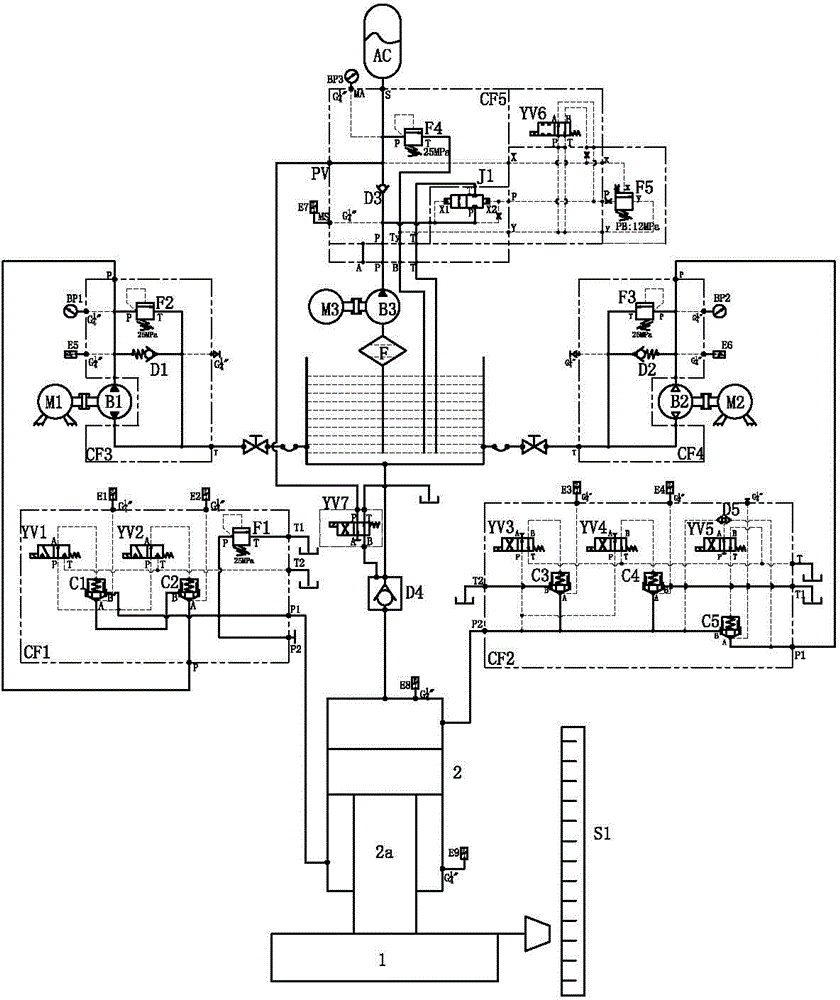

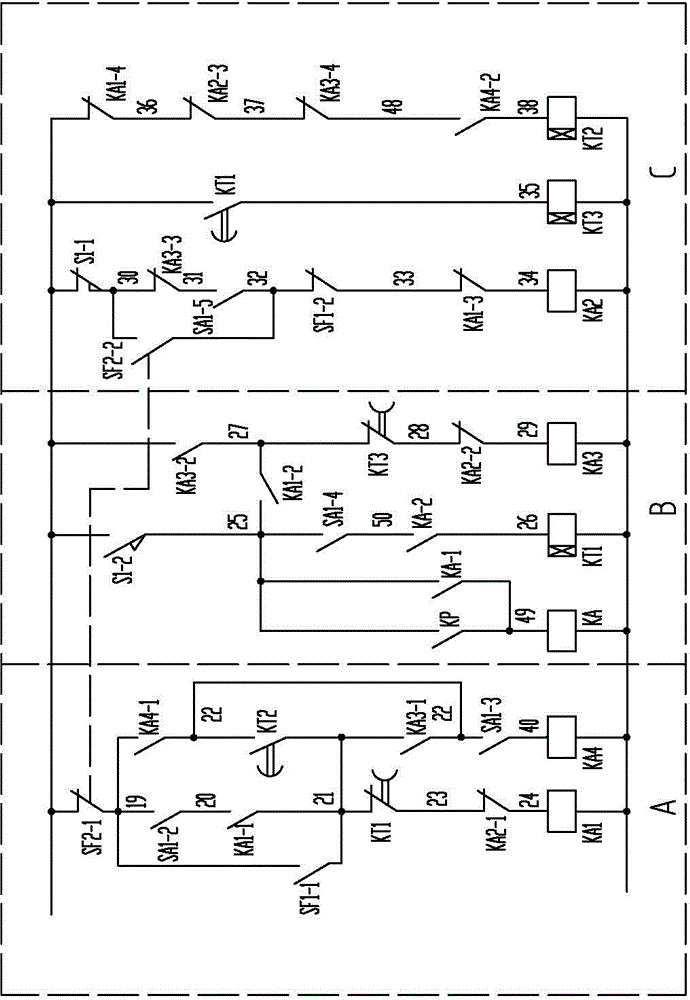

[0038] like figure 1 As shown, the slider control system of the hydraulic press of the present invention includes a slider 1, a column, a master cylinder 2, a hydraulic control system and an electrical control system. The lower end of the piston rod 2a of the master cylinder 2 is connected to the upper end of the slider 1, and the slider 1 Driven by the piston rod of the master cylinder, it can move up and down along the column guide rail. A displacement sensor S1 is installed on one side of the slider 1 to detect the moving position of the slider. The hydraulic chamber of the master cylinder is divided into an upper chamber and a lower chamber by the piston rod. An eighth pressure sensor E8 for detecting the pressure in the upper chamber is installed, and a ninth pressure sensor E9 for detecting the pressure in the lower chamber is installed in the lower chamber; the hydraulic control system includes a lower chamber safety module CF1, an upper chamber safety module CF2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com