Limiting and fixing device for bending machine

A technology of limit fixation and limit device is applied in the field of bending machine manufacturing to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

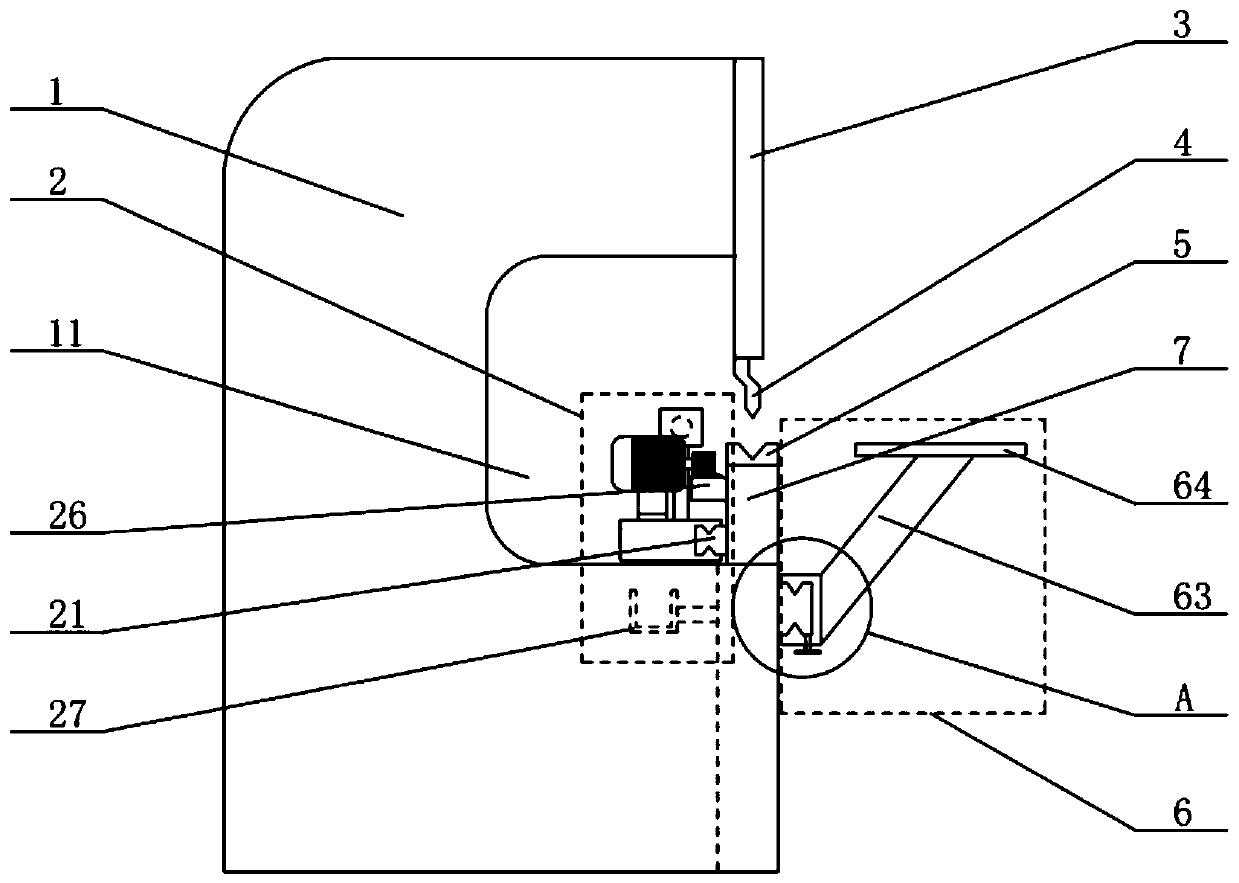

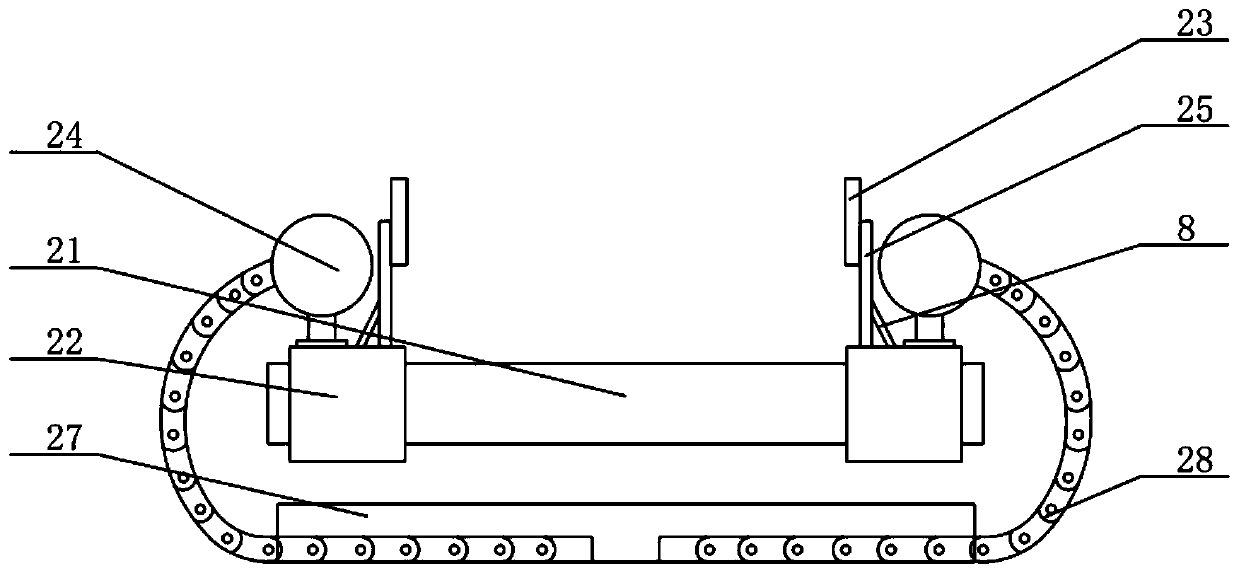

[0023] see Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is: it includes a shearing machine main body 1, a limit device 2, a moving plate 3, an upper mold 4, a lower mold 5, a supporting device 6, and a workbench 7. The front middle position of the shearing machine main body 1 is provided with a working area 11, and the moving plate 3 is installed above the front portion of the shearing machine main body 1, and the moving plate 3 is connected with the hydraulic device of the shearing machine main body 1, so The upper mold 4 is connected below the moving plate 3, the workbench 7 is installed on one side of the work area 11, the lower mold 5 is installed directly above the workbench 7, and the supporting device 6 Installed on the front of the main body 1 of the shearing machine, the limiting device 2 is installed on the inner side of the workbench 7 .

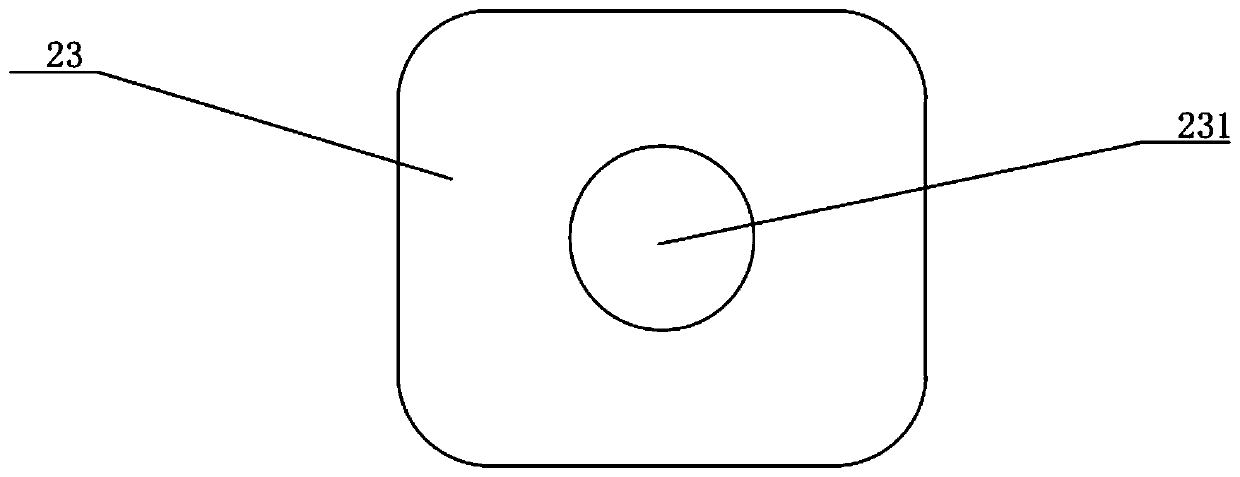

[0024] The limiting device 2 includes a connecting chute 21, a slide block 22, a lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com