Four-face enclosed box bending mold and using method thereof

A technology for bending dies and bounding boxes, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of workpiece affecting positioning accuracy and high labor intensity, so as to improve processing efficiency, high degree of automation, and expand processing range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

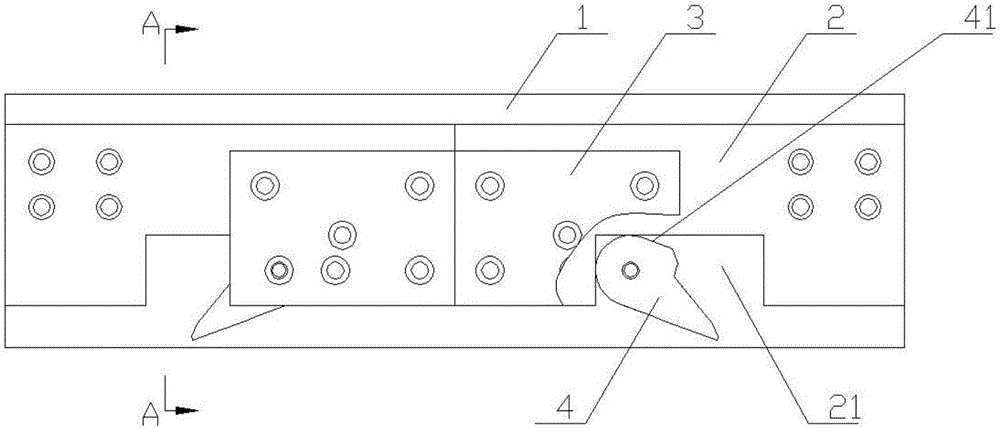

[0048] Such as Figure 8 As shown, a four-sided box body bending mold includes an upper mold and a lower mold, such as image 3 As shown, the upper mold includes an upper mold base 1, two upper mold knives 2 symmetrically arranged left and right, a rotary knife seat 3 and a rotary knife 4; the upper mold knives 2 are fixedly arranged on the upper mold base 1 outside; the lower end of the upper mold knife 2 is provided with a rotating chamber 21; the rotating knife seat 3 is fixed on the outer side of the upper mold knife 2, and one end thereof extends to the rotating chamber 21; The said rotary knife 4 is arranged in the said rotary chamber 21, as Figure 5 shown, and is rotatably and fixedly arranged on the said rotary tool seat 3 through the rotary pin 5;

[0049] Such as Figure 4 Shown, the upper mold knife bottom surface 23 of described upper mold knife 2 is an inclined plane, and the included angle of this inclined plane and horizontal plane is 5 °; The included angle...

Embodiment 2

[0061] A box bending mold surrounded by four sides is basically the same as in Example 1, the difference is that in Example 1, the rotary knife 4 still has the problem that the downward movement is not limited, which leads to the need for manual assistance in its upward movement in the next processing. Here, the rotary knife 4 in this embodiment also includes a downward stopper 42 and an avoidance cavity 43; the lower end of the upper mold knife 2 faces a corner of the rotary cavity 21 to set a limit protrusion 22; the downward stopper 42 Corresponding to the limiting protrusion 22, when the rotary knife 4 is at the lowest position, the two contact;

[0062] In addition, the upper mold knife bottom surface 23 of the upper mold knife 2 described in the present embodiment is an inclined plane, and the angle between the inclined plane and the horizontal plane is 3°; the rotary knife bottom surface 44 of the described rotary knife 4 is an inclined plane, and the inclined plane and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com