Electrical discharge machining method of sheet electrolysis with high-frequency vibration

A high-frequency vibration and processing method technology, applied in the field of electric discharge machining, can solve the problems of low processing efficiency, low processing accuracy, and electrode wire fusing, and achieve the effects of high processing accuracy, high controllability, and small gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

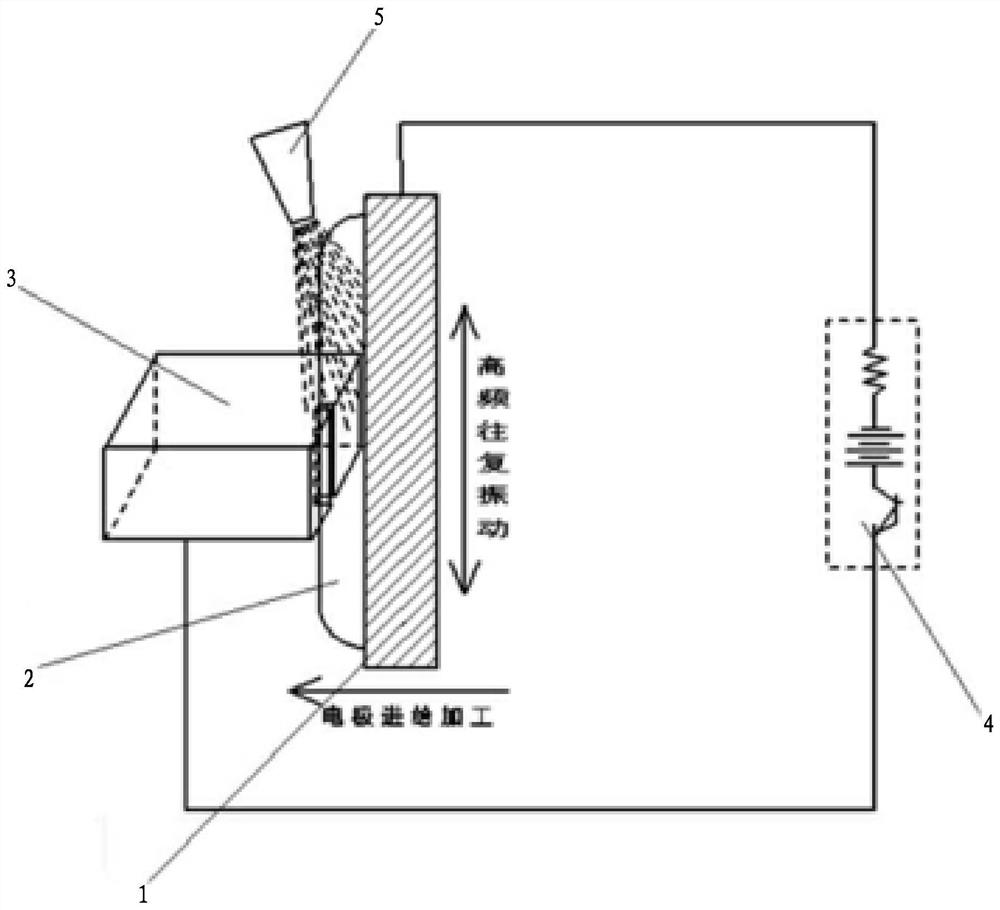

[0026] refer to figure 1 , the present embodiment relates to a sheet electrolytic electric discharge machining method with high-frequency vibration, comprising the following steps:

[0027] 1) A thin sheet 2 is vertically fixedly installed on the front end of the clamping base 1, and the thin sheet 2 is a conductive material;

[0028] 2) Connect the clamping base 1 and the workpiece 3 to be processed with the positive pole and the negative pole of the pulse power supply 4 respectively;

[0029] 3) During processing, the clamping base 1 drives the sheet 2 to move horizontally to the workpiece 3 to form feed processing; at the same time, the clamping base 1 drives the sheet 2 to reciprocate in the vertical direction; the sheet 2 and the workpiece 3 to be processed between line contact;

[0030] 4) Spray the machining solution onto the contact surface between the sheet 2 and the workpiece 3 to be machined.

[0031] The method utilizes the metal flake 2 to carry out electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com