Clamping and processing method for organic working medium generator shell

A processing method and generator technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of less contact surface, clamping, adjustment and alignment, and small inner hole for rounding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

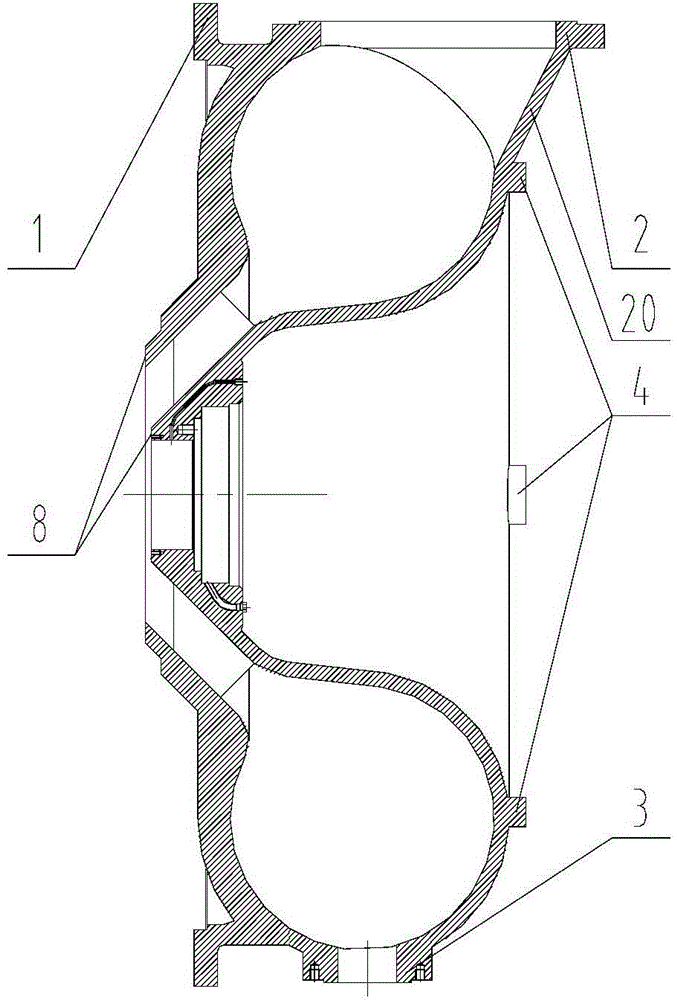

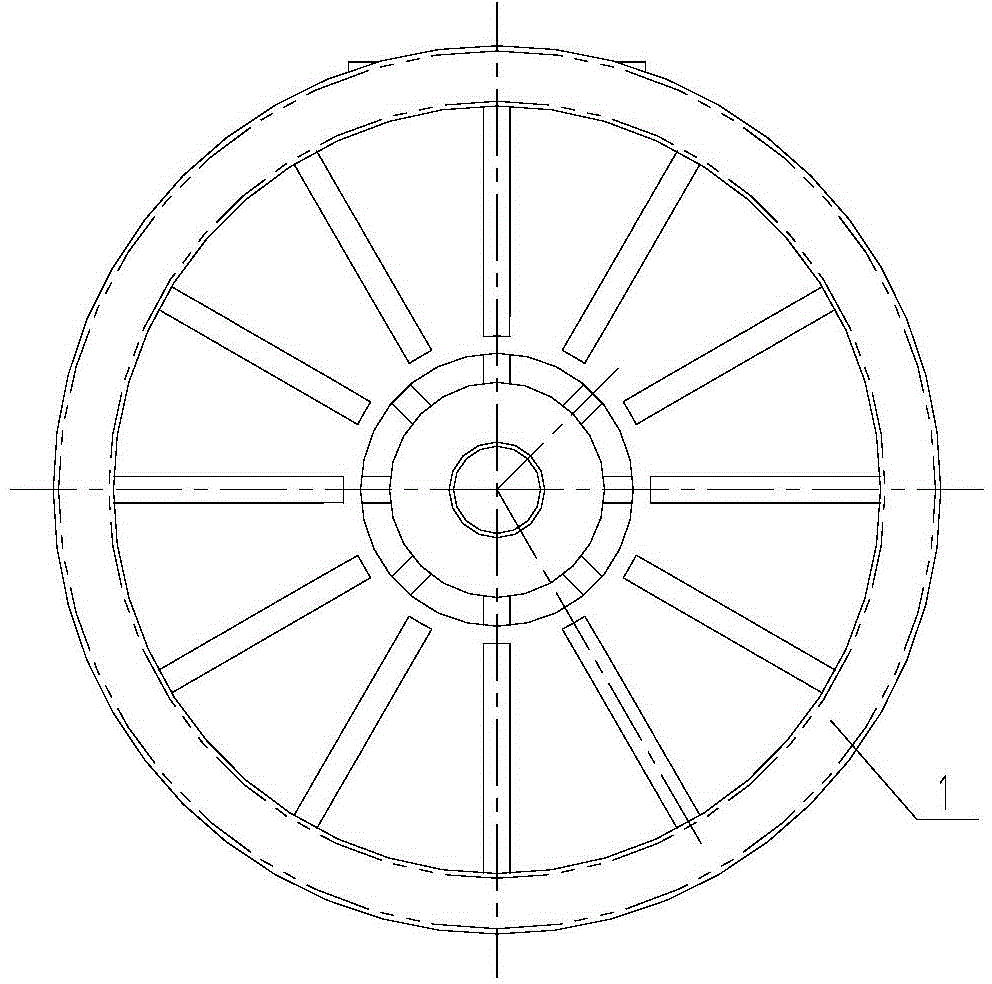

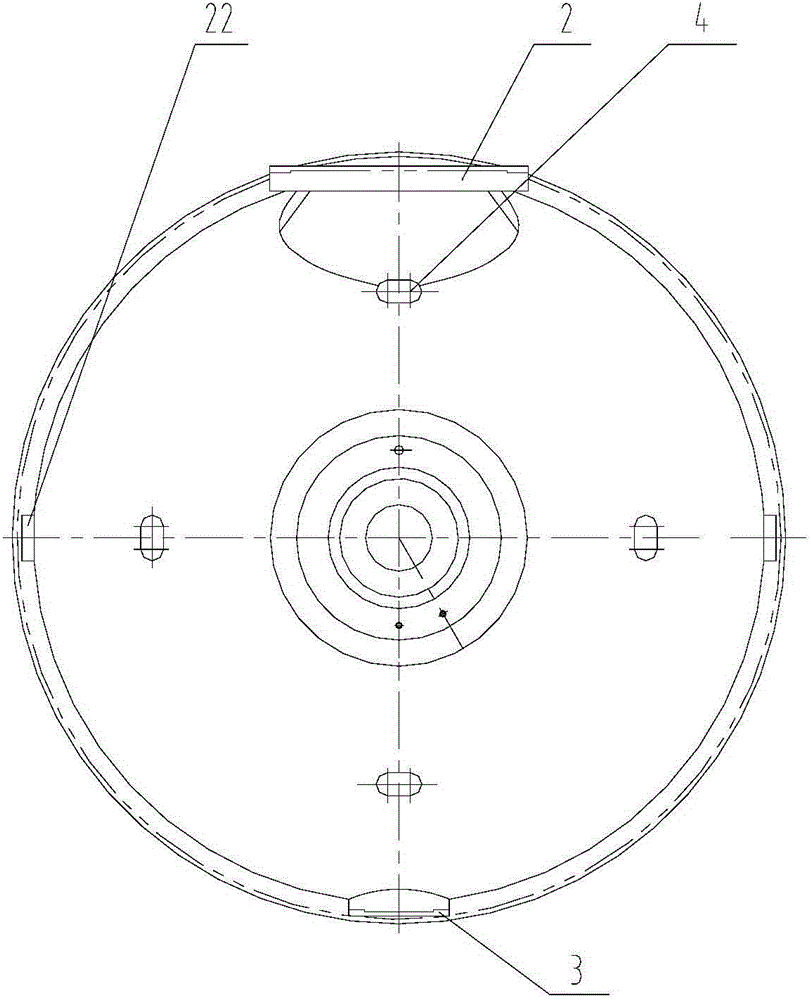

[0057] see Figure 1 to Figure 8 , is a preferred embodiment of the clamping and processing method of the organic working medium generator housing, and the processing method is carried out according to the following steps:

[0058] Step 1) Draw the line

[0059] Level the inner end face of flange 1 at the big end of the shell, and align the 2-axis center line of the shell exhaust flange and the 3-axis center line of the drain flange, according to the 2-axis center line of the shell exhaust flange and the drain flange 3 The design distance between the center line of the axis and the outer end face of the big end flange 1 of the shell, taking into account the design thickness of the big end flange 1 of the shell at the same time, and drawing the axial cutting processing line of the big end flange 1 of the shell according to the design size ;

[0060] To align the axis line of the shell, draw a calibration line for alignment on the outer end face of the shell big end flange 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com