Making machine of PVC (Polyvinyl Chloride) foaming plate

A technology for making machines and foam boards, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of reducing the density of the board, poor effect, changing the foaming effect of PVC, etc., and achieves the reduction of product density and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

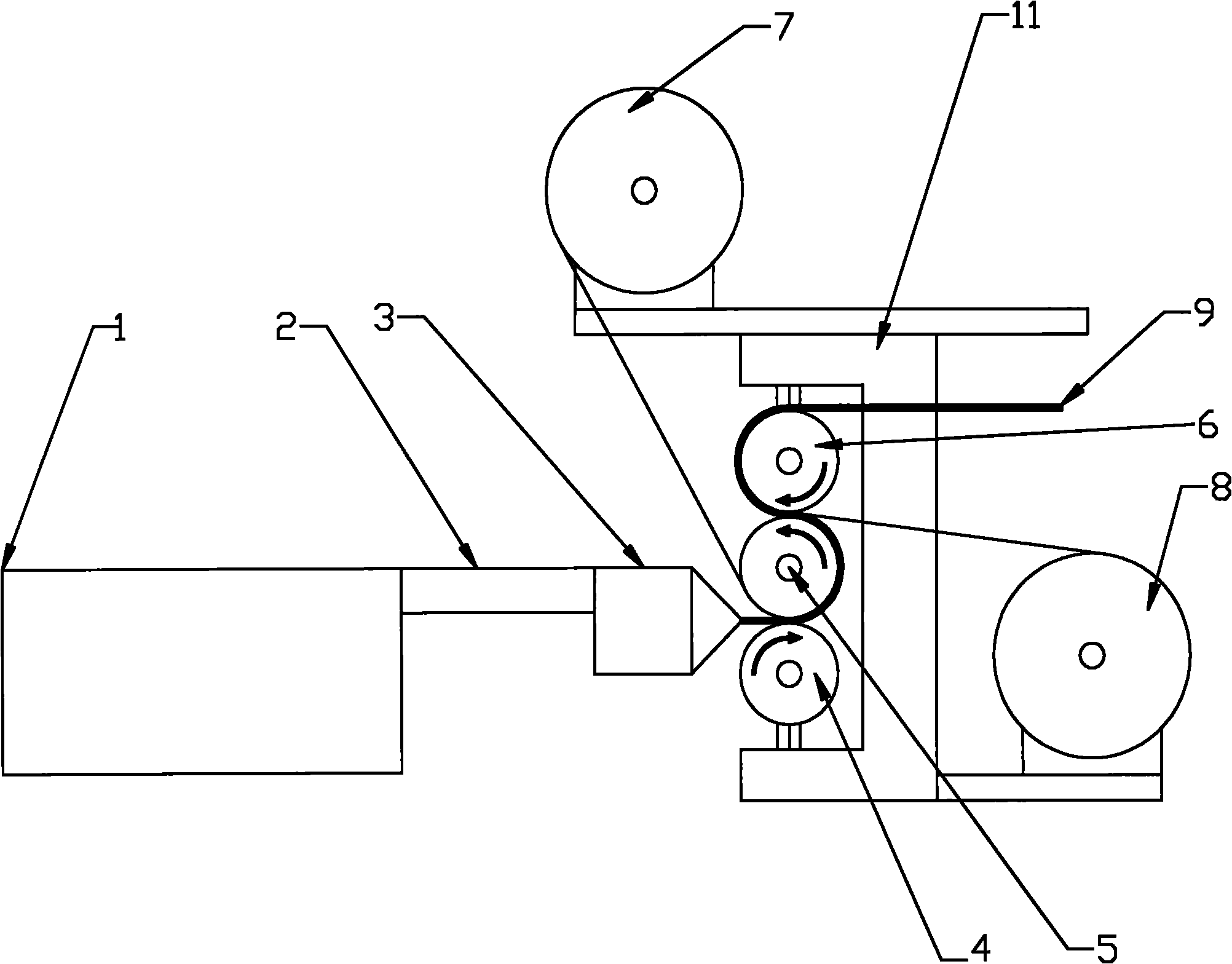

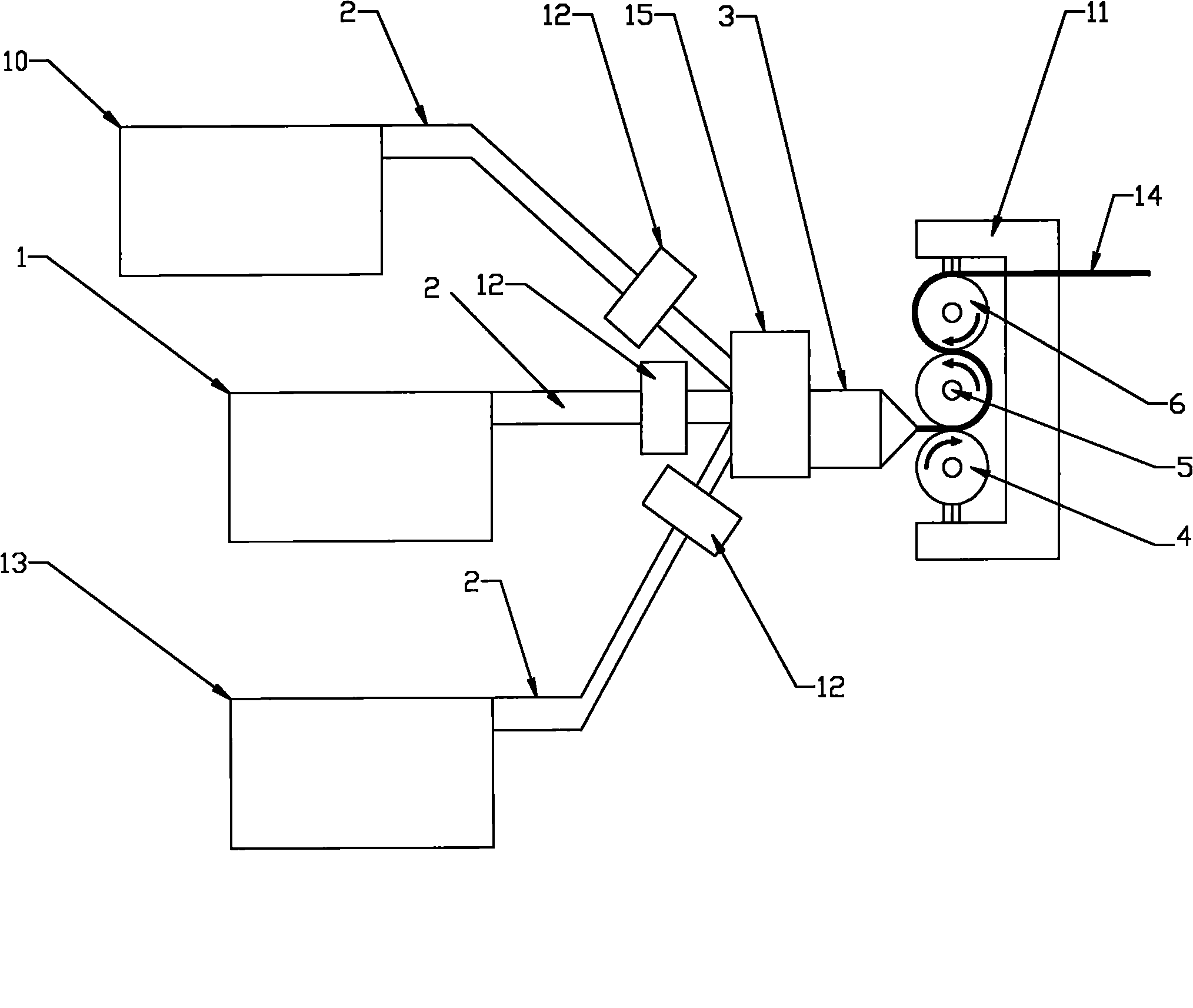

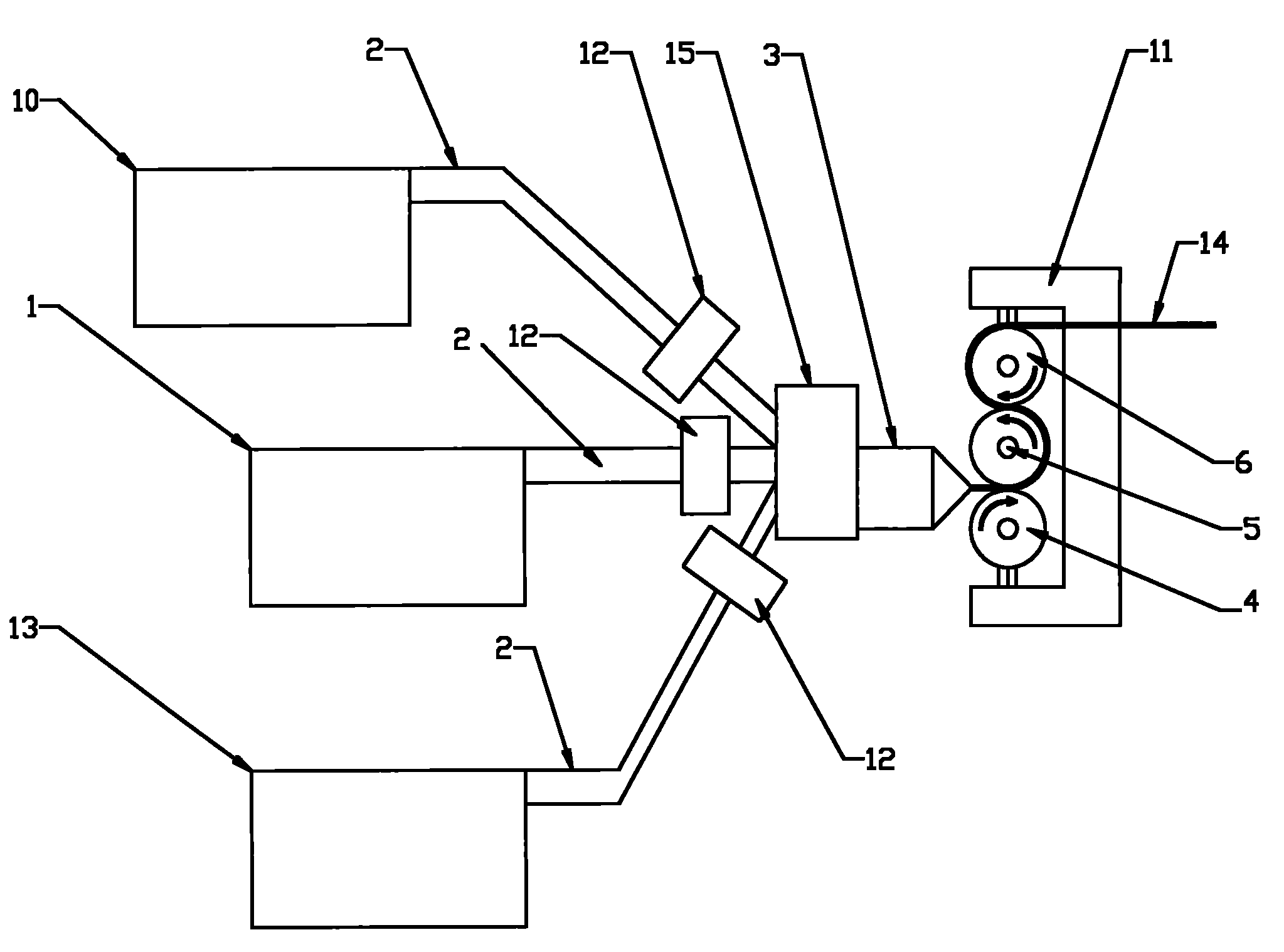

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

[0019] A PVC foam board making machine, on a vertical frame 11, three tangential calender rolls 4, 5 and 6 are arranged from bottom to top; Extruder 1 enters an inlet of proportional valve 5 through runner 2 and quantitative pump 12; a surface-enhanced layer extruder 10 and a surface aesthetic layer extruder 13 are respectively arranged above and below the extruder 1, and two extruders Exit the machine through the respective runners 2 and respective quantitative pumps 12, and enter the other two inlets of the proportional valve 15 respectively; an outlet of the proportional valve 5 is connected to the flat mold 3; the outlet of the flat mold 3 is aimed at entering the calender roll 4 and Cut-out for calender roll 5.

[0020] The proportional valve 15 is for adjusting the different flow ratios of the three inlets. Electro-hydraulic proportional valves can be used to facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com