Worktable equipment for machining

A technology of mechanical processing and workbench, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as difficult to change, unable to process different workpiece adjustments, difficult to popularize and apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

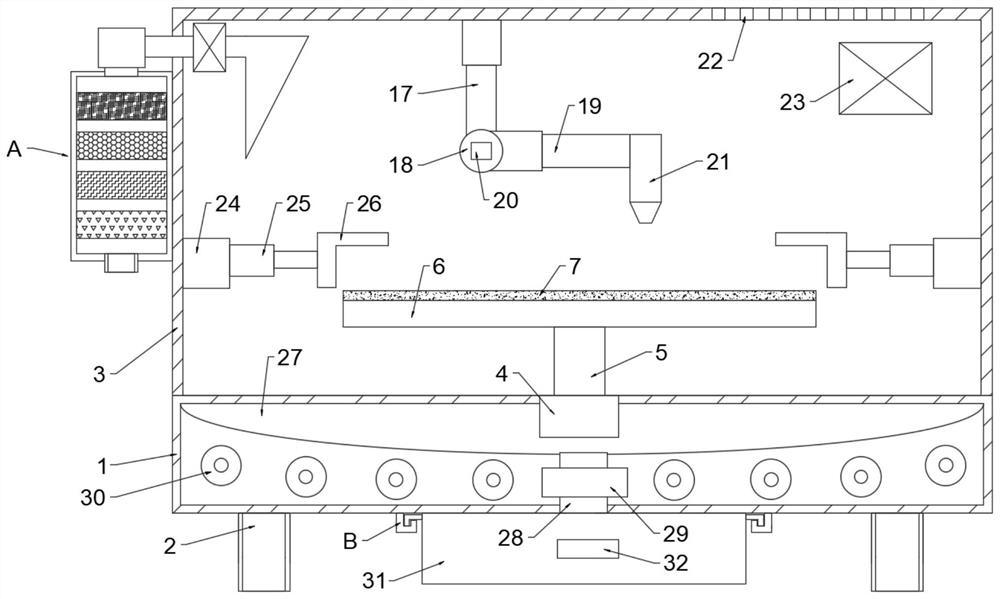

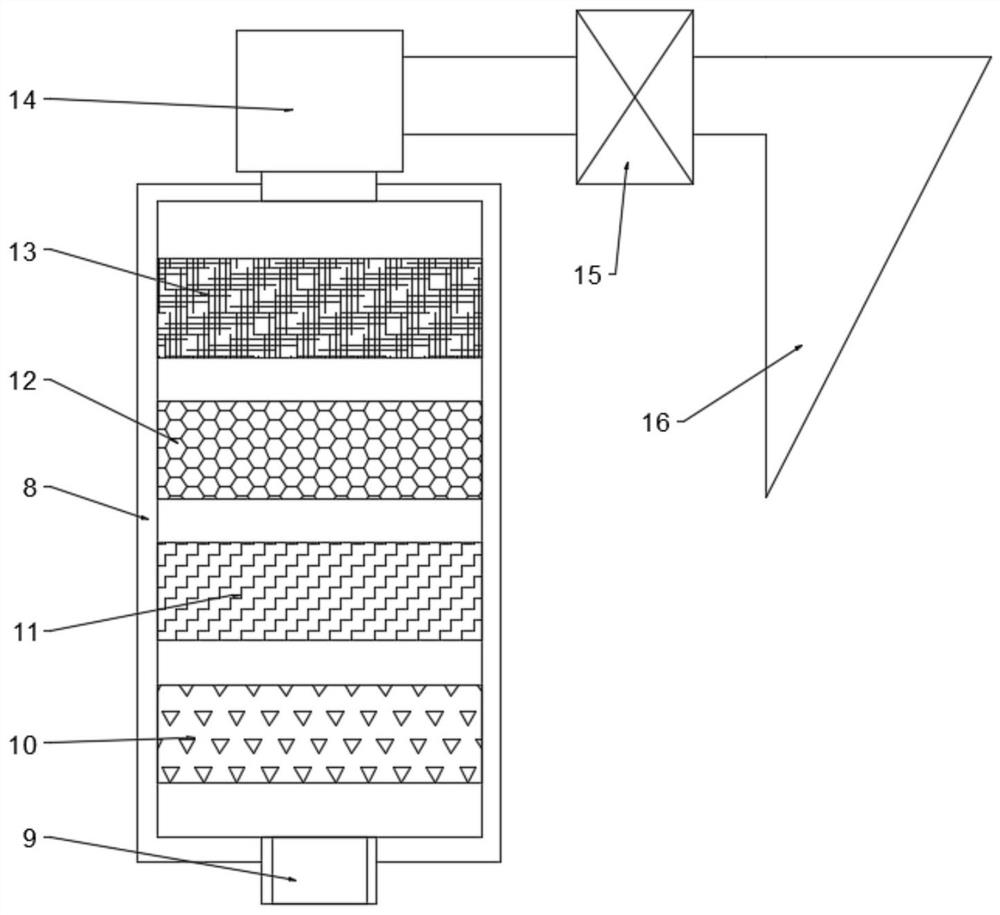

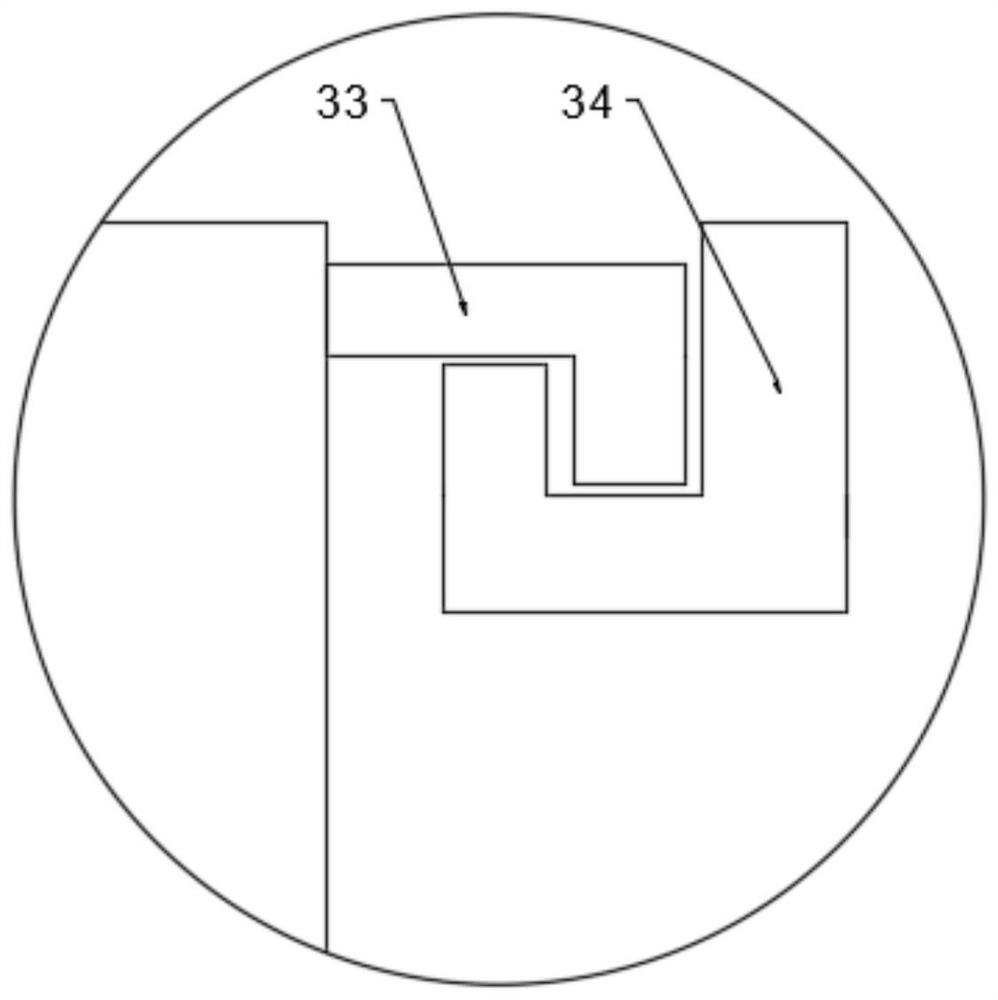

[0031]SeeFigure 1 ~ 3 A mechanical processing table device, including a base 1, and a support leg 2 is provided below, the base 1 is fixed, and the discharge dust cover 3 is fixed, and the base 1 is provided with a rotary electric machine 4. The rotary electric machine 4 is disposed at the center position of the base 1, and the output end of the rotary motor 4 is fixedly coupled to the rotating shaft 5, the rotating shaft 5 away from one end of the rotary electric machine 4 fixed to the processing backplane 6, the drop in dust. A first electric telescopic rod 17 is provided on the cover 3, the first electric telescopic rod 17, away from one end of the dropping dust cover 3, which is connected to the second electric telescopic rod 19, said The second electric telescoping rod 19 is fixed from one end of the electric rotary shaft 18, and the height of the machining center 21 can be effectively adjusted by the first electric telescopic rod 17, the electric rotary shaft 18, the electric ...

Embodiment 2

[0039]SeeFigure 1 ~ 5A mechanical processing table device, including base 1, further comprising mounting lever 35, pulley 36, support block 37, threaded through hole 38, rotating handle 39, threaded column 40, stop block 41, and anti-slip pad 42, Next, a support leg 2 is provided below, and a rotating dust cover 3 is fixed to the base 1, and a rotating electric machine 4 is provided, the rotating motor 4 is disposed at the center position of the base 1, the The output end of the rotary electric machine 4 fixed to the rotating shaft 5, the rotating shaft 5 away from one end of the rotary electric machine 4 to fix the workpiece 6, and a first electric telescopic rod 17 is provided on the prolonel dust cover 3, and the first An electric telescopic rod 17 is disposed at one end of the dropping dust cover 3, which is connected to the second electric telescopic rod 19, the second electric telescopic rod 19 away from one end of the electric spindle 18 fixed connection processing. The cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com