Semiconductor processing method and system

A processing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, manufacturing computing systems, electrical components, etc., can solve problems such as product quality impact, imperfect ingredients settings, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

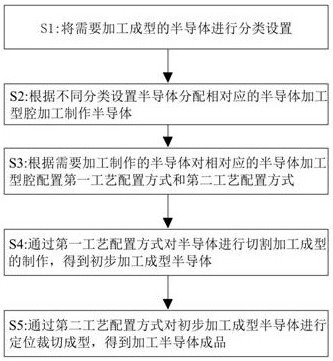

[0043] A semiconductor processing method, see figure 1 , the method includes the following steps:

[0044] S1: classify and set the semiconductors that need to be processed and formed;

[0045] S2: according to different classifications, semiconductor processing cavities corresponding to semiconductor allocation are set to process and manufacture semiconductors;

[0046] S3: configure the first process configuration mode and the second process configuration mode for the corresponding semiconductor processing cavity according to the semiconductor that needs to be processed and fabricated;

[0047] S4: by the first process configuration mode, the semiconductor is cut, processed and shaped to obtain a preliminary processing and shaped semiconductor;

[0048] S5: Positioning, cutting, and molding the preliminarily processed and formed semiconductor through the second process configuration to obtain a finished semiconductor product.

[0049] In the above process of manufacturing...

Embodiment 2

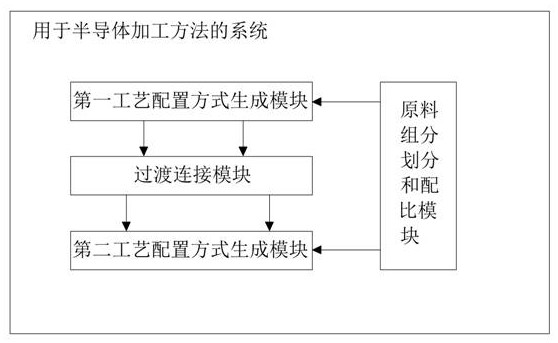

[0058] A system for a semiconductor processing method, see figure 2 , the system is used to realize the semiconductor processing method disclosed in Embodiment 1, and the advantages are that it is convenient for the processing and production of semiconductors, and improves the processing efficiency of semiconductors. ; Realize the connection between the first generation module and the second generation module through the structure used in the process of use

[0059] The second process configuration mode generates a module for processing the molded semiconductor;

[0060] a transition connection module, used for transferring the information of the first process configuration mode generation module to the second process configuration mode generation module;

[0061] The raw material component division and proportioning module is used to provide the detailed raw material component distribution ratio to the first process configuration mode module or the second process configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com