Transition chain plate bending method

A chain plate and bending forming technology, applied in the field of chain transmission, can solve the problems of poor forming effect of transition chain plates, and achieve the effect of shortening maintenance time, improving bending quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A bending method of a transition link plate, comprising the step of simultaneously stamping the planar structures on both sides of the transition link plate using a mold, and in the step, the slope structure of the transition link plate is formed naturally.

[0034] In this embodiment, by allowing the inclined structure 02 to form naturally, the mutual interference between the planar structure 01 and the inclined structure 02 during the stamping process can be effectively avoided, so that the transition link plate can obtain a better forming effect.

Embodiment 2

[0036] On the basis of Embodiment 1, this embodiment discloses the specific structure of the bending forming punch:

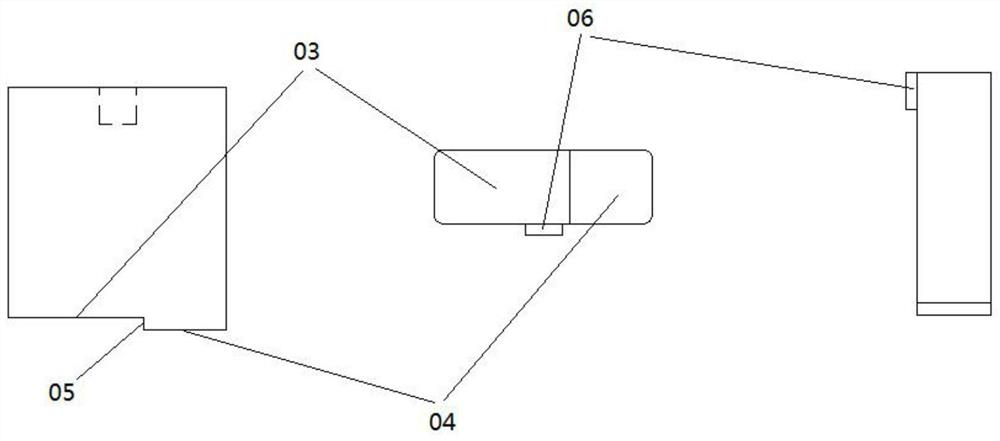

[0037] Such as image 3 , 4As shown, a kind of bending forming punch used in the bending method of a transitional chain plate includes an upper bending forming punch 12 and a lower bending forming punch 13, and the upper bending forming punch 12 A first plane C03 and a second plane C04 are provided on the lower end surface of the bottom surface, and a vertical plane C05 is connected between the first plane C03 and the second plane C04. The upper end surface of the lower bending forming punch 13 is provided with a second plane C04. A plane D07 and a second plane D08, a vertical plane D016 is connected between the first plane D07 and the second plane D08, the first plane C03 and the first plane D07 cooperate with each other to stamp the transition chain The plane structure on one side of the plate, the second plane C04 and the second plane D08 cooperate with ea...

Embodiment 3

[0042] On the basis of embodiment 2, this embodiment discloses the concrete structure of the mold that is provided with bending forming punch:

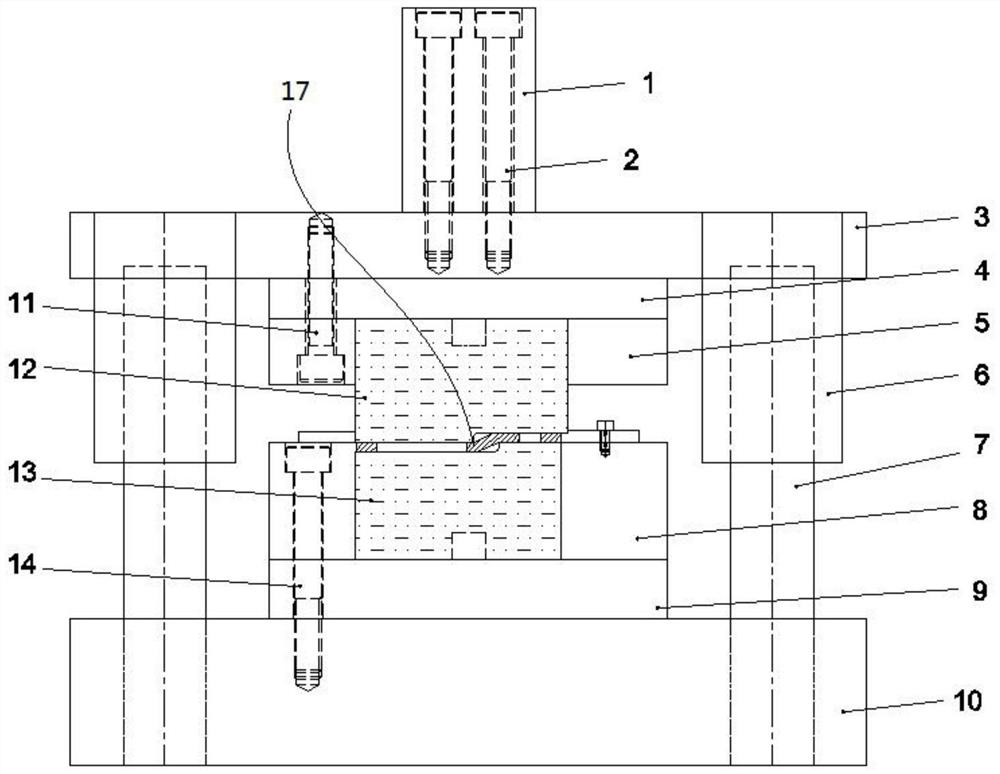

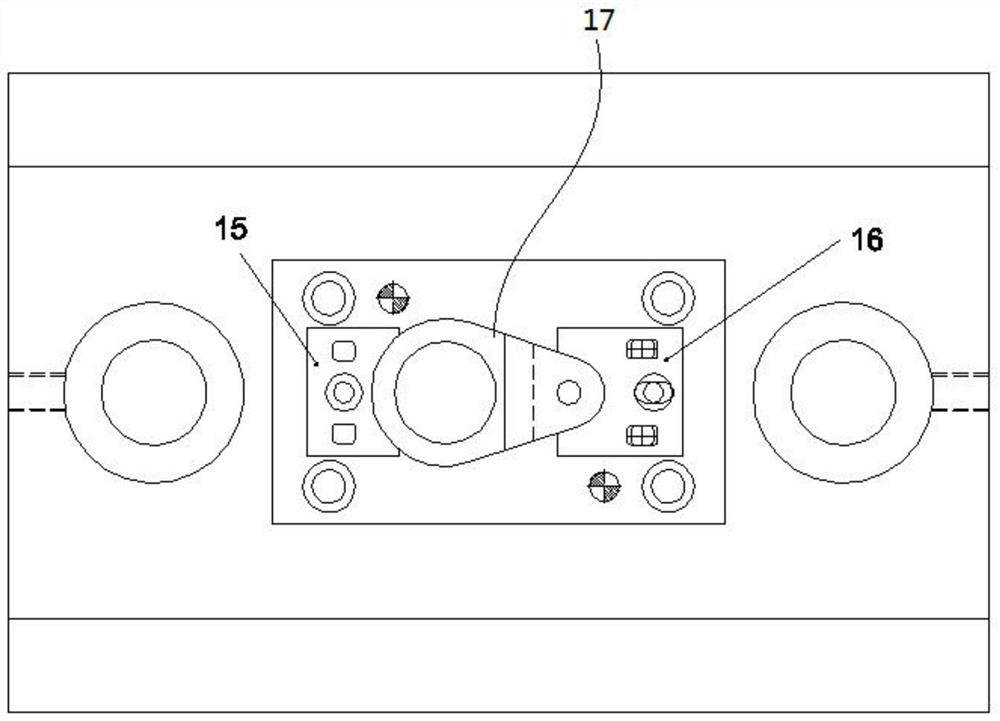

[0043] Such as figure 1 , 2 , as shown in 9:

[0044] A mold for a bending forming punch is provided, including an upper die and a lower die, the upper die is equipped with an upper bending forming punch 12, and the lower die is equipped with a lower bending forming punch 13, and the upper die is equipped with a lower bending forming punch 13. The upper bending forming punch 12 is used in conjunction with the lower bending forming punch 13;

[0045] The upper die includes a mold handle 1, an upper template 3, an upper backing plate 4, and an upper fixing plate 5 from top to bottom, and the lower mold includes a lower template 10, a lower backing plate 9, and a lower backing plate from bottom to top. The fixed plate 8, the two sides of the lower end surface of the upper template 3 are respectively provided with guide sleeves 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com