Golf ball iron rod batter side and method for machining groove of batter side

A technology of golf balls and processing methods, applied in the field of golf balls, can solve problems such as easy tool breakage, increased manufacturing costs, small diameter of vertical milling cutters, etc., and achieve the effect of avoiding tool breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with specific embodiments.

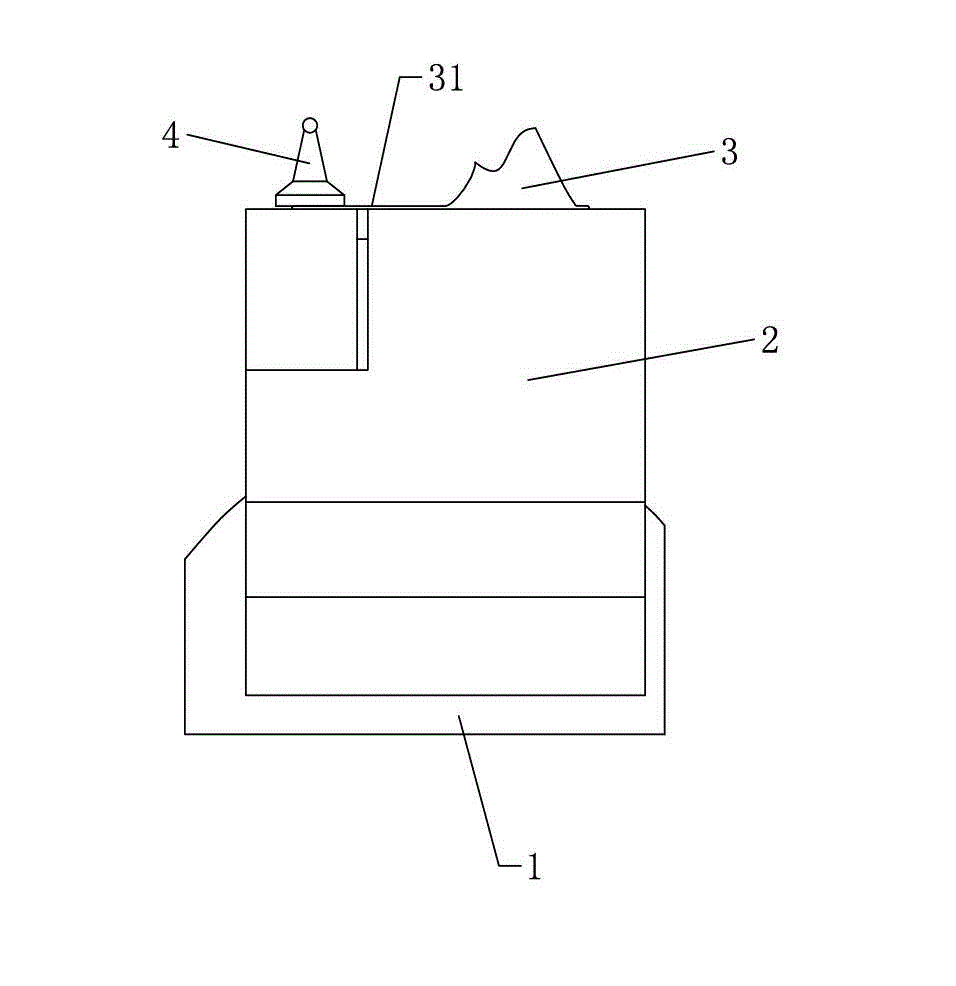

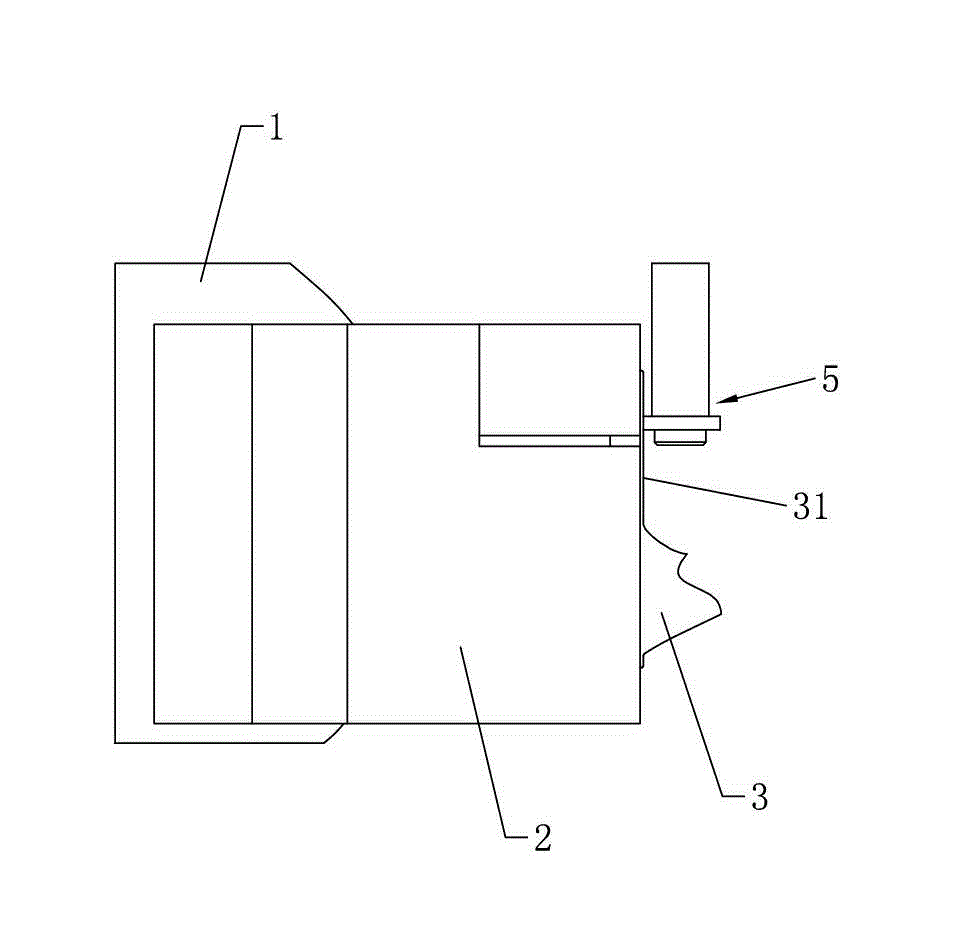

[0022] Such as Figure 1 to Figure 5 Shown, 1, a kind of processing method of golf iron club batting surface and batting surface line groove, comprises following technological steps, specifically is:

[0023] a. Clamp the golf iron 3 rough into the clamp 2 of the four-axis machining machine table 1, and keep the striking surface 31 of the golf iron 3 rough facing upward;

[0024] b. Milling the hitting surface 31 of the golf iron 3 blank by the face milling cutter 4 installed on the spindle of the four-axis machining machine tool, removing the black leather residue on the surface of the hitting surface 31 of the golf iron 3 blank by milling and making the hitting surface 31 flat;

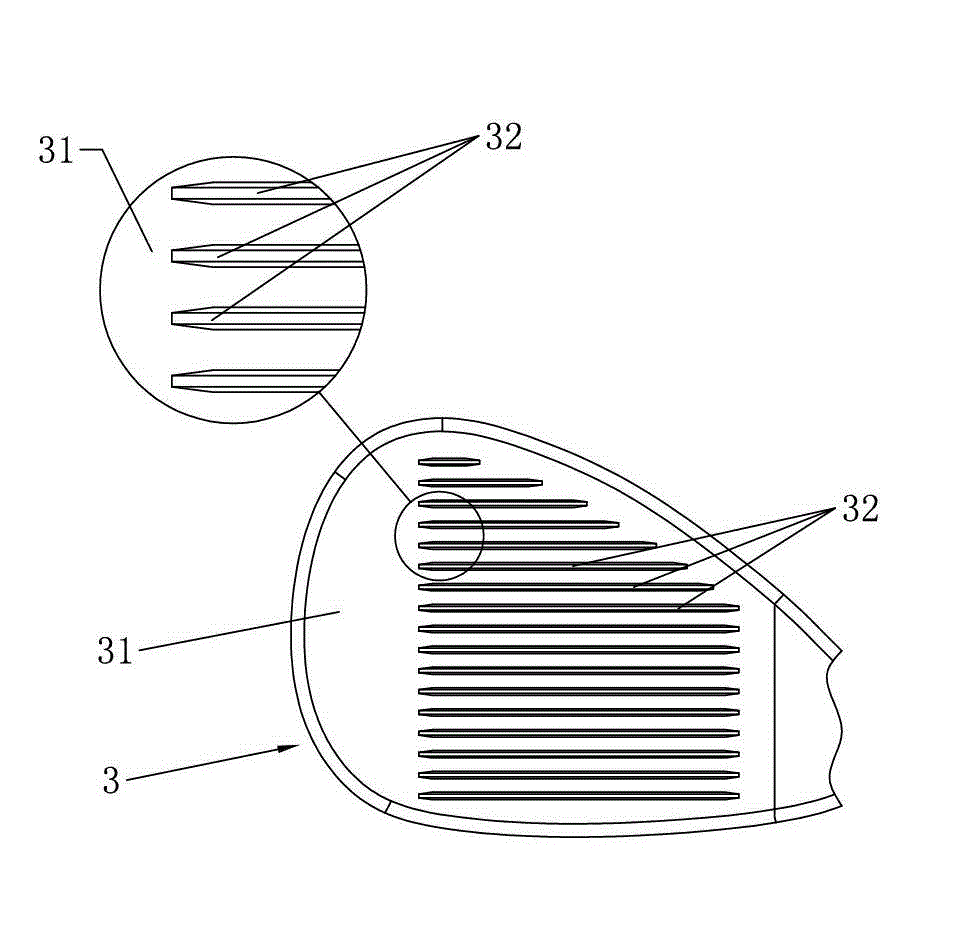

[0025] c. After the striking surface 31 is milled flat, the face milling cutter 4 used in step b is replaced with a line groove molding tool 5 for milling the line groove 32 of the striking surface 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com