Tempered curved glass and equipment with stress pattern weakening effect

A glass tempering and stress spot technology, applied in the direction of glass tempering, glass manufacturing equipment, glass production, etc., can solve the problems affecting the appearance and use effect of glass, and achieve the effect of improving appearance and quality and reducing fluid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

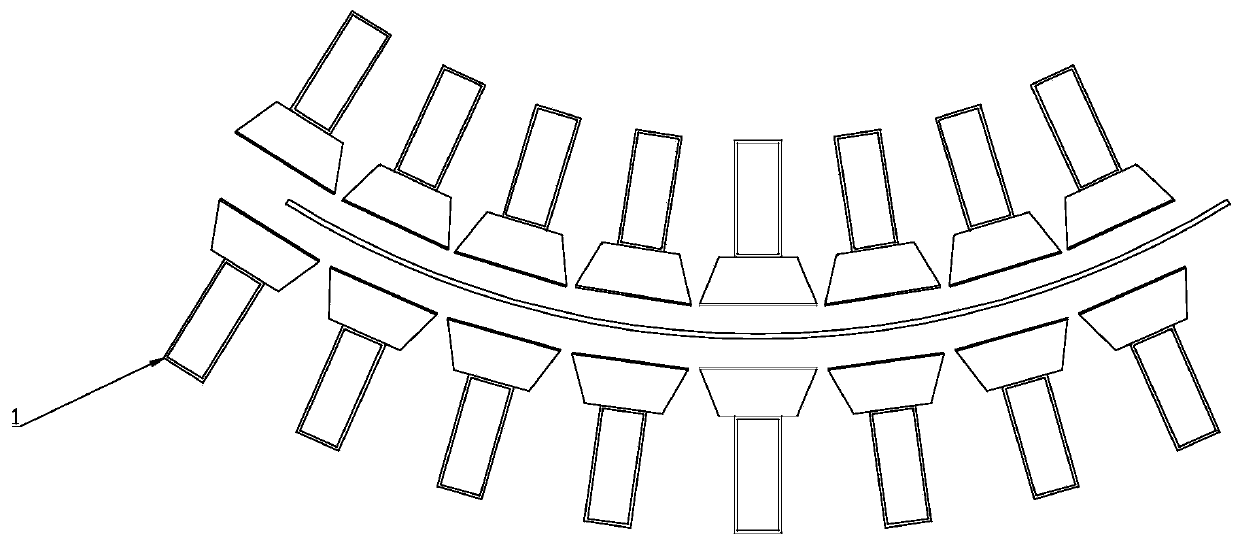

[0063] When processing toughened glass, the main air supply duct 1 and the flexible air grid unit 2 Figure 5 Arranged in the center, at both ends of the main air supply duct, there is a variable arc mechanism (for the variable arc mechanism, please refer to the glass bending and forming mechanism in CN201220306623.8). When the arc changing mechanism bends, the flexible air grid unit 2 will also change the arc accordingly.

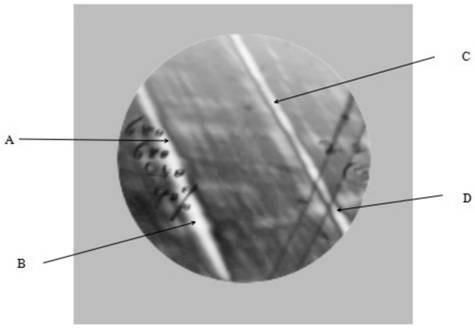

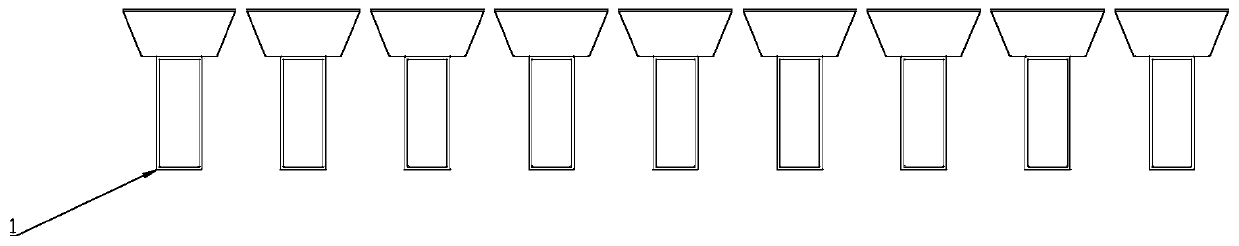

[0064] This embodiment provides a curved glass tempering device with a stress spot weakening effect, refer to image 3 , used for flexible shaft bending glass tempering, the equipment includes a flexible air grid, the flexible air grid is composed of one or more flexible air grid units 2, the flexible air grid unit 2 is a bendable flexible tubular structure penetrating inside, the flexible air grid The grid unit 2 is provided with a plurality of air outlets 22 and air inlets 21 communicating with its internal space, the air outlets 22 facing the glass to ...

Embodiment 2

[0072] This embodiment is further defined on the basis of Embodiment 1. A plurality of flexible air grid units 2 are arranged in parallel between the gaps between the flexible shaft roller tables, and the main air supply duct 1 is located on the side of the flexible air grid units 2 away from the glass to be processed. , the parallel main air supply duct 1 and the multiple parallel flexible air grid units 2 are projected in the vertical direction to intersect with each other to form a network, and the main air supply duct 1 and the flexible air grid unit 2 are projected from the intersection point of the projection to the air inlet 21 connected, refer to Figure 5 ; The arc-changing mechanism located at both ends of the main air supply duct 1 arranged in parallel drives the flexible air grid unit 2 to bend with the arc-changing mechanism when the glass to be processed is bent and formed. The axial ends of the flexible air grille unit 2 are closed structures to ensure that the ...

Embodiment 3

[0076] On the basis of Embodiment 1, this embodiment provides a curved glass tempering device with an air outlet mechanism, which also includes an air outlet mechanism. The air outlet mechanism is arranged on the flexible air grille unit 2, including The fluid smooth structure and / or the outlet airflow directional stabilization structure arranged on the outer wall of the flexible air grille unit 2; the fluid smooth structure is used to reduce the resistance of the air flow in the flexible air grille, and the outlet airflow directional stability structure is used to control the jet Constrains the direction of the airflow while making the velocity and flow of the airflow more uniform.

[0077] The smooth fluid structure and the directional stability structure of the outlet airflow can be arranged alternatively or cooperatively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com