A sinking type rigid-flex board and its manufacturing method

A technology of soft and hard combination board and manufacturing method, which is applied in the field of optoelectronic information, can solve the problems of ineffective use of installation space, increase of production cost, and obstruction of cameras, etc., and achieve the effect of small thickness, low cost, and reduced manufacturing process

Active Publication Date: 2015-12-23

NINGBO SUNNY OPOTECH CO LTD

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the traditional printed circuit boards have the following deficiencies in product assembly: 1. There is no flexibility, and the installation space cannot be used effectively; 2. The connection between the printed circuit board and the flexible substrate needs to be realized by conductive adhesive bonding, which increases the production cost. Cost; 3. Conductive adhesive bonding requires a certain thickness, which hinders the development of camera processing to a smaller size

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

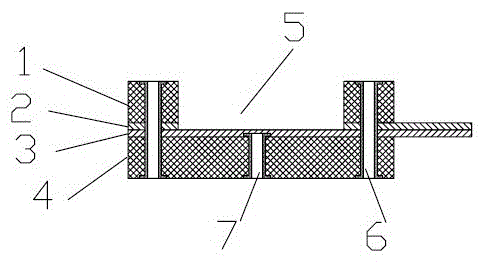

[0029] According to the thickness of the sensor of 0.2mm, the depth of the groove 5 of the rigid-flex board is controlled at 0.18mm, and the sensor is higher than the rigid-flex board.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

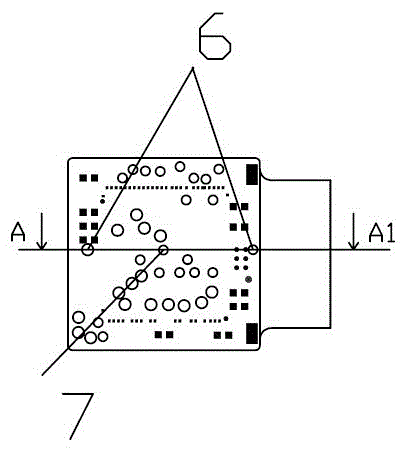

A sinking type rigid-flex board and its manufacturing method, which at least consists of a printed circuit board and an upper and lower two layers of flexible substrates thermosetting adhesive Pressing to make a rigid-flex board, the sensor position on the rigid-flex board is provided with grooves; a lower printed circuit board is provided under the lower flexible substrate, and the printed circuit board has two flexible upper and lower layers. The base plate and the lower printed circuit board are laminated by thermosetting glue; the present invention adopts the design scheme of the sunken rigid-flex board, and changes the design of the traditional printed circuit board by adding grooves to the rigid-flex board. The advanced processing method reduces the module manufacturing process, improves the flexibility of assembly, and provides more space for the development of thin packaging, especially in the consumer field.

Description

technical field [0001] The invention relates to a sinking type soft-hard combination board and a manufacturing method thereof, belonging to the field of photoelectric information technology. Background technique [0002] At present, the traditional printed circuit boards have the following deficiencies in product assembly: 1. There is no flexibility, and the installation space cannot be used effectively; 2. The connection between the printed circuit board and the flexible substrate needs to be realized by conductive adhesive bonding, which increases the production cost. Cost; 3. Conductive adhesive bonding requires a certain thickness, which hinders the development of camera processing to a smaller size. Contents of the invention [0003] The purpose of the present invention is to overcome the deficiencies in the prior art, and provide a new design scheme of sunken rigid-flex board, aiming to solve the deficiencies of traditional printed circuit boards in product assembly....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05K1/14H05K3/36

Inventor 张宝忠张扣文郭巍赵波杰吴业

Owner NINGBO SUNNY OPOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com