steel bending machine

A steel bar bending and steel bar technology is applied in the field of construction machinery, which can solve the problems of low work efficiency, high labor intensity, quality changes, etc., and achieve the effect of improving work efficiency, ensuring the bending quality of steel bars, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

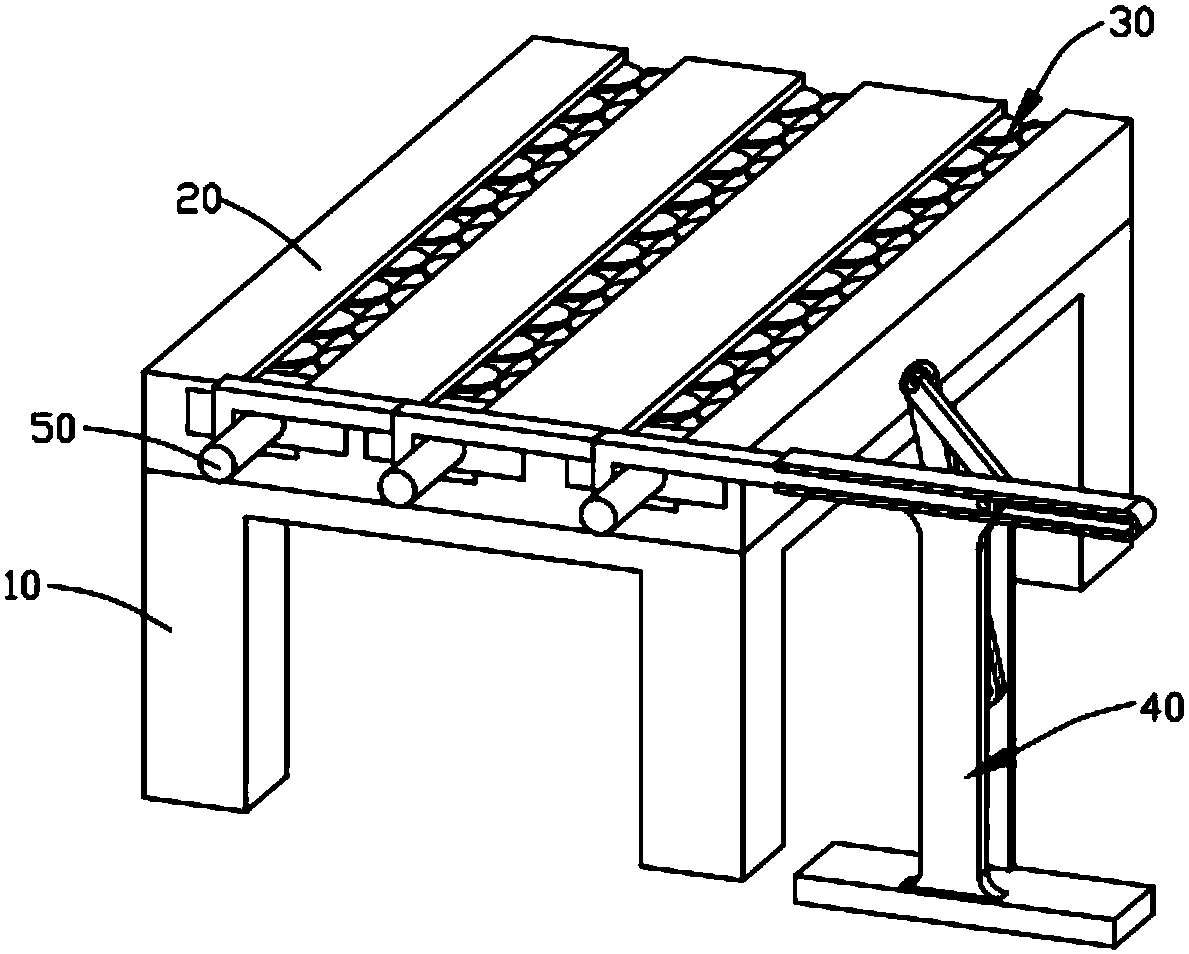

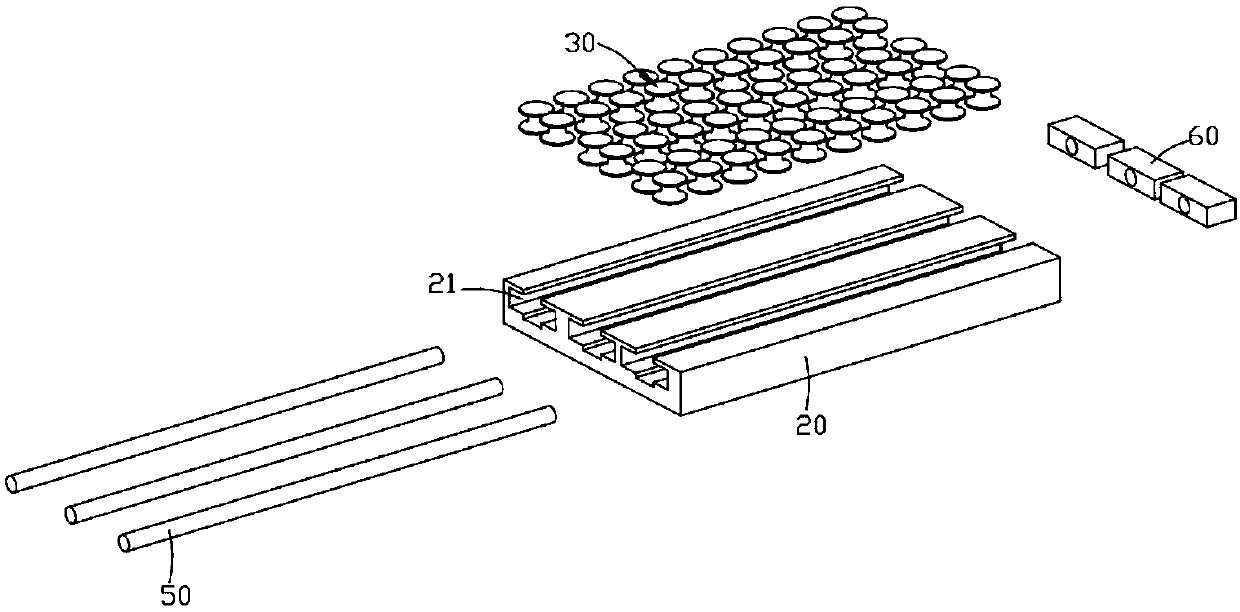

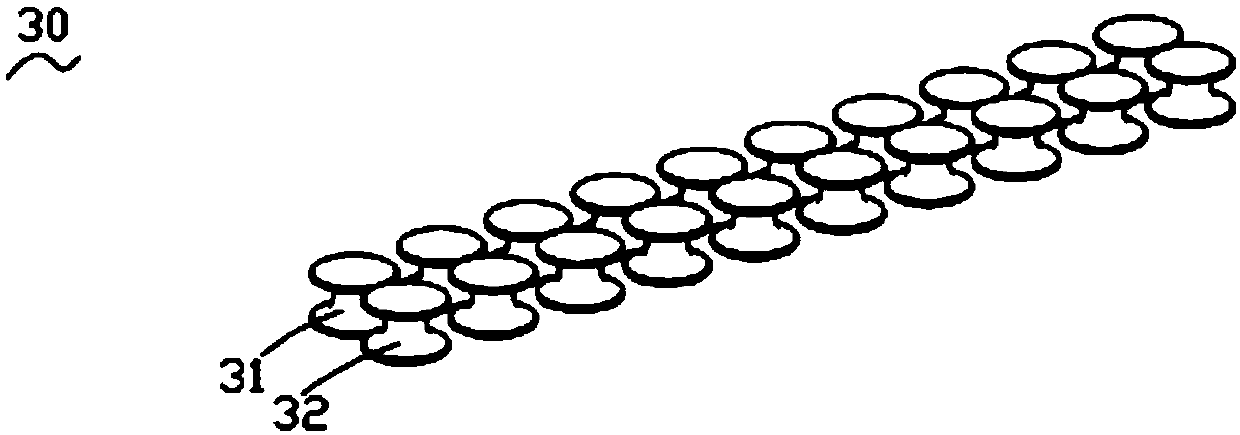

[0022] See figure 1 and figure 2 As shown, a steel bar bending machine includes: a frame 10, a material seat 20, a conveying wheel unit 30, and a linkage mechanism located on one side of the material seat 20 for bending a steel bar 50 into a 90° bend angle 40 and a fixed block 60, the material seat 20 is installed on the frame 10, and a groove 21 is formed on the material seat 20; the conveying wheel unit 30 for transporting the steel bar 50 is arranged in the groove 21, The groove 21 is also provided with the fixing block 60, the fixing block 60 is located on one side of the delivery wheel unit 30, and the fixing block 60 is formed with a through hole for the steel bar 50 to pass through. The interference connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com