Bending machine with assisted locating jig

An auxiliary positioning and bending machine technology, applied in the field of bending machines, can solve problems such as torsion deformation, affecting product quality, scratches, etc., and achieve the effect of ensuring bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

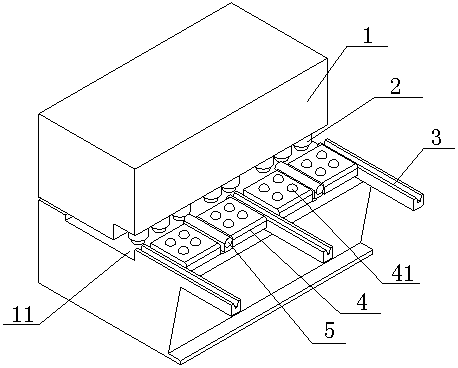

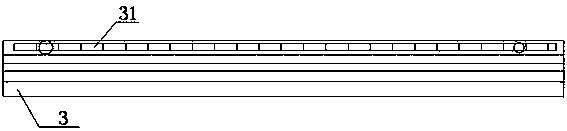

[0013] figure 1 A bending machine with an auxiliary positioning fixture is shown, including a bending machine body 1, on which a workbench 11 for placing plates and a stamping plate for extruding the plates are provided (not shown), a set of positioning columns 2 is also set on one side of the stamping plate, and three guide rods 3 are arranged at equal intervals on the workbench 11, and the guide rods 3 are fixed on the workbench 11 by bolts, A group of anti-deviation mechanisms are arranged between the guide rods 3 .

[0014] Further, the anti-deflection mechanism is composed of a positioning plate 4 and a smooth column 5. There are two positioning plates 4. The smooth column 5 is fixed laterally between the two positioning plates 4. The positioning plate 4 is fixed on the On the workbench 11 , at least one light ball 41 is embedded in the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com