Copper pipe bend forming device

A technology for bending and forming copper tubes, applied in the field of copper tube bending and forming devices, can solve the problems of low efficiency, high bending cost of copper tubes, affecting the transmission loss of microwave signals, etc., and achieves the effect of convenient use and guaranteed bending quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

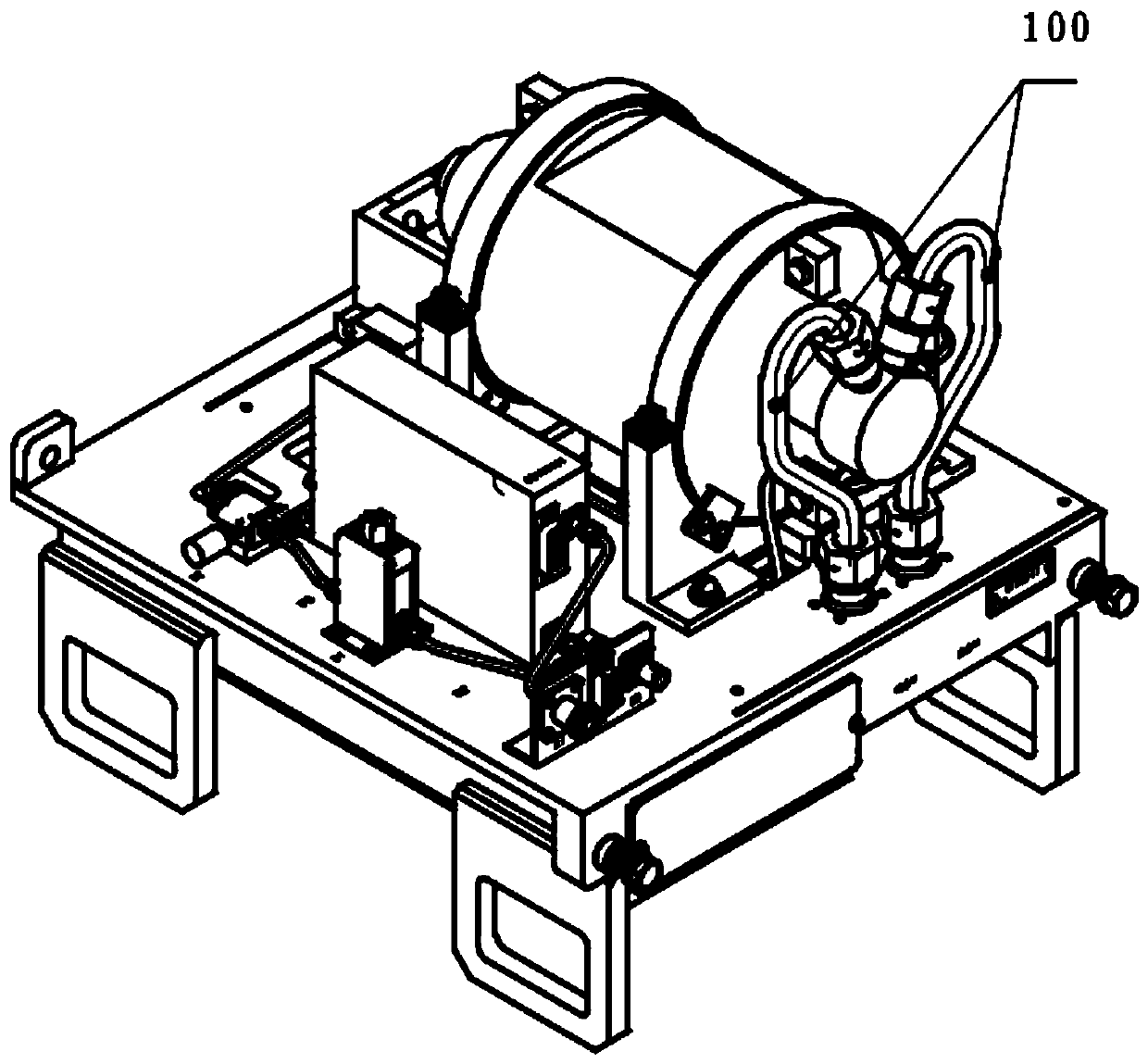

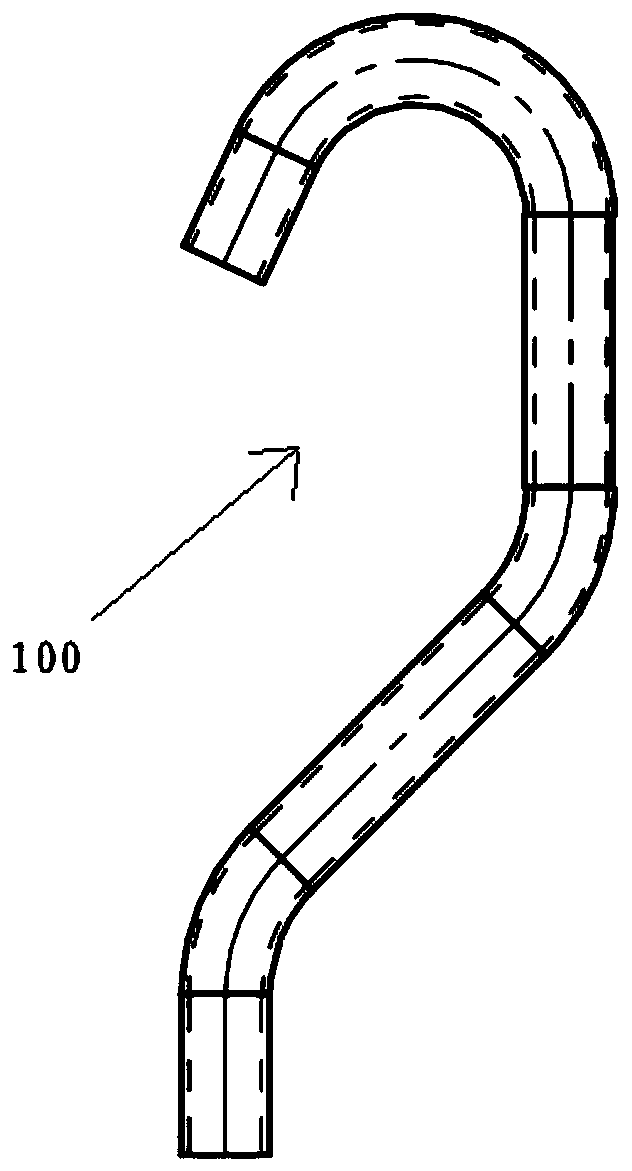

[0038] Such as Figure 1-10 As shown, a copper tube bending forming device is used to bend copper tubes 5 into preset products, including a bottom plate 1 and a guide groove block 2, the guide groove block 2 is fixedly installed on the bottom plate 1, and the guide groove block 2 An open curved groove 21 matching the preset product shape is arranged on the top.

[0039] The beneficial effect of this embodiment is: the bottom plate 1 is the installation basis of the guide groove block 2, and at the same time as the bottom plane limit when the copper pipe 5 is bent, after the guide groove block 2 is installed on the bottom plate 1, the curved copper pipe to be treated 5. During the bending process, the bottom plate 1 is equivalent to a workbench, providing a stable foundation for applying force; according to the preset shape of the bent pipe product 100 formed by bending, a corresponding open curved groove 21 is set on the guide groove block 2, and the During the bending proces...

Embodiment 2

[0041] Such as Figure 1-10 As shown, a copper tube bending forming device is used to bend copper tubes 5 into preset products, including a bottom plate 1 and a guide groove block 2, the guide groove block 2 is fixedly installed on the bottom plate 1, and the guide groove block 2 An open curved groove 21 matching the preset product shape is arranged on the top.

[0042] The open curved groove 21 is designed and manufactured according to the bending shape of the copper pipe 5, and is used to limit the bending direction of the copper pipe 5 when it is bent. The open curved groove 21 is provided with a circular arc surface whose bending radius is consistent with the radius of the copper tube 5 , and is used to closely adhere to the outer surface of the copper tube 5 during bending.

[0043]It can be understood that the bottom plate 1 is the installation basis of the guide groove block 2, and at the same time serves as the bottom plane limit when the copper pipe 5 is bent. After ...

Embodiment 3

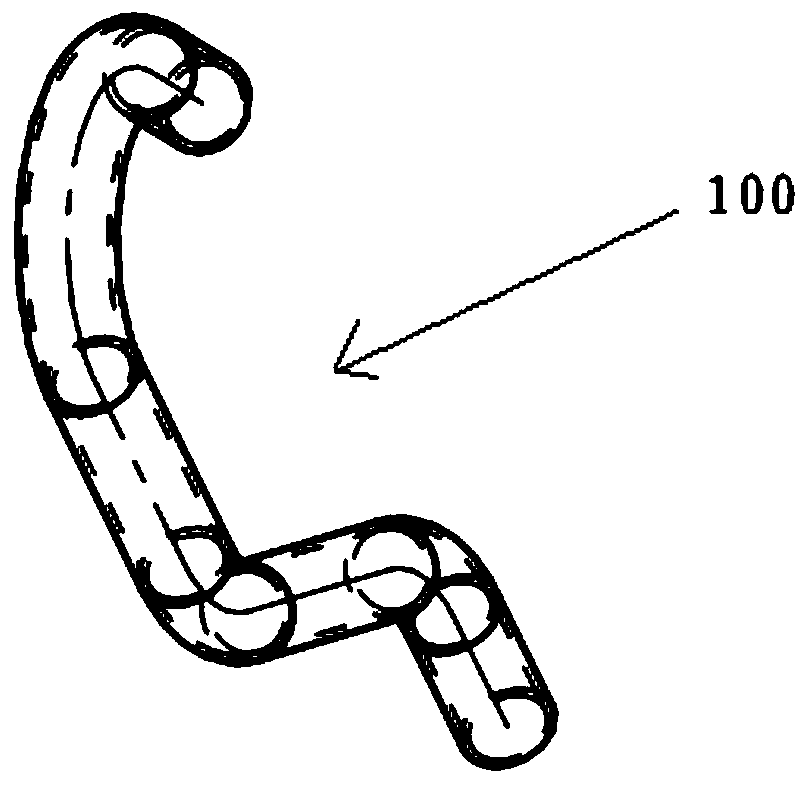

[0066] A copper tube 5, comprising a copper tube 5 body and a snap ring 3, the snap ring 3 is fixedly sleeved on one end of the copper tube 5, and is used for snap-fitting with a snap-fit part of a copper tube bending and forming device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com