Processing method for cold bending pipes by medium frequency heating

A processing method and technology of cold-formed pipes, which are applied in induction heating, metal processing equipment, manufacturing tools, etc., can solve the problems of cold-formed equipment that cannot be bent, there are many space bends for boiler connecting pipes, and the pipeline bending process is prolonged. , to achieve good production efficiency, reduce labor intensity of workers, and good heat penetration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

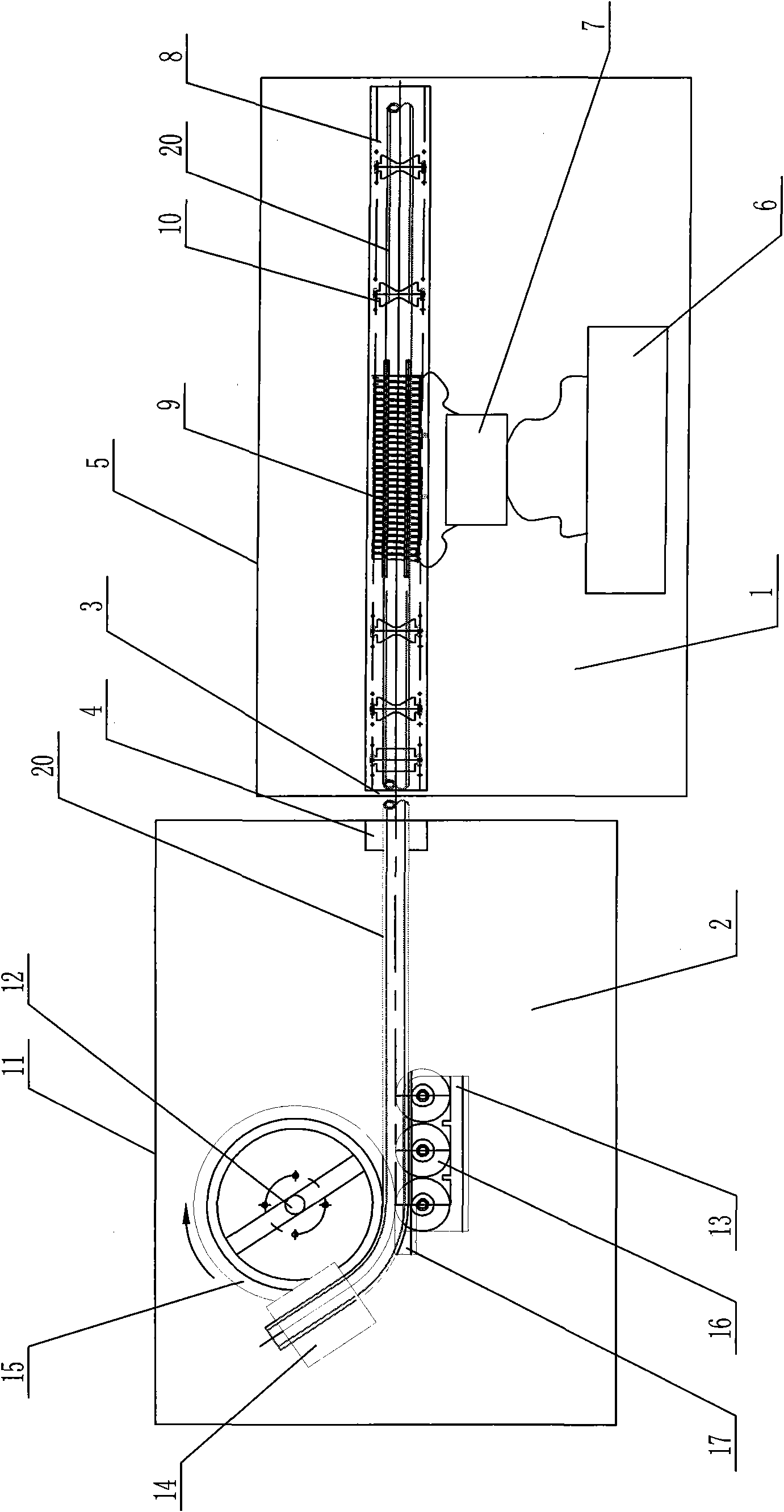

[0019] The intermediate frequency heating cold bending pipe processing method of the present invention adopts such as figure 1 The processing equipment shown in the figure includes an intermediate frequency heating device 1 and a cold bending machine 2 fixedly connected together, and the outlet 3 of the intermediate frequency heating device 1 is connected to the feeding port 4 of the cold bending machine 2 . The intermediate frequency heating device 1 includes a fixed frame 5, and the fixed frame 5 is provided with an intermediate frequency power supply 6, a capacitor 7, a heating channel 8, and an induction coil 9. Connected by wires, several rollers 10 are arranged on the heating channel 8 . Cold bender 2 comprises frame 11, and frame 11 is provided with rotating shaft 12, boosting roller frame 13 and clamping block 14, and rotating shaft 12 is provided with disc-shaped pipe bending die 15, and boosting roller frame 13 A booster roller 16 is provided on the top, and the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com