Thermoplastic FRP rib bending device

A bending device and thermoplastic technology, which is applied in the field of fiber composite material processing equipment, can solve the problems that FRP bars do not have secondary molding, the tensile strength of thermosetting FRP bars is reduced, and secondary processing cannot be performed, etc., so as to avoid Error, high mechanical bending accuracy, and the effect of ensuring bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

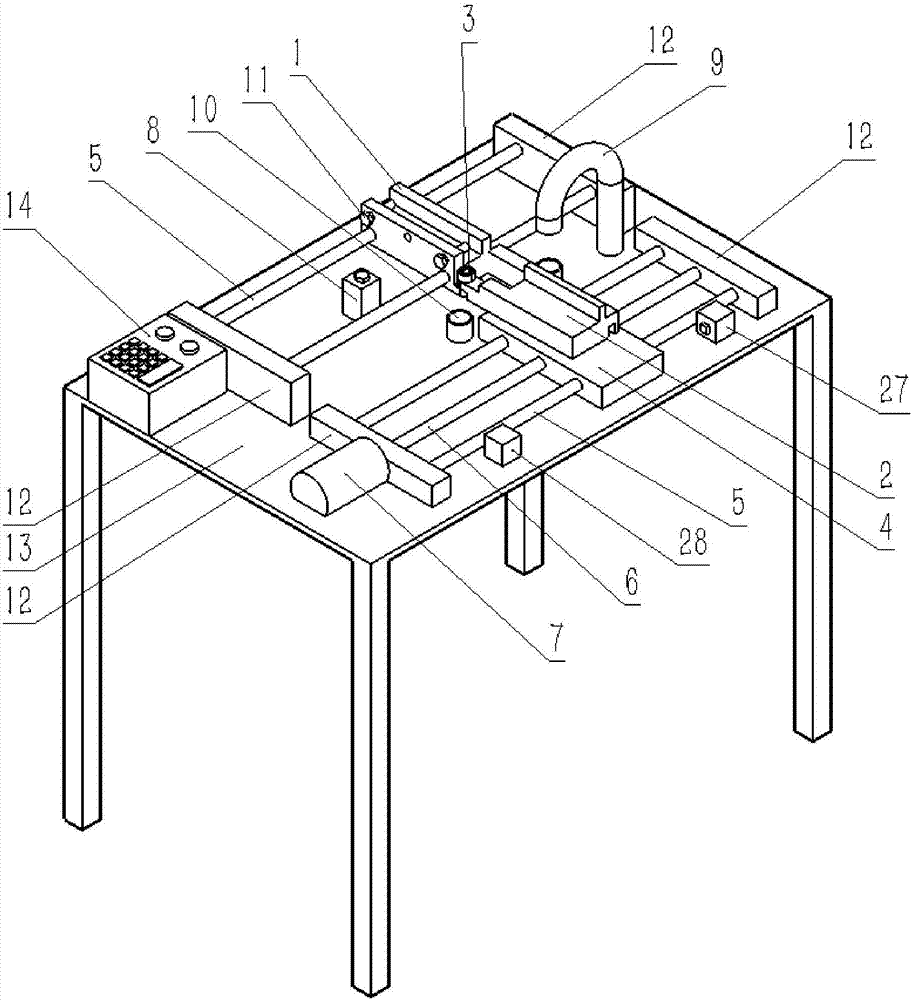

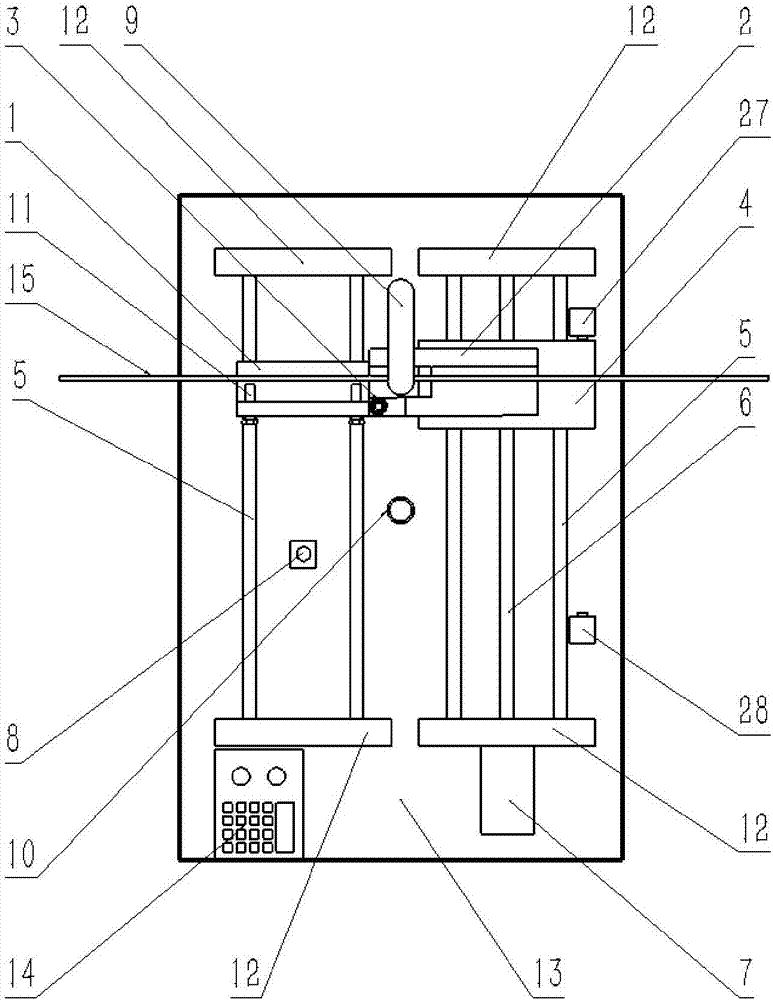

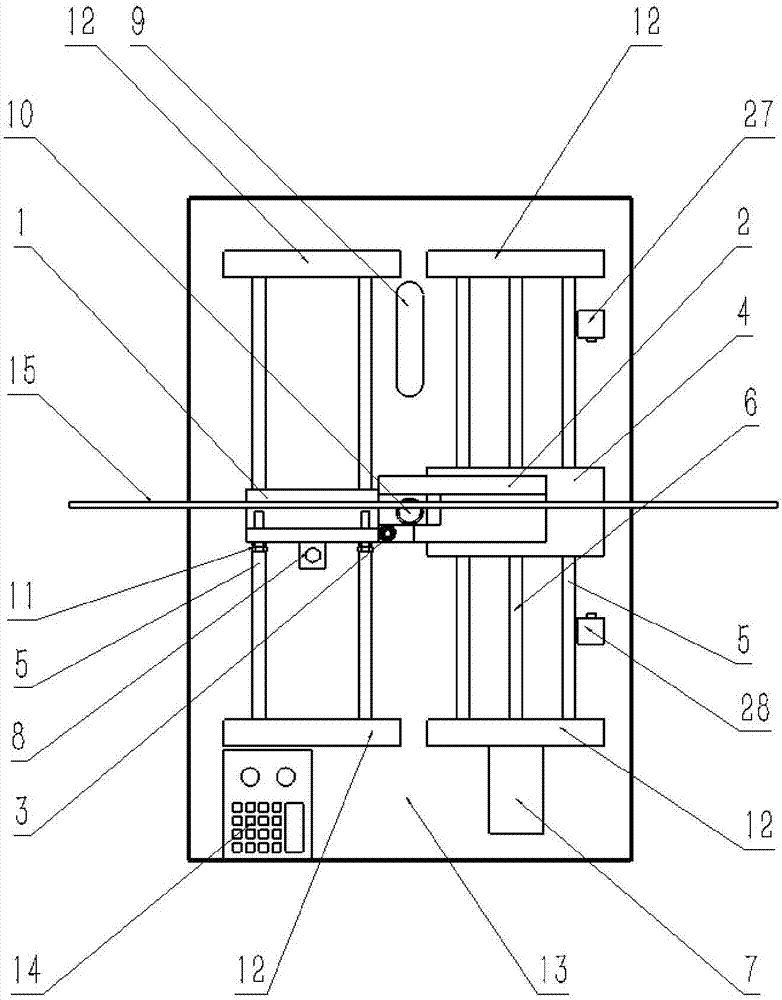

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] combine Figure 1 to Figure 9 , a thermoplastic FRP tendon bending device of the present invention includes a fixing mechanism 1 , a rotating mechanism 2 , a slider 4 , a heater 9 and a cooler 10 . A clockwork spring 3 is arranged between the fixed mechanism 1 and the rotating mechanism 2, the guide rail 5 passes through the fixed mechanism 1 and the slider 4, the two ends of the guide rail 5 are fixed on the working platform 13 with the base 12, and the stepping motor 7 passes through the screw rod 6. Drive and control the slider 4. Under the action of the slider 4, the rotating mechanism 2 and the fixing mechanism 1 can undergo translation and rotation. Through the translation, the FRP bars move between the heater 9 and the cooler 10, and through the rotation, the FRP The tendon bends.

[0023] The fixing mechanism 1 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com