A kind of preparation method of high-strength low-expansion PVC floor

A low-expansion, PVC resin powder technology, used in floors, buildings, building structures, etc., can solve the problems of limiting the application of chopped glass fibers, unavoidable precipitation of plasticizers, and gaps in paving, and achieve excellent tension. , Avoid the precipitation of plasticizer, improve the effect of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

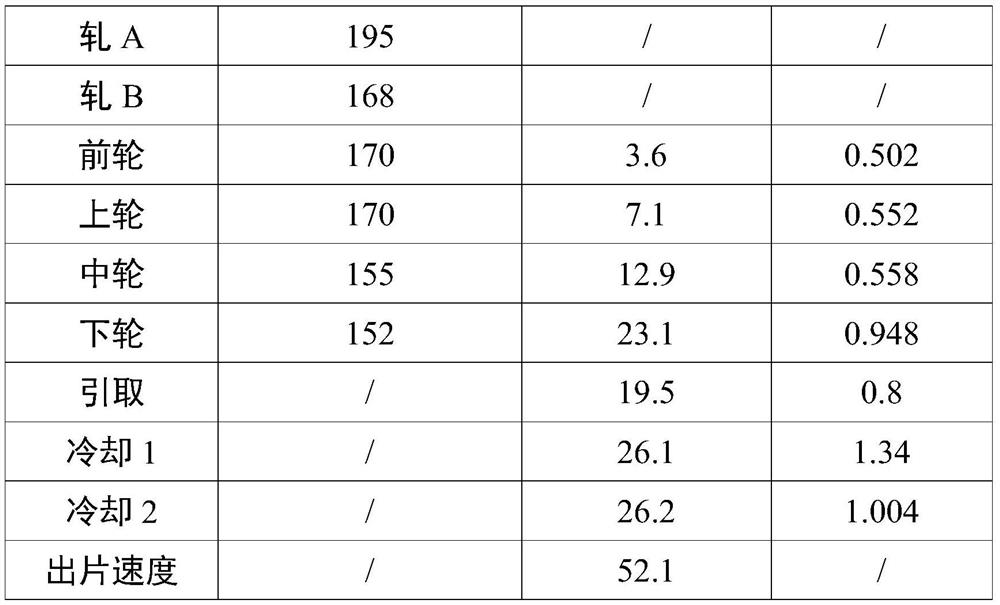

[0049] A preparation method of high-strength low-expansion PVC floor, comprising the following steps:

[0050] Step 1: Drawing of reinforcement layer

[0051] Mix 10% of PVC resin powder, 0.5% of stabilizer and 4% of plasticizer and stir for 3 minutes, then add 70% of calcium carbonate and 15.5% of modified chopped glass fiber, and stir at high speed for 8 minutes; put the mixed raw materials into Banbury mixer, banbury for 2 minutes, when the raw materials are formed into small pieces, they are discharged to the open-mixing equipment, and then rolled through four rolls, and then cooled, cut and drawn to obtain a reinforced material layer;

[0052] Step 2: Drawing of the base layer

[0053] Mix 10% modified PVC resin powder, 0.5% stabilizer and 10% plasticizer for 3 minutes, then add 79.5% calcium carbonate, and stir at high speed for 8 minutes; put the mixed raw materials into the internal mixer, and mix for 2 minutes, when the raw materials are formed into small pieces, th...

Embodiment 2

[0073] A preparation method of high-strength low-expansion PVC floor, comprising the following steps:

[0074] Step 1: Drawing of reinforcement layer

[0075] Mix and stir 15% of PVC resin powder, 1.0% of stabilizer and 12% of plasticizer for 5 minutes, then add 62% of calcium carbonate and 10% of modified chopped glass fiber, and stir at high speed for 10 minutes; put the mixed raw materials into Banbury mixer, banbury for 6 minutes, when the raw materials are formed into small pieces, the material is discharged to the open-mixing equipment, then rolled through four rolls, and then cooled, cut and drawn to obtain a reinforced material layer;

[0076] Step 2: Drawing of the base layer

[0077] Mix 15% modified PVC resin powder, 1.0% stabilizer and 12% plasticizer for 5 minutes, then add 72% calcium carbonate, and stir at high speed for 10 minutes; put the mixed raw materials into the mixer, and mix for 6 minutes, when the raw materials are formed into small pieces, they are ...

Embodiment 3

[0094] The difference between this embodiment and Embodiment 1 is only:

[0095] Step 1: Drawing of reinforcement layer

[0096] 10% of PVC resin powder, 1.0% of stabilizer and 7% of plasticizer were mixed and stirred for 4 minutes, and then 62% of calcium carbonate and 20% of modified chopped glass fibers were added.

[0097] The thickness of the TPU anti-slip film layer is 0.12 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com