Male pin bending device

A bending device and stud technology, applied in the direction of using a stable bending force to test the strength of materials, can solve the problems of impact force, affecting the test effect, time-consuming and laborious, etc., to achieve simple structure, improve test accuracy, and ensure bending quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

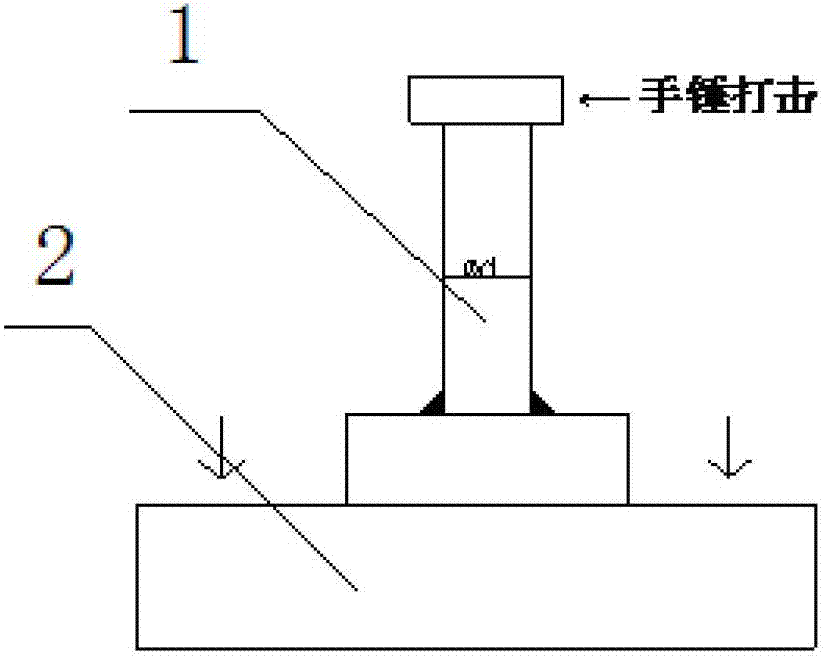

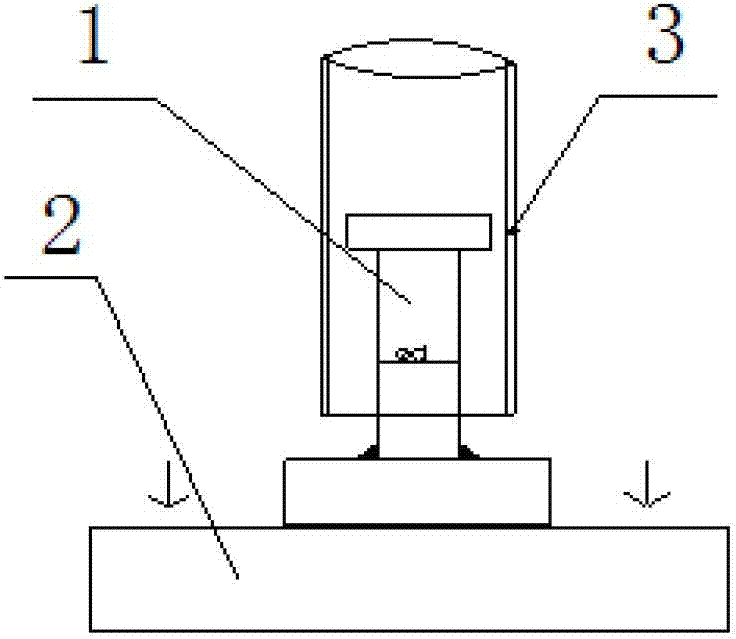

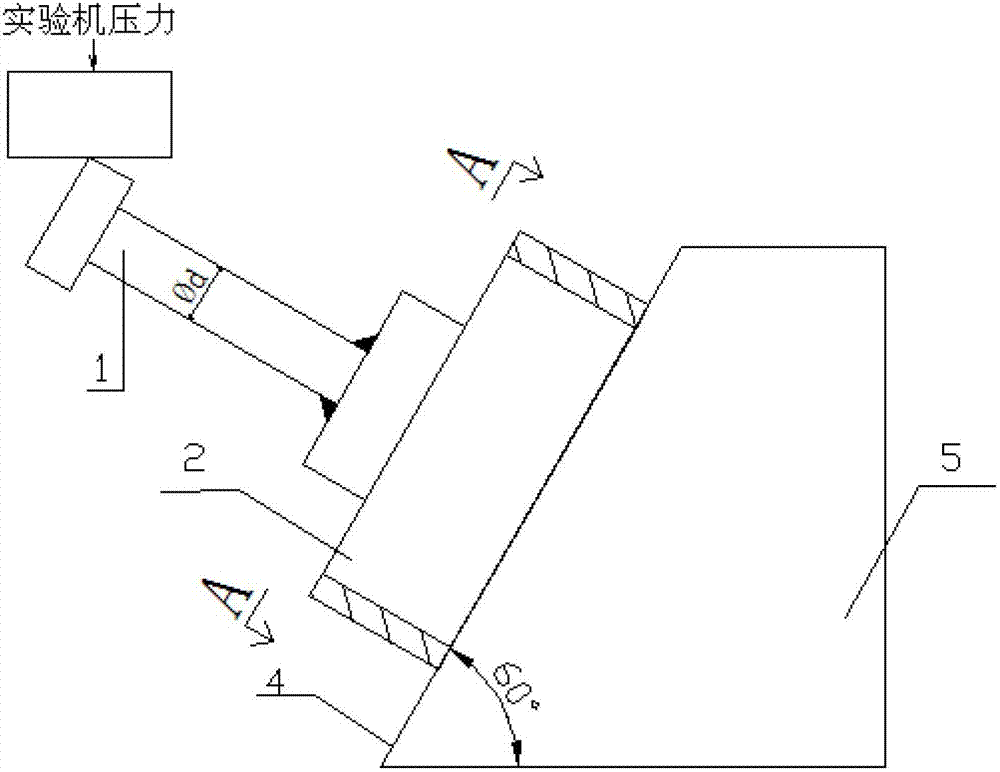

[0014] A kind of stud bending device of this embodiment such as image 3 , Figure 4 As shown, it includes a triangular base with a bevel, and the angle between the bevel and the triangular base is 60°; the bevel is vertically provided with a welding stud fixing base.

[0015] The fixing base of the welding stud test piece is provided with a groove, and the groove is perpendicular to or parallel to the slope, and the fixing base of the welding stud test piece is a cube base.

[0016] In the specific test process of welding stud bending in the present invention, a special bending device is used to change manual bending into mechanical oil pressure bending, and the welding stud bending sample is placed in the triangular shape of the special bending device by using test equipment such as a universal material testing machine and a press machine. In the slope groove of the seat, since the slope is inclined 60° to the triangular base, the cylindrical head of the welding stud is ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com