Supporting plate mechanism used for bending machine

A bending machine and pallet technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of affecting the accuracy of the sheet, hitting the workbench, falling, etc., and achieve the effect of ensuring the bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

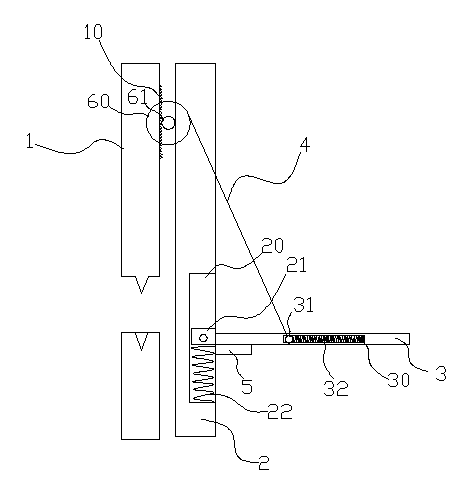

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a pallet mechanism for a bending machine, including a pressing head 1 of the bending machine, and a mounting bracket 2 arranged at the feed inlet of the bending machine, a chute 20 is set in the mounting bracket 2, and the The slider 21 is slidably arranged in the chute 20, and also includes a first spring 22, one end of the first spring 22 abuts against the lower end surface of the chute 20, and the other end of the first spring 22 abuts against the slider 21. A supporting plate 3 is arranged to rotate in the slider 21, a slide rail 30 is provided on the side wall of the supporting plate 3, a roller 31 and a second spring 32 are slidably arranged in the slide rail 30, and the roller 31 Against the second spring 32, a gear 61 is rotated on the mounting bracket 2, and a tooth surface 10 meshing with the gear 61 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com