Visual automatic bending alignment mechanism

A technology of visual alignment and bending mechanism, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of inaccurate positioning, difficult to control the size of the force, low production efficiency, etc., to achieve high market competitiveness, Ensure the accuracy and ensure the effect of bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

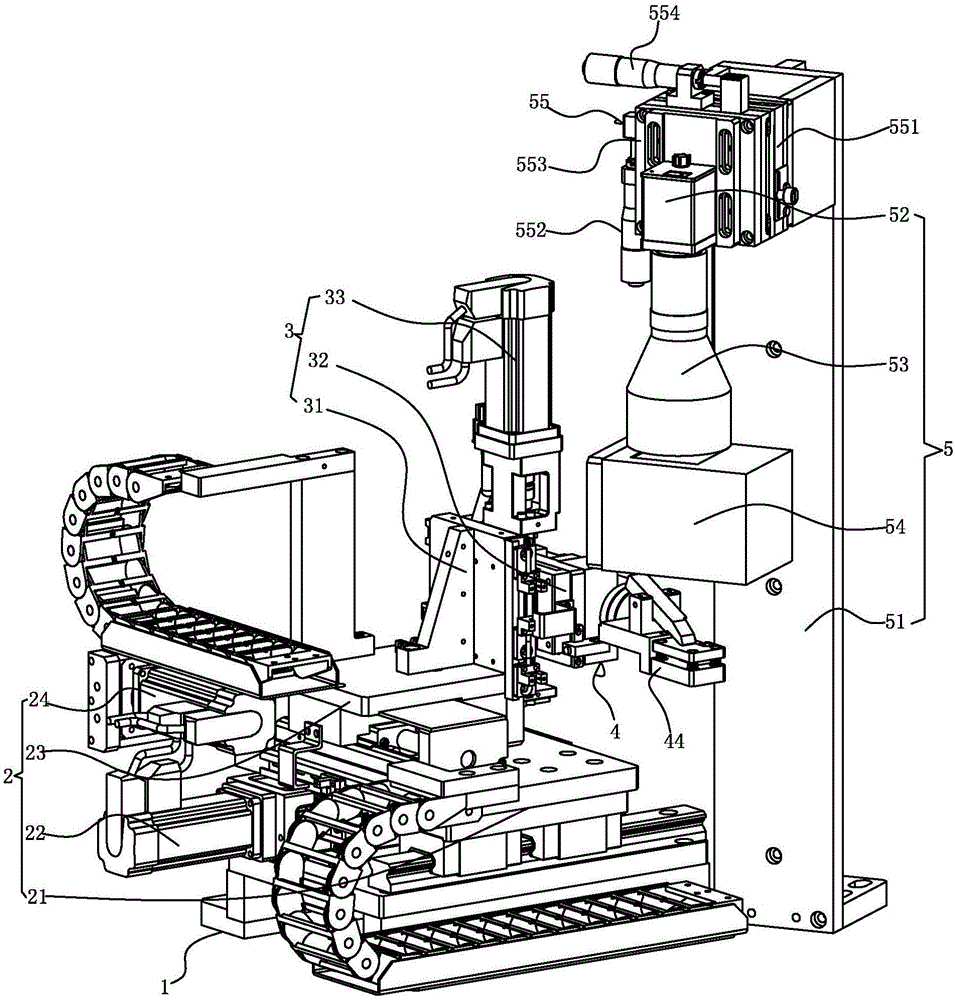

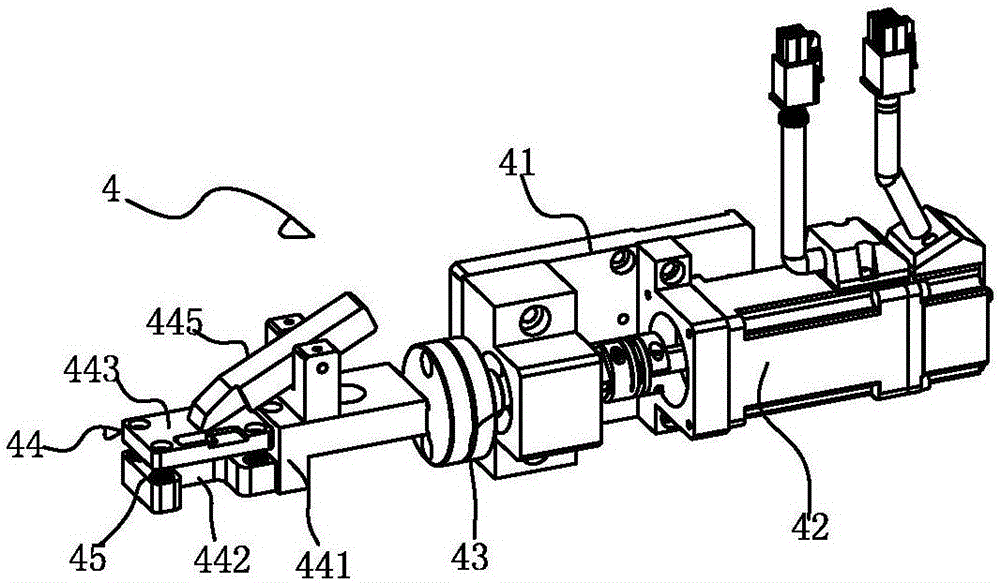

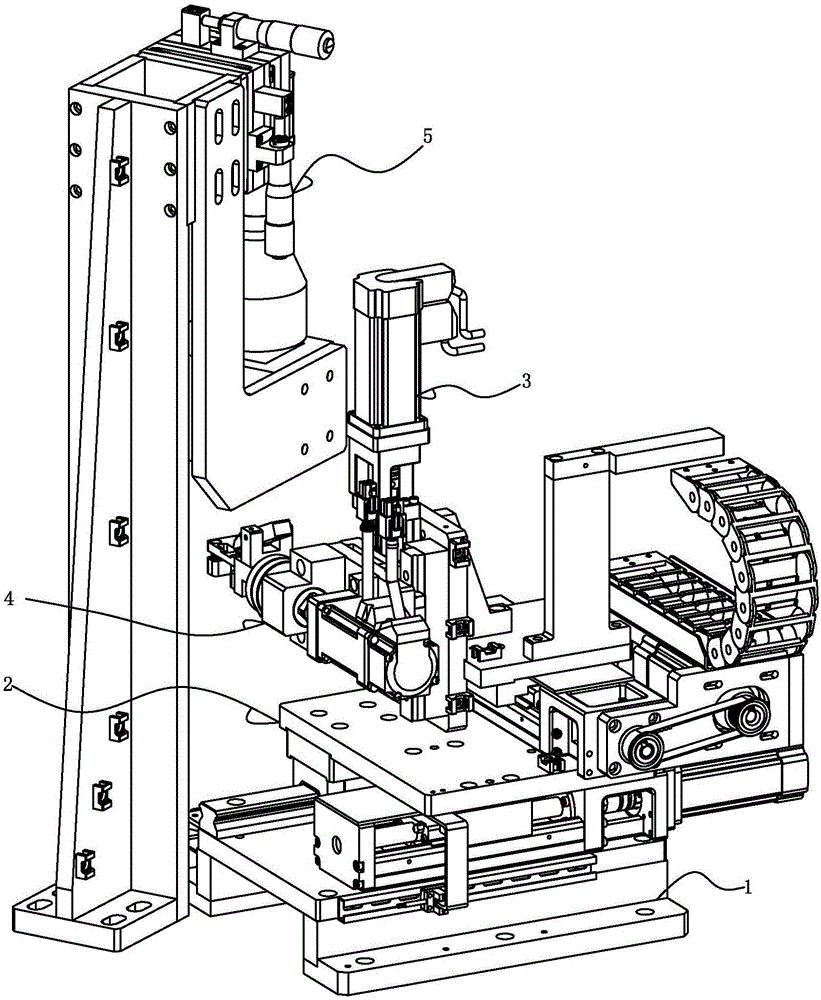

[0027] See Figure 1-3 As shown, it is a visual automatic bending alignment mechanism, which includes: a base 1, an XY moving platform mechanism 2 installed on the upper end of the base 1, and a clamping folding mechanism installed on the XY moving platform mechanism 2 through a Z-axis driving mechanism 3. The bending mechanism 4 and the visual alignment mechanism 5 installed on the side of the base 1, the visual alignment mechanism 5 cooperates with the XY moving platform mechanism 2 to automatically shift and compensate the clamping bending mechanism 4, so that the bending alignment can be ensured High precision and guaranteed bending quality make the invention highly competitive in the market.

[0028] The XY mobile platform mechanism 2 includes an X-axis mobile platform 21 mounted on the base 1 in a movable manner in the X-axis direction, moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com