Plate bending machine and method

A technology for bending machines and plates, applied in the field of plate bending machines, can solve the problems of inaccurate right-angle bending, easy generation of cold brittleness, affecting austenite transformation, etc., to improve bending accuracy and save intermediate swivels process, the effect of improving bending stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

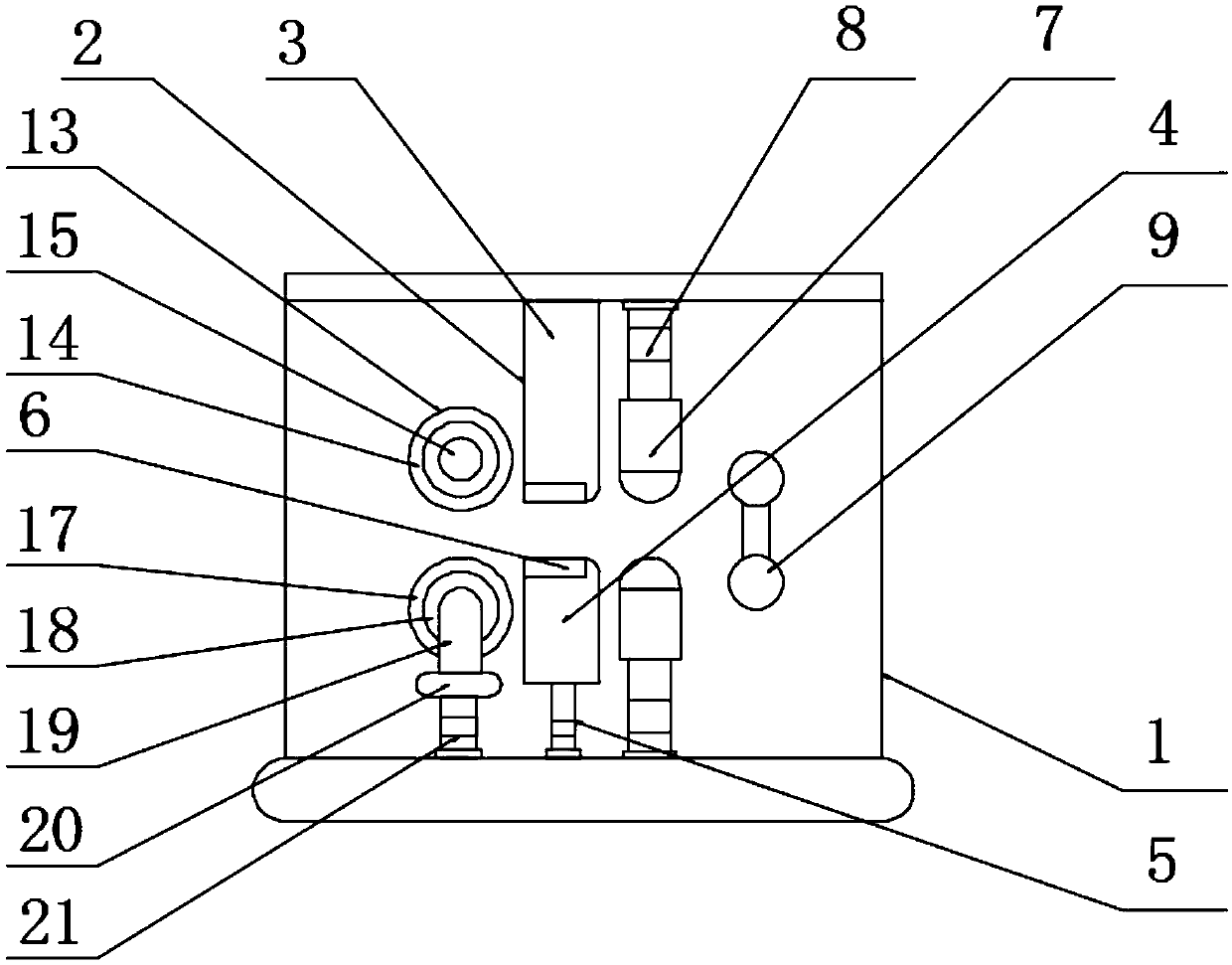

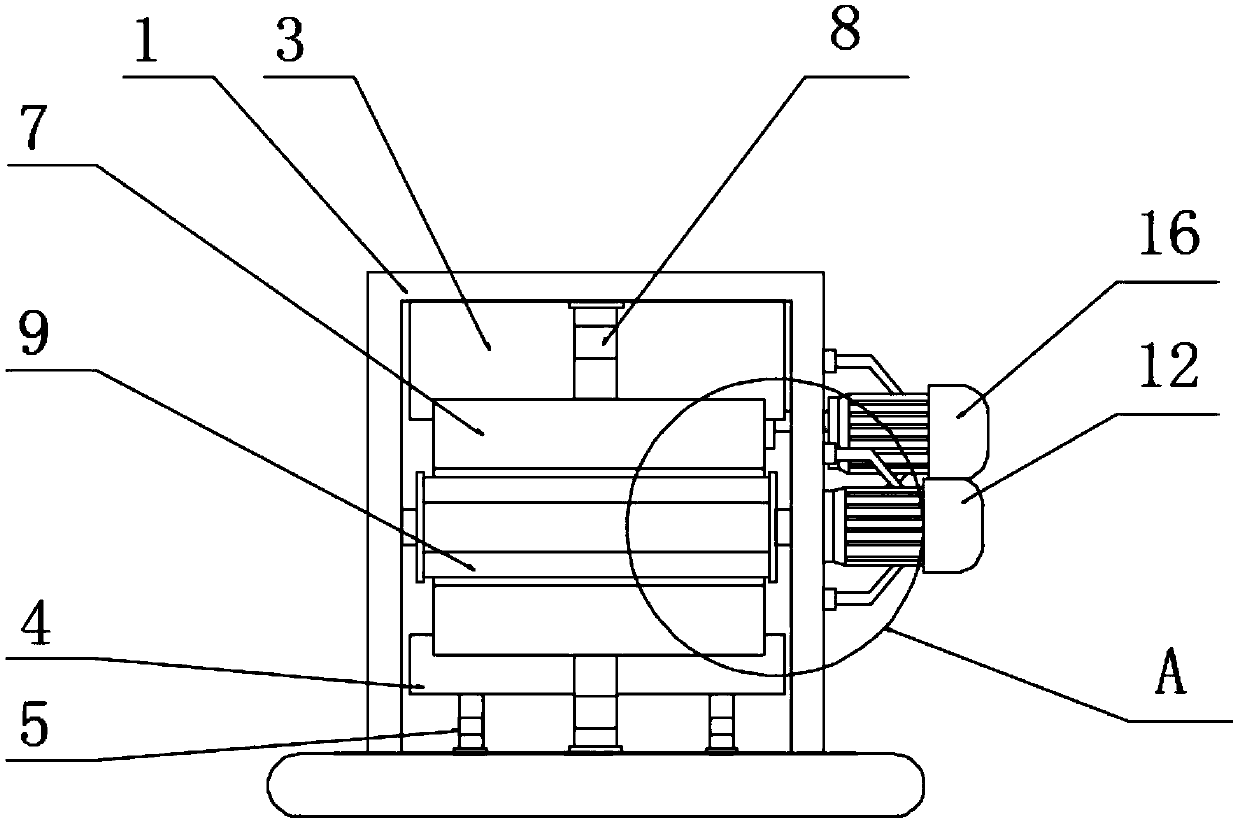

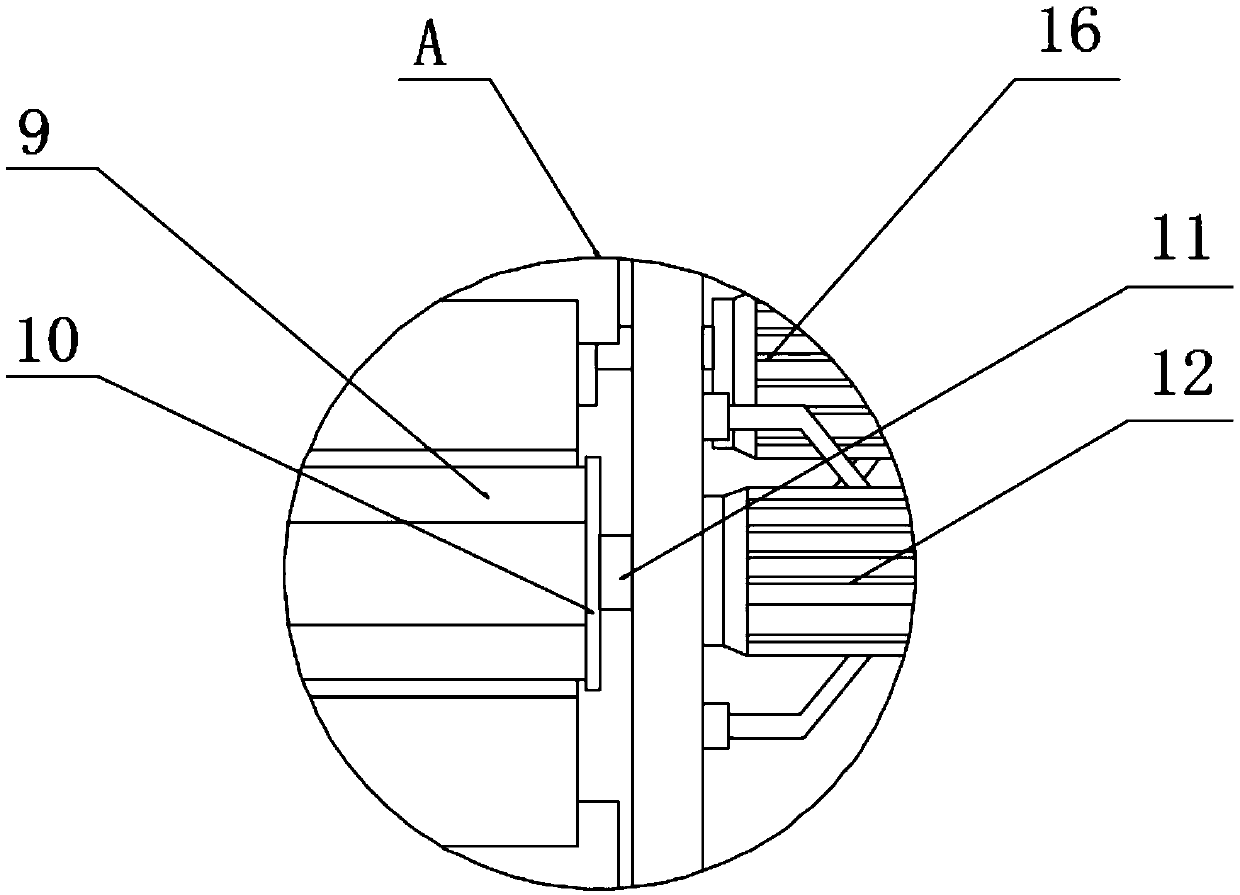

[0025] The present invention provides such Figure 1-3 The plate bending machine shown includes a chassis 1, and a bending device 2 is provided inside the chassis 1. The bending device 2 includes an upper fixing block 3, and the upper fixing block 3 is fixedly connected to the chassis 1. The bottom of the upper fixed block 3 is provided with a lower fixed block 4, the bottom of the lower fixed block 4 is provided with a first hydraulic rod 5, the output shaft of the first hydraulic rod 5 is fixedly connected with the lower fixed block 4, and the upper fixed block A heater 6 is provided on the surface of the block 3 and the lower fixed block 4, and a bending block 7 is provided on one side of the upper fixing block 3 and the lower fixing block 4, and a second hydraulic rod 8 is provided at one end of the bending block 7, The output shaft of the second hydraulic rod 8 is fixedly connected with the bending block 7, and the cross-sectional shape of one end of the bending block 7 i...

Embodiment 2

[0035] A sheet bending method, including the sheet bending machine, also includes the following steps:

[0036] S1: Conveying the forged plate between the upper fixing block 3 and the lower fixing block 4;

[0037]S2: Turn on the heater 6 to heat the plate to ensure that the plate is in a high temperature state;

[0038] S3: Open the second hydraulic rod 8 when it is necessary to perform intermediate bending, push the bending block 7 through the second hydraulic rod 8 to bend the plate upward or downward, and at the same time, the second hydraulic rod 8 pushes the bending block at the same time 7 to fix the plate;

[0039] S4: Turn on the stepping motor 12, and the stepping motor 12 drives the bending roller 9 through the first rotating shaft 11 to bend the plate in a corresponding arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com