Hydraulic pipe bender

A pipe bending machine and hydraulic technology, which is applied in the field of hydraulic pipe bending machines, can solve the problems of steel pipe waste and increase production costs, and achieve the effects of stable transmission, cost saving, and guaranteed bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

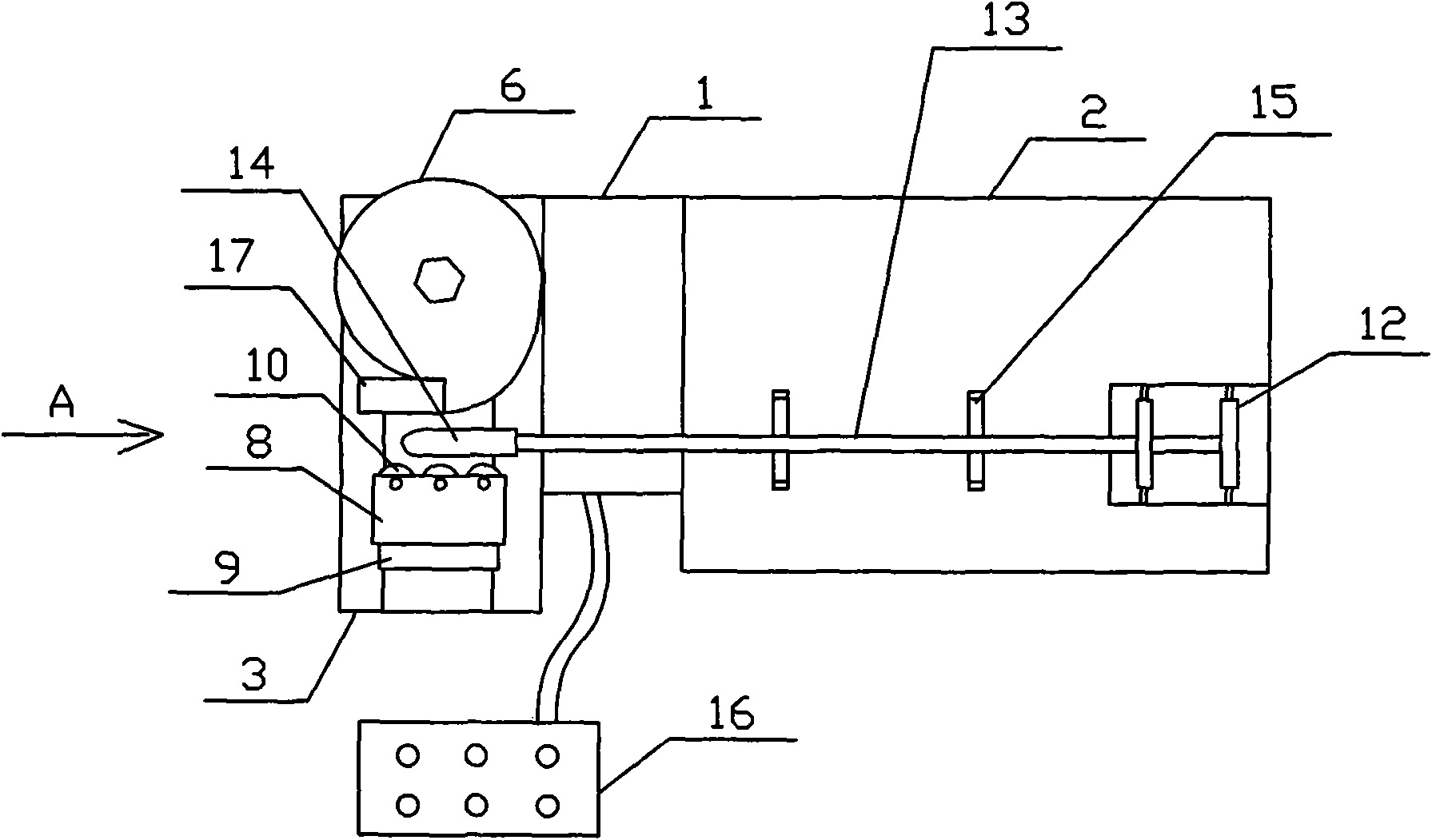

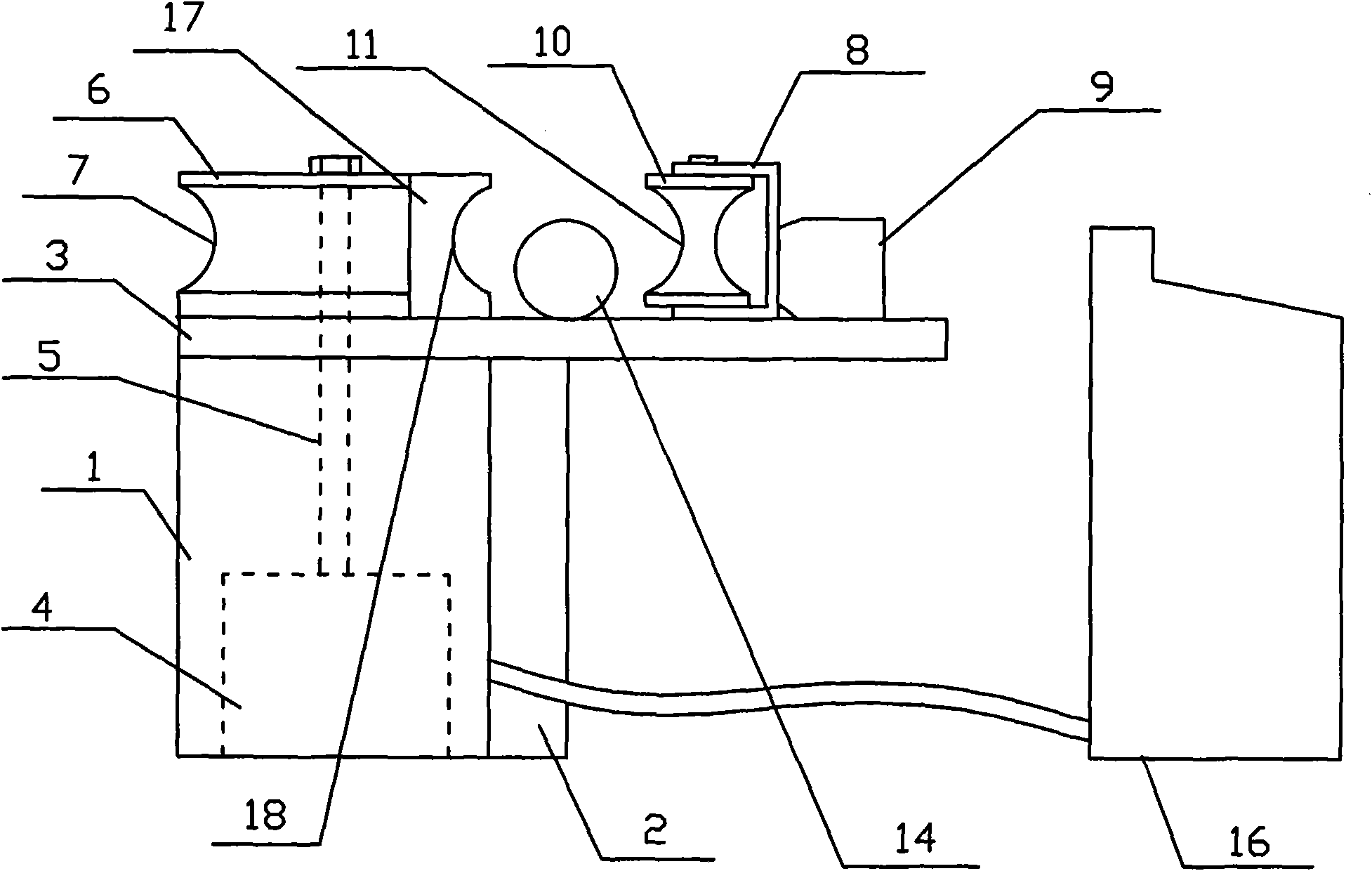

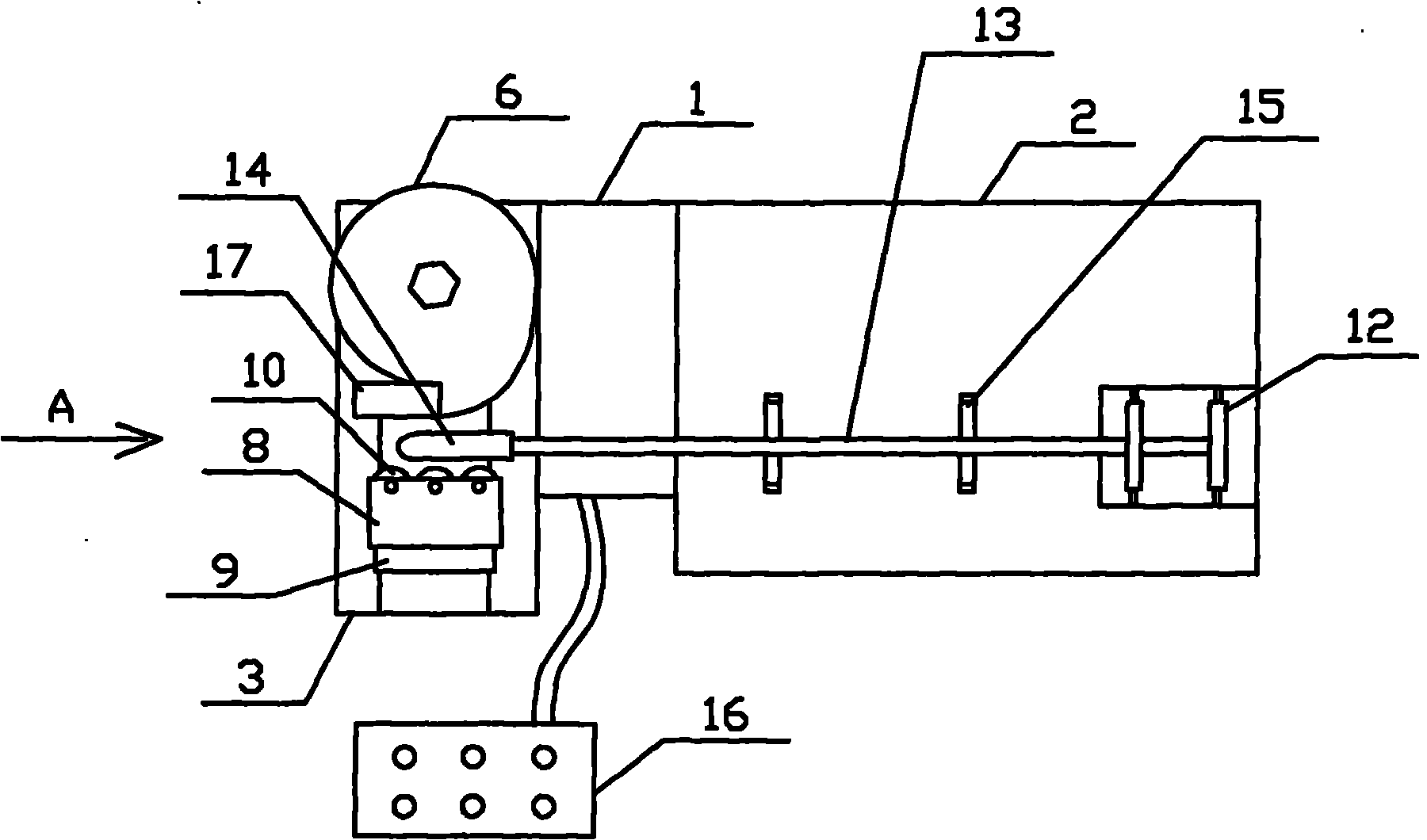

[0011] Such as figure 1 , figure 2 An embodiment of the hydraulic pipe bending machine of the present invention is shown, including a workbench 1 and a fuselage 2. The workbench 1 is connected to one end of the fuselage 2. The upper surface of the workbench 1 is longitudinally connected with a first platform 3. One end of a platform 3 is placed outside the workbench 1. A hydraulic system 4 is provided inside the workbench 1. A first turntable 6 is provided on the rear surface of the first platform 3. The hydraulic system 4 is connected to a vertical shaft 5, and the vertical shaft 5 passes through the Through the workbench 1, the first platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com