Grounding grid reinforcing steel bar bending device

A bending device and grounding grid technology, applied in the field of machinery and equipment, can solve the problems of grounding grid corrosion, time-consuming and laborious, galvanized layer damage, etc., to reduce labor intensity, reduce safety hazards, and ensure the effect of bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

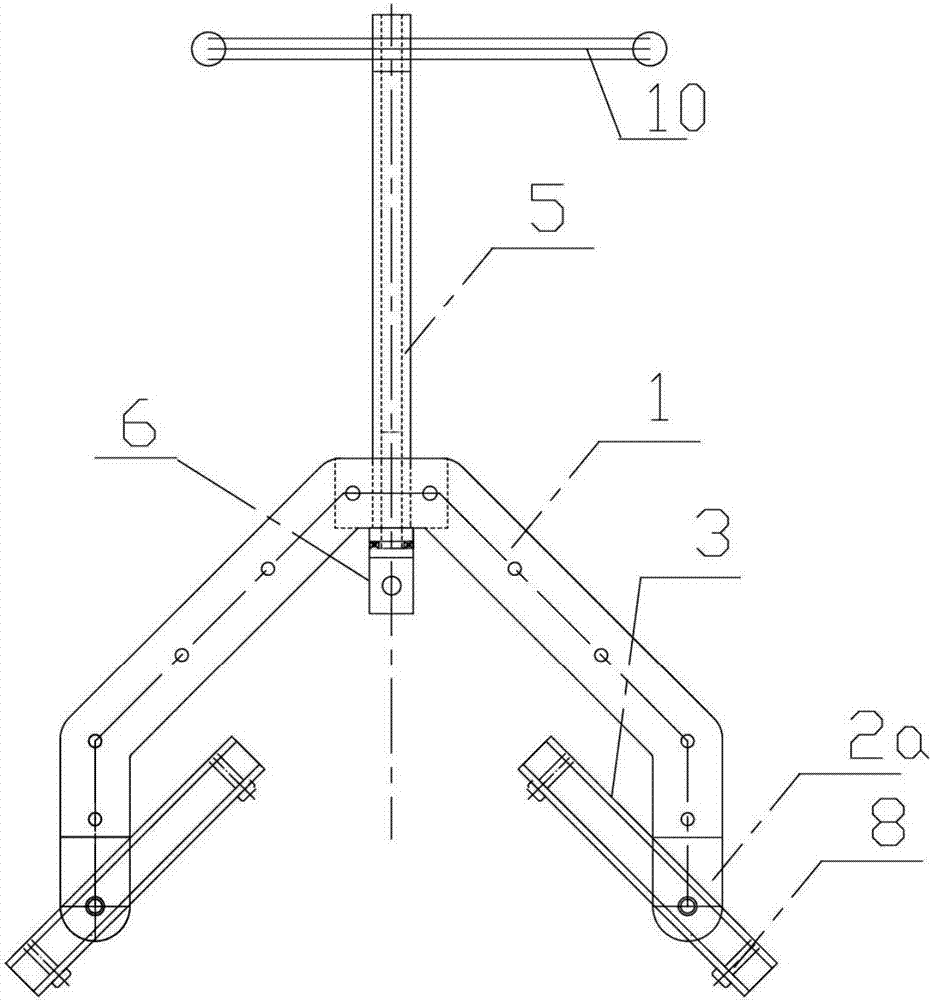

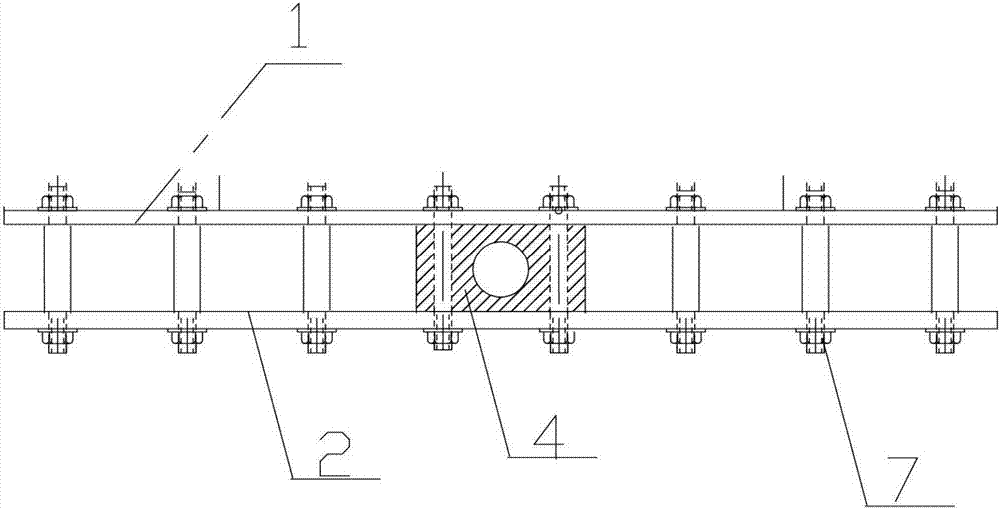

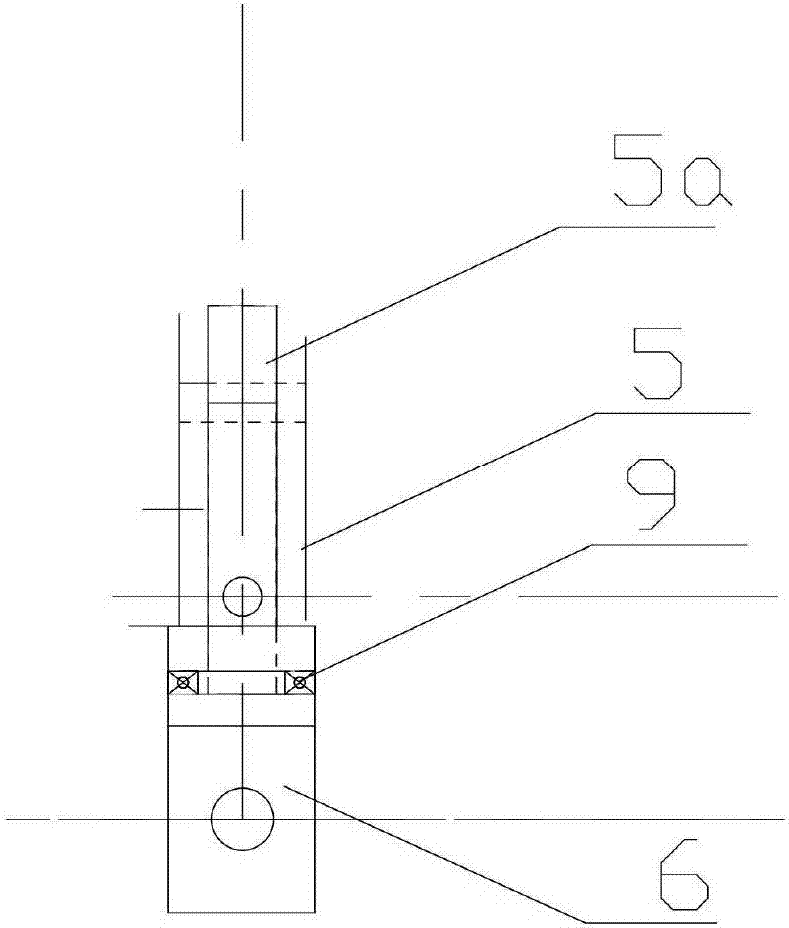

[0015] Example 1, such as Figure 1-3 Shown: the grounding grid steel bar bender of the present invention is made of front fixed plate 1, rear fixed plate 2, steel bar rotating channel steel 3, screw seat 4, leading screw 5, steel bar fixed frame 6, front and rear fixed plate bolts 7, steel bar Locking bolt 8, bearing 9, leading screw handle 10 are formed.

[0016] Both the front fixing plate 1 and the rear fixing plate 2 include a top connecting arm, a left support arm and a right support arm. The two ends of the arm, the length of the left support arm and the right support arm of the rear fixed plate 2 are greater than the left support arm and the right support arm length of the front fixed plate 1, and the left support arm of the rear fixed plate 2 and the right support arm bottom bend downward Folded into a vertical bent portion 2a, the bottom of the front fixing plate 1 is also bent downwards, but the length of the bent portion bent downwards is less than the length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com