Graduation line steel bar bender

A technology of steel bar bending and tick marks, applied in the field of steel bar bending machines, can solve the problems of not being able to control the bending angle of steel bars well and the scope of application is narrow, and achieve the effect of convenient reading, accurate bending angle and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

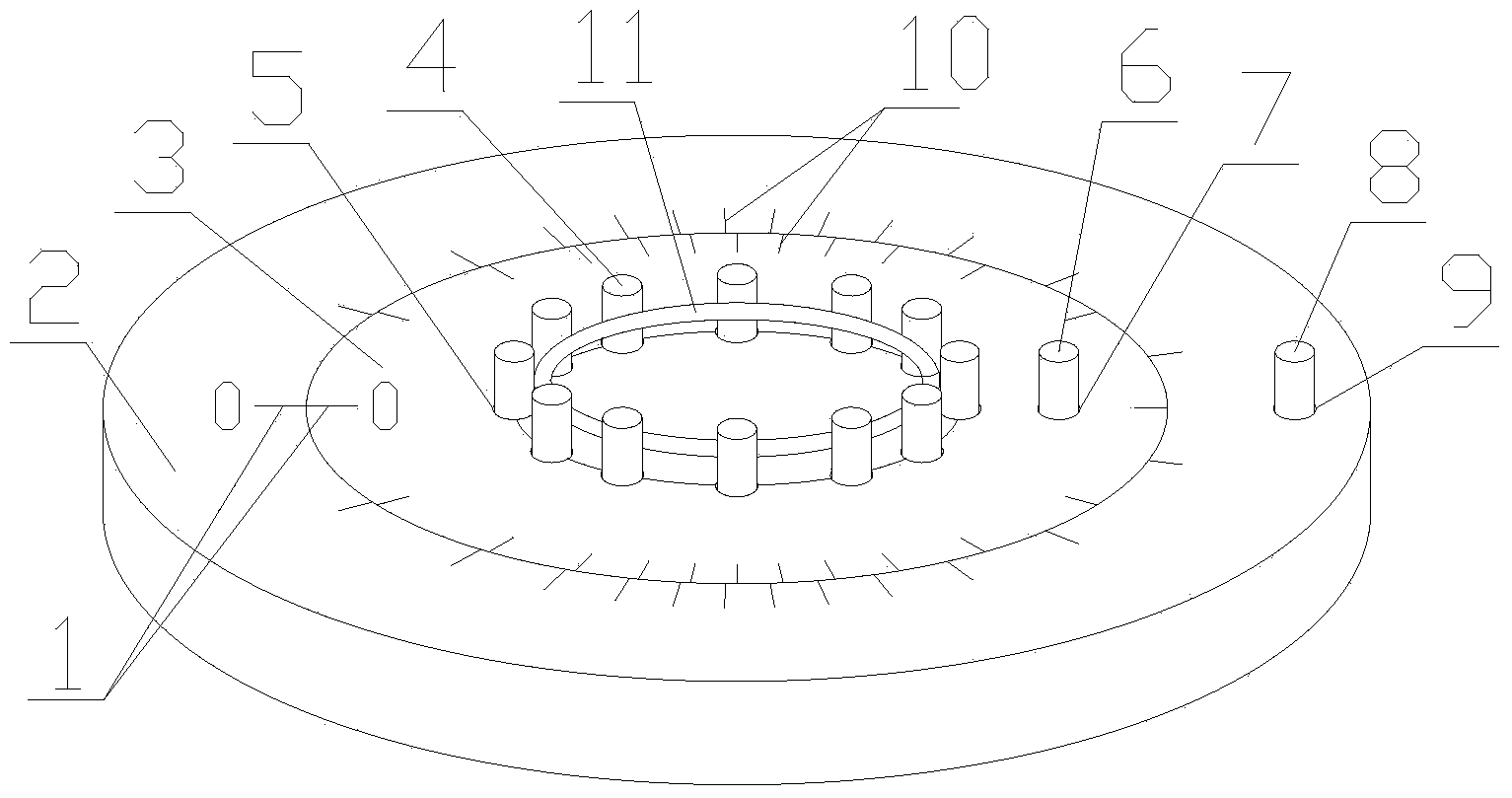

[0029] A graduated steel bar bending machine such as figure 1 As shown, including the fuselage and the working plate on top of the fuselage. The working disk includes a fixed disk 2 on the outside and a rotating disk 3 on the inside of the fixed disk 2, and the fixed disk 2 is connected with the fuselage and fixed. The rotating disk 3 is connected with the driving device inside the fuselage, and the driving device can drive the rotating disk 3 to rotate around its own axis. A number of positioning shaft holes 5 and clamping shaft holes 7 are evenly distributed on the rotating disc 3 along the circumferential direction of the rotating disc 3, and the distance between the positioning shaft holes 5 and the clamping shaft holes 7 is adapted to the diameter of the steel bar to be bent , a number of positioning shaft holes 5 are distributed in a circle on the rotating disk 3, and the center of the circularly distributed positioning shaft holes 5 coincides with the center of the rot...

Embodiment 2

[0032] On the basis of Embodiment 1, the distribution of several positioning shaft holes 5 on the rotating disk 3 is set as several concentric circles, so that several positioning shaft holes 5 form multiple circles of positioning shaft holes 5 on the rotating disk 3, and The multi-circle positioning shaft holes 5 are concentric circles with each other. When the scale line steel bending machine is working, the positioning shaft hole 5 is only placed in a certain circle of the positioning shaft hole 5 located at a certain radius value, and it is not necessary to place the positioning shaft 4 on all the positioning shaft holes 5. Place the clamping shaft 6 in the clamping shaft hole 7 at the outer position of the positioning shaft hole 5 . The positioning shaft holes 5 form several concentric circles on the rotating disk 3, and the positioning shaft holes 5 located at different diameters can process steel bars with different bending radii, thereby expanding the scope of applicat...

Embodiment 3

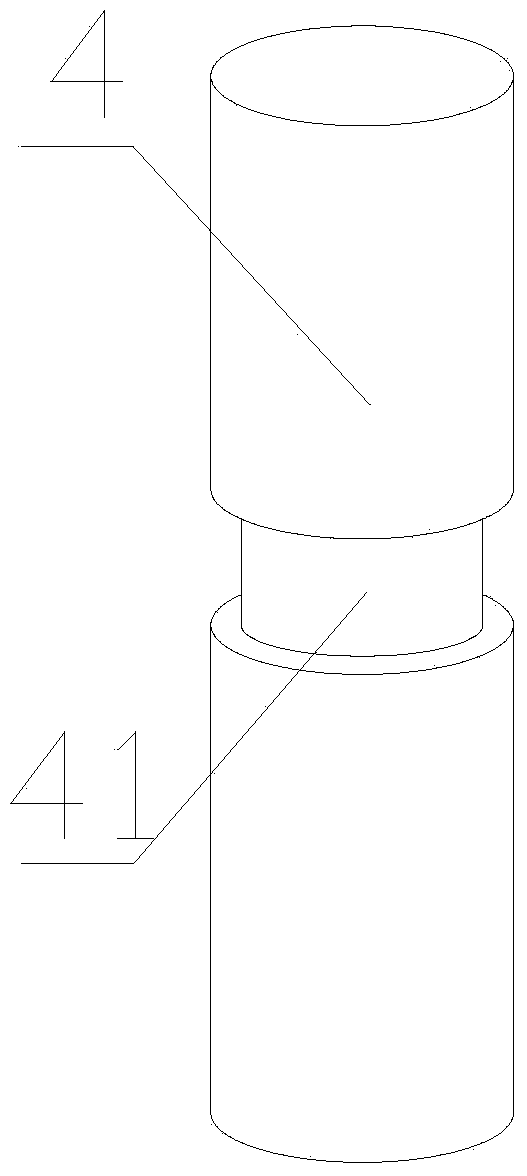

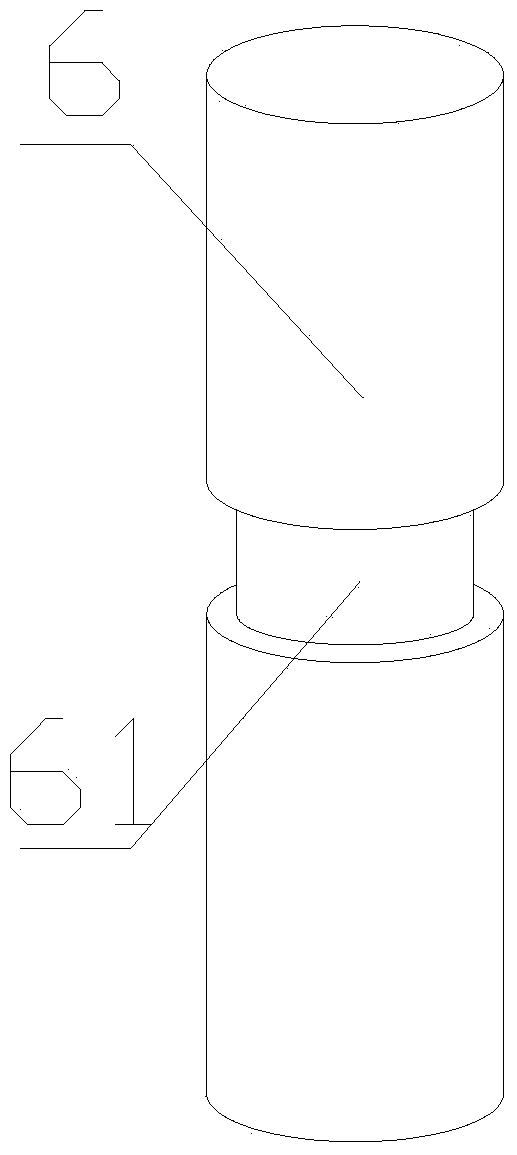

[0034] On the basis of the first or second embodiment, the positioning shaft 4 is provided with a positioning collar 41 ; the clamping shaft 6 is provided with a clamping collar 61 . The positioning collar 41 is set on the positioning shaft 4, which can effectively prevent the steel bar from slipping during the bending process, ensuring the bending accuracy and bending quality of the graduated steel bar bending machine; the clamping shaft 6 is provided with a clamping collar 61, It can further prevent the steel bar from slipping during bending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com