Patents

Literature

86results about How to "Guaranteed bending accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

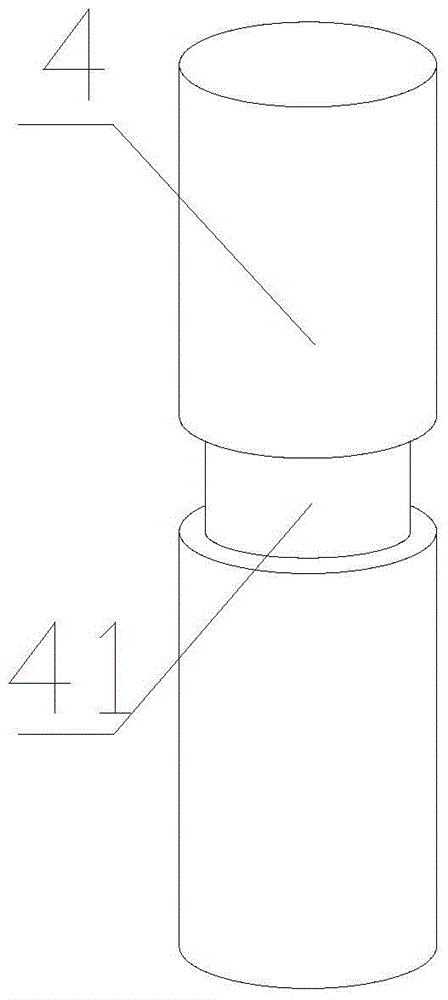

High-precision hydraulic plate bending machine

ActiveCN103691777AHigh degree of mechanizationImprove machining accuracyMetal-working feeding devicesPositioning devicesDrive shaftMachine tool

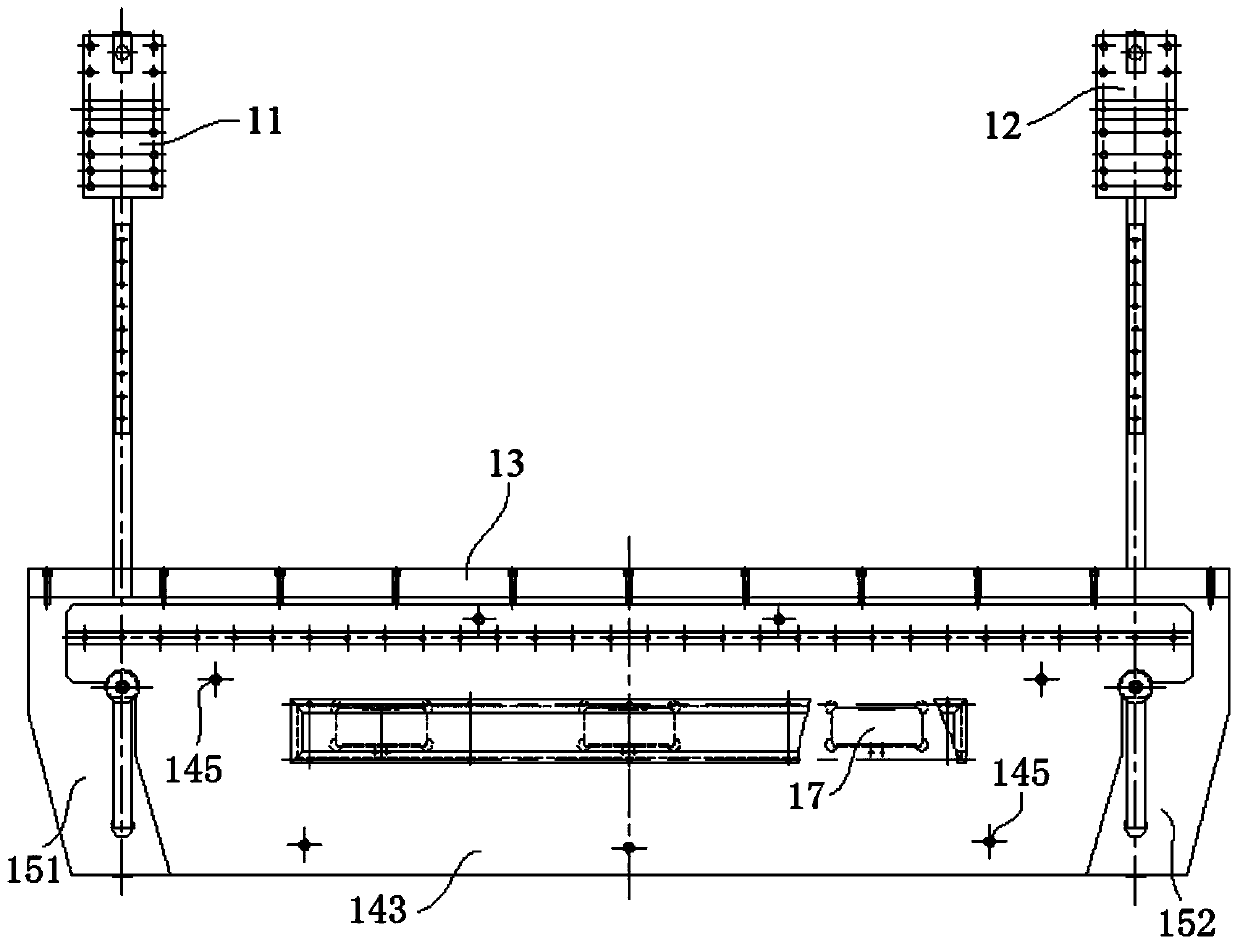

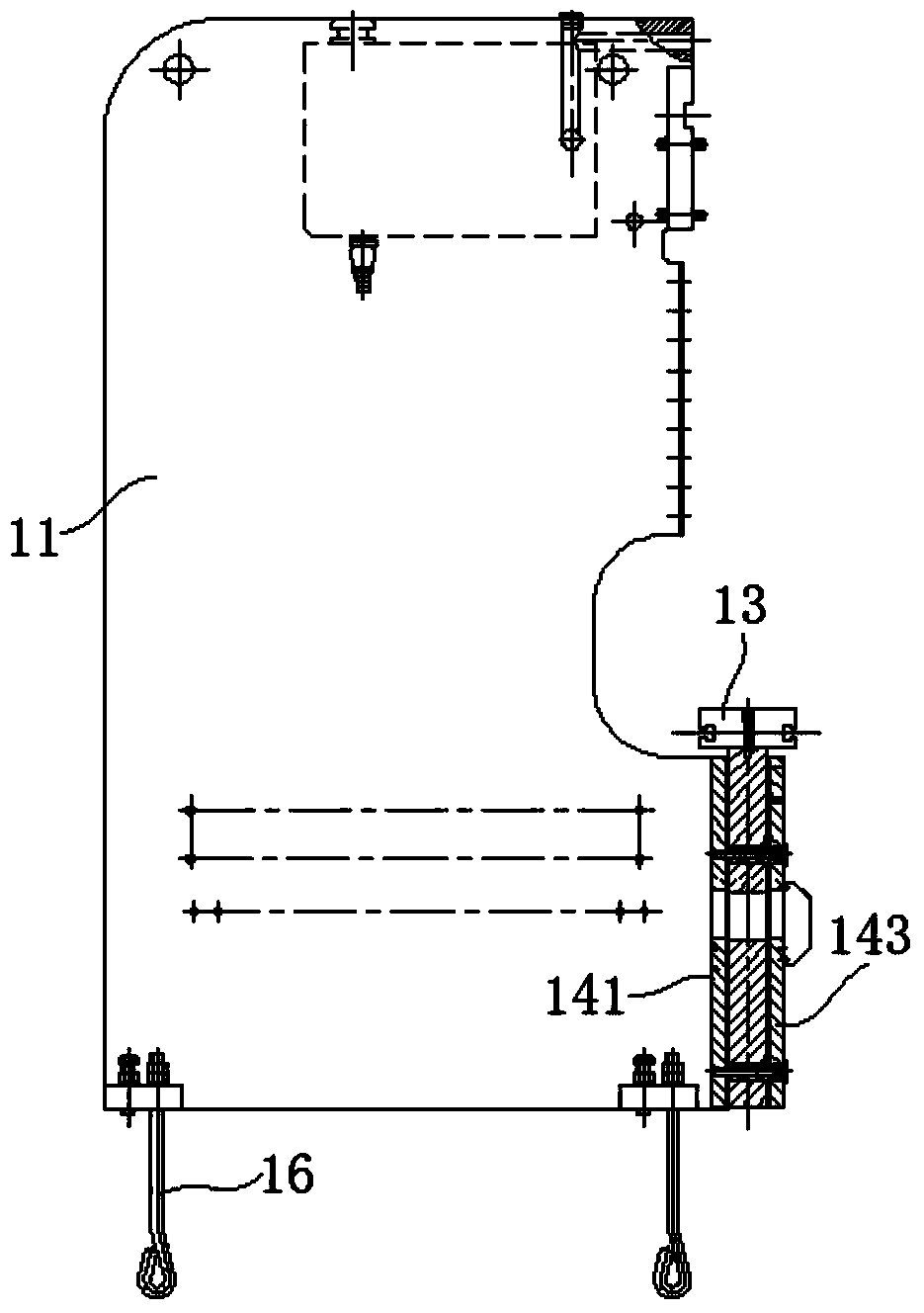

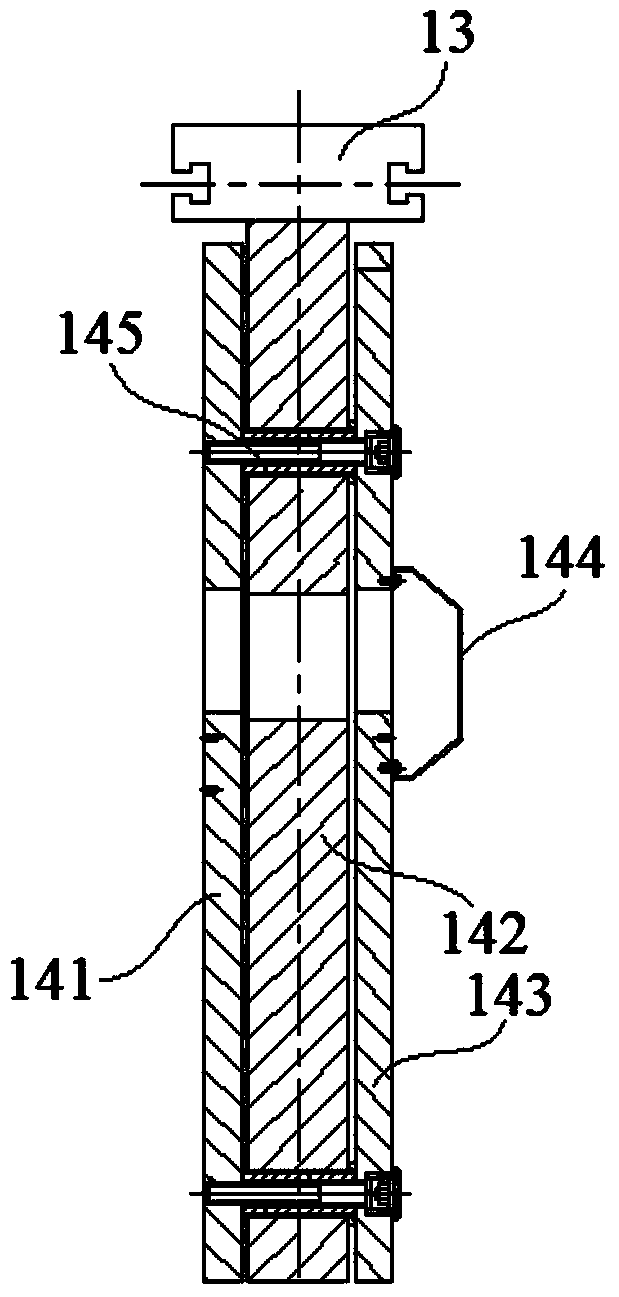

The invention discloses a high-precision hydraulic plate bending machine and belongs to the technical field of machine tool manufacturing. The high-precision hydraulic plate bending machine comprises a frame, a slider assembly, a slider travel adjustment mechanism, a synchronous mechanism, and a rear stop mechanism. The middle of each of rear, main and front vertical plates of the frame is provided with a cylinder holding cavity which three compensating cylinders are mounted inside. The lower portion of a slider is connected with an upper die through a clamping component. The upper die is composed of twenty upper die segments. In the slider travel adjustment mechanism, a first worm and a second worm are driven through a transmission shaft so as to drive a first screw and a second screw to adjust up and down; two synchronous forks are fixedly connected to a synchronous shaft of the synchronous mechanism, and the moving ends of the synchronous forks are both connected with the slider through a fork joint bearing. The rear stop mechanism comprises a transmission system component and a slide carriage system component. The high-precision hydraulic plate bending machine has the advantages that precision of the machine bending work pieces is greatly improved and work efficiency of workers is also improved.

Owner:安徽中瑞机床制造有限公司 +1

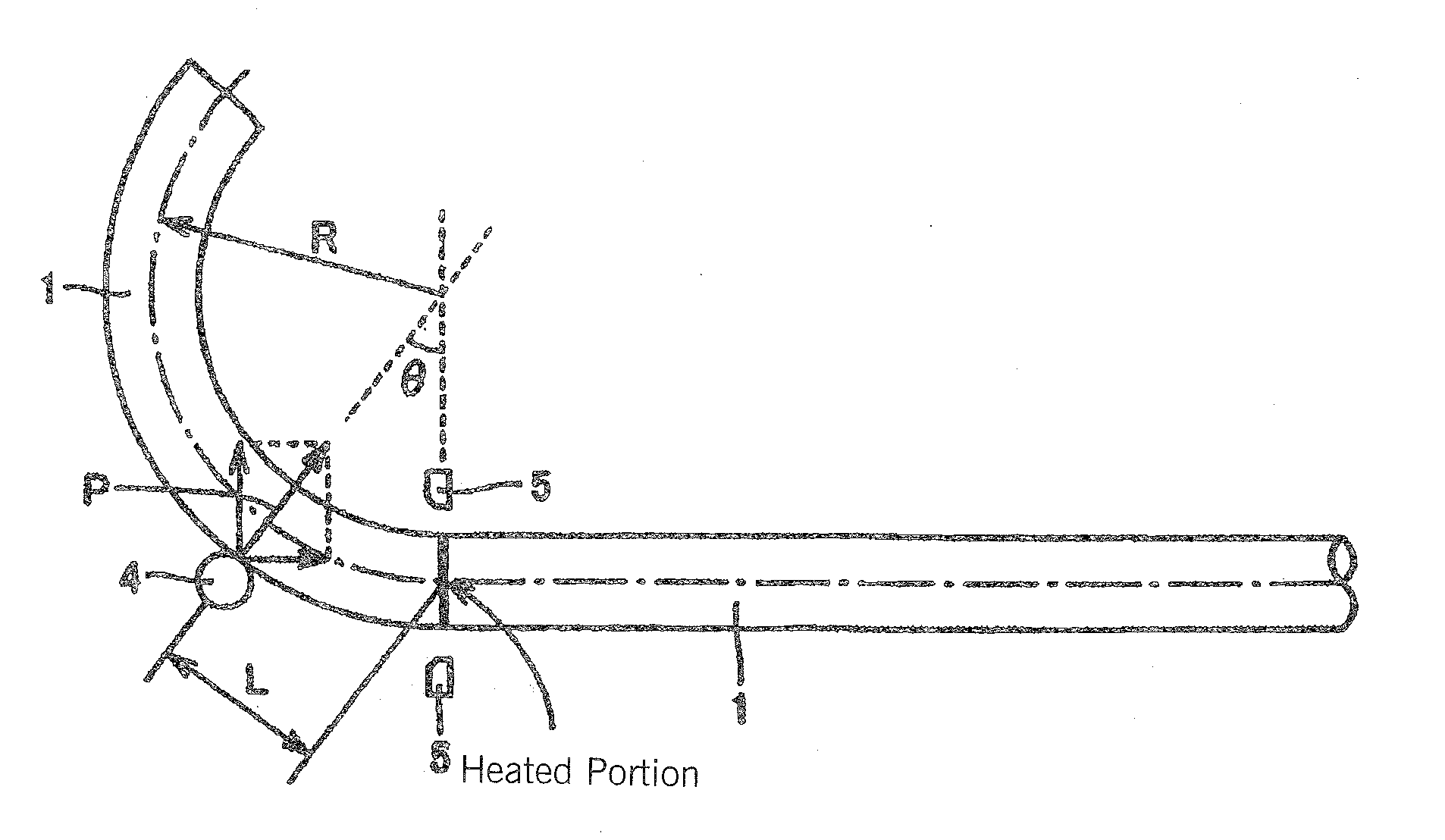

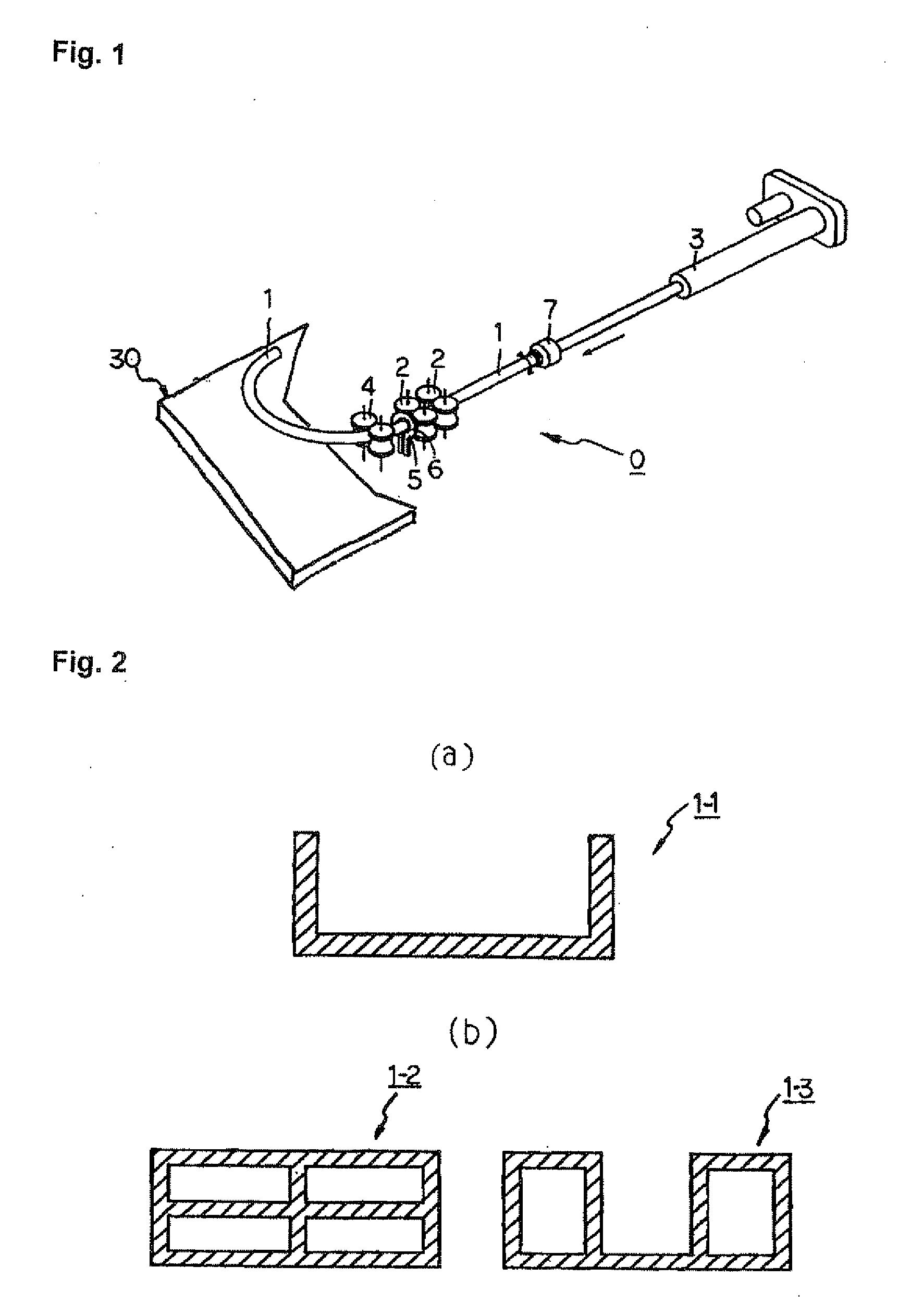

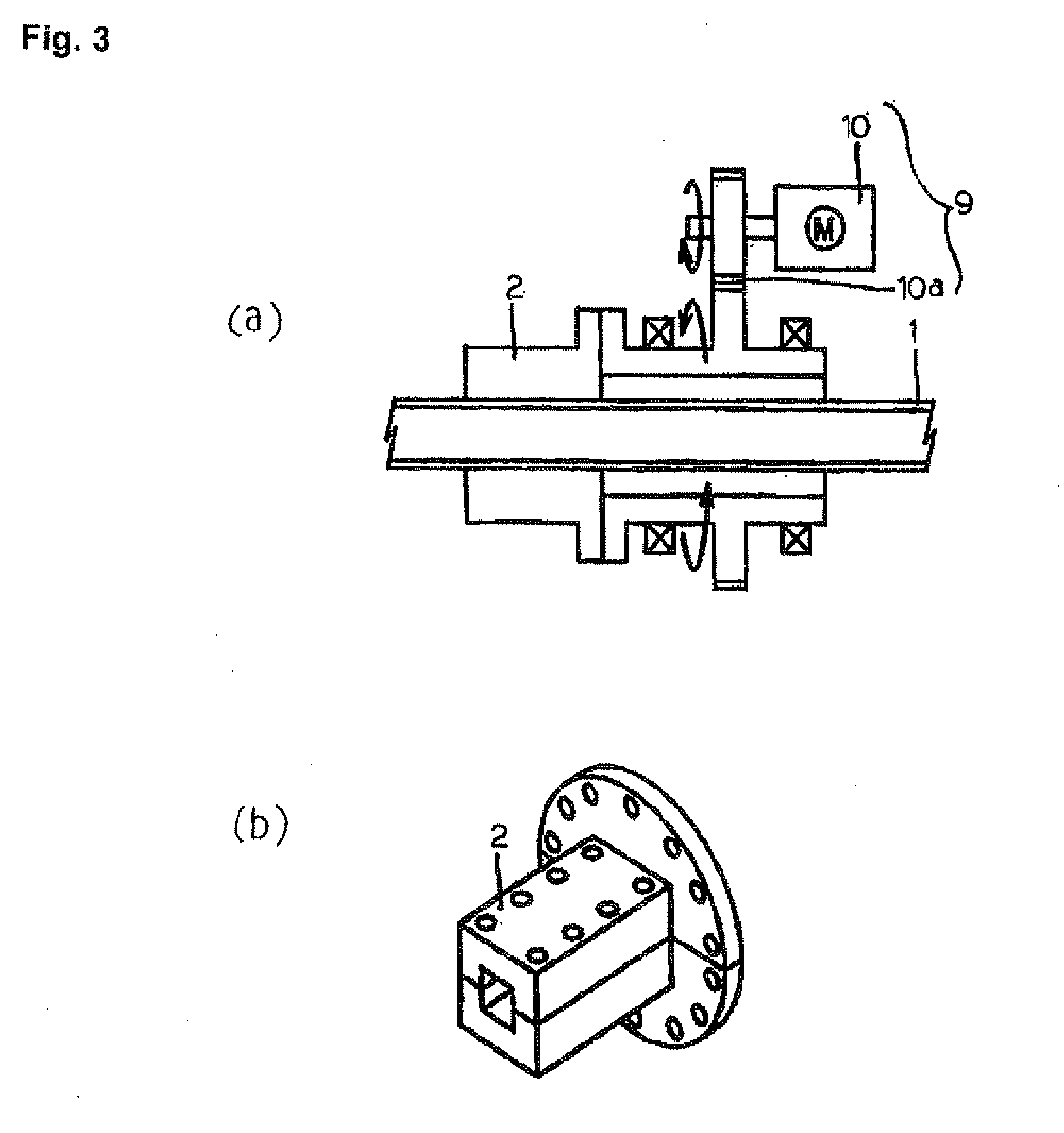

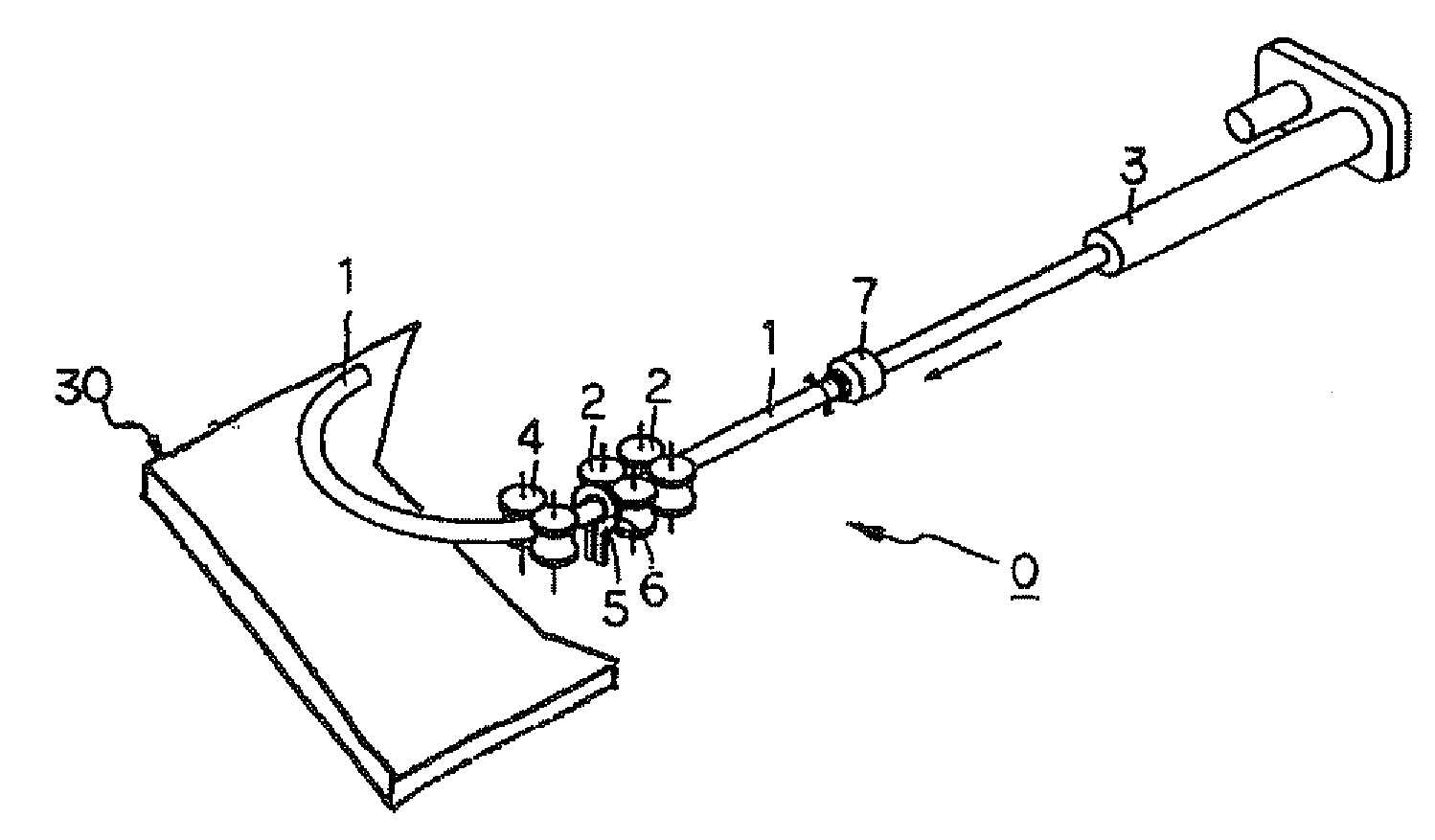

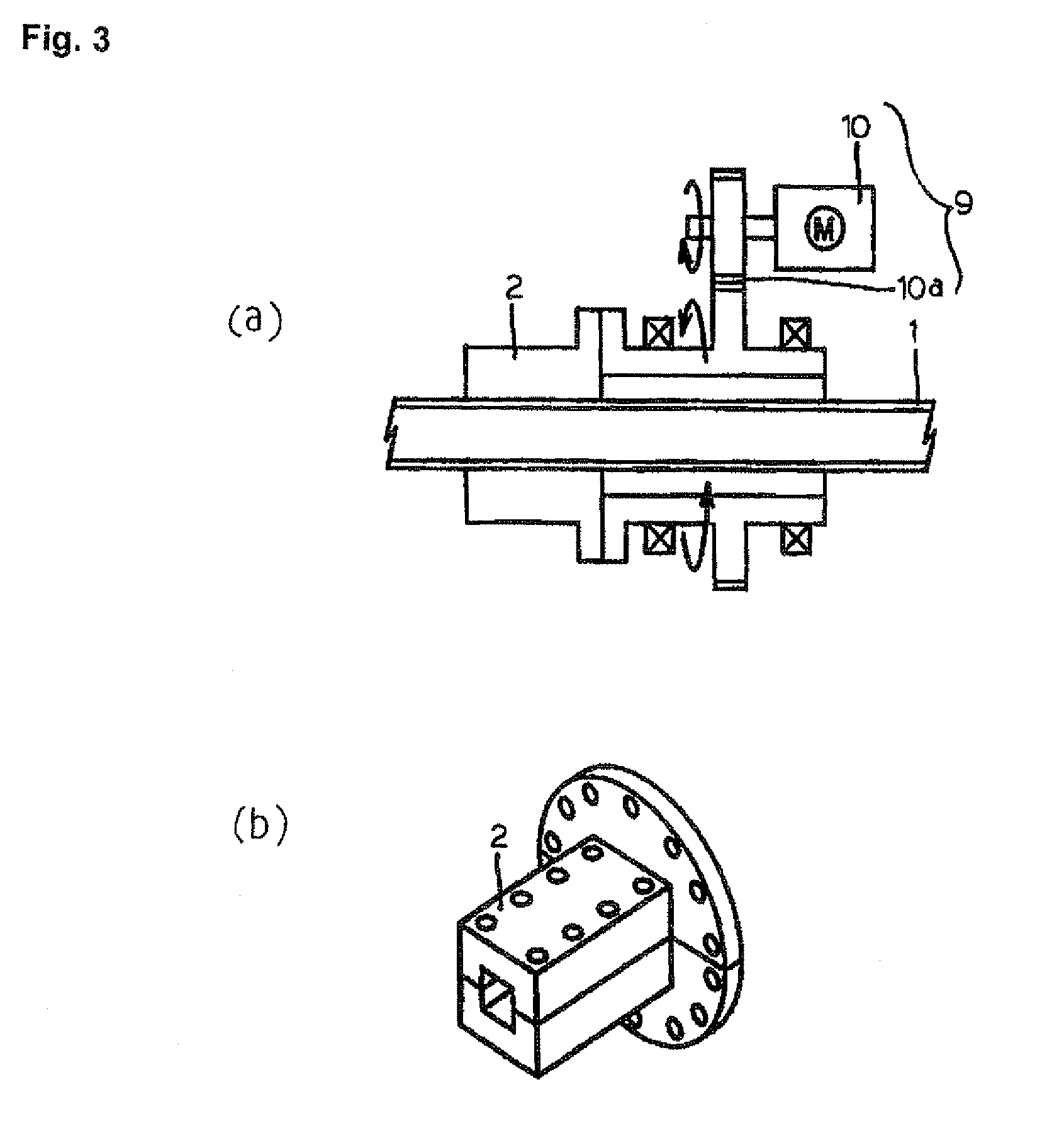

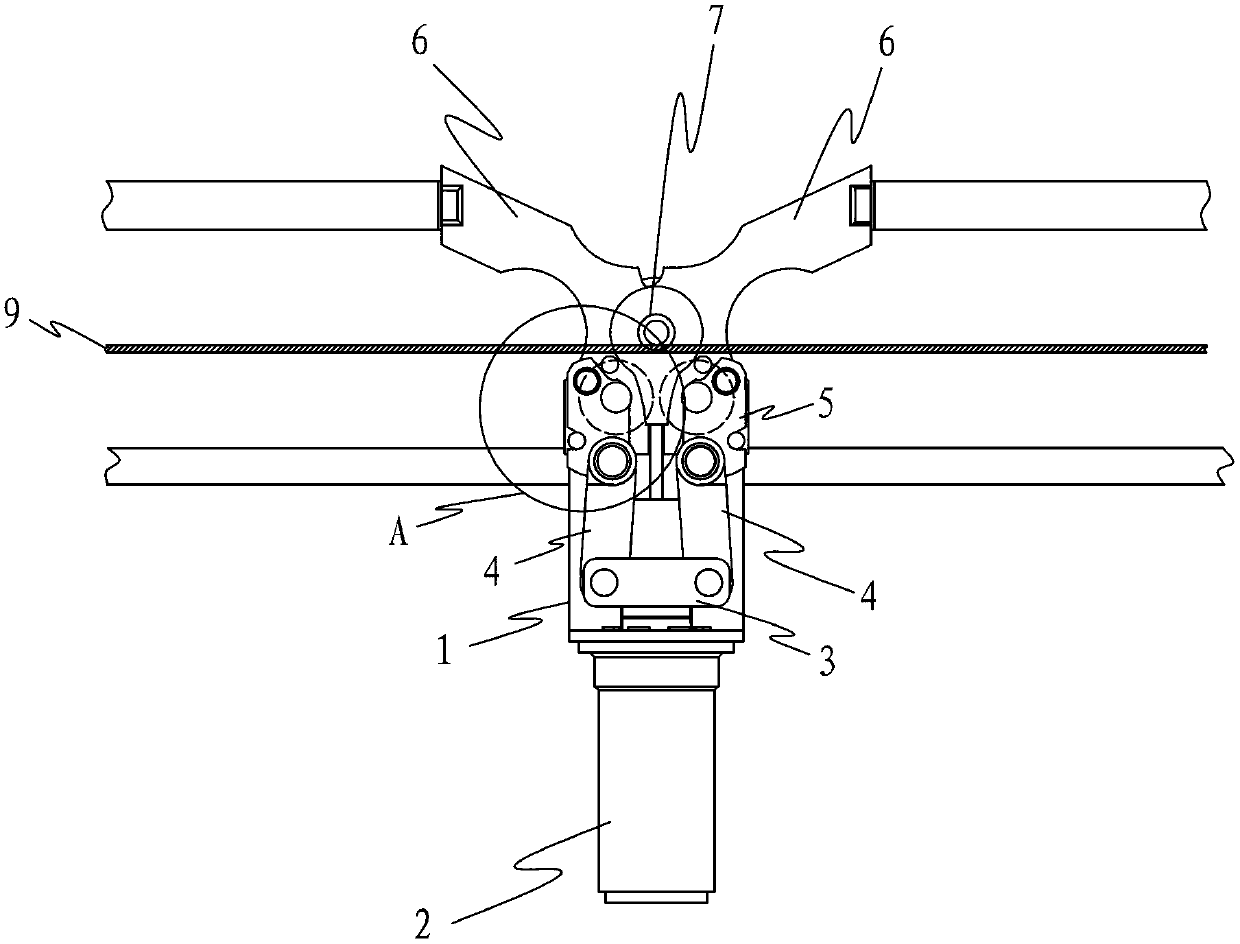

Method of manufacturing a bent product and an apparatus and a continuous line for manufacturing the same

InactiveUS20100088882A1Inexpensive and efficient to manufactureHigh strengthShaping toolsWork manipulationMetallic materialsManufacturing line

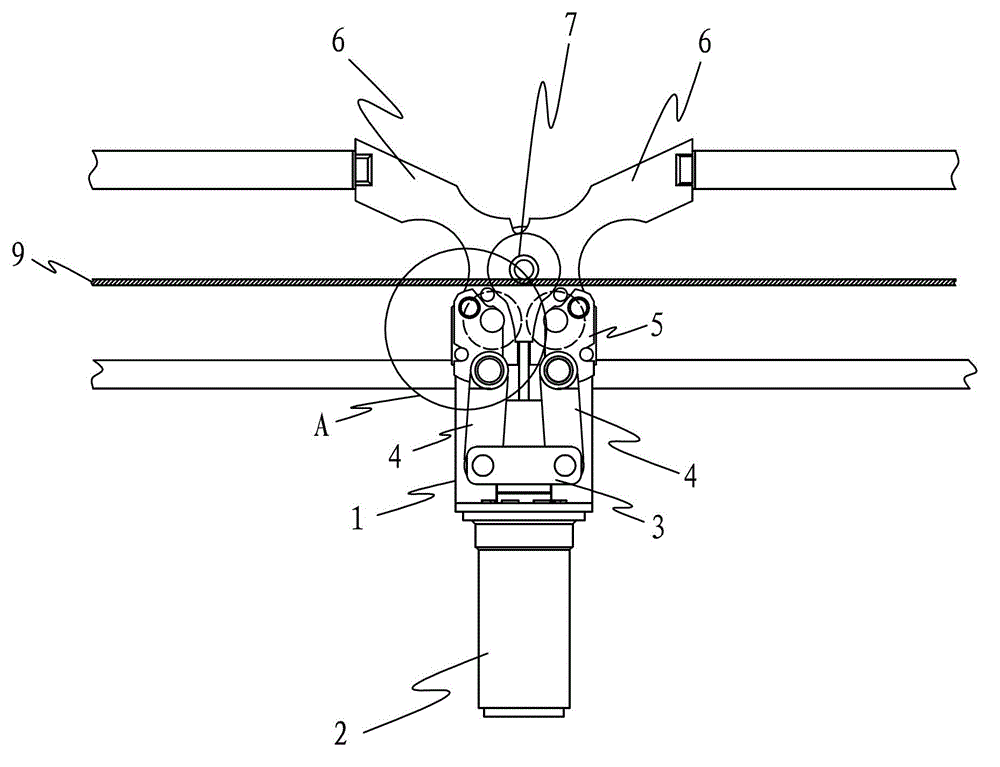

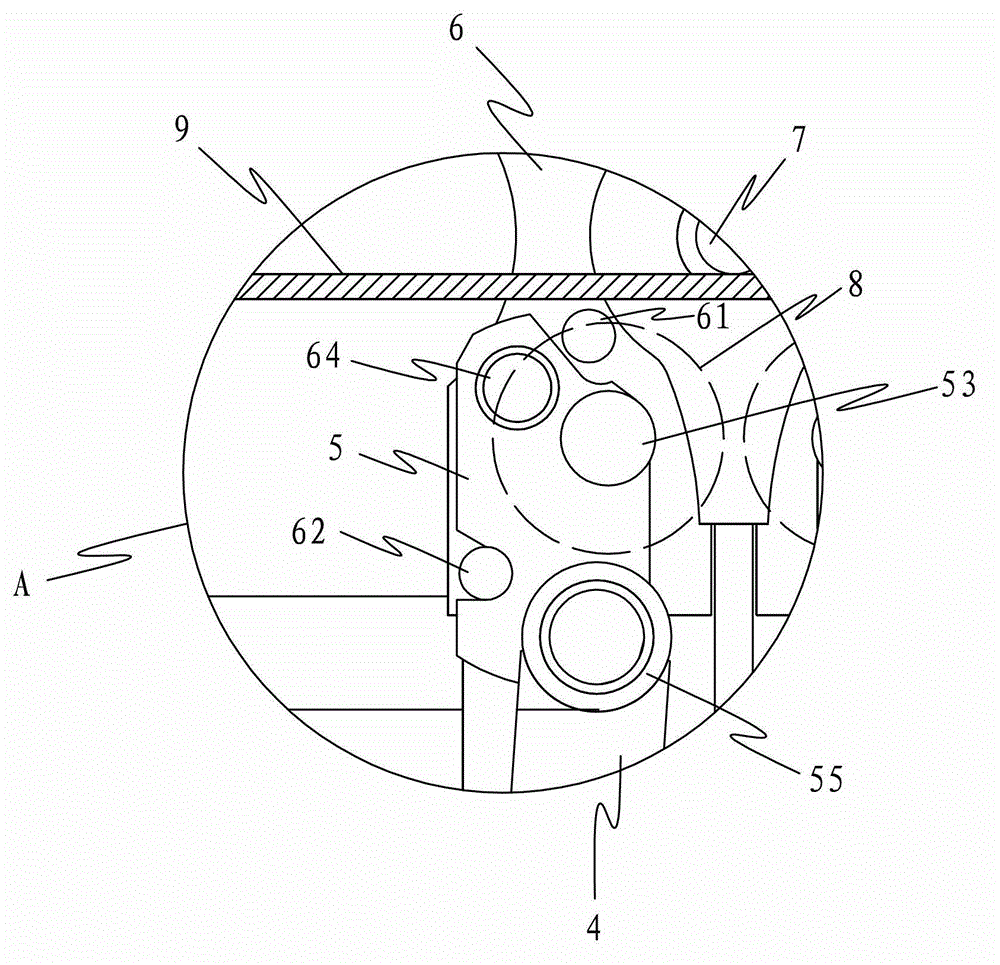

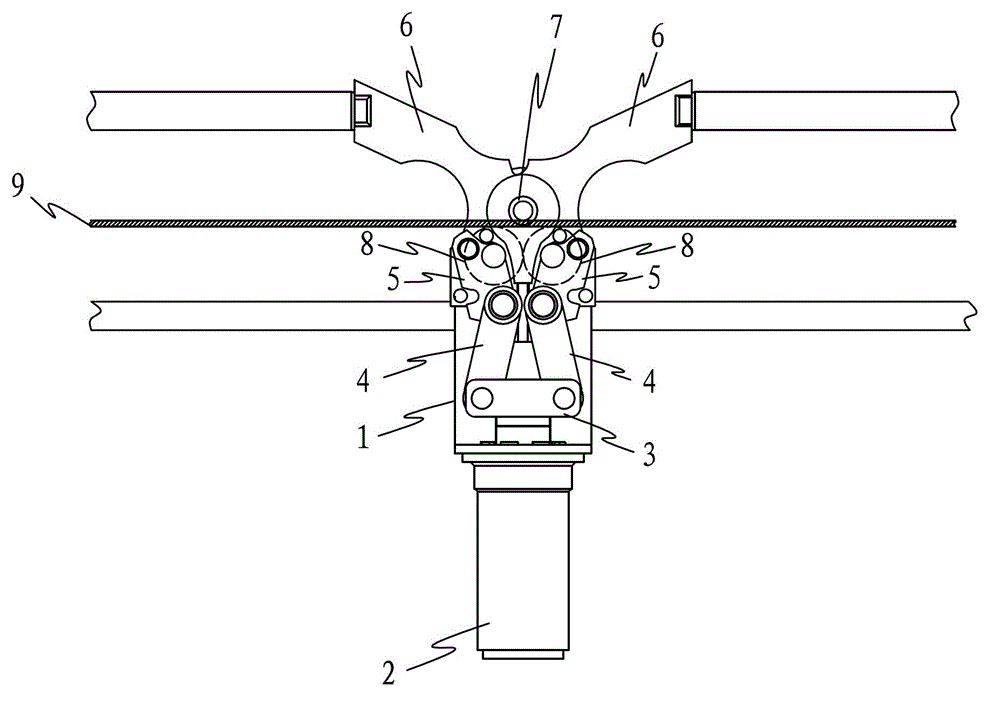

A method and apparatus for three-dimensionally bending a metal material are provided. A product intermittently having a bent portion which curves three-dimensionally and a quenched portion is manufactured by a bending method which performs bending downstream of a support means while feeding a metal material which is supported by the support means from an upstream side towards a downstream side. A portion of the metal material is heated by a heating means for the metal material downstream of the support means, a bending moment is imparted to the portion of the metal material which was heated by the heating means to carry out bending by three-dimensionally changing the position of a movable roller die which is disposed downstream of the heating means and has a plurality of rolls which feed the metal material which was heated by the heating means in the axial direction, and the metal material is quenched by spraying a cooling medium at the portion of the metal material which was heated by the heating means by a cooling means disposed between the heating means and the movable roller die. Errors in a product due to bending are suppressed by supporting a portion of the metal material which has exited from the movable roller die.

Owner:SUMITOMO METAL IND LTD +1

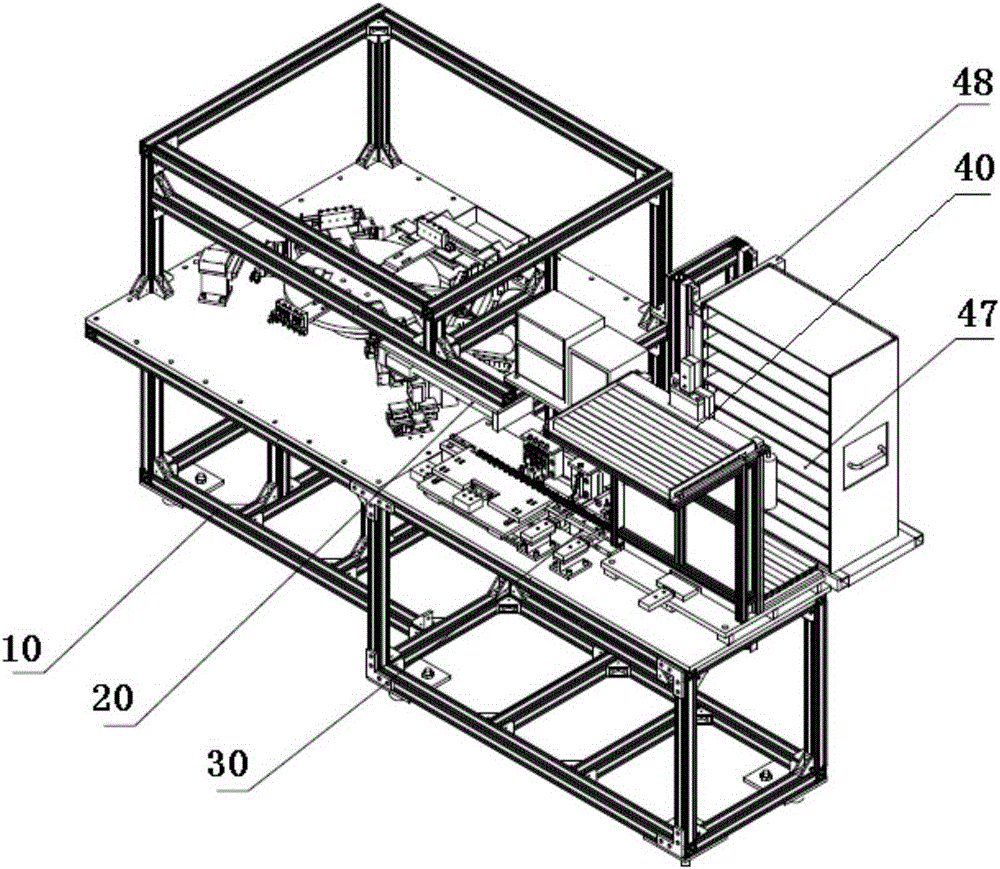

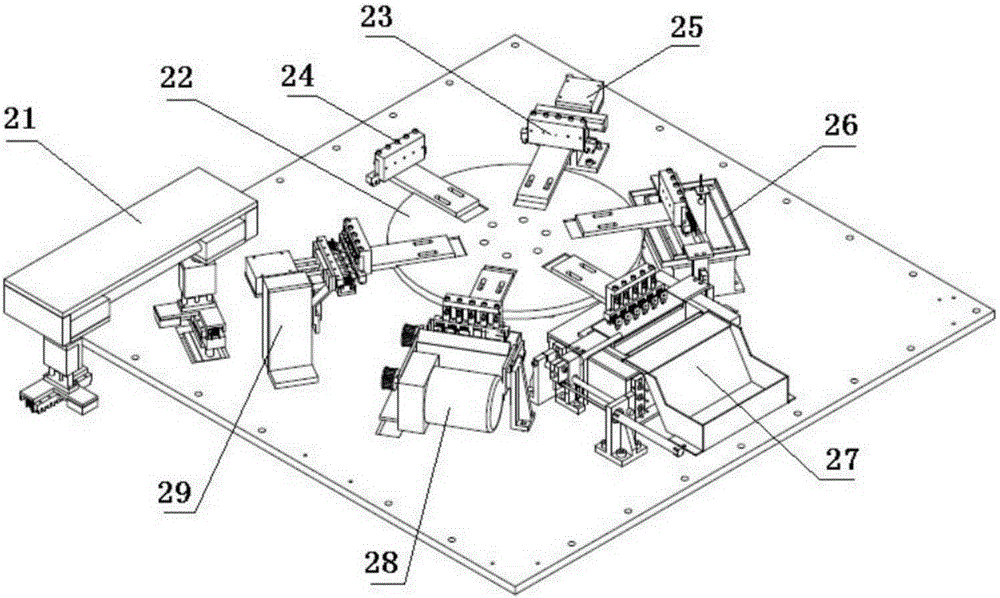

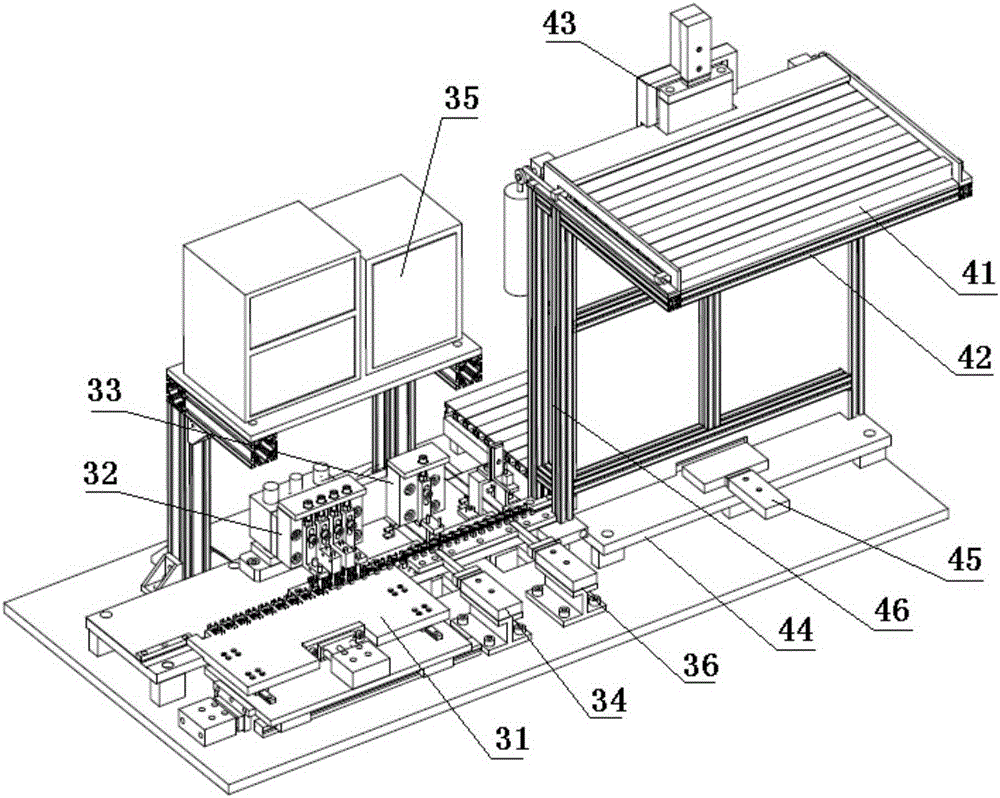

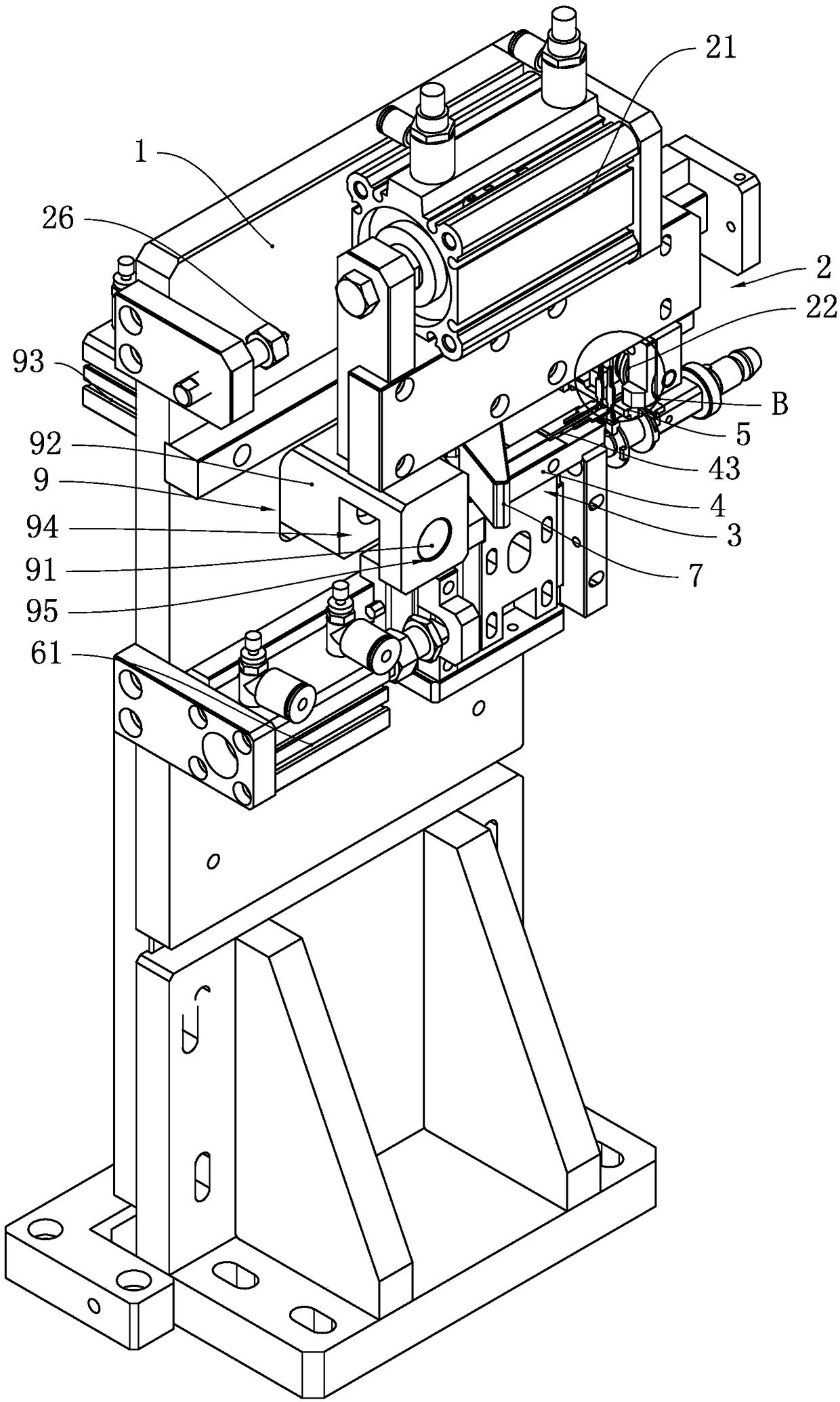

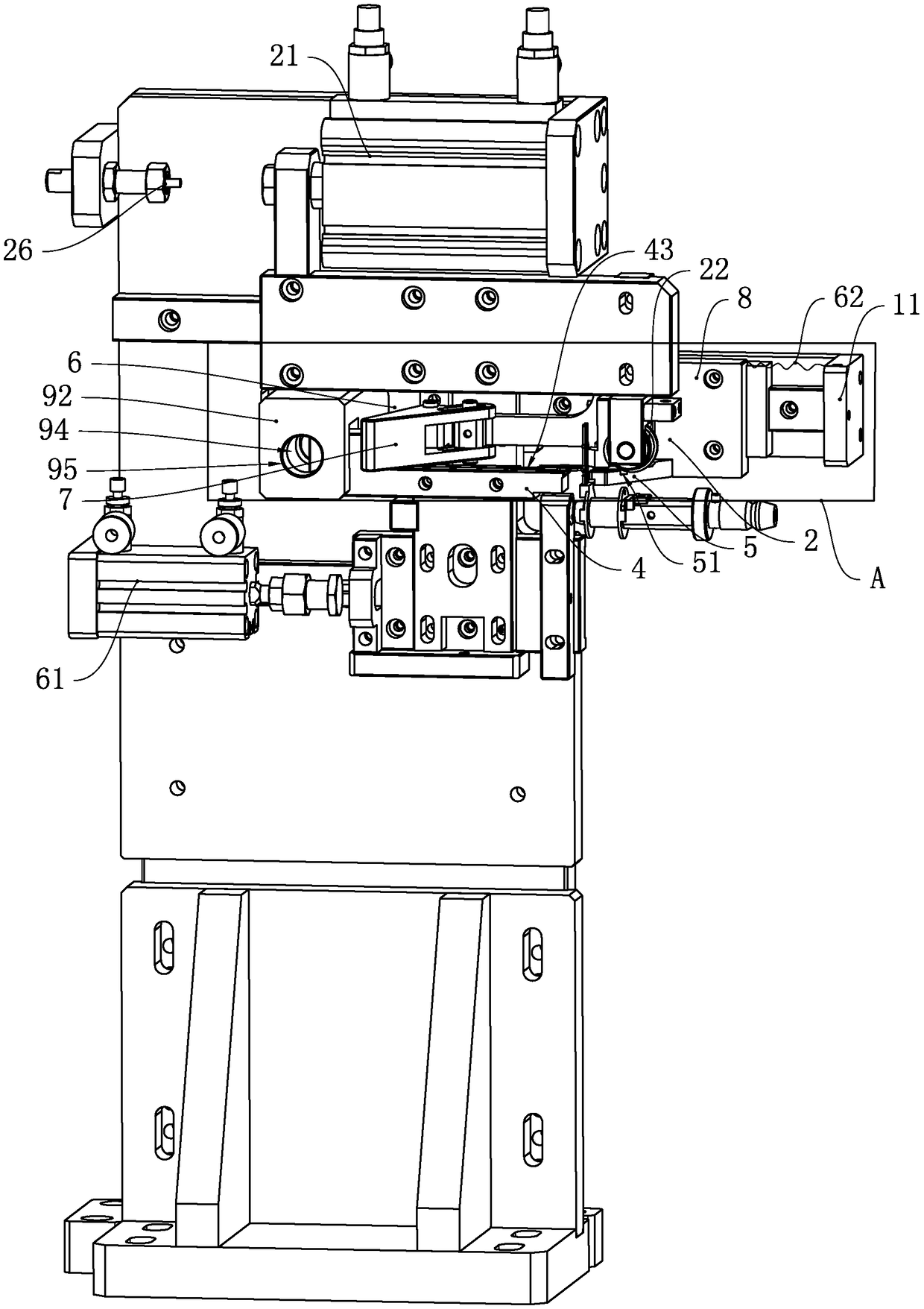

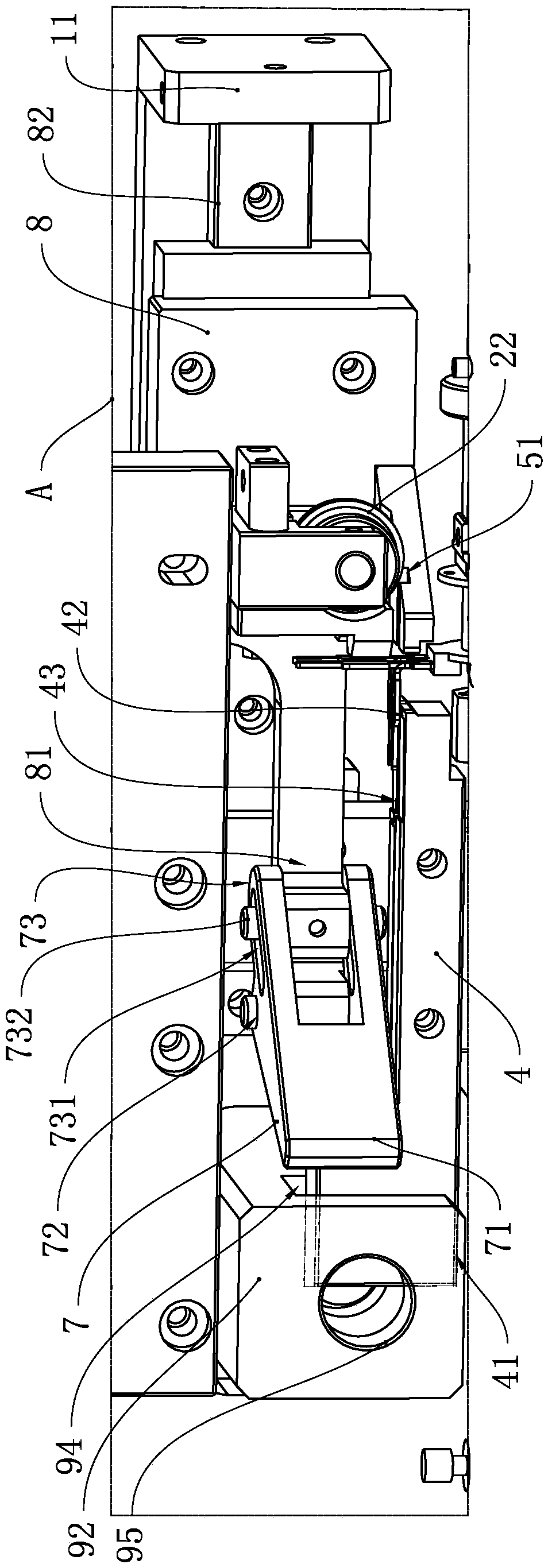

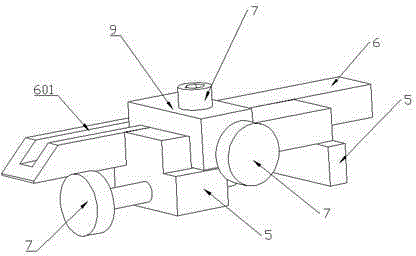

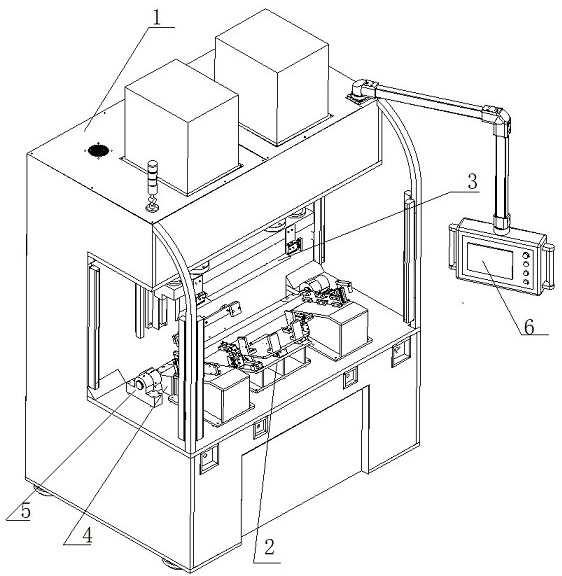

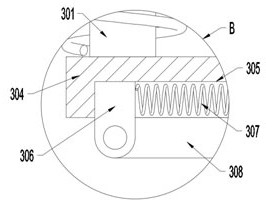

Tinning, shaping, and testing equipment for relay terminal

ActiveCN105321775AEliminate timeEliminate labor wasteTesting dielectric strengthRelaysTinningSoldering

The invention discloses tinning, shaping, and testing equipment for a relay terminal. The tinning, shaping, and testing equipment comprises a stand, a tin soldering host machine, a bending detection part and a material loading mechanism; the tin soldering host machine comprises a discharging conveying air cylinder; the discharging conveying air cylinder automatically conveys the completely-processed relays to the bending detection part; the bending detection part comprises a bending table, a bending mechanism, a detection apparatus and an unqualified product removing mechanism; the bending mechanism is used for bending the relay terminals on the bending table; the material loading mechanism comprises IC tubes for installing the relays; and the qualified relays are loaded in the IC tubes. By adoption of the technical scheme, the fully-automatic tin soldering, bending and material loading of the semi-finished terminals can be realized, so that the waste of time and manpower in station conversion is eliminated, and the product quality is improved; and the bending mechanism bends the relay terminals in four times for gradually bending the workpiece contact pins into specified shapes to ensure the bending precision and to further improve the percent of pass of the products.

Owner:SUZHOU HEROIC AUTOMATION TECH

Method of manufacturing a bent product and an apparatus and a continuous line for manufacturing the same

InactiveUS8316683B2Inexpensive and efficient to manufactureHigh strengthShaping toolsWork manipulationMetallic materialsManufacturing line

A product intermittently having a bent portion which curves three-dimensionally and a quenched portion is manufactured by performing bending downstream of a support means while feeding a metal material which is supported by the support means from an upstream side towards a downstream side. A portion of the metal material is heated by a heating means downstream of the support means. A bending moment is imparted to the portion of the metal material heated by the heating means to three-dimensionally change the position of a movable roller die which is disposed downstream of the heating means and has a plurality of rolls which feed the heated metal material in the axial direction, and the metal material is quenched by spraying a cooling medium at the portion of the metal material which was heated by a cooling means disposed between the heating means and the movable roller die.

Owner:SUMITOMO METAL IND LTD +1

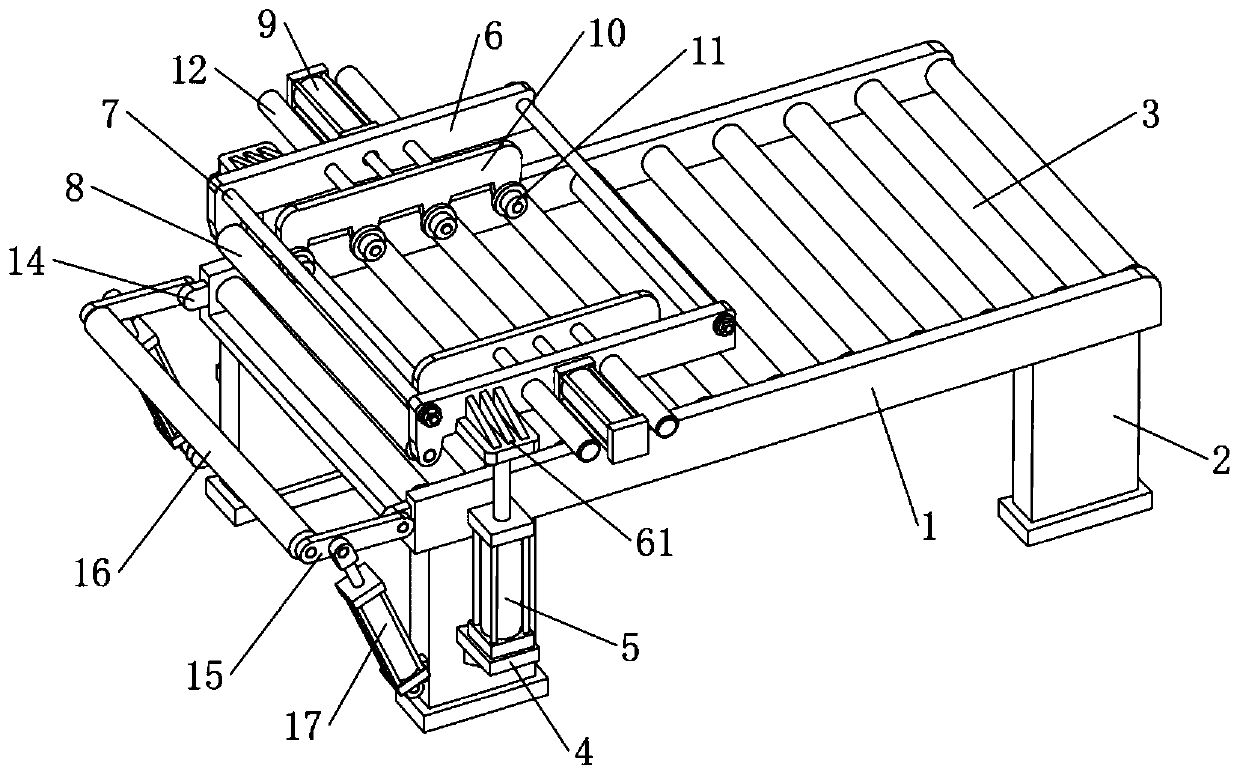

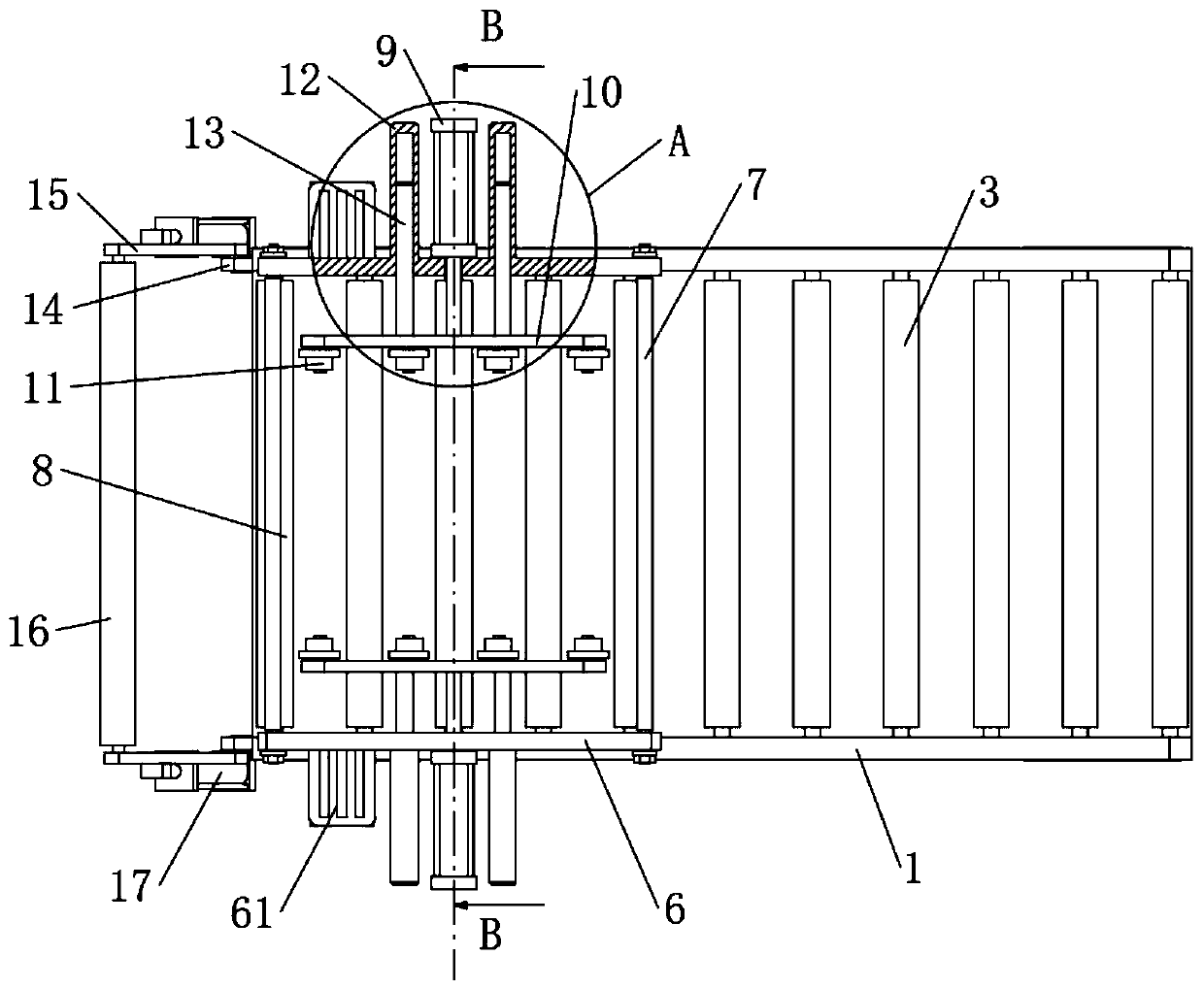

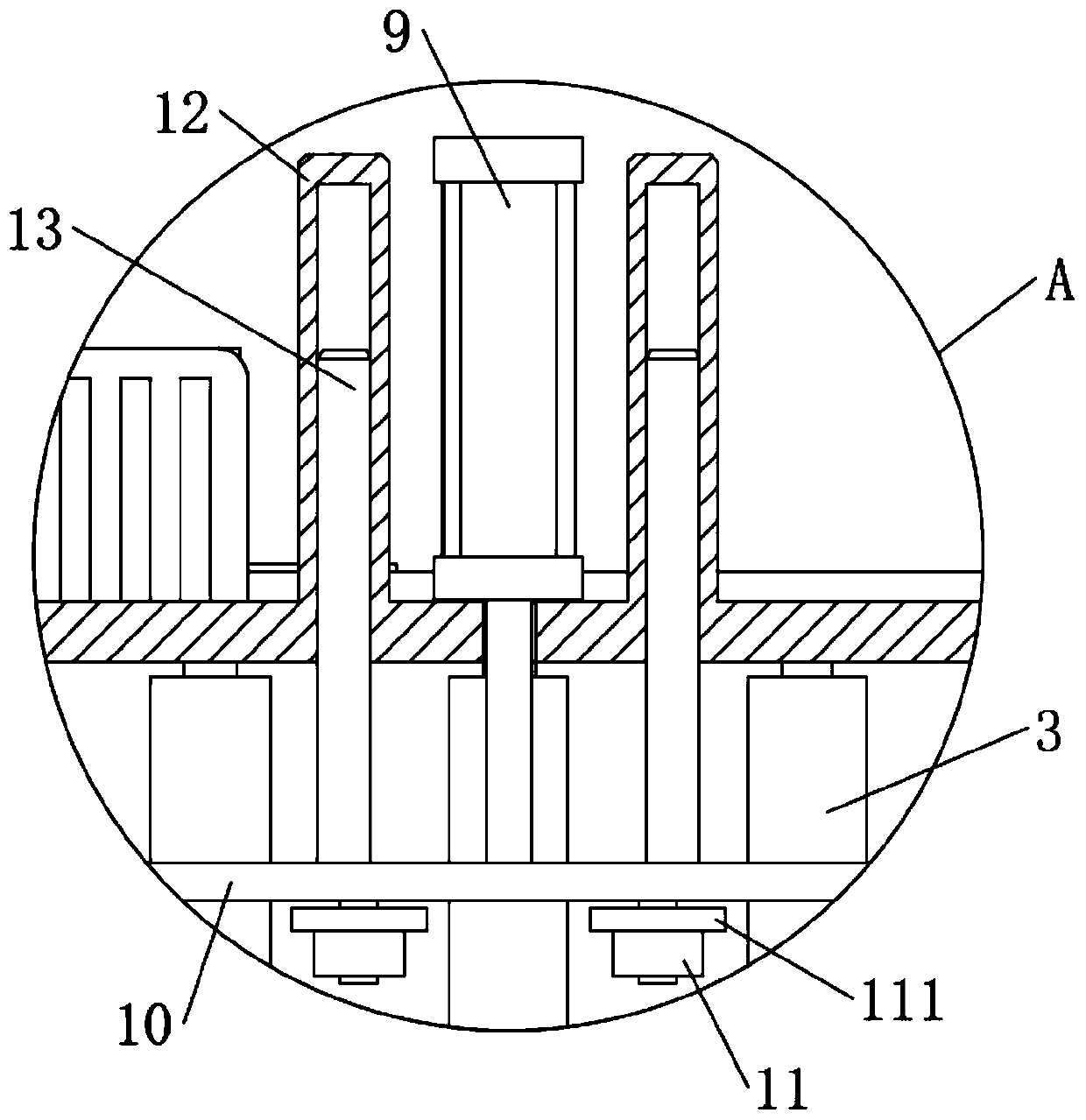

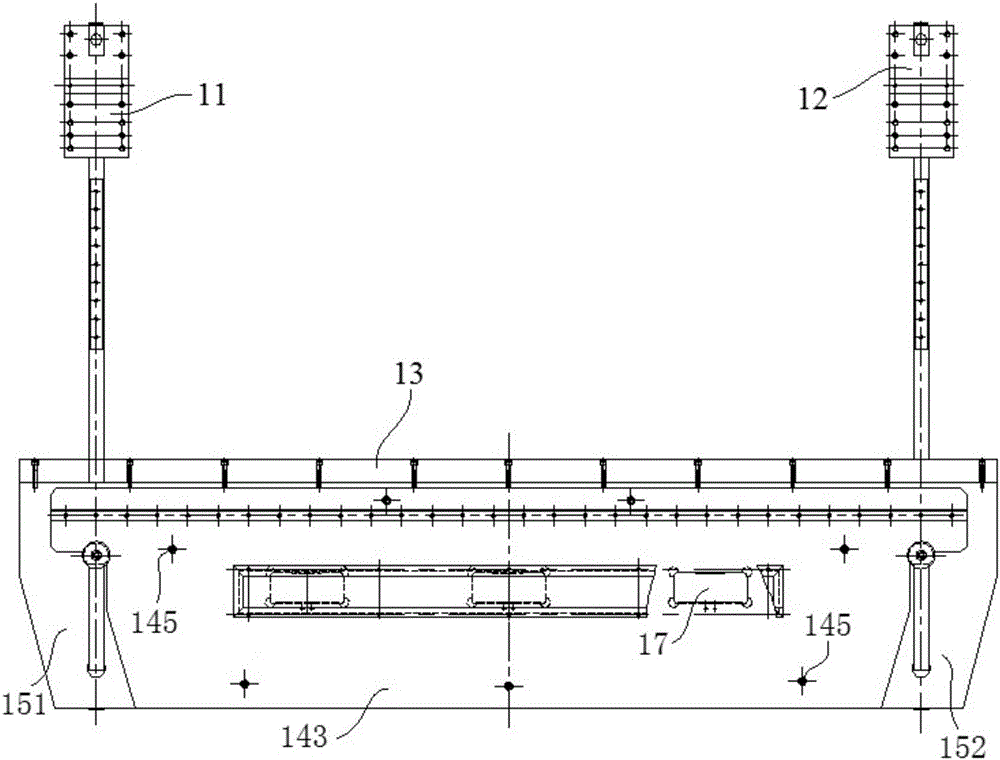

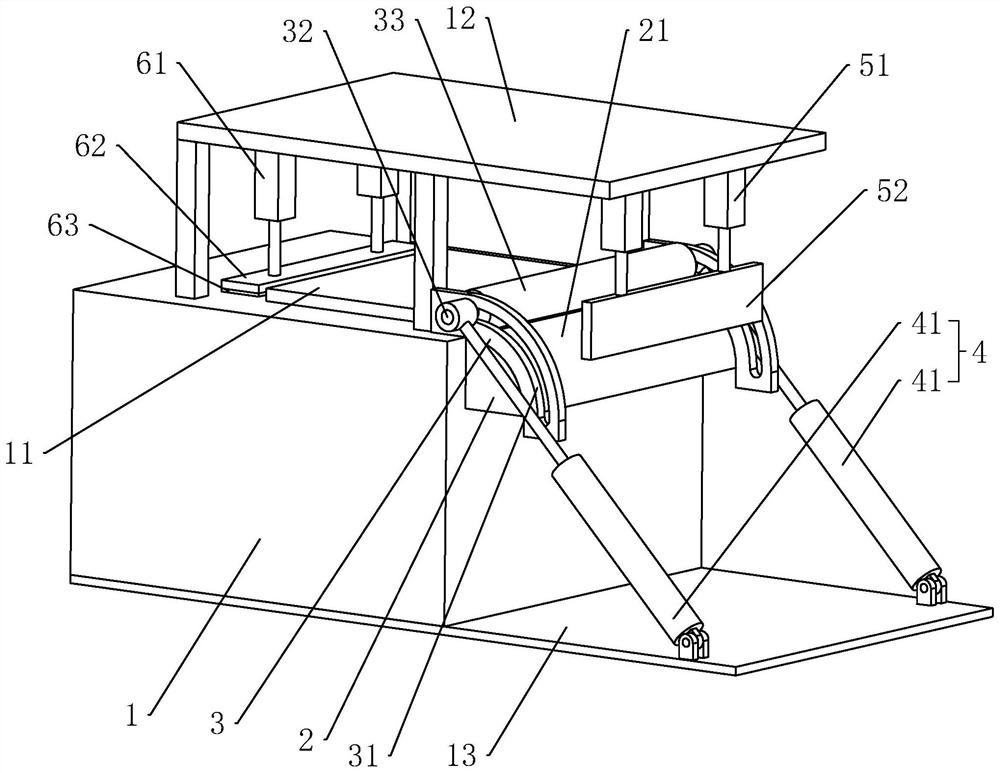

Iron sheet hardware part pressing-bending device

InactiveCN111558662AEfficient processing continuityImprove processing efficiencyMetal-working feeding devicesMetal working apparatusHydraulic cylinderStructural engineering

The invention discloses an iron sheet hardware part pressing-bending device and relates to the field of hardware machining devices. The device comprises a machine frame, a pressing plate device and abending device. The machine frame is provided with a feeding roller way, the pressing plate device is arranged above one end of the machine frame, and the portion, close to the end provided with the pressing plate, of the machine frame is provided with the bending device. When the device works, when a metal plate is conveyed by the feeding roller way to the position below the pressing plate device, telescopic rods in two lifting hydraulic cylinders are controlled to retract, a pressing roller and multiple pressing wheels press the upper surface of the metal plate conveyed on the feeding rollerway, rolling contact is carried out, meanwhile, telescopic rods of distance adjusting hydraulic cylinders arranged on the outer side walls of two lifting plate frames are controlled to stretch and retract, a stop ring integrally formed on the multiple pressing wheels carries out pushing abutting on the side of the metal plate, therefore, the metal plate is aligned, the metal plate is prevented from shifting when bent, and the bending precision of the metal plate is ensured.

Owner:徐敏旺

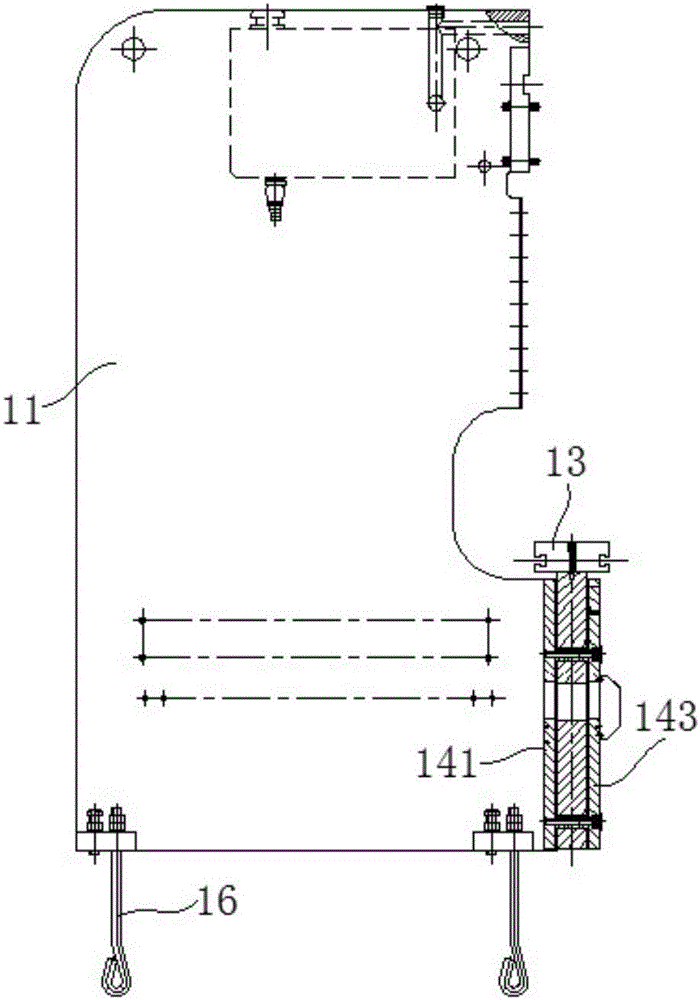

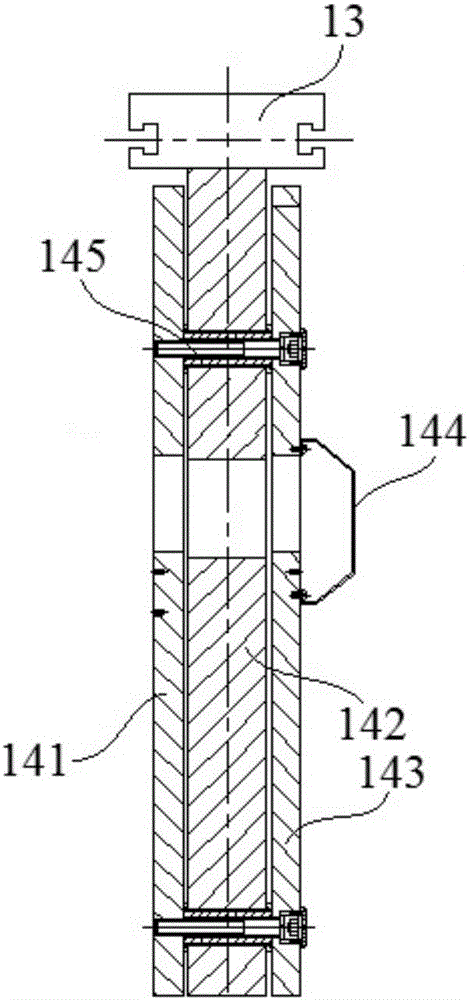

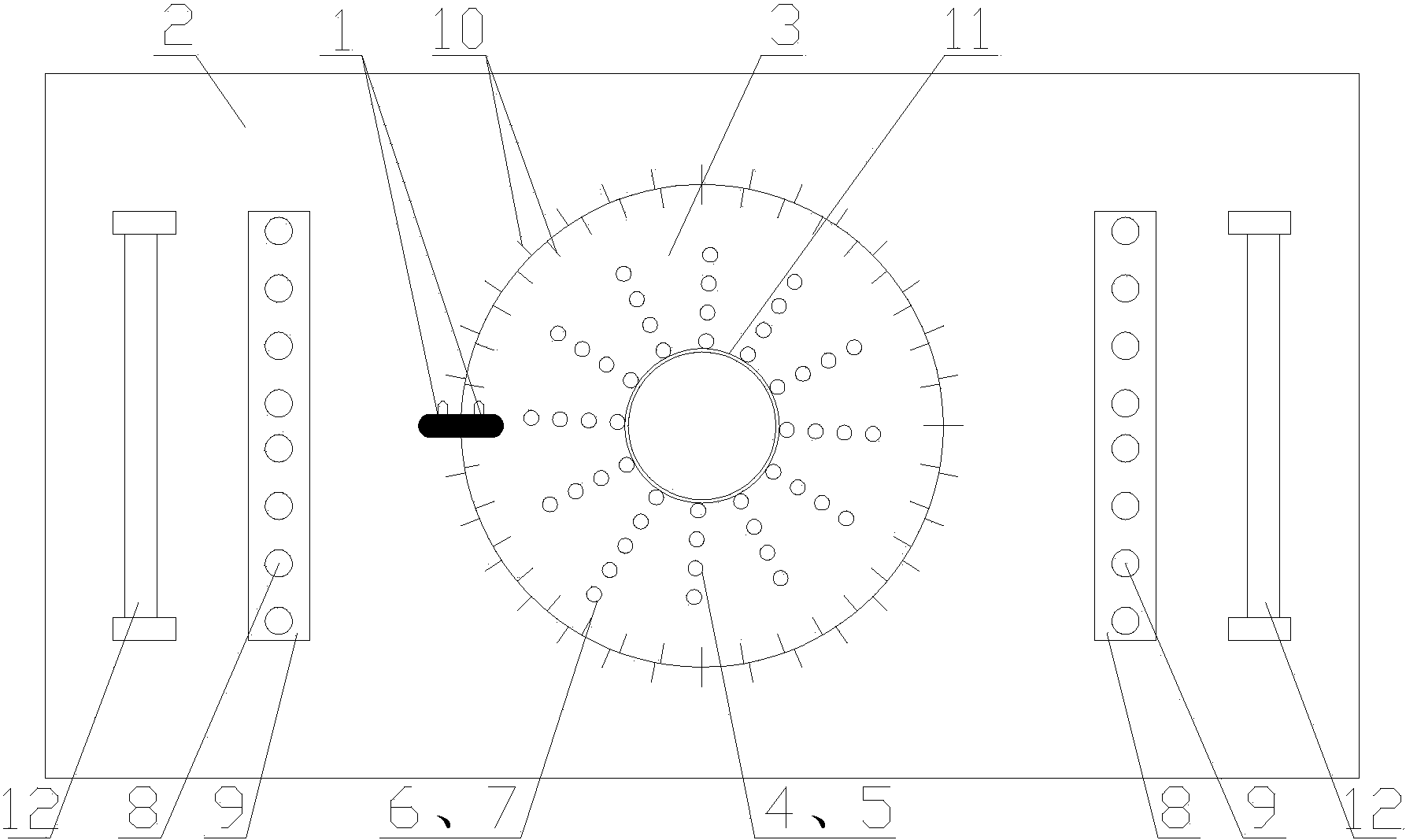

Hydraulic plate bending machine

ActiveCN104985030AHigh degree of mechanizationHigh transmission precisionEngineeringUltimate tensile strength

The invention discloses a high-precision hydraulic plate bending machine and belongs to the technical field of machine tool manufacturing. The high-precision hydraulic plate bending machine comprises a frame, a slider assembly, a slider travel adjustment mechanism, a synchronous mechanism, and a rear stop mechanism. The middle of each of rear, main and front vertical plates of the frame is provided with a cylinder holding cavity which three compensating cylinders are mounted inside. The lower portion of a slider is connected with an upper die through a clamping component. The upper die is composed of twenty upper die segments. In the slider travel adjustment mechanism, a first worm and a second worm are driven through a transmission shaft so as to drive a first screw and a second screw to adjust up and down; two synchronous forks are fixedly connected to a synchronous shaft of the synchronous mechanism, and the moving ends of the synchronous forks are both connected with the slider through a fork joint bearing. The rear stop mechanism comprises a transmission system component and a slide carriage system component. The high-precision hydraulic plate bending machine has the advantages that precision of the machine bending work pieces is greatly improved and work efficiency of workers is also improved.

Owner:安徽中瑞机床制造有限公司

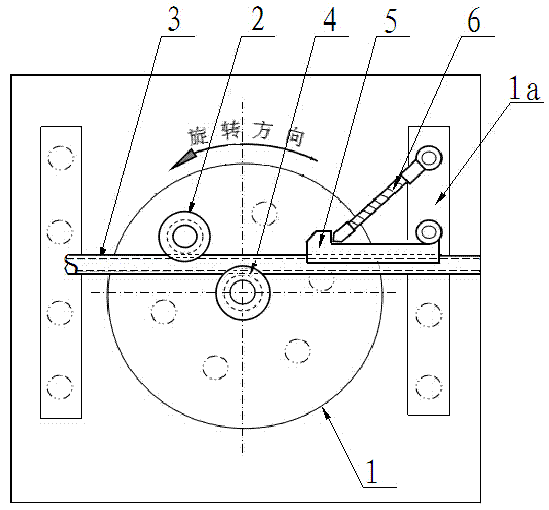

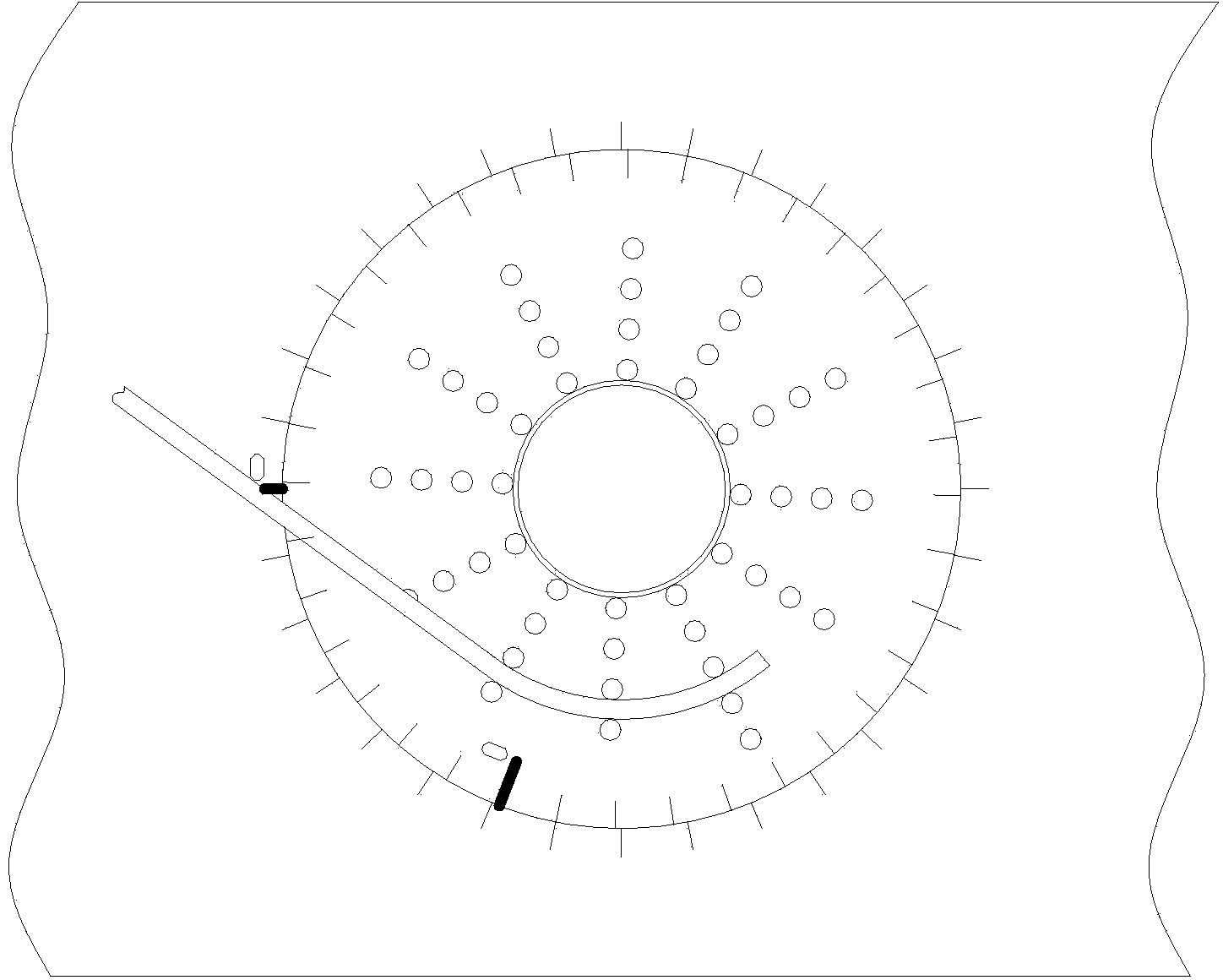

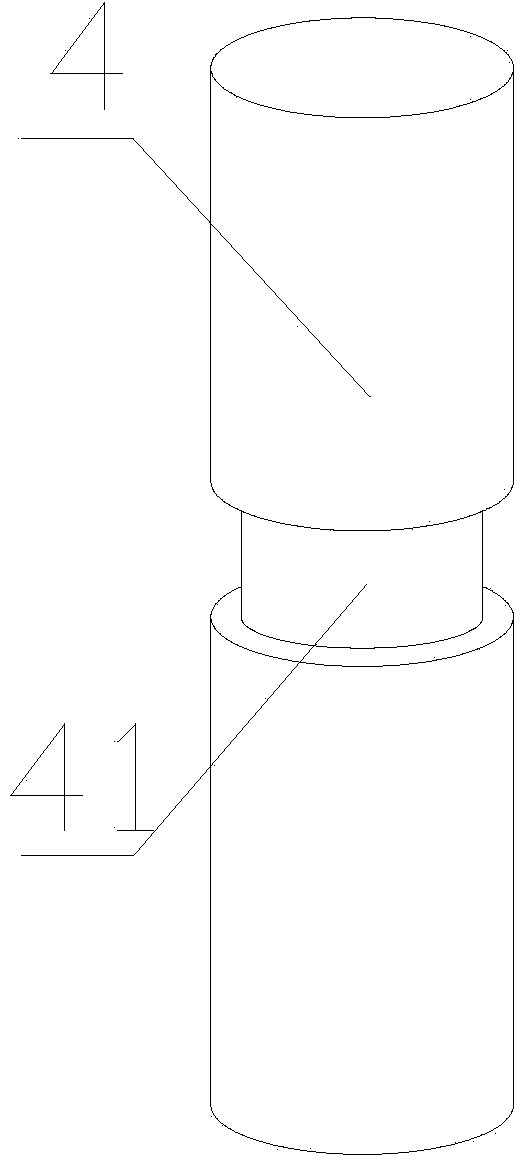

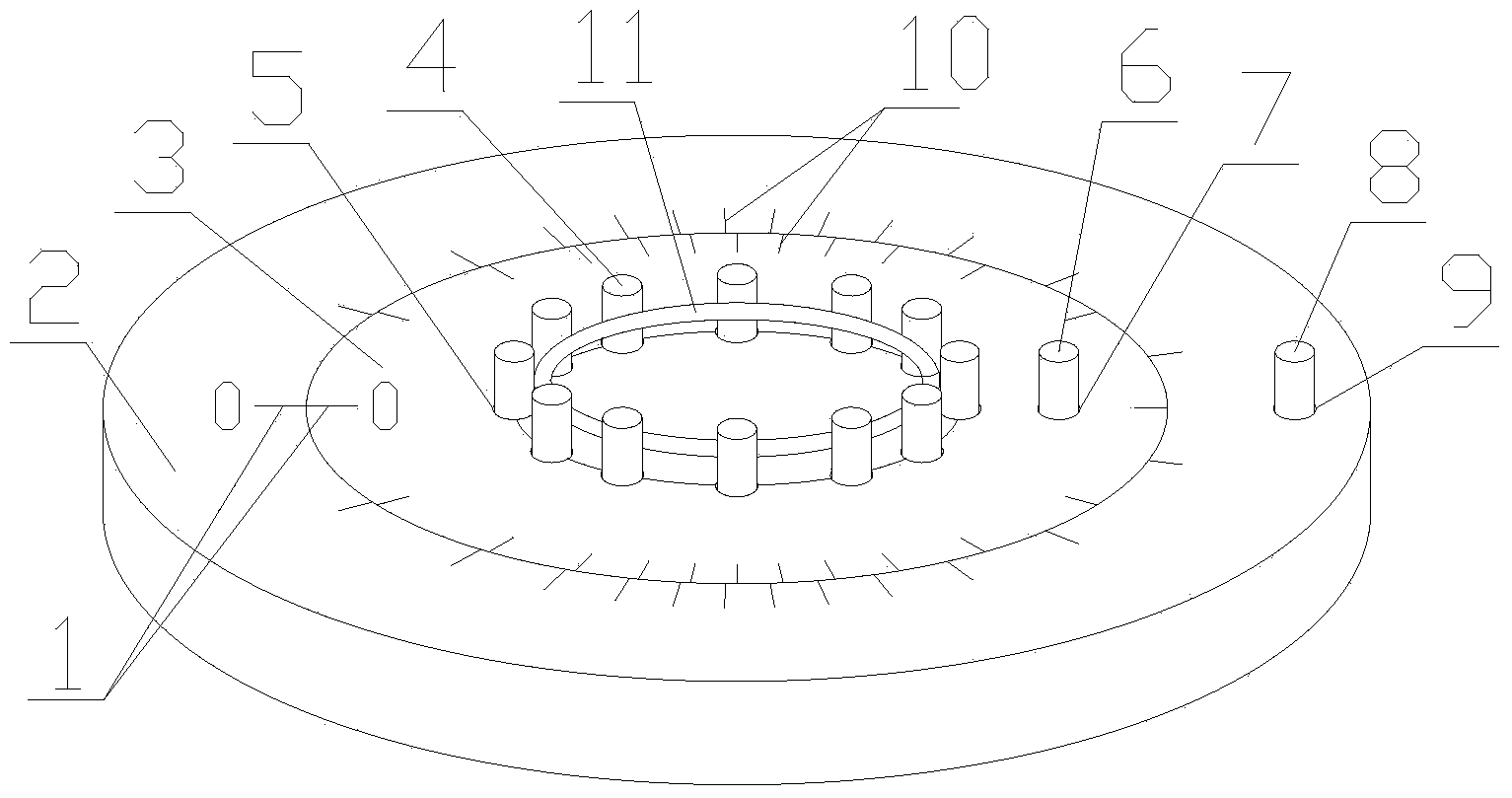

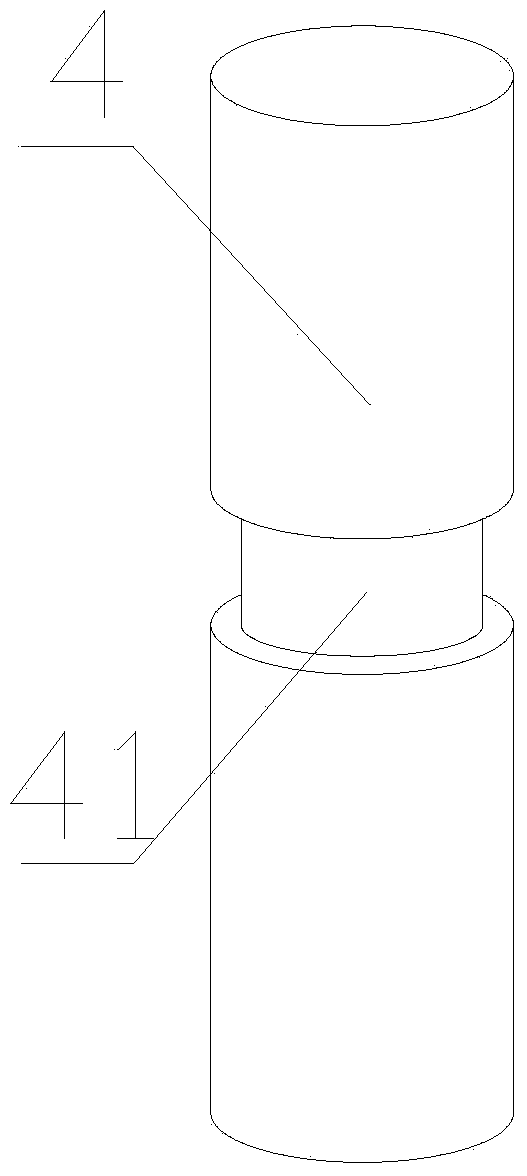

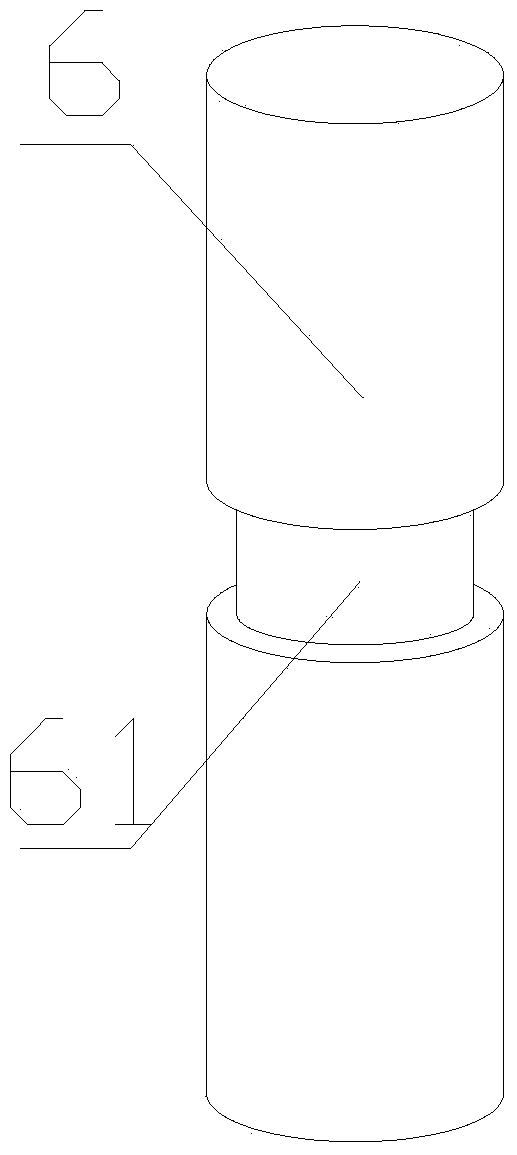

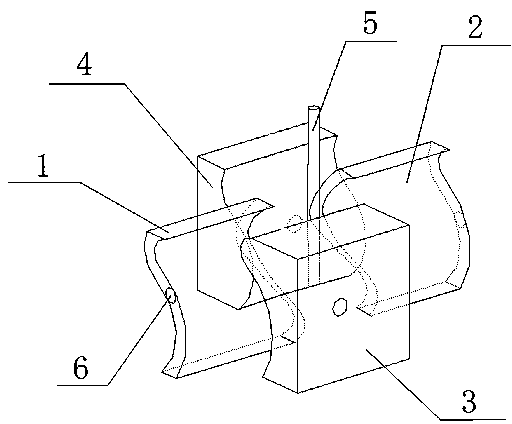

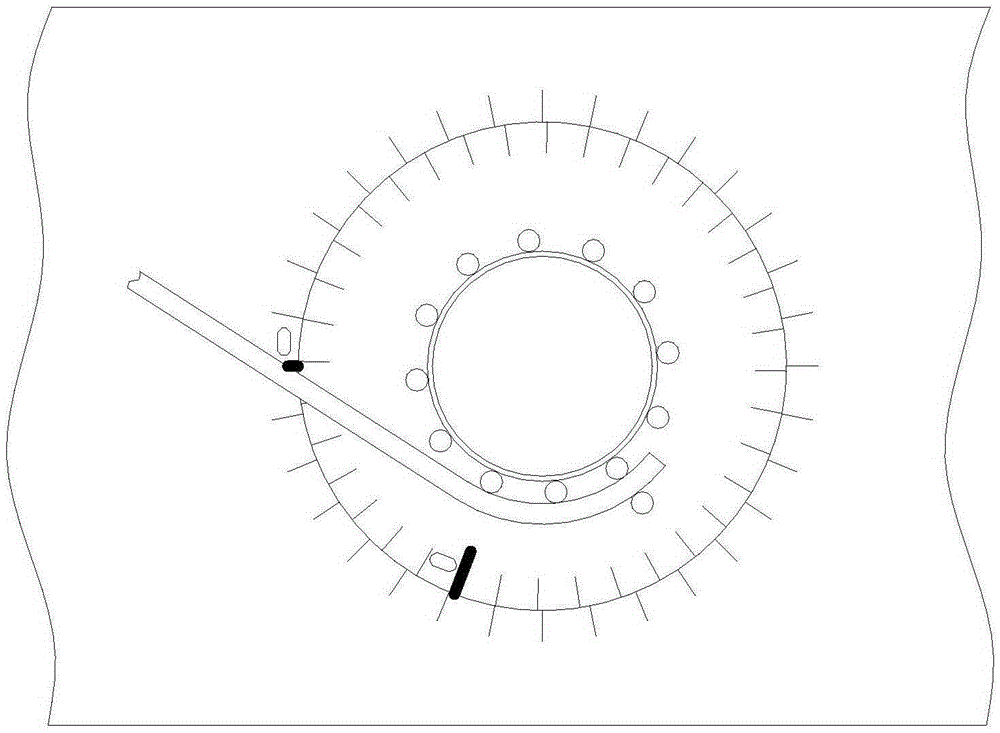

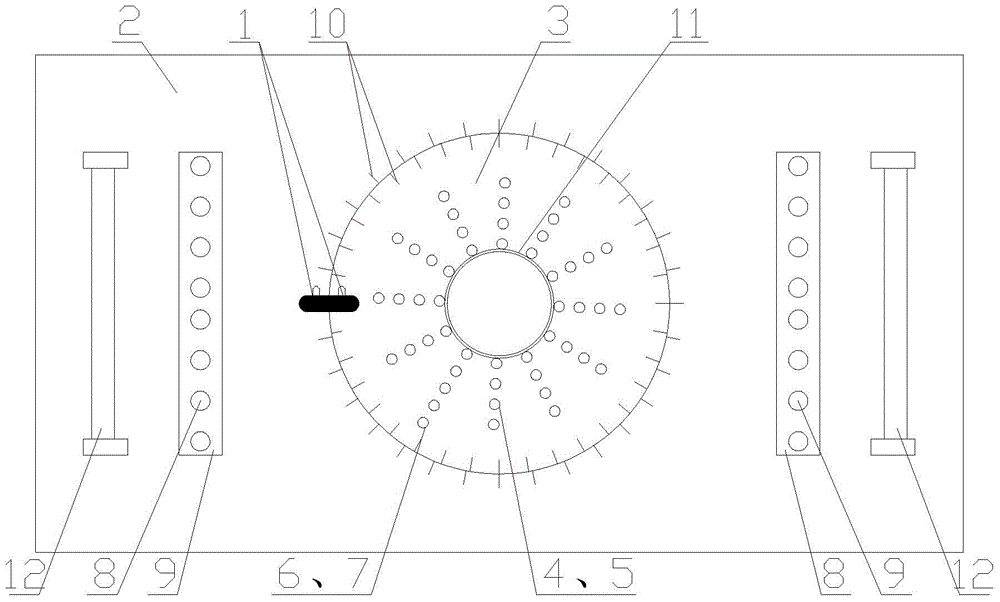

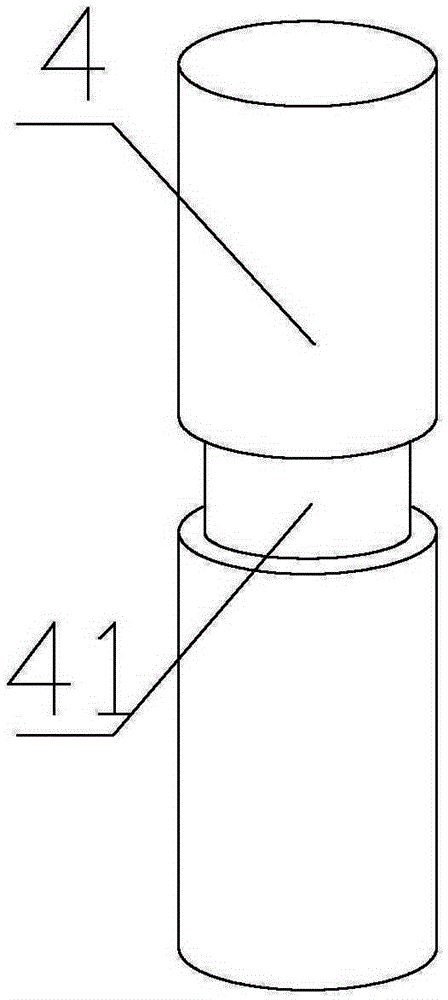

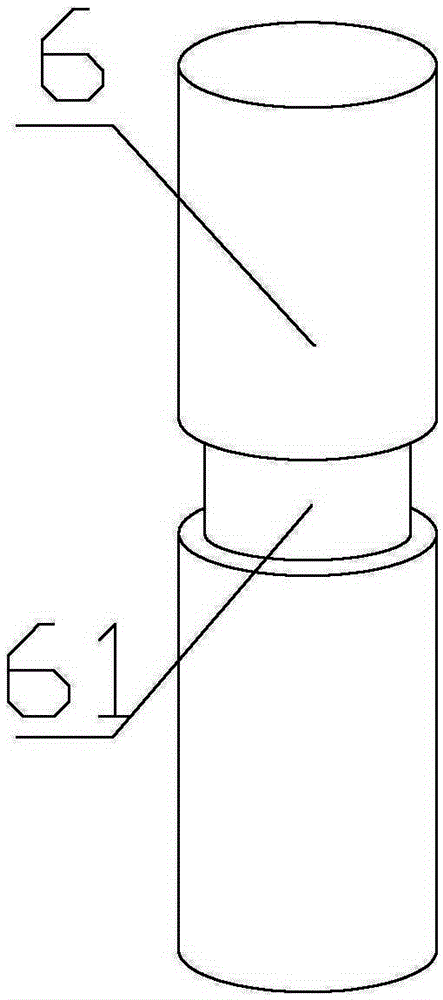

Steel bar bender and use method thereof

InactiveCN104741487AExtended service lifeGuaranteed bending accuracyCircular discClassical mechanics

The invention relates to a steel bar bender and a use method thereof. The steel bar bender comprises a working disc, which is arranged on the upper portion of a machine tool and drivingly matched with a transmission mechanism; the working disc is provided with a central shaft hole and a bent shaft hole; the central shaft hole is provided with a central pile casing wheel, and the outer surface of the central pile casing wheel is provided with a circumferentially arranged first groove; the bent shaft hole is provided with an auxiliary pile guide wheel, and the outer surface of the auxiliary pile guide wheel is provided with a circumferentially arranged second groove. The steel bar bender also comprises a positioning baffle between a positioning plate and the working disc, and the side surface of the positioning baffle, which faces towards the central pile casing wheel when in use, is provided with a third groove. By means of the first groove, the second groove and the third groove, the steel bar bender can avoid sliding of straight steel bars during a bending process and prolong the service life, and meanwhile, can ensure the bending precision and during bending operation, can achieve the effects of avoiding out-of-circularity of the straight steel bars as well as ensuring equal diameter of bent sections of non-bent sections.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

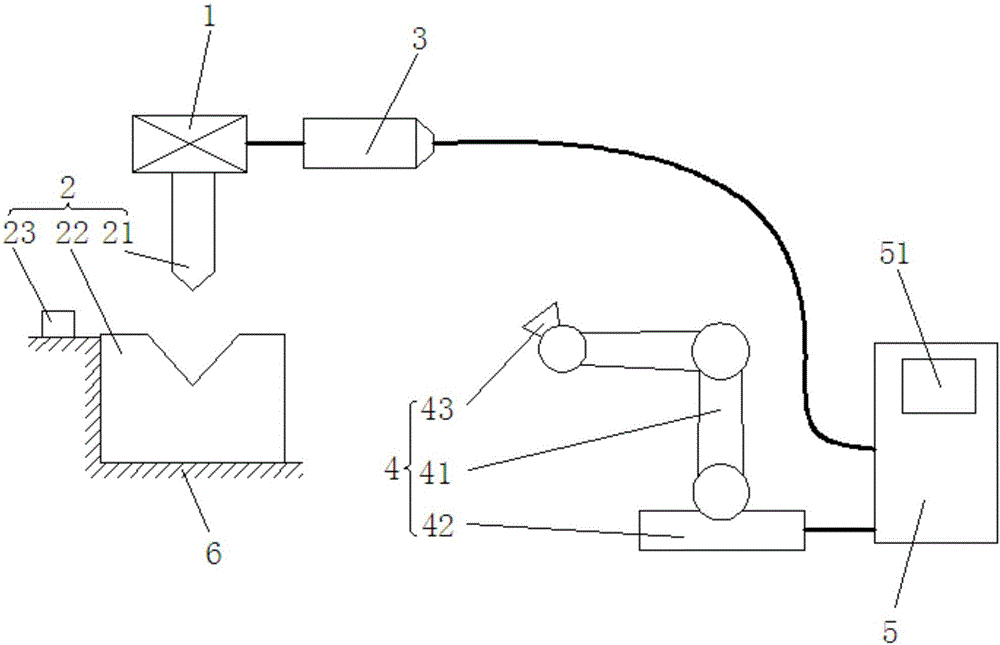

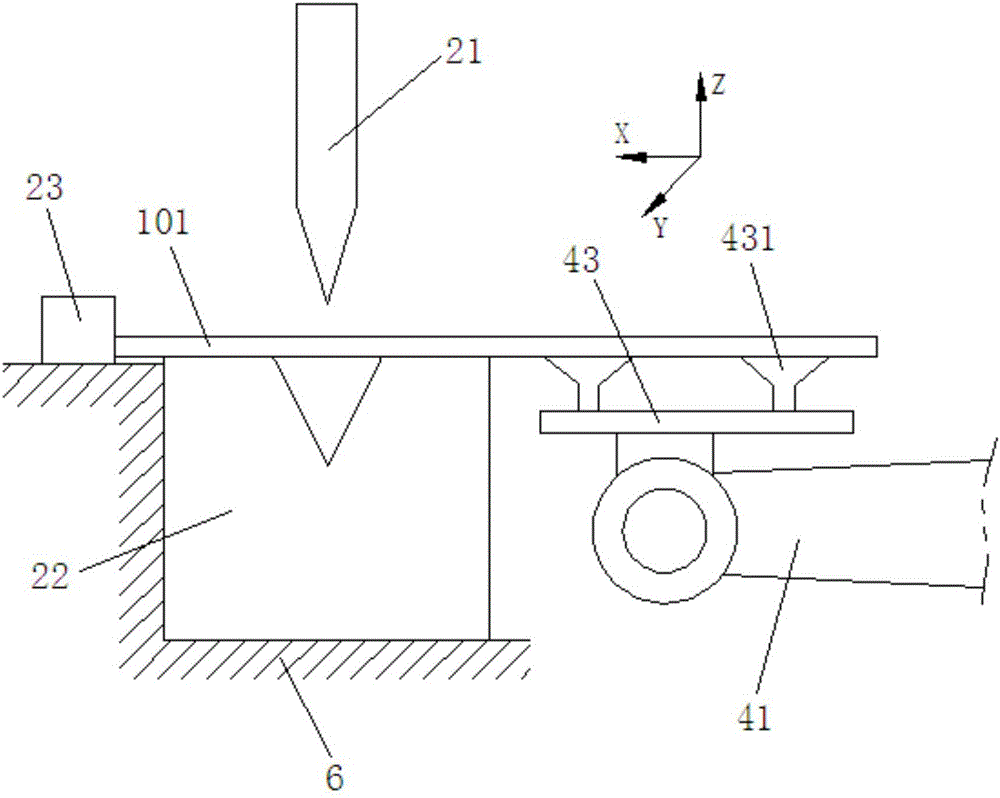

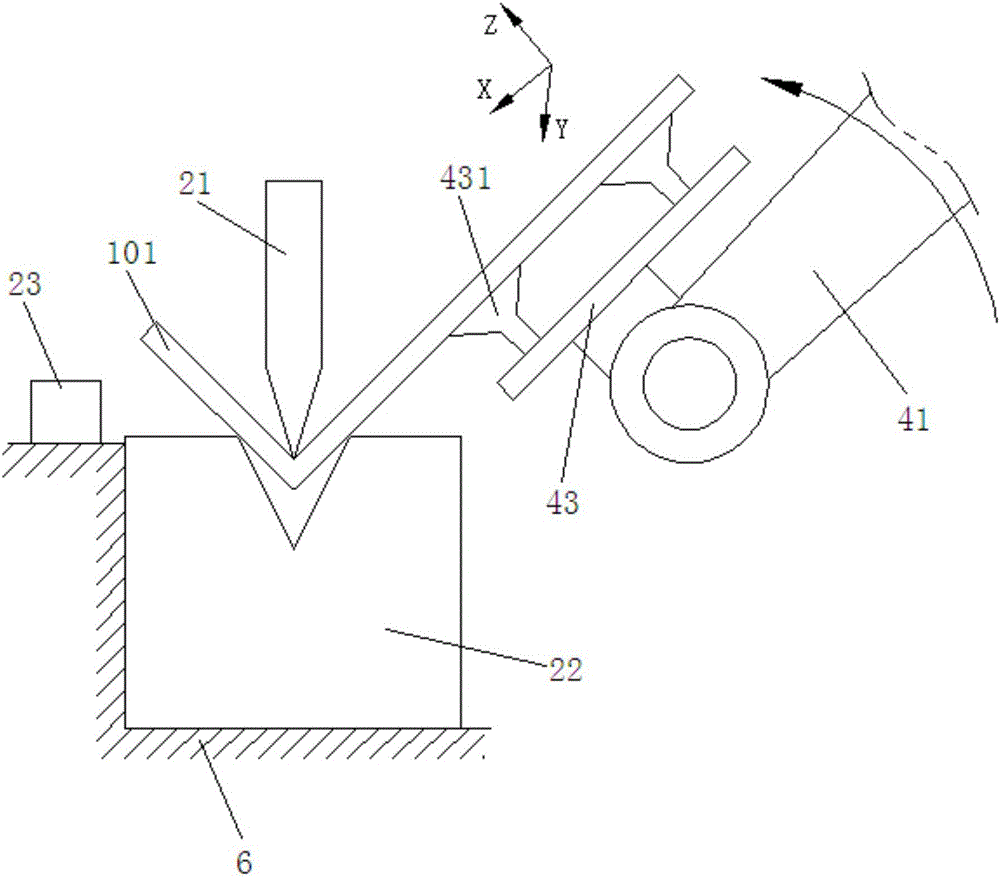

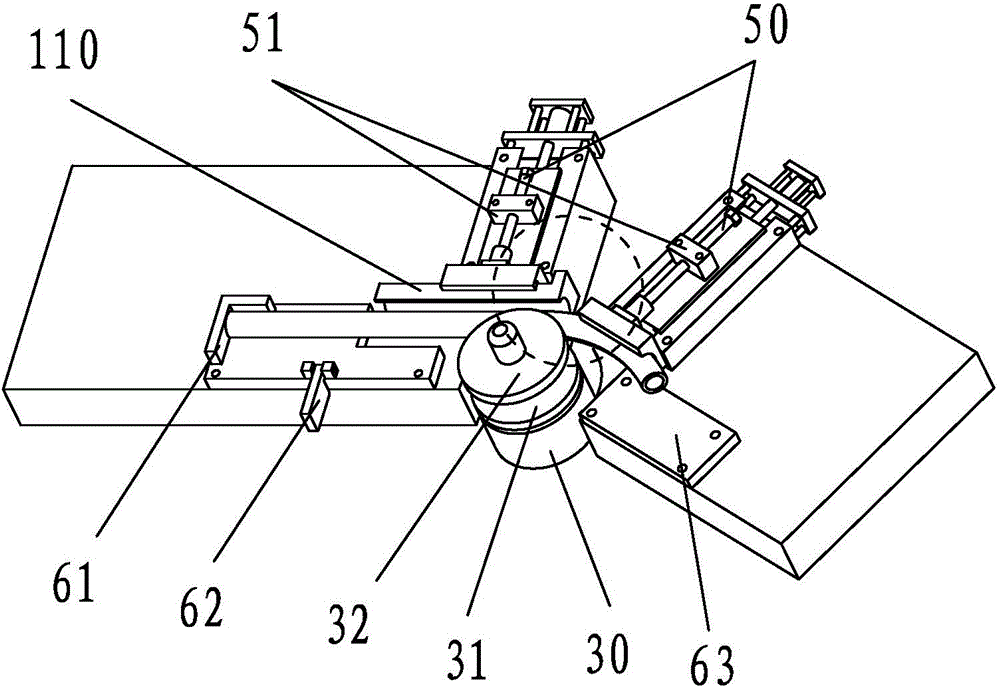

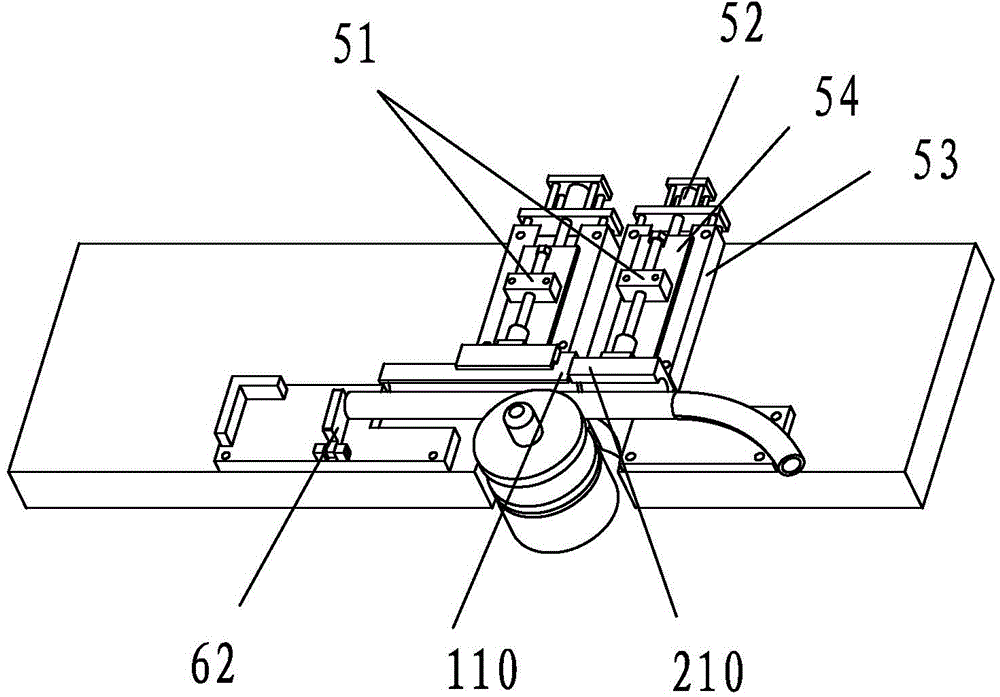

Robot servo bending system

InactiveCN105921558AAvoid motion lagImprove real-time tracking accuracyMetal-working feeding devicesManipulatorControl systemClosed loop

The invention discloses a robot servo bending system. The robot servo bending system comprises a speed reduction mechanism, a bending device, a servo motor set, a joint robot and a robot controller, wherein the bending device comprises a bending knife installed at the lower end of the speed reduction mechanism and a female die matched with the bending knife; the servo motor set is electrically connected with the speed reduction mechanism; the joint robot is used for carrying and lifting to-be-bent workpieces towards the bending device; and the robot controller is electrically connected with the servo motor set and the joint robot, so that movement of the bending knife and movement of the joint robot form an overall closed-loop control system. In the robot servo bending system, the robot controller serves as a unique movement control unit to enable movement of the bending knife and movement of the joint robot to form the overall closed-loop control system for controlling, the dragged movement phenomenon of the joint robot is avoided, and accordingly the real-time following precision of the joint robot in the workpiece bending process is improved, and then the bending precision and bending efficiency of the workpieces are effectively ensured.

Owner:SHANGHAI FANUC ROBOTICS

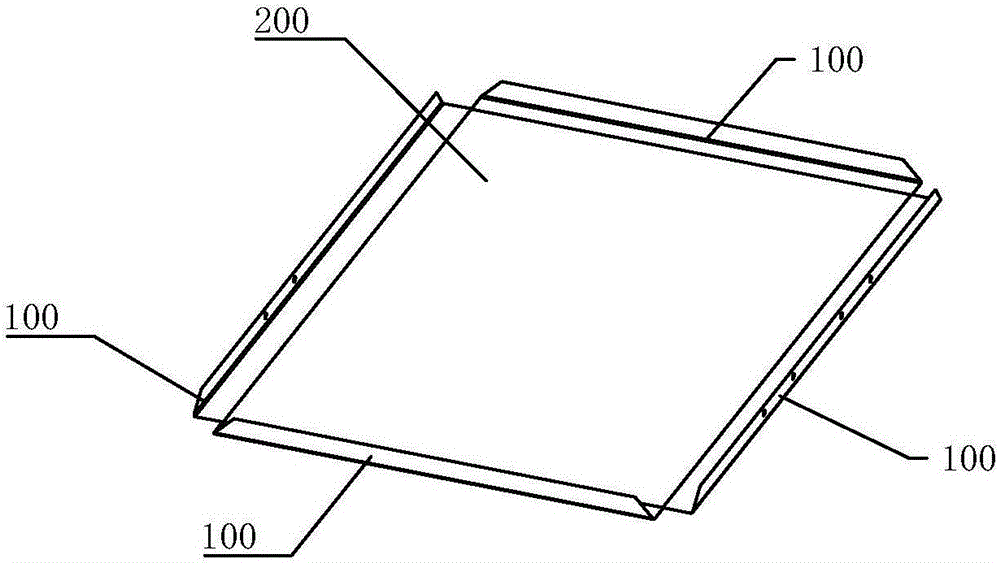

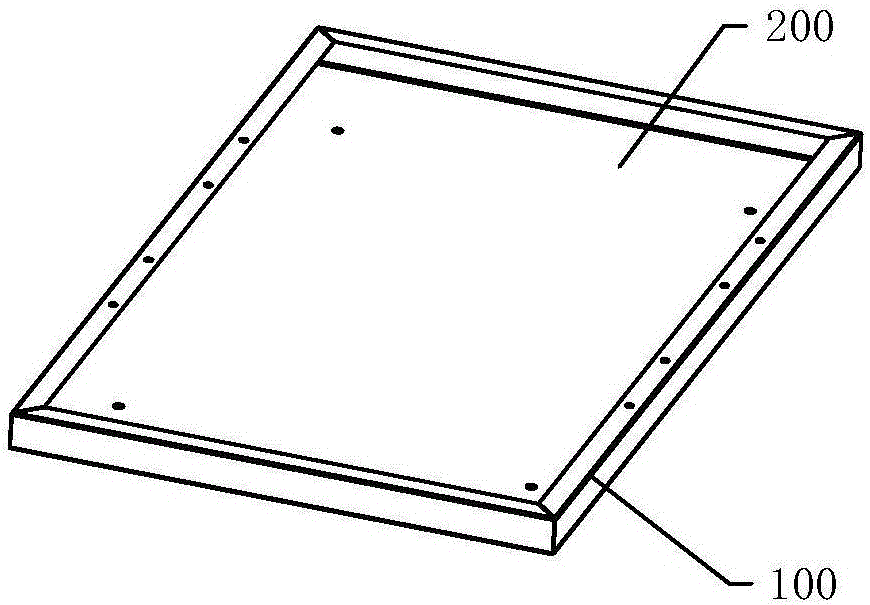

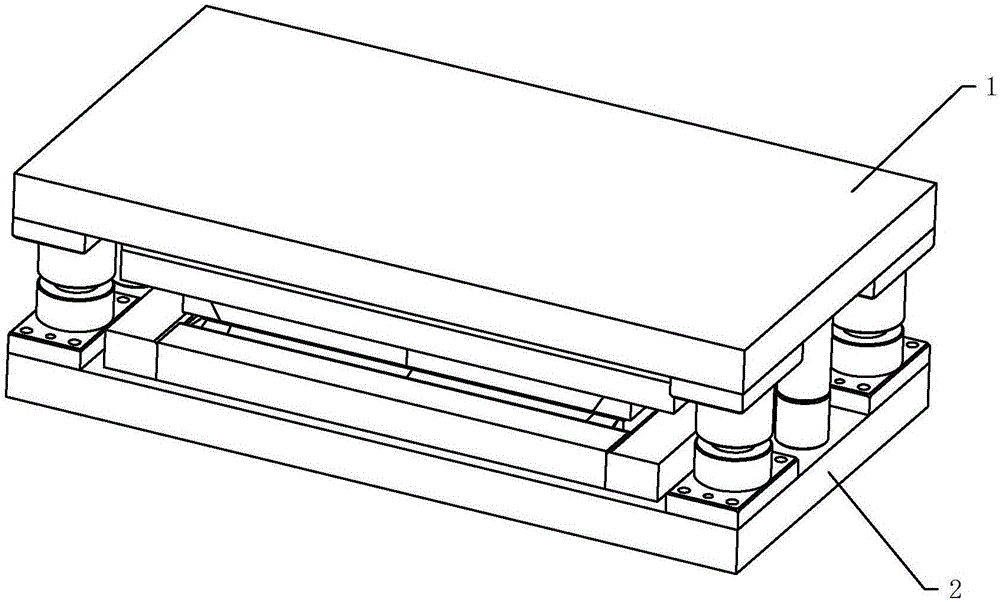

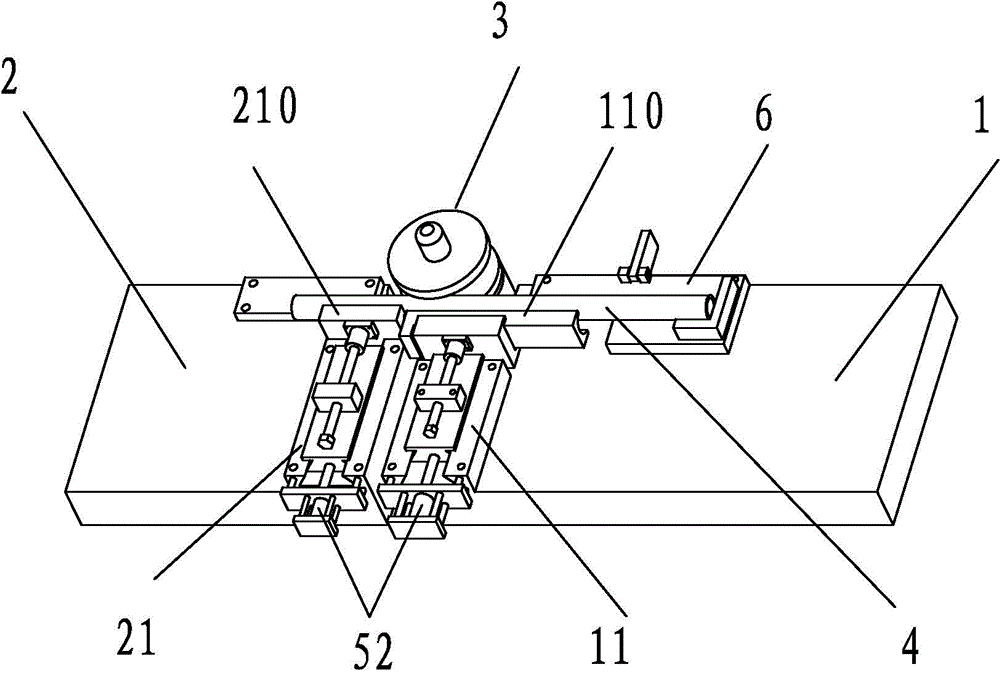

Bending mould

ActiveCN106363055AImprove processing efficiencyGuaranteed bending accuracyShaping toolsStripping-off devicesEngineering

The invention discloses a bending mould which comprises an upper mould and a lower mould; the upper mould comprises an upper mould seat, a fixed plate, two groups of transverse main slide blocks, two groups of longitudinal side slide blocks and a drive block; the lower mould comprises a lower mould seat and a rectangular bending frame fixedly arranged on the lower mould seat; the rectangular bending frame is used for placing a to-be-bent workpiece; and an inner cavity of the rectangular bending frame is adaptive to a rectangular body. The upper mould is equipped with the rectangular body with a telescopic size, and the rectangular body is matched with the rectangular frame of the lower mould, so that bending and mould-molding of the four-side bent workpiece can be easily realized, and the formed workpiece is taken out after being de-molded, and therefore, processing efficiency is greatly improved, and bending precision further can be guaranteed.

Owner:中山市新朴精密模具有限公司

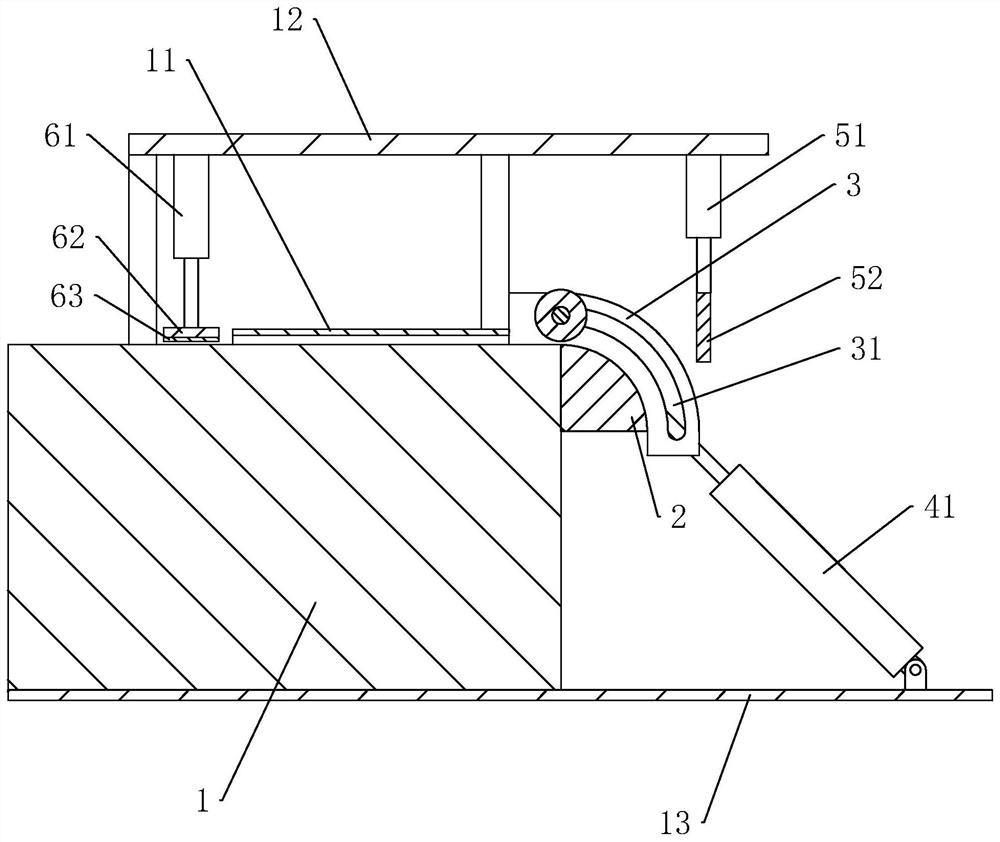

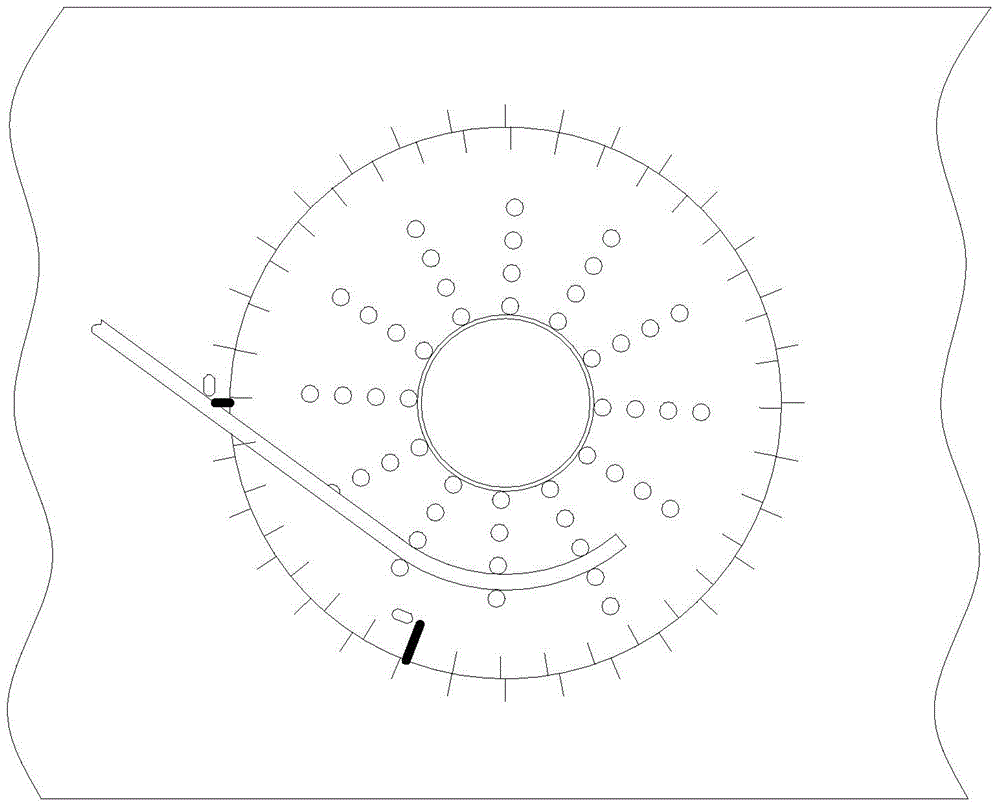

Device for bending pipe with relatively small abrasion

InactiveCN104874651AAvoid damageFlexible bending methodMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The present invention discloses a device for bending a pipe with relatively small abrasion. The device comprises a stationary work table and a rotary work table capable of rotating; a freely rotating rotary circular bench is disposed between the stationary work table and the rotary work table; a circular pipe is bended by the rotary work table in a rotation direction by using a side wall of the rotary circular bench as a bending point; the stationary work table is provided with a first chuck for clamping the front portion of the circular pipe; the rotary work table is provided with a second chuck for clamping the rear portion of the circular pipe; the first chuck can freely slide in a length direction of the circular pipe; the side wall of the rotary circular bench is provided with an arc-shaped recessed surface; and the central section of the circular pipe is attached to the arc-shaped recessed surface of the side wall of the rotary circular bench. The device is simple in structure and good in bending precision, and abrasion of the circular pipe is small.

Owner:ZHEJIANG LIFAN FURNITURE

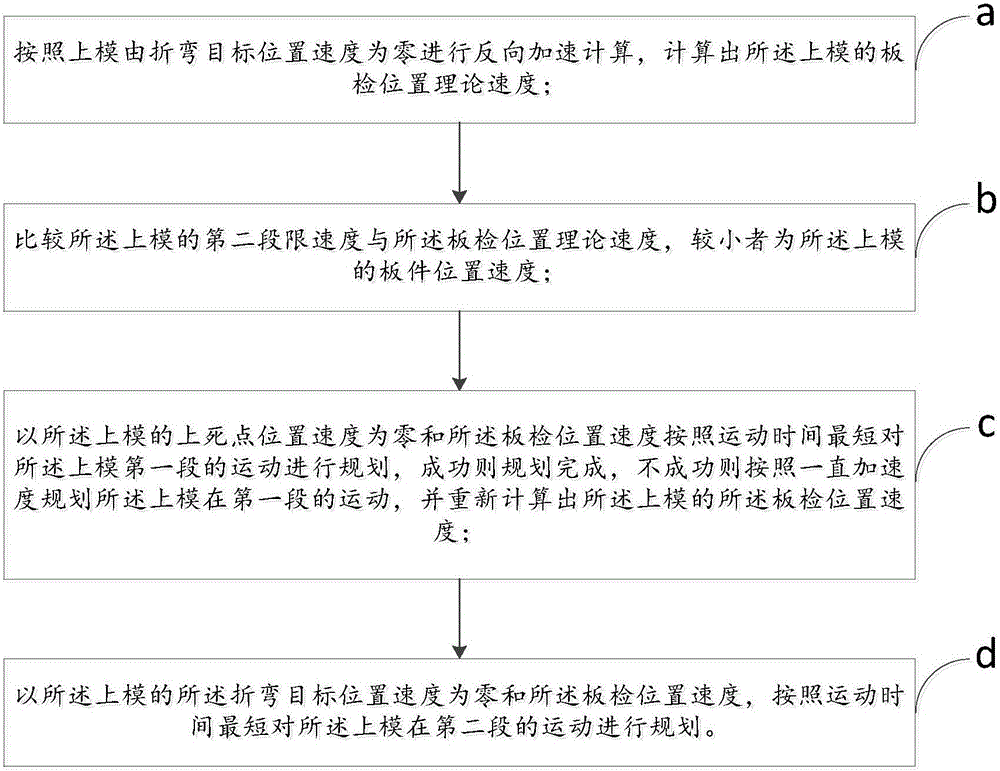

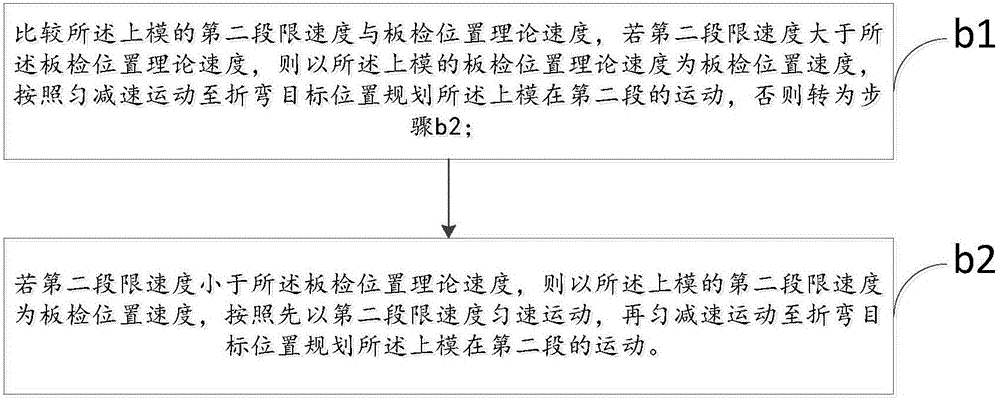

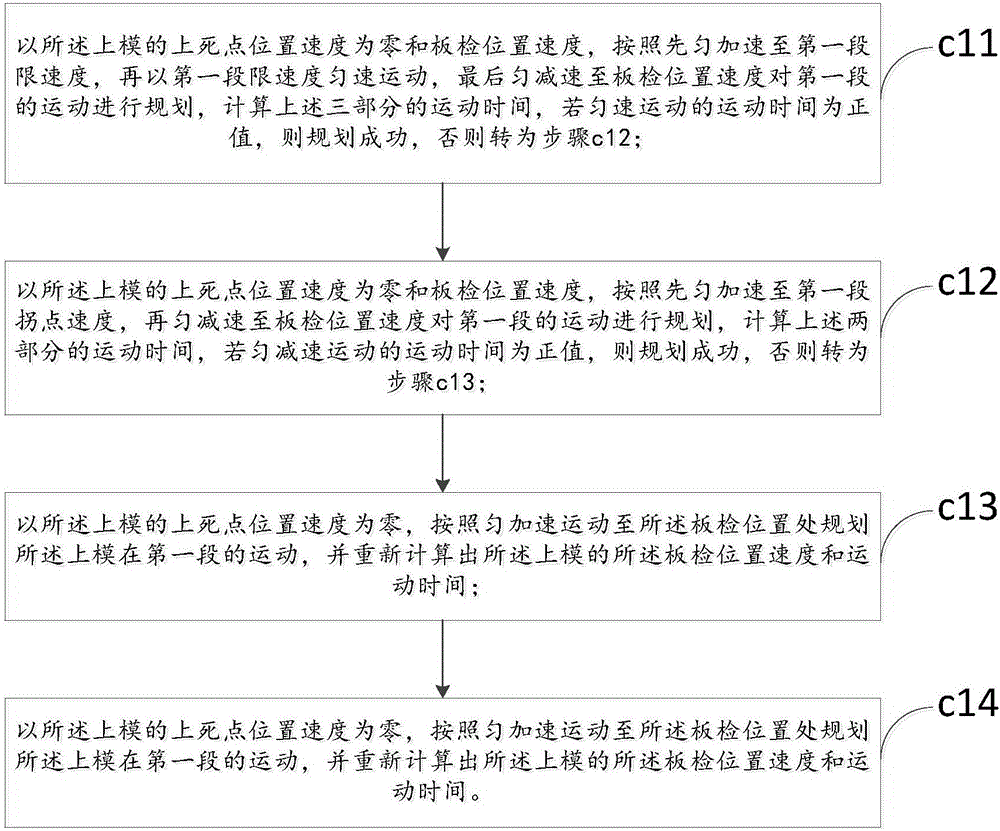

Bender speed planning method and device

ActiveCN105892408AImprove velocity planning efficiencyShorten exercise timeMetal working apparatusNumerical controlControl engineeringMechanical engineering

A bender speed planning method and device are disclosed. The method comprises the following steps: in step a, a theoretical board inspection position speed of an upper mold is calculated; in step b, a second segment limit speed of the upper mold is compared with the theoretical board inspection position speed, a lower one is board inspection position speed of the upper mold; in step c, a dead centre position speed is zero and the board inspection position speed, first segment movement of the upper mold is planned based on a minimal time principle, planning is finished when the planning succeed, otherwise the board inspection position speed is recalculated; in step d, a bending object position speed of the upper mold is zero and the board inspection position speed, and second segment movement of the upper mold is planned based on a minimal movement time principle; the device comprises a calculation module, a comparison module, a first segment planning module and a second segment planning module that are orderly connected. Thus, after speed planning is done, a pressing plate drives the upper mold to move as planned, movement time can be shortened, and bending efficiency can be improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG

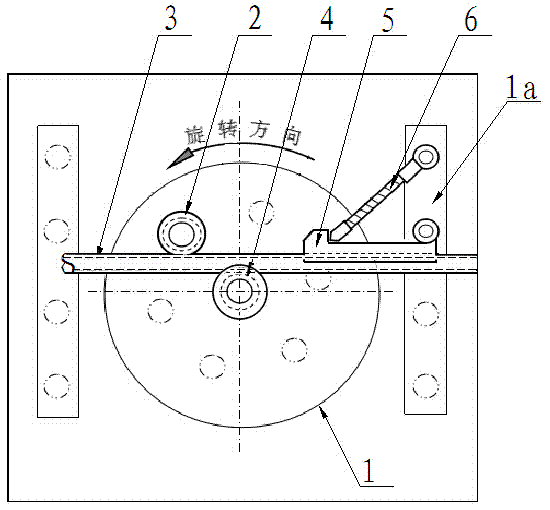

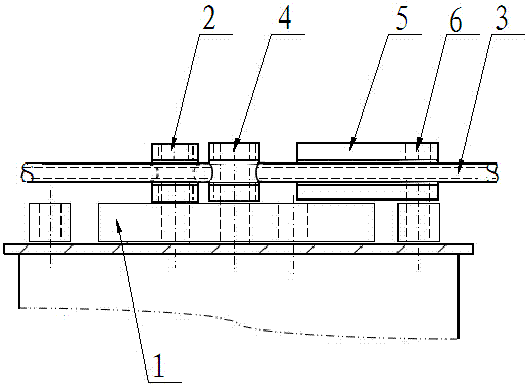

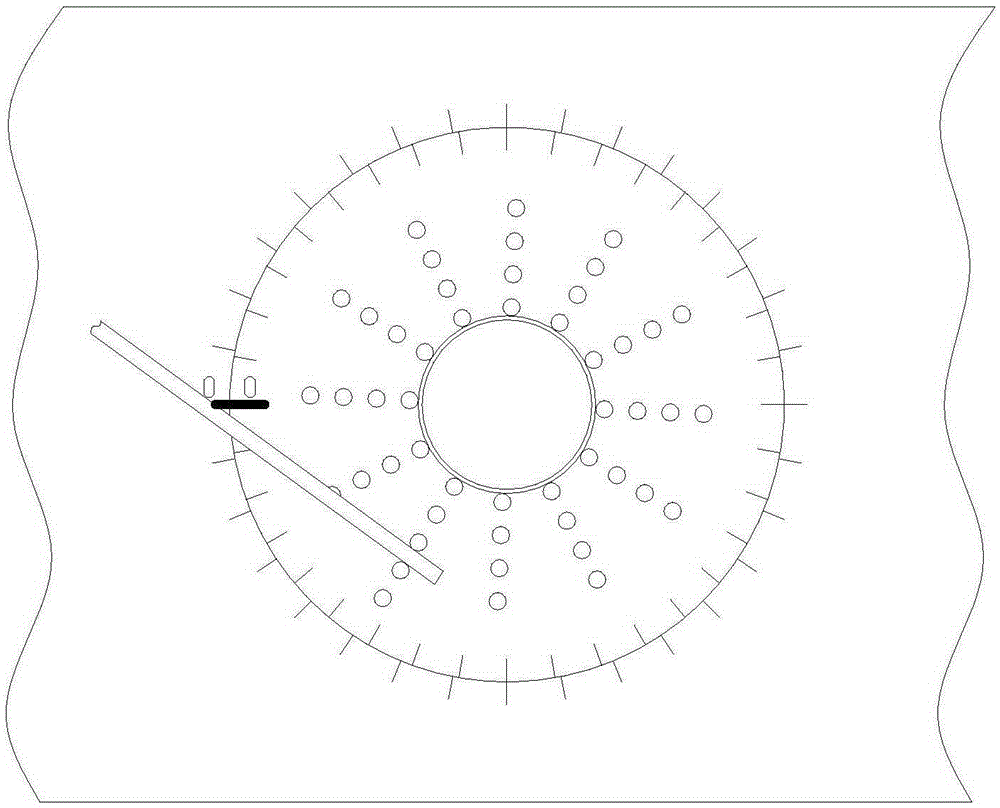

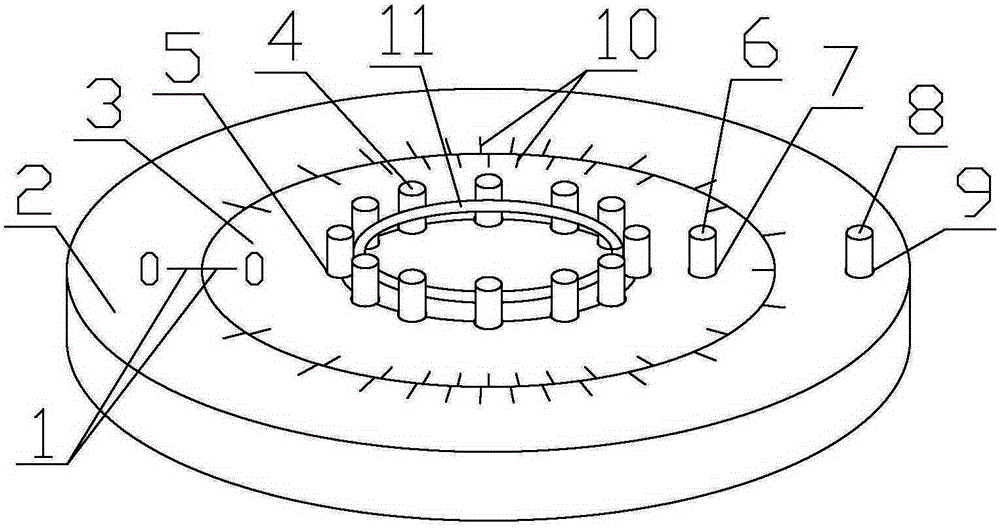

Semiautomatic steel bar bender

InactiveCN104226857AIncrease the scope of applicationReasonable size and location designRebarMachine tool

The invention discloses a semiautomatic steel bar bender, which relates to the technical field of steel bar-bending equipment. The invention aims to provide the semiautomatic steel bar bender which can deal with steel bars with different bending radii. The technical scheme of the invention is as follows: the semiautomatic steel bar bender comprises a machine bed, a working plate which is connected with the machine bed is arranged on the top of the machine bed, a rotary disk is arranged at the center of the working plate, the rotary disk is connected with a power mechanism in the machine bed and can rotate around the axis of the rotary disk, a plurality of positioning shaft holes and clamping shaft holes are evenly distributed along the circumferential direction of the rotary disk on the rotary disk, the positioning shaft holes form a plurality of concentric circles on the rotary disk, positioning shafts and clamping shafts are respectively correspondingly placed in the positioning shaft holes and the clamping shaft holes, backing pin blocks and rollers are arranged on both sides of the working plate, and backing pins are arranged on the backing pin blocks. The invention is applicable to steel bar bender.

Owner:FUZHOU COLLEGE OF FOREIGN STUDIES & TRADE

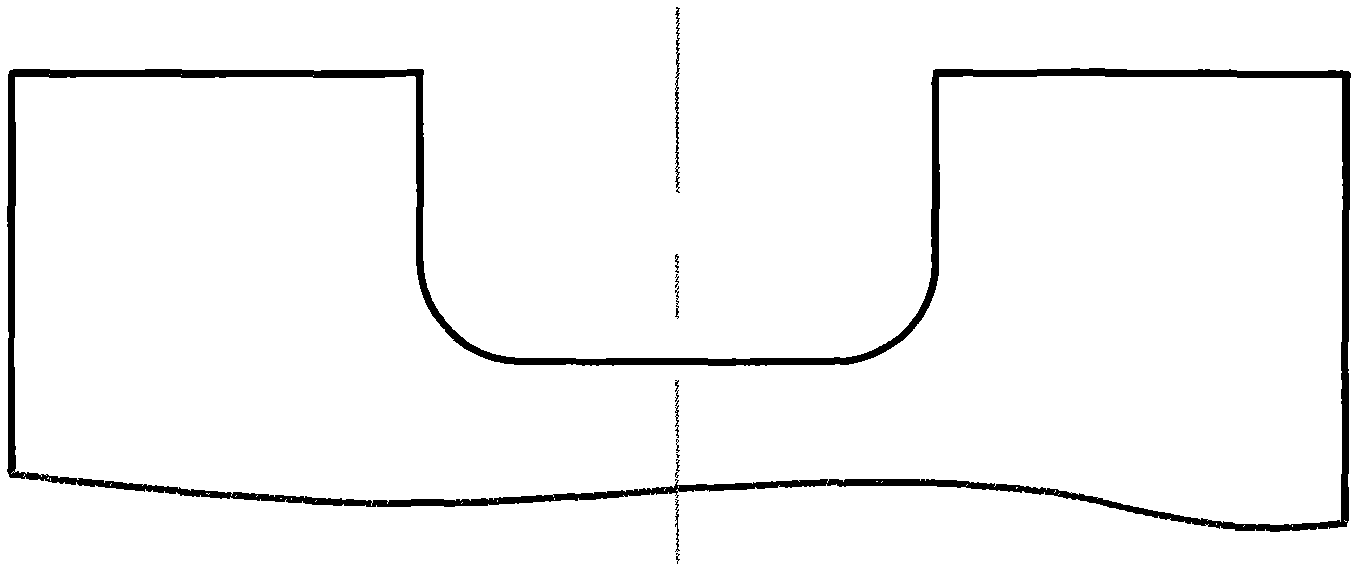

Method for bending and cutting plate with notch

InactiveCN102513794AReduce labor intensityGuaranteed bending accuracyEngineeringUltimate tensile strength

A method for bending and cutting a plate with a notch relates to a method for machining a plate and solves the technical problem that an existing manufacturing method cannot meet the requirement on bending radian while ensuring cutting quality, and cannot ensure cutting quality while meeting the requirement on bending radian. The method includes the specific steps: firstly, cutting a square hole at the root of the notch on the plate by means of numerical control; secondly, stamping and bending the plate to meet assembly requirements according to design requirements; and thirdly, manually cutting a redundant portion of the plate into the notch meeting assembly requirements along two sides of the square hole. The method is used for bending and cutting the plate with the notch, not only can meet the requirement of the plate with the notch on radian after bending, but also can ensure cutting quality, and reduces the labor intensity of workers.

Owner:TAIYUAN HEAVY IND

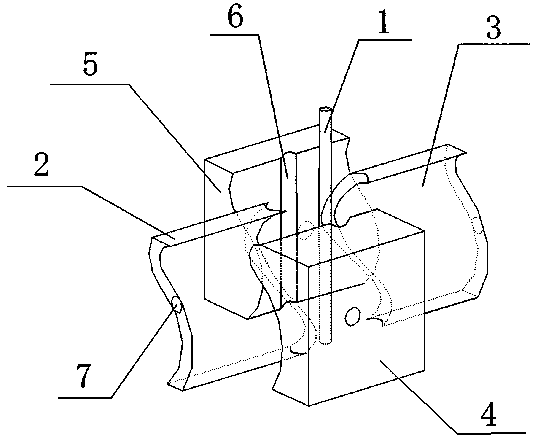

Connecting-rod-type bending device for bending steel in steel forming machine

The invention discloses a connecting-rod-type bending device for bending steel in a steel forming machine. The connecting-rod-type bending device for bending the steel in the steel forming machine comprises a hinged pin shaft, a locating pin, a push rod, a connecting rod, a pin shaft thrust base and a hinged plate. The push rod, the connecting rod, the pin shaft thrust base and the hinged plate are sequentially connected in a hinged mode. The hinged plate is provided with an inner limiting pin which is used for limiting the inner rotation distance of the pin shaft thrust base and an outer limiting pin which is used for limiting the external rotation distance of the pin shaft thrust base. An inner clamping part and an outer clamping part are correspondingly arranged on the pin shaft thrust base. A location pin is arranged on the pin shaft thrust base. When steel is bent, the locating pin is pushed by the pin shaft thrust base to move forward a certain distance and matched with the hinged pin shaft to tightly press the steel, and the inner limiting pin is enabled to reach the inner clamping part. The pin shaft thrust base is stressed to move forward and the hinged plate is driven to swing. At the same time, the locating pin rotates around the hinged pin shaft to bend the steel. The connecting-rod-type bending device for bending the steel in the steel forming machine has the advantages that the distance between the hinged pin shaft and the locating pin can be changed when the steel is bent, and requirements for high working efficiency and high bending accuracy are simultaneously met when the steel is bent.

Owner:冯广建

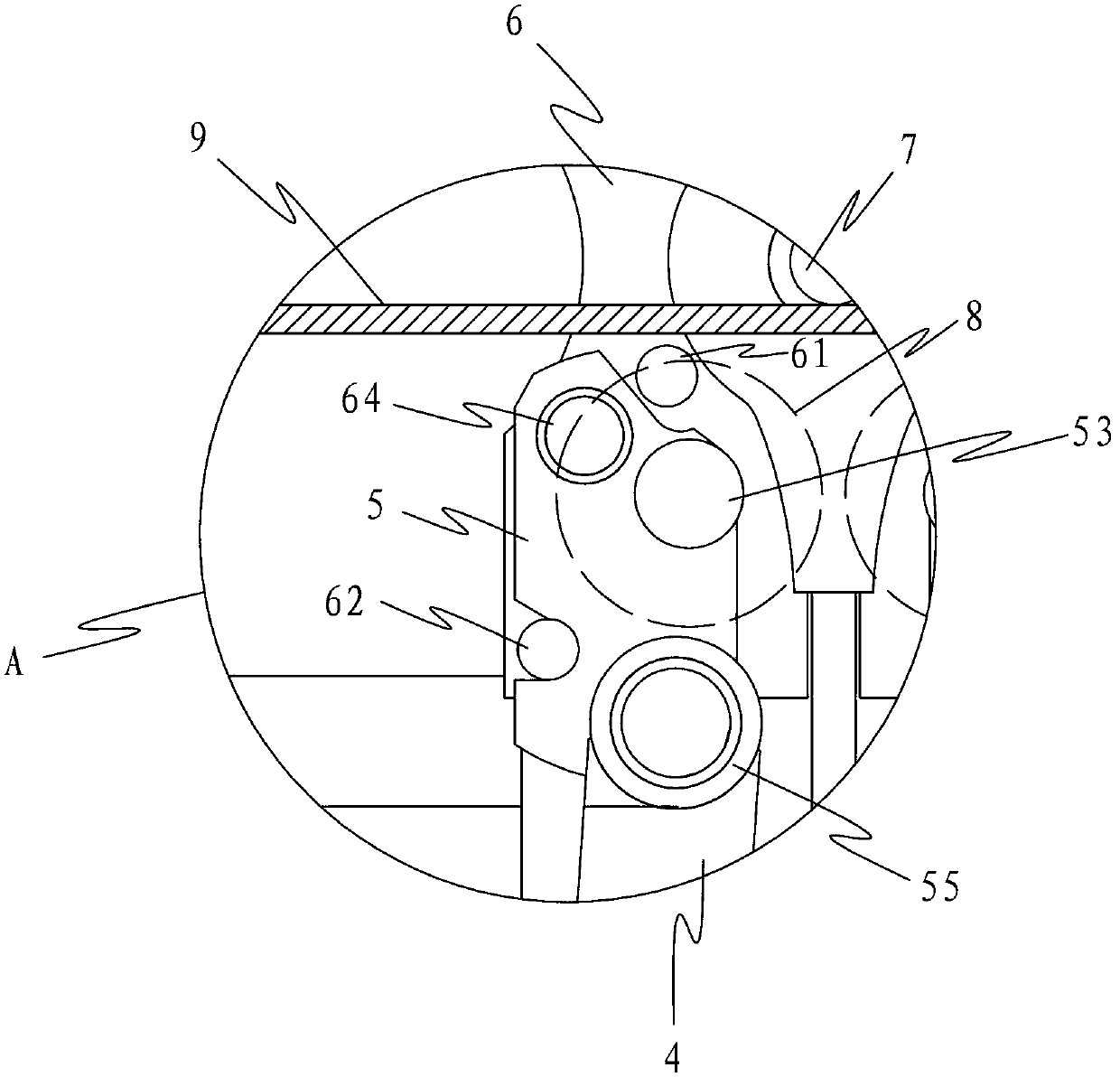

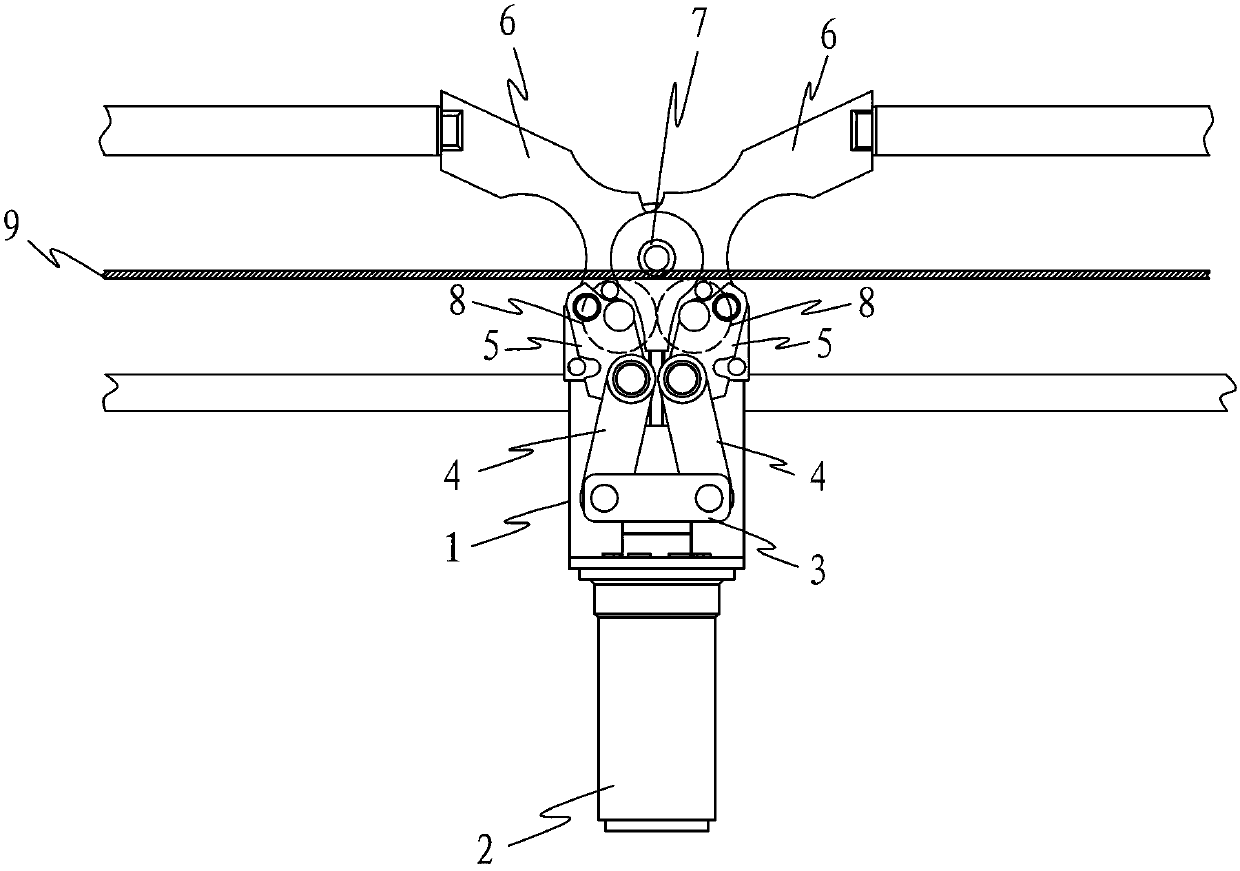

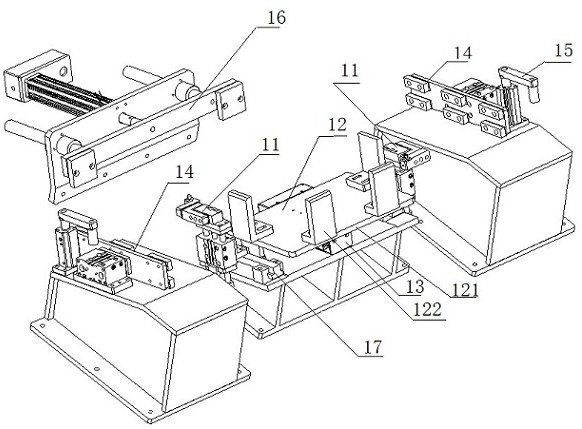

Terminal bending mechanism and bending method thereof and automobile coil winding spot welding assembly line

ActiveCN109108654AGuaranteed accuracyGuaranteed bending accuracyContact member manufacturingOther manufacturing equipments/toolsAssembly lineSpot welding

The invention provides an automobile coil winding spot welding assembly line. The automobile coil winding spot welding assembly line comprises a terminal bending mechanism, wherein the terminal bending mechanism comprises a bending assembly and a clamping assembly. The bending assembly comprises a first driving device and a roller. The first driving device is connected with the roller, and a positioning groove is formed in the roller. The clamping assembly comprises a first clamping block, a second clamping block and a second driving device, wherein the second driving device drives the first clamping block to move towards the second clamping block. By adopting the structure, a clamping block driving assembly drives the first clamping block to move towards the second clamping block, a PIN positioned in the first clamping block and the second clamping block is clamped, the PIN is prevented from moving in the bending process, bending precision is ensured, and the first driving device drives the roller to enable the clamped PIN to be bent on the first clamping block. The PIN is positioned in the positioning groove of the roller, the positioning groove is used for positioning the bending position of the PIN to ensure bending precision, and full-automatic bending is achieved without manual intervention.

Owner:珠海市艾森工匠科技有限公司

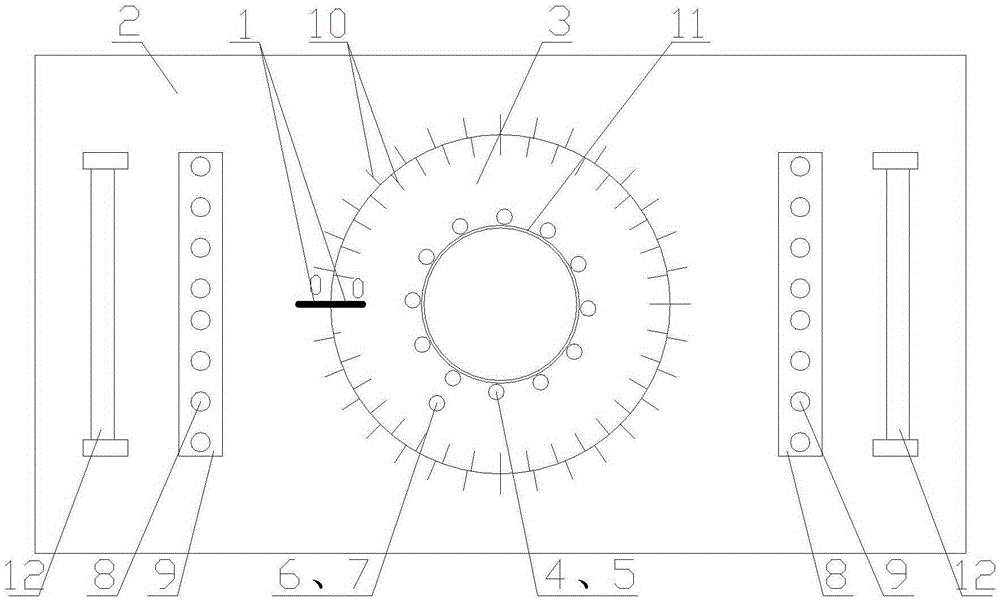

Graduation line steel bar bender

The invention discloses a graduation line steel bar bender, which relates to the technical field of steel bar bending molding equipment, and aims to provide the graduation line steel bar bender with accuracy in bending angle. The graduation line steel bar bender has the technical scheme that the graduation line steel bar bender comprises a working plate located on the top part of a machine body, a locating shaft and a clamping shaft, wherein the working plate comprises a fixed plate and a rotary plate; the rotary plate is connected with a drive device in the machine body and is rotated around the axis of the rotary plate; a plurality of locating shaft holes and clamping shaft holes are uniformly distributed in the rotary plate along the circumferential direction of the rotary plate; the locating shaft and the clamping shaft are respectively and correspondingly placed in the locating shaft holes and the clamping shaft holes; graduation lines are respectively arranged on the fixed plate and the rotary plate; the number of the graduation lines on the rotary plate is more than the number of the graduation lines on the fixed plate. The rotated angle of the rotary plate can be obtained through the position relationship between zero graduation lines on the fixed plate and the rotary plate, and the graduation line on the rotary plate coincident to the graduation line on the fixed plate. The invention is applicable to the steel bar bender.

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

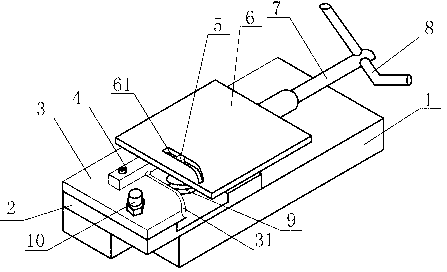

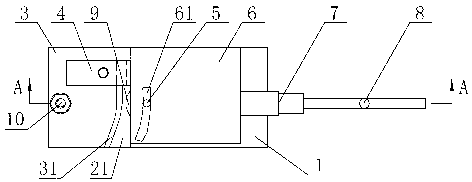

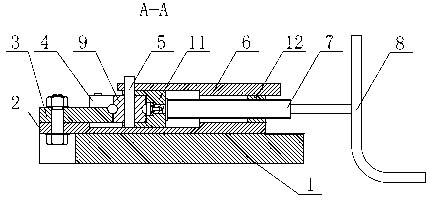

Conduit bending molding device

The invention relates to a conduit bending molding device which comprises a bottom plate; a lower plate is fixedly connected to the bottom plate; a groove is formed in the lower plate; a push plate is arranged in the groove, and is provided with a mounting groove; mounting holes are formed in two side walls of the mounting groove; a roller is arranged in the mounting groove; circular grooves are formed in the circumference of the roller; a connecting pin passes through a center hole of the roller and the mounting holes of the mounting groove; a bent pipe seat is fixedly connected to the lower plate, and is provided with an arc-shaped bent face; a circular arc pressing plate is fixedly connected to the tail end of the arc-shaped bent face of the bent pipe seat; the circular arc pressing plate is provided with a semicircular groove; the semicircular groove is matched with the arc-shaped bent face of the bent pipe seat to form a circular hole; a rear plate is mounted on the lower plate, and is provided with a long hole; a connecting rod penetrates into the long hole, and is connected with the push rod; a handle is arranged on the connecting rod; an upper plate is fixedly connected to the rear plate, and is provided with an arc-shaped long hole; and the connecting pin is matched with arc-shaped long hole. The conduit bending molding device has a simple structure, and is simple and convenient to operate, and high in processing efficiency and processing precision.

Owner:WUXI HANGHU TECH

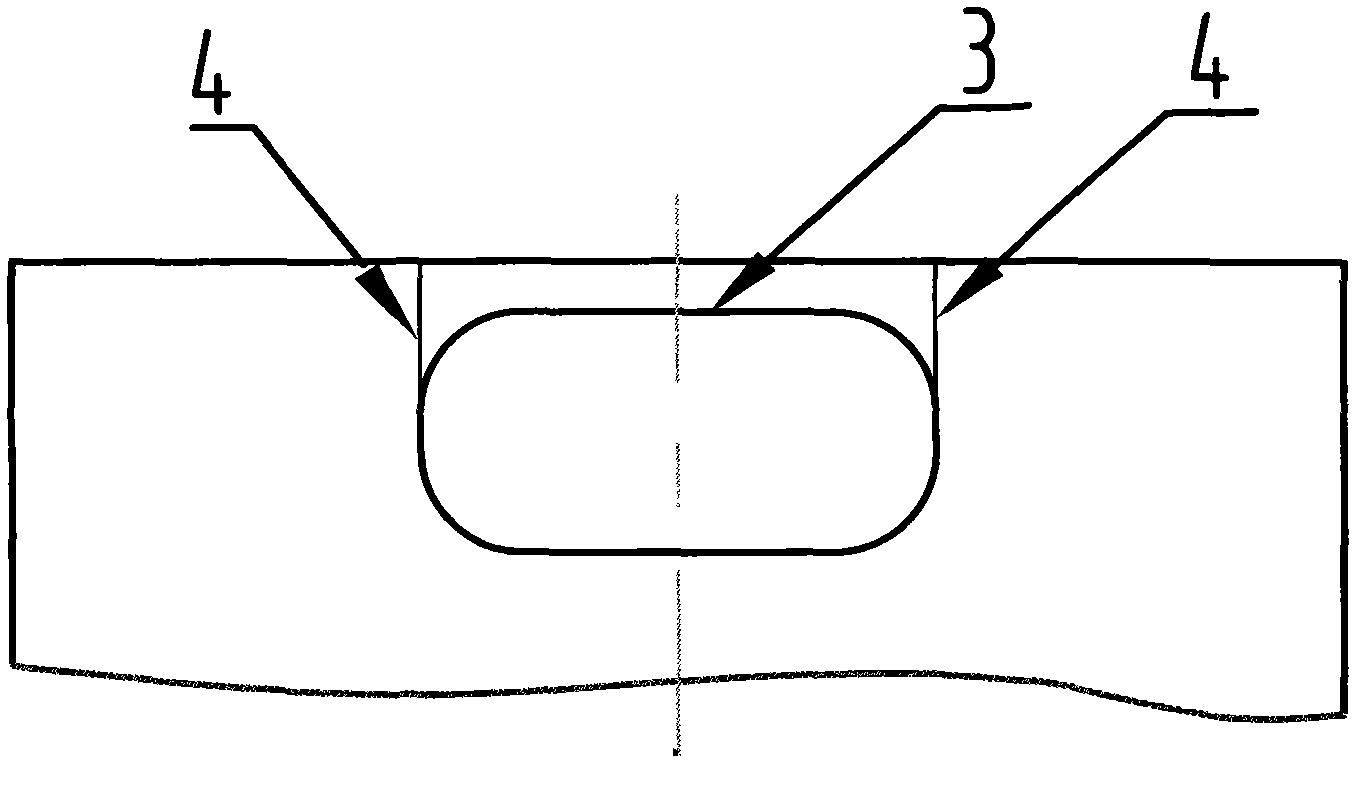

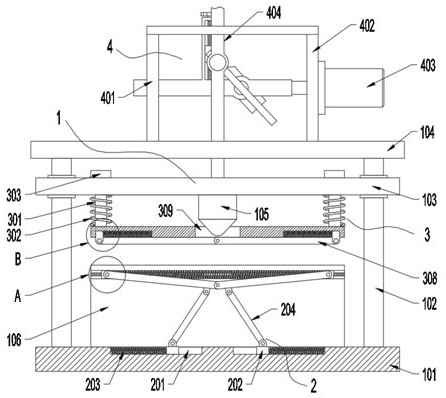

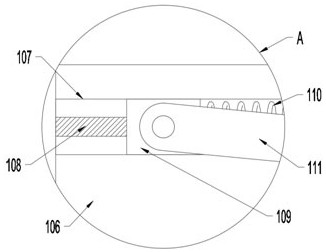

Arc bending device and arc bending method for polygonal plate

InactiveCN111992598AThe arc bending process is simpleGuaranteed bending accuracyPilot holeEngineering

The invention relates to an arc bending device and an arc bending method for a polygonal plate. A workbench, a pressure bearing body, two guide rails, a rotation shaft, a pressing roller and a drive device are included. The workbench is provided with a limiting plate, and a channel for a workpiece to pass through is formed between the limiting plate and the upper surface of the workbench; the pressure bearing body is arranged on the surface of one side of the workbench, a curved surface is arranged on the pressure bearing body, and the curved surface is tangent to the upper surface of the workbench; the two guide rails are fixed to the workbench and located on the two sides of the pressure bearing body respectively, guide holes are formed in the guide rails, and the radian of the guide holes is consistent with that of the curved surface; the rotation shaft is arranged on the two guide rails, and the two ends of the rotation shaft respectively penetrate through the guide holes; the pressing roller is arranged on the rotation shaft and coaxially connected with the rotation shaft, the pressing roller is located between the two guide rails, and a gap allowing the workpiece to pass through is formed between the pressing roller and the curved surface; and when the drive device controls the rotation shaft to slide along the guide holes, the side edge of the workpiece is rolled and formed. The arc bending device and the arc bending method have the effects of being high in machining efficiency and machining precision.

Owner:SHANGHAI LANTIAN BUILDING DECORATION ENG CO LTD

Bending forming die for solid lifting hook of automobile

InactiveCN103506494AGuaranteed bending accuracySimple structureShaping toolsLeft directionEngineering

The invention provides a bending forming die for a solid lifting hook of an automobile. The bending forming die for the solid lifting hook of the automobile comprises a left die, a right die, a front die and a rear die, wherein the left die and the right die are arranged on the left side and the right side of a pipe fitting to be bent respectively, the front die and the rear die are arranged on the front side and the rear side of the pipe fitting to be bent respectively, the shape of the rear end face of the front die and the shape of the front end face of the rear die are the same as the bending shape of the needed lifting hook when a user observes the lifting hook in the left direction, the left die and the right die are of a plate-shaped structure which is the same as the bending shape of the needed lifting hook when the user observes the lifting hook in the left direction, and the shape of the right end face of the left die and the shape of the left end face of the right die are the same as the bending shape of the needed lifting hook when the user observes the needed lifting hook in the front direction. Two bending forming dies are used for carrying out 360-degree extrusion forming on the pipe fitting to be processed, one-time processing forming can be carried out on the solid lifting hooks with any continuous curvatures, bending accuracy is ensured, the structure is simple, operation is convenient, labor cost is saved, product quality is improved, and working efficiency is improved.

Owner:芜湖开瑞金属科技有限公司

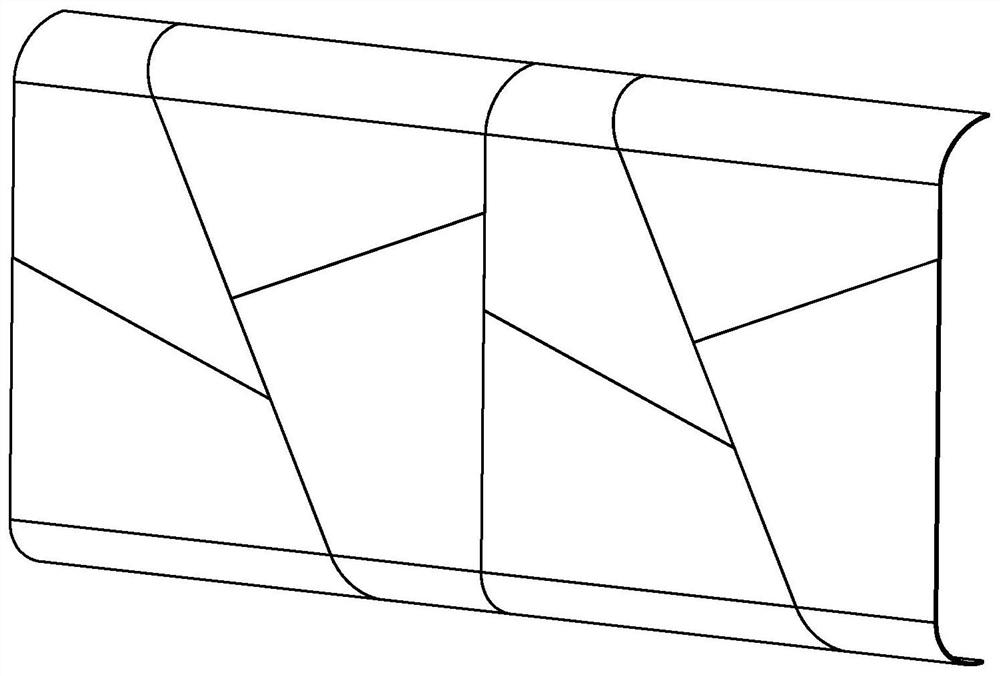

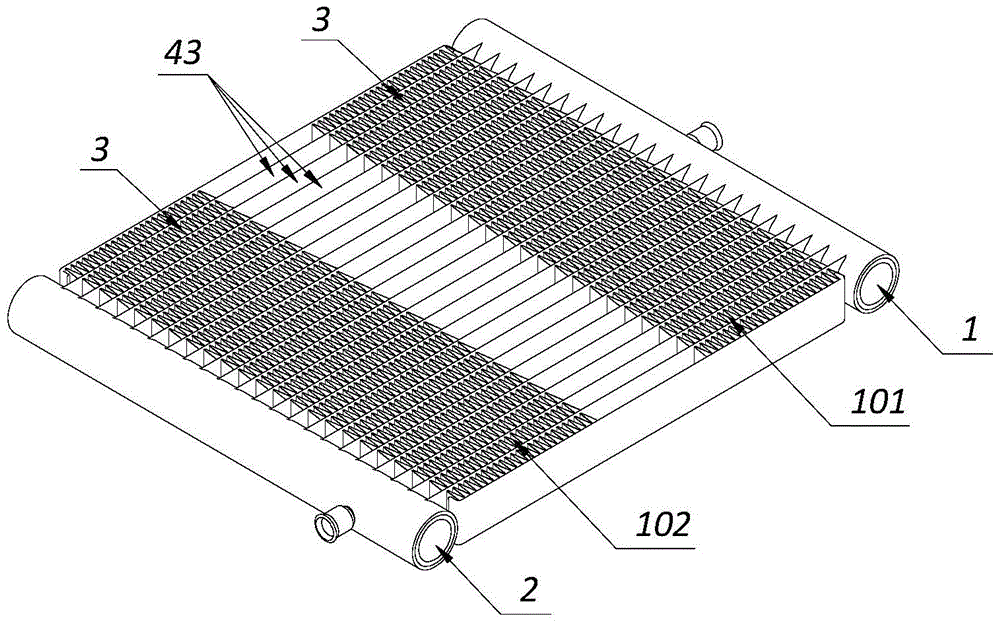

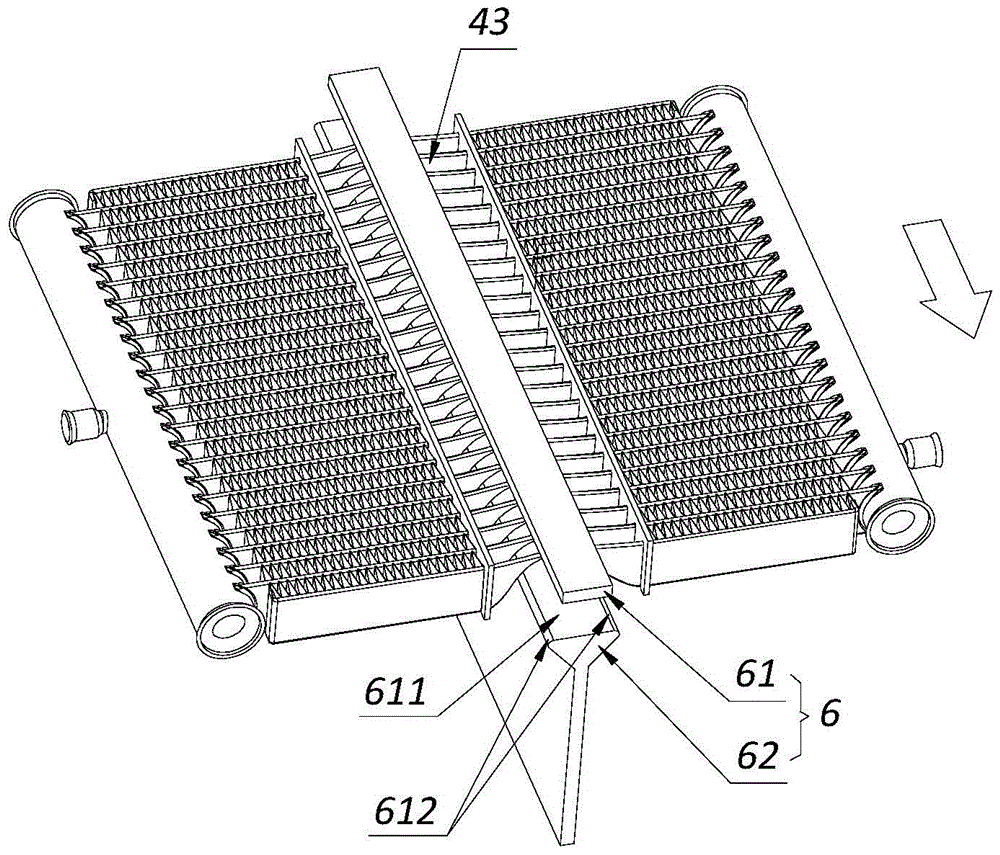

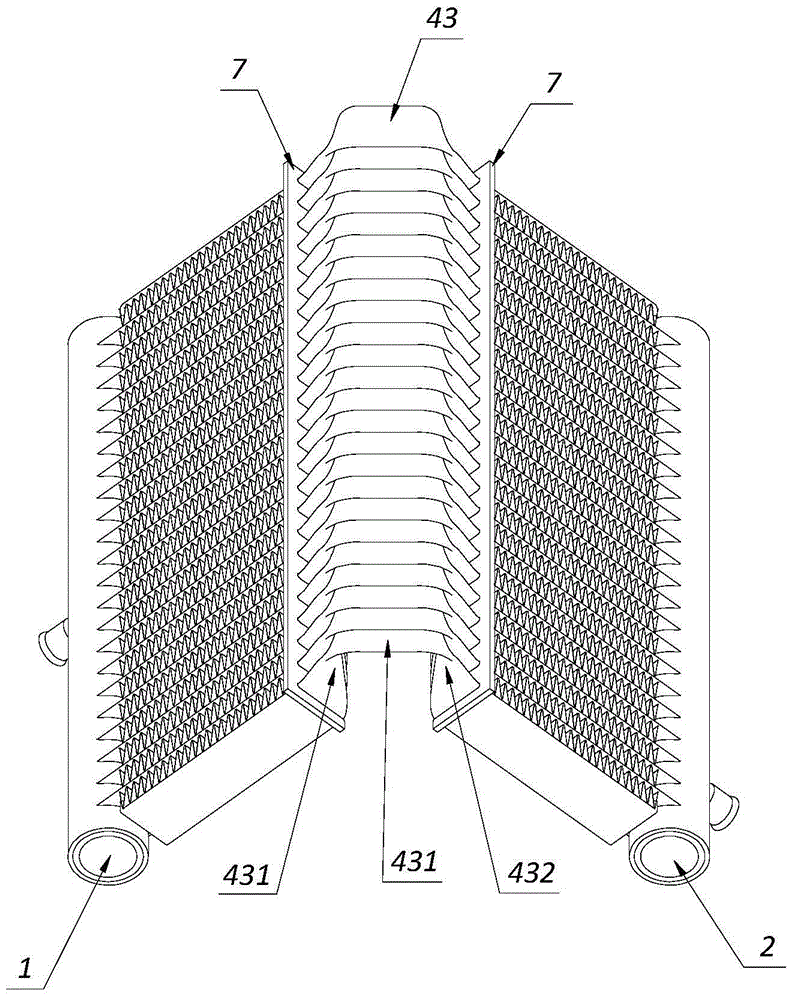

Bending heat exchanger and bending method of heat exchanger

ActiveCN104713387BLower the altitudeImprove heat transfer effectStationary conduit assembliesHeat exchange apparatusEngineeringHeat exchanger

The invention discloses a bending heat exchanger and a bending method of the heat exchanger. The bending heat exchanger comprises a first collecting pipe, a second collecting pipe, a plurality of fins and a plurality of flat pipes. Each flat pipe comprises a first portion, a second portion and a middle portion connected with the first portion and the second portion; and the first portions and the second portions are in contact with the fins respectively. Each middle portion comprises a first twisting portion, a second twisting portion and a straightness portion, wherein the first twisting portion is connected with the corresponding first portion, the second twisting portion is connected with the corresponding second portion, and the straightness portion is connected with the first twisting portion and the second twisting portion. The straightness portions of the flat pipes are sequentially overlapped partly and are sequentially and tightly attached together. Each straightness portion comprises an inner surface and an outer surface, and the inner surfaces and the outer surfaces of the straightness portions are flat on the flat. According to the arrangement, the bending precision can be ensured, and in addition, the flat bending portions can reduce the height of the bending heat exchanger; and under the condition of the same length of the flat pipes, the length of fin segments is increased, and therefore the heat exchange performance of the heat exchanger can be improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

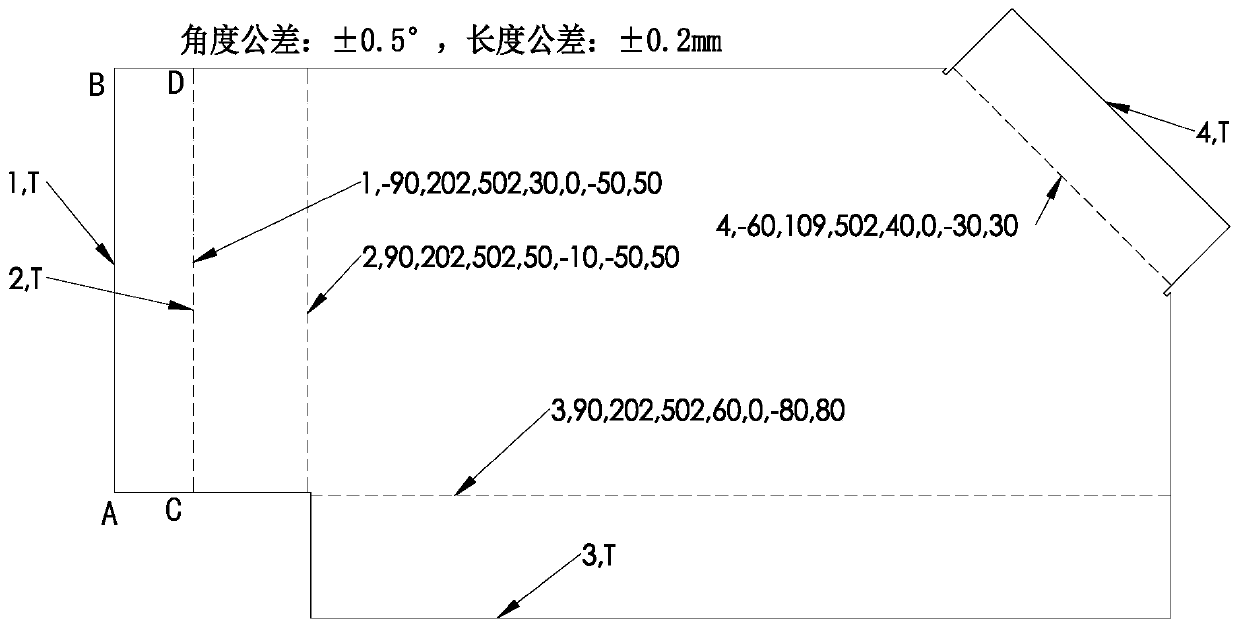

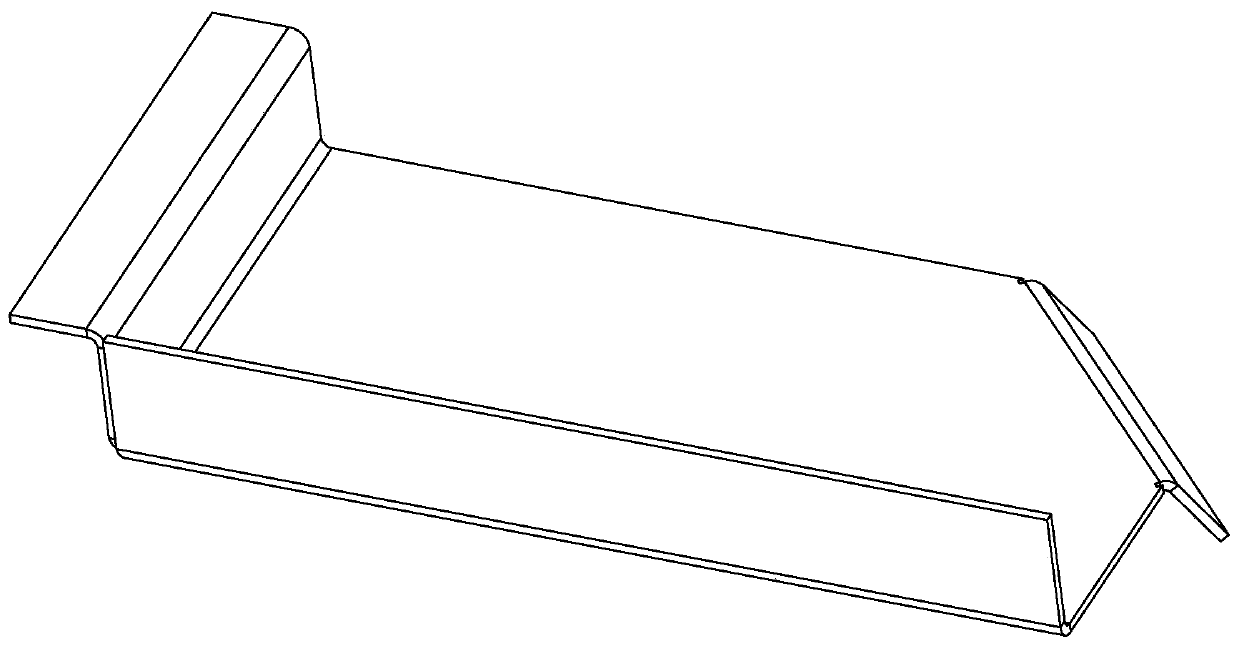

Bending method for numerical-control bending machine

ActiveCN110814125ASimple processEasy to operateProgramme controlComputer controlNumerical control systemReading (computer)

The invention provides a bending method for a numerical-control bending machine. The method comprises the following steps that a technologist draws an expanded view drawing of a workpiece on a computer; data is marked on the drawing, wherein the data comprises two parts including data for reference of a bending operator and data, with a specific specification, for reading of a numerical-control system; a drawing file is transmitted to the numerical-control system of the bending machine, and the numerical-control system reads the data and converts the data to a self-execution step; and the bending machine is started to perform bending. According to the bending method for the numerical-control bending machine, the technologist can directly mark the technology data on the drawing, a part of data is used for reference of the operator during bending, the other part of bending process step technology data has a specific specification and can be identified and read by the numerical-control system of the bending machine, the data is converted into an execution step of the numerical-control system, and the operator does not need to manually input the technology data and does not need to useoffline programming software. The technology process is simplified, operation is simple, the production efficiency is improved, and the bending method is suitable for the field of bending processing.

Owner:广州纽蓝客智能科技有限公司

Bending and forming die for automobile hollow lifting hook

InactiveCN103506495AEliminate bad deformationGuaranteed bending accuracyShaping toolsPipe fittingForming processes

The invention aims to provide a bending and forming die for an automobile hollow lifting hook. The bending and forming die comprises two pairs of forming dies. One pair of the forming dies comprises a left die and a right die, and the left die and the right die are arranged on the left side and the right side of a hollow pipe fitting respectively. The other pair of the forming dies comprises a front die and a back die, and the front die and the back die are arranged on the front side and the back side of the hollow pipe fitting respectively. The shape of the back end surface of the front die and the shape of the front end surface of the back die are identical with the bent shape of the needed lifting hook of left view. The left die and the right die are of plate structures identical with the bent shape of the needed lifting hook of left view. The shape of the right end surface of the left die and the shape of the left end surface of the right die are identical with the bent shape of the needed lifting hook of principal view. Grooves of the same shape are formed in the end surfaces, close to the hollow pipe fitting, of the left die, the right die, the front die and the back die in the vertical direction. Due to two pairs of the forming dies, the hollow lifting hook of any continuous curvature can be machined and formed at a time. The arc-shaped grooves are formed in the forming dies, and therefore bad deformation of the hollow pipe fitting in the forming process is eliminated, the bending accuracy is guaranteed, and the work efficiency is improved.

Owner:芜湖开瑞金属科技有限公司

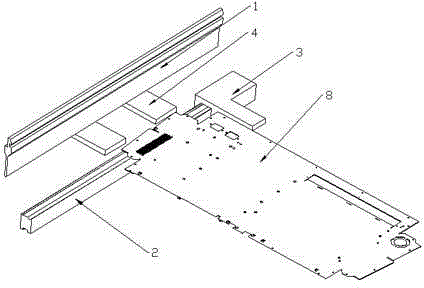

Semi-automatic graduated steel bar bending machine

InactiveCN104259339BGuaranteed bending precisionStable clampingMetal working apparatusSemi automaticEngineering

The invention discloses a semi-automatic scale mark reinforcing steel bar bending machine, relates to the technical field of reinforcing bar bending forming devices, and aims at providing the semi-automatic scale mark reinforcing steel bar bending machine with the accurate bending angle. According to the technical scheme, the semi-automatic scale mark reinforcing steel bar bending machine comprises a machine tool. A working disc connected with the machine tool is arranged at the upper portion of the machine tool. A rotating disc is arranged at the center of the working disc and connected with a power mechanism inside the machine tool and rotates around the axis of the rotating disc. A plurality of positioning shaft holes and a plurality of clamping shaft holes are evenly distributed in the rotating disc in the circumferential direction of the rotating disc. Positioning shafts and clamping shafts are correspondingly placed in the positioning shaft holes and the clamping shaft holes respectively. The working disc and the rotating disc are each provided with scale marks. The number of the scale marks on the rotating disc is larger than the number of the scale marks on the working disc. Through the position relation between the zero scale mark on the working disc and the zero scale mark on the rotating disc and through the scale marks, coinciding with the scale marks on the working disc, of the rotating disc, the rotation angle of the rotating disc can be obtained.

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

Processing technology for glass with super-large arc length

ActiveCN109020176AGuaranteed bending accuracyGlass reforming apparatusGlass tempering apparatusBlow moldingFlat glass

The invention provides a processing technology for glass with a super-large arc length. The processing technology comprises the steps of heating and air-blowing molding. In the step of heating, plateglass performs reciprocating movement in a heating section under the transferring of a heating roller table group and is simultaneously heated by upper lower heating wires, wherein the heating temperature of the middle sections of the upper heating wires is higher than the heating temperature of the middle sections of the lower heating wires. In the step of air-blowing molding, the sizes of air openings of upper and lower air grids in a horizontal toughening furnace are adjusted so as to allow the opening size of the air opening of the upper air grid to be gradually increasing from two ends ofthe length direction of a horizontal air grid roller way to the center of the length direction and the opening size of the air opening of the lower air grid to be gradually increasing from center totwo ends; then the horizontal air grid roller way is adjusted to realize alignment with a heating roller way and an unloading roller way; then the horizontal air grid roller way, the upper air grid and the lower air grid are opened; and finally, the heated and softened glass is rapidly transferred into the horizontal air grid roller way, and is allowed to deform under the actions of the upper airgrid and the lower air grid and then to be corrected and molded. The processing technology provided by the invention can produce the glass with an ultra-large arc length of 4,000 to 5,000 mm and guarantees bending precision of the glass.

Owner:合肥中科衡金工业自动化有限公司

Connecting-rod-type bending device for bending steel in steel forming machine

The invention discloses a connecting-rod-type bending device for bending steel in a steel forming machine. The connecting-rod-type bending device for bending the steel in the steel forming machine comprises a hinged pin shaft, a locating pin, a push rod, a connecting rod, a pin shaft thrust base and a hinged plate. The push rod, the connecting rod, the pin shaft thrust base and the hinged plate are sequentially connected in a hinged mode. The hinged plate is provided with an inner limiting pin which is used for limiting the inner rotation distance of the pin shaft thrust base and an outer limiting pin which is used for limiting the external rotation distance of the pin shaft thrust base. An inner clamping part and an outer clamping part are correspondingly arranged on the pin shaft thrust base. A location pin is arranged on the pin shaft thrust base. When steel is bent, the locating pin is pushed by the pin shaft thrust base to move forward a certain distance and matched with the hinged pin shaft to tightly press the steel, and the inner limiting pin is enabled to reach the inner clamping part. The pin shaft thrust base is stressed to move forward and the hinged plate is driven to swing. At the same time, the locating pin rotates around the hinged pin shaft to bend the steel. The connecting-rod-type bending device for bending the steel in the steel forming machine has the advantages that the distance between the hinged pin shaft and the locating pin can be changed when the steel is bent, and requirements for high working efficiency and high bending accuracy are simultaneously met when the steel is bent.

Owner:冯广建

Lateral positioning bending mold

InactiveCN104785641AGuaranteed bending accuracyNo need to add micro-jointsShaping toolsPulp and paper industryLateral positioning

The invention discloses a lateral positioning bending mold. The lateral positioning bending mold comprises an upper bending mold body, a lower bending mold body, lateral abutting parts fixed to the lower bending mold body and back abutting parts aligned with bent positioning points of a product. Each lateral abutting part comprises a lower mold fixing base fixed to the lower bending mold body and an adjustment piece for adjusting the distance between the lateral abutting part and the product. The lateral positioning bending mold is suitable for products in various shapes; accurate positioning is achieved through the lateral abutting parts and the back abutting parts, the bending accuracy is guaranteed, micro-connection does not need to be additionally arranged, cost is saved, and the bending efficiency is improved.

Owner:昆山荣科钣金科技有限公司

Semi-automatic steel bar bending machine

The invention discloses a semiautomatic steel bar bender, which relates to the technical field of steel bar-bending equipment. The invention aims to provide the semiautomatic steel bar bender which can deal with steel bars with different bending radii. The technical scheme of the invention is as follows: the semiautomatic steel bar bender comprises a machine bed, a working plate which is connected with the machine bed is arranged on the top of the machine bed, a rotary disk is arranged at the center of the working plate, the rotary disk is connected with a power mechanism in the machine bed and can rotate around the axis of the rotary disk, a plurality of positioning shaft holes and clamping shaft holes are evenly distributed along the circumferential direction of the rotary disk on the rotary disk, the positioning shaft holes form a plurality of concentric circles on the rotary disk, positioning shafts and clamping shafts are respectively correspondingly placed in the positioning shaft holes and the clamping shaft holes, backing pin blocks and rollers are arranged on both sides of the working plate, and backing pins are arranged on the backing pin blocks. The invention is applicable to steel bar bender.

Owner:FUZHOU COLLEGE OF FOREIGN STUDIES & TRADE

Steel bending machine

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

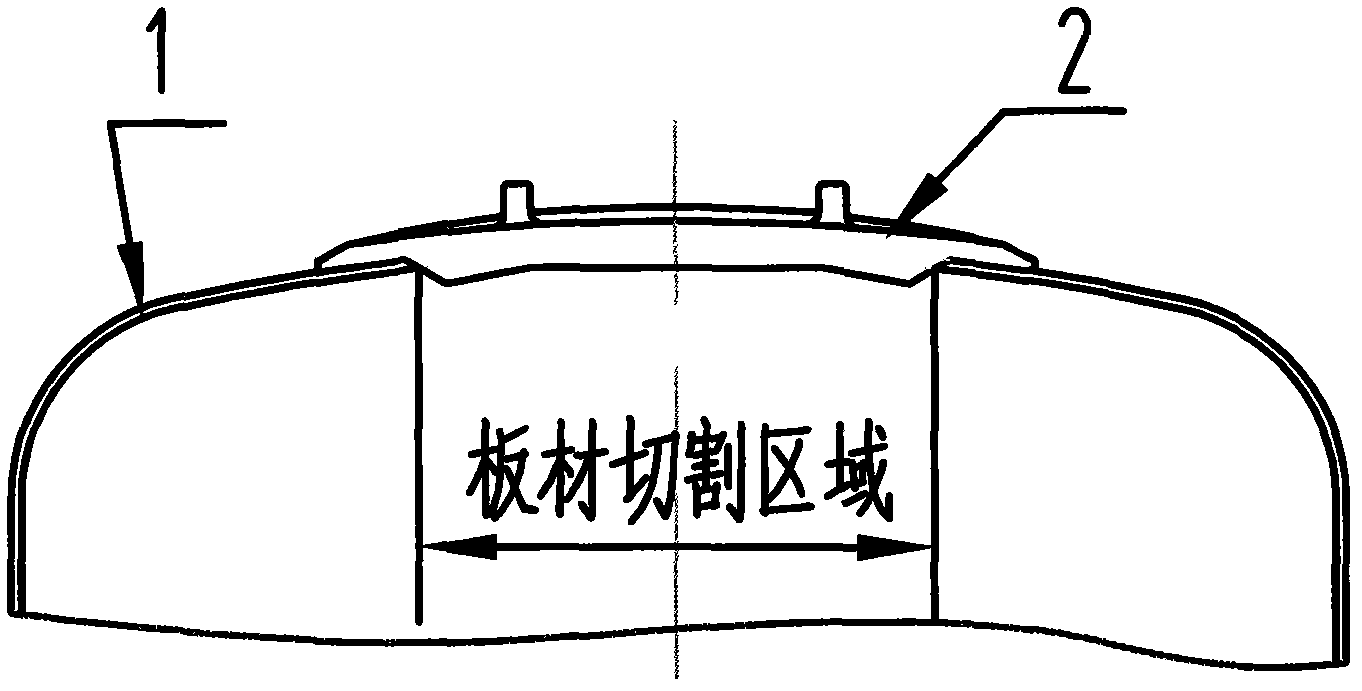

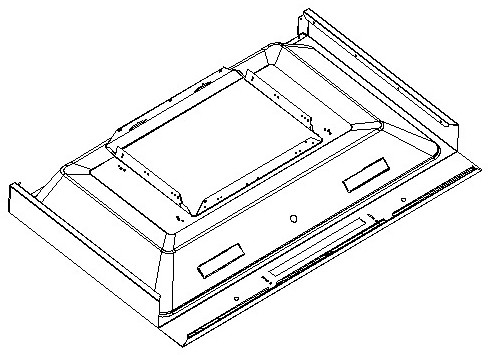

Flanging and bending equipment for metal plate shell of range hood

PendingCN113042629APrecise positioningGuaranteed adjustment accuracyShaping toolsMetal-working feeding devicesEngineeringStructural engineering

The invention discloses flanging and bending equipment for a metal plate shell of a range hood. The flanging and bending equipment comprises an equipment body, a product positioning tool, an upper pressing cutting die assembly, a lower pressing cutting die and a lower overturning cutting die assembly, wherein the product positioning tool, the upper pressing cutting die assembly, the lower pressing cutting die and the lower overturning cutting die assembly are mounted on the surface of the body. An auxiliary feeding assembly and a rear auxiliary feeding assembly of the product positioning tool are used for feeding and fixing. Left and right mounting supports are located on the left side and the right side of a to-be-machined metal plate and used for clamping the metal plate. A bending upper cutting die of the upper pressing cutting die assembly is located at the upper end of the bent edge of the fed to-be-machined metal plate and used for pressing the upper portion of a to-be-bent line. The lower overturning cutting die assembly rotates the to-be-bent edge upwards. According to the flanging and bending equipment for the metal plate shell of the range hood, the bending line position of the metal plate can be accurately adjusted, and the bending precision of metal plates made of different materials is guaranteed.

Owner:南京英田激光科技有限公司

Metal plate bending machining forming device

ActiveCN113414253APrevent slidingGuaranteed bending accuracyMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention is suitable for the technical field of metal plate machining, and provides a metal plate bending machining forming device. The metal plate bending machining forming device comprises a fixing base and further comprises a bending mechanism, wherein the bending mechanism is installed on the fixing base, the bending mechanism comprises a bending assembly, an elastic pressing assembly, a driving assembly and an adjusting assembly, the driving assembly drives the bending assembly to bend a metal plate through telescopic movement, the adjusting assembly is used for changing the telescopic stroke of the driving assembly, and the driving assembly adjusts the bending angle of the metal plate by adjusting the telescopic stroke. A metal plate is placed on the bending assembly, the telescopic stroke of the driving assembly is adjusted by controlling the adjusting assembly, then the bending angle of the bending assembly to the metal plate is controlled, and when the driving assembly drives the bending assembly to bend the metal plate after adjustment is completed, the bending assembly drives the elastic pressing assembly to limit the metal plate, so that the metal plate is prevented from sliding in the bending process, and the bending precision is ensured.

Owner:烟台佑利技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com