Steel bar bender and use method thereof

A technology for steel bar bending and bending axis, which is applied in the field of steel bar bending machines, can solve problems such as inability to bend metal pipes, low efficiency of single bending, and out-of-round steel bars, and achieve the effects of simple and convenient configuration of tooling, improvement of work efficiency, and cost savings in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

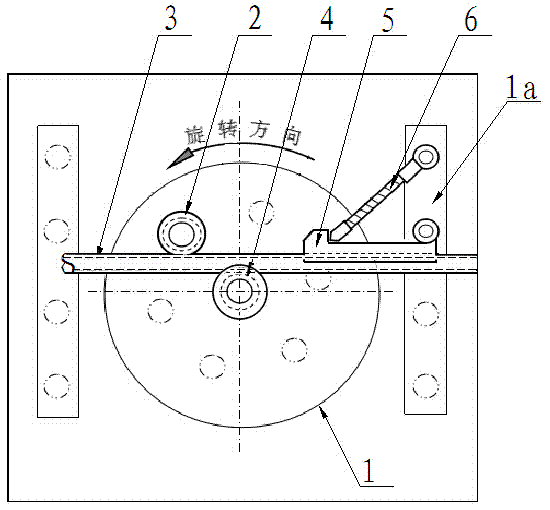

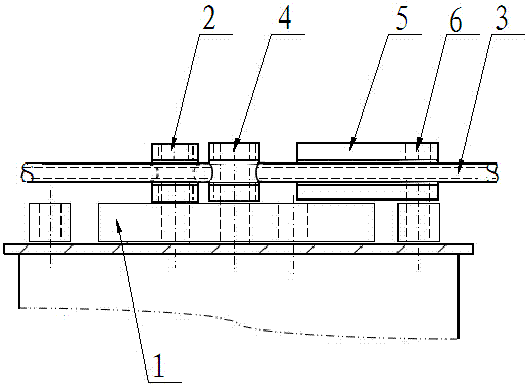

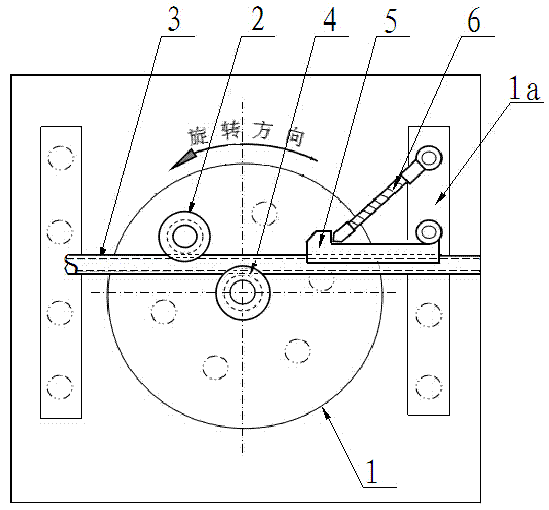

[0023] Example 1: see Figure 1 to Figure 4 , a steel bar bending machine, comprising a machine tool and a transmission mechanism installed on it, the upper part of the machine tool is connected to the transmission mechanism, and a working disc 1 driven to rotate by the transmission mechanism is provided with a positioning plate 1a and a feeding roller, and The positioning plate 1a and the feeding roller are symmetrically arranged on both sides of the working disc 1. Specifically, the positioning plate 1a is preferably made of square steel, which is not only convenient for installation, but also facilitates the installation of the positioning plate 5 (detailed below). Has a central shaft hole and a curved shaft hole.

[0024] The central shaft hole is located at the center of the working disk 1, and a central pile sleeve wheel 4 is installed in the central shaft hole, and the outer surface of the central pile sleeve wheel 4 has a first groove arranged along its circumference...

Embodiment 2

[0027] Example 2: A method of using a steel bar bending machine, the steel bar bending machine is described in embodiment 1;

[0028] Step 1: According to the description in Embodiment 1, a plurality of first grooves are processed on the outer surface of the central pile sleeve wheel 4, and a plurality of second grooves are processed on the outer surface of the auxiliary pile guide wheel 2. When the plate 5 is in use, a plurality of third grooves are processed towards the side of the central pile sleeve wheel 4;

[0029] Step 2: Then install the central pile sleeve wheel 4 in the center shaft hole, install the auxiliary pile guide wheel 2 in the curved shaft hole, install the positioning baffle plate 5 between the positioning plate 1a and the working disc 1, and adjust the screw rod 6 is installed between the positioning baffle plate 5 and the square steel 1a;

[0030] Step 3: Pass the straight steel bar or metal pipe 3 to be bent through the first groove, the second groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com