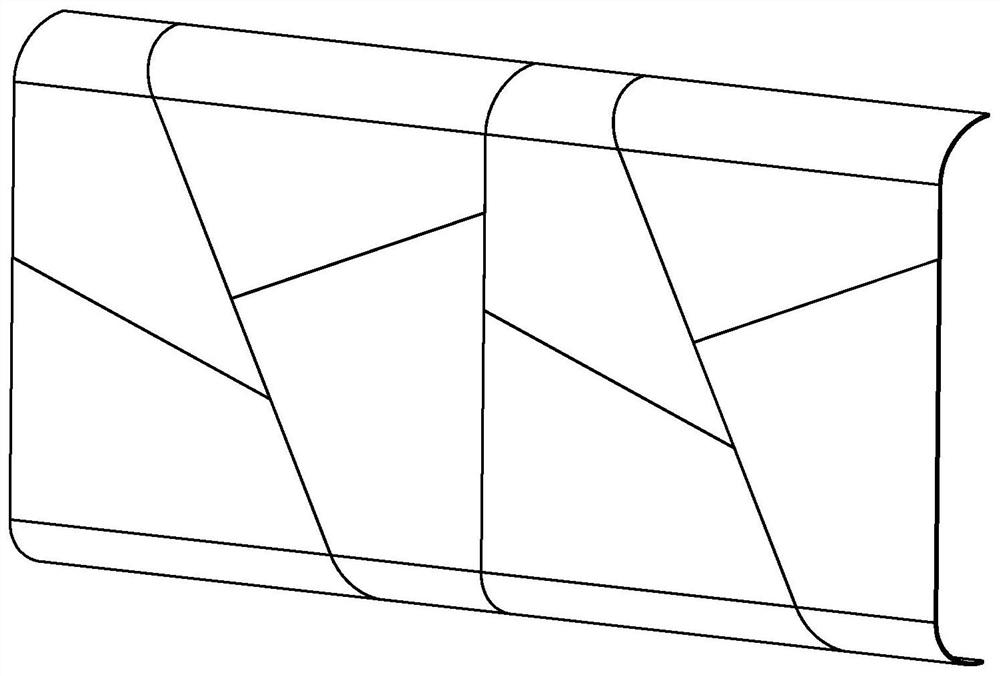

Arc bending device and arc bending method for polygonal plate

An arc bending device and polygonal technology, which is applied in the field of polygonal plate production and processing, can solve the problems of insufficient arc surface accuracy, long processing cycle, and uneven unevenness, and achieve the effect of simple processing and guaranteed arc bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The application will be described in further detail below in conjunction with the accompanying drawings.

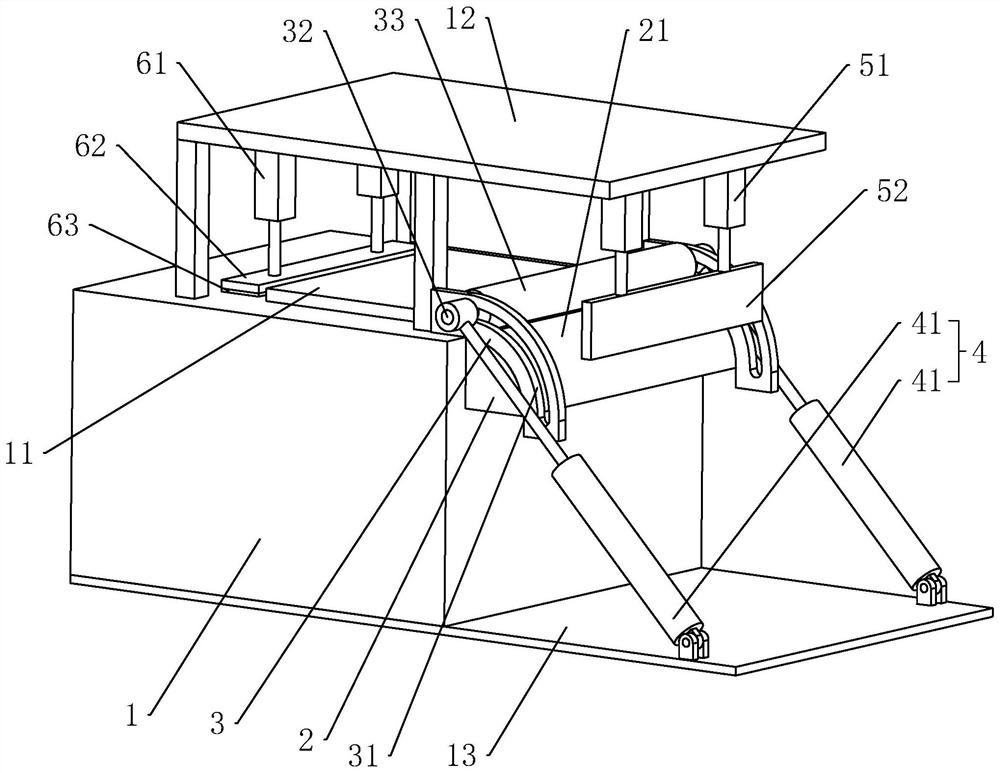

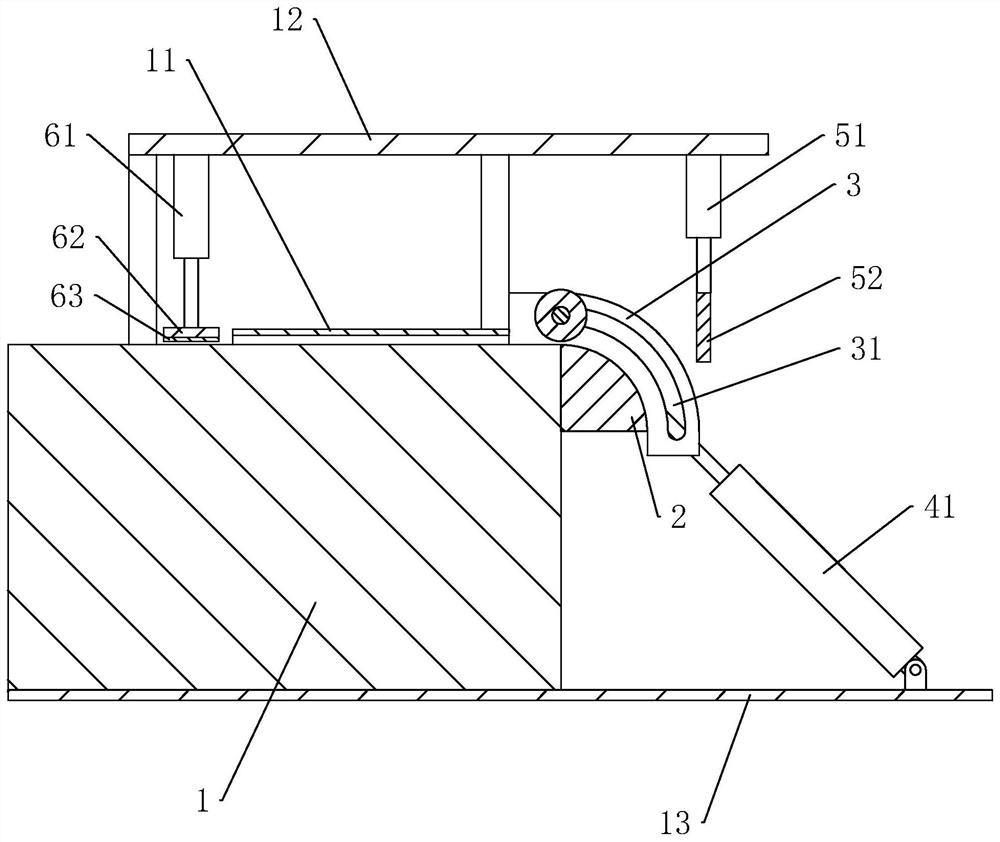

[0048] refer to figure 2 , is a polygonal plate bending device disclosed in the embodiment of the present application, including a worktable 1 , a pressure body 2 , a guide rail 3 , a rotating shaft 32 , a pressure roller 33 and a driving device 4 .

[0049] refer to figure 2 and image 3 , the workbench 1 has a square structure as a whole; the pressure-bearing body 2 is fixed on the upper part of one side of the workbench 1, and a curved surface 21 is formed on the pressure-bearing body 2, and the curved surface 21 is tangent to the upper surface of the workbench 1. In this embodiment The middle curved surface 21 is a quarter arc surface, and during production and processing, the radian of the curved surface 21 can be processed according to the actual situation.

[0050] There are two groups of guide rails 3, which are fixedly connected with the workbench 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com