Lateral positioning bending mold

A technology of bending die and side positioning, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing production costs and increasing the amount of materials used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

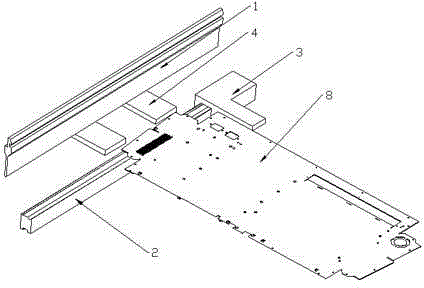

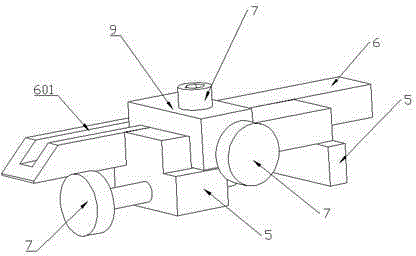

[0018] Side positioning bending mold, including: bending upper die 1, bending lower die 2, side backing 3 fixed on bending lower die 2, rear backing 4 aligned with product 8 bending positioning points; side backing 3 includes : fixed on the lower mold fixing seat 5 of the lower bending die 2, an adjusting piece for adjusting the distance between the side backing 3 and the product 8; The adjustable side block 6 is provided with a chute 601, the position of the adjustable side block 6 is adjusted through the chute 601, and the locking screw 7 is used to fix it to ensure that the product 8 can be completely aligned with the side 3 when bending. Alignment, it needs to be explained that the lower mold fixed block 5 and the adjustable side block 6 are connected through the connecting block 9; the connecting block 9 is clipped in the chute 601 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com