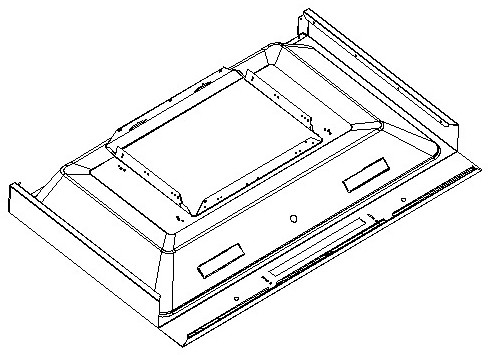

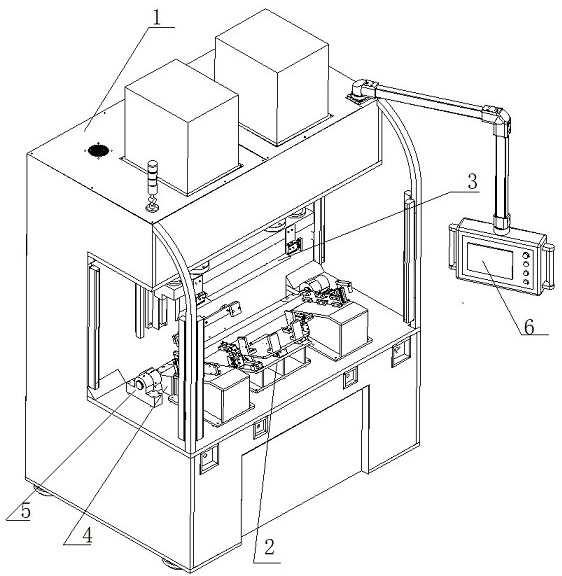

Flanging and bending equipment for metal plate shell of range hood

A machine sheet metal and equipment technology, which is applied in the field of flanging and bending equipment for range hood sheet metal shells, can solve the problems of increased scrap rate, low work efficiency, and high labor intensity, and achieve the effect of precise and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

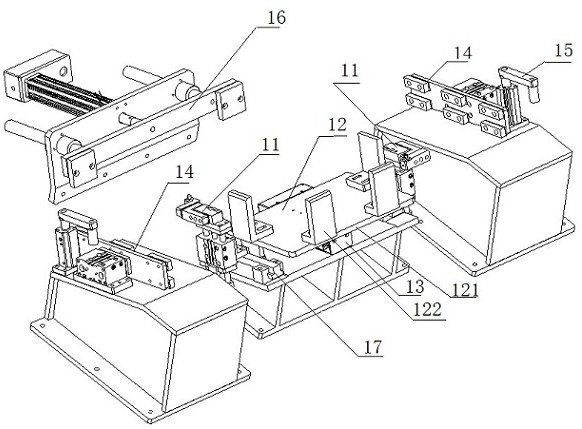

[0044] When feeding, put the edge of the sheet metal to be bent into the surface of the inner lower turning die assembly, and the cavity of the sheet metal is inserted into the multiple pins of the auxiliary feeding assembly, and manually adjust the position of the sheet metal until the sheet metal The through hole on the surface coincides with the pin hole on the surface of the main and auxiliary positioning pin assembly, and inserts the pin column into the through hole of the sheet metal and the main and auxiliary positioning pin hole. The clamping cylinder presses the sheet from above, and the cylinders on the left and right mounting brackets press the sheet from both sides. At this time, after the sheet is fixed, the upper pressing die assembly falls, driving the upper bending die to press the sheet and fold it. Bending position, then rotate left and right to compress the cylinder, and the cylinder on the left and right mounting brackets releases the sheet metal at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com