Patents

Literature

40results about How to "Consistent Dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

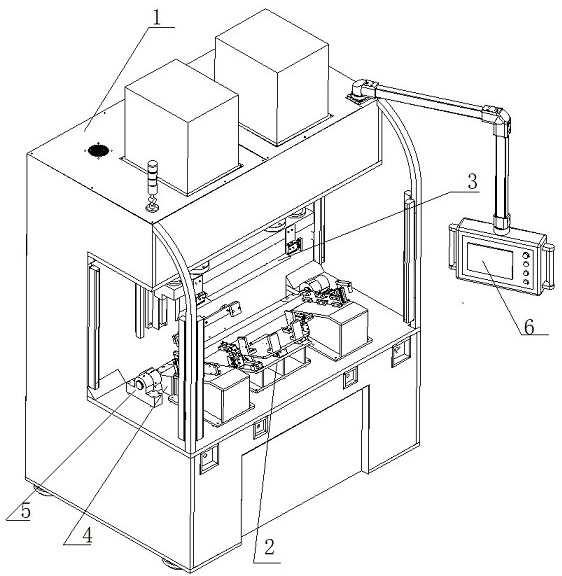

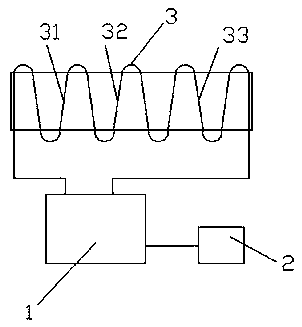

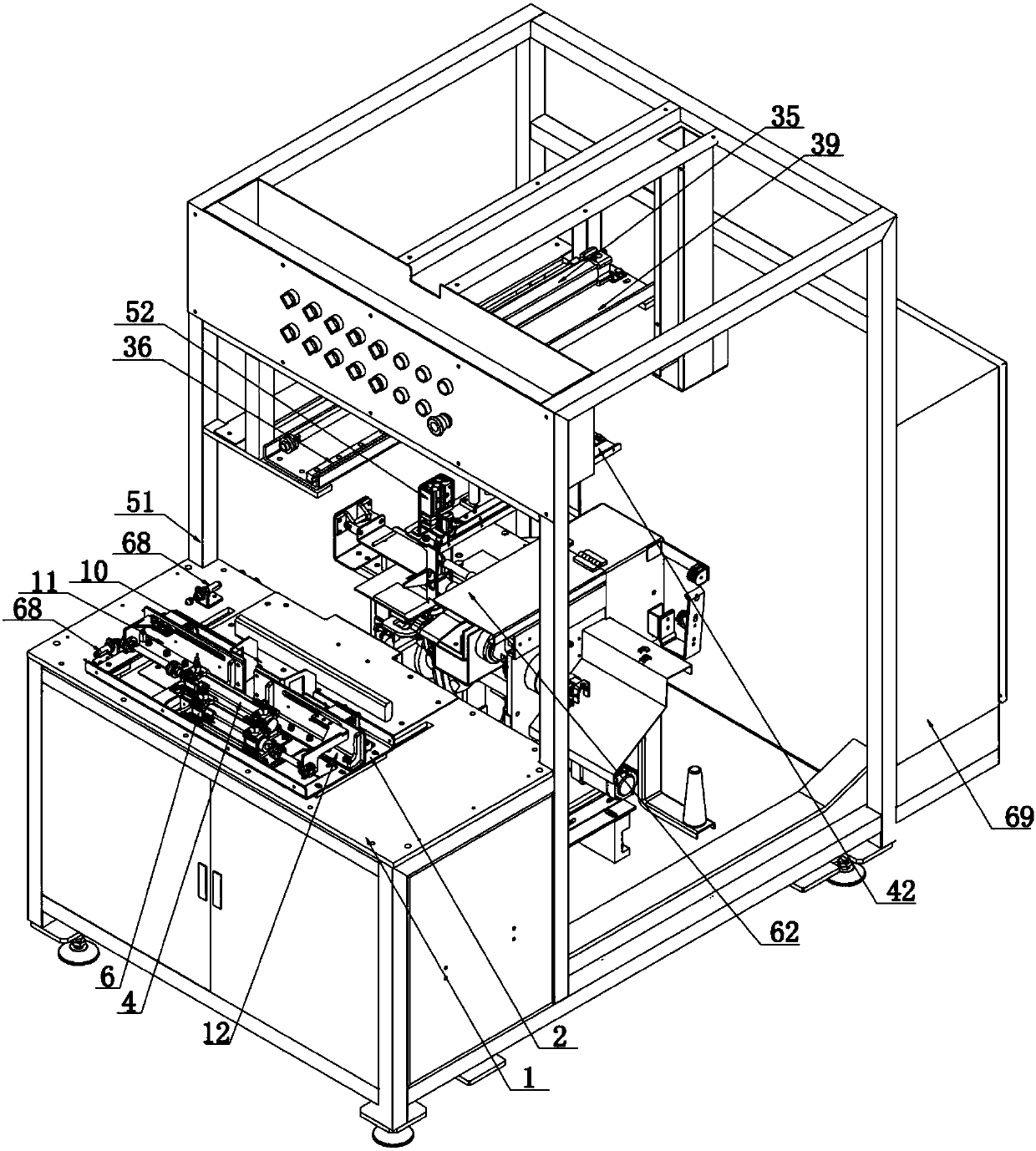

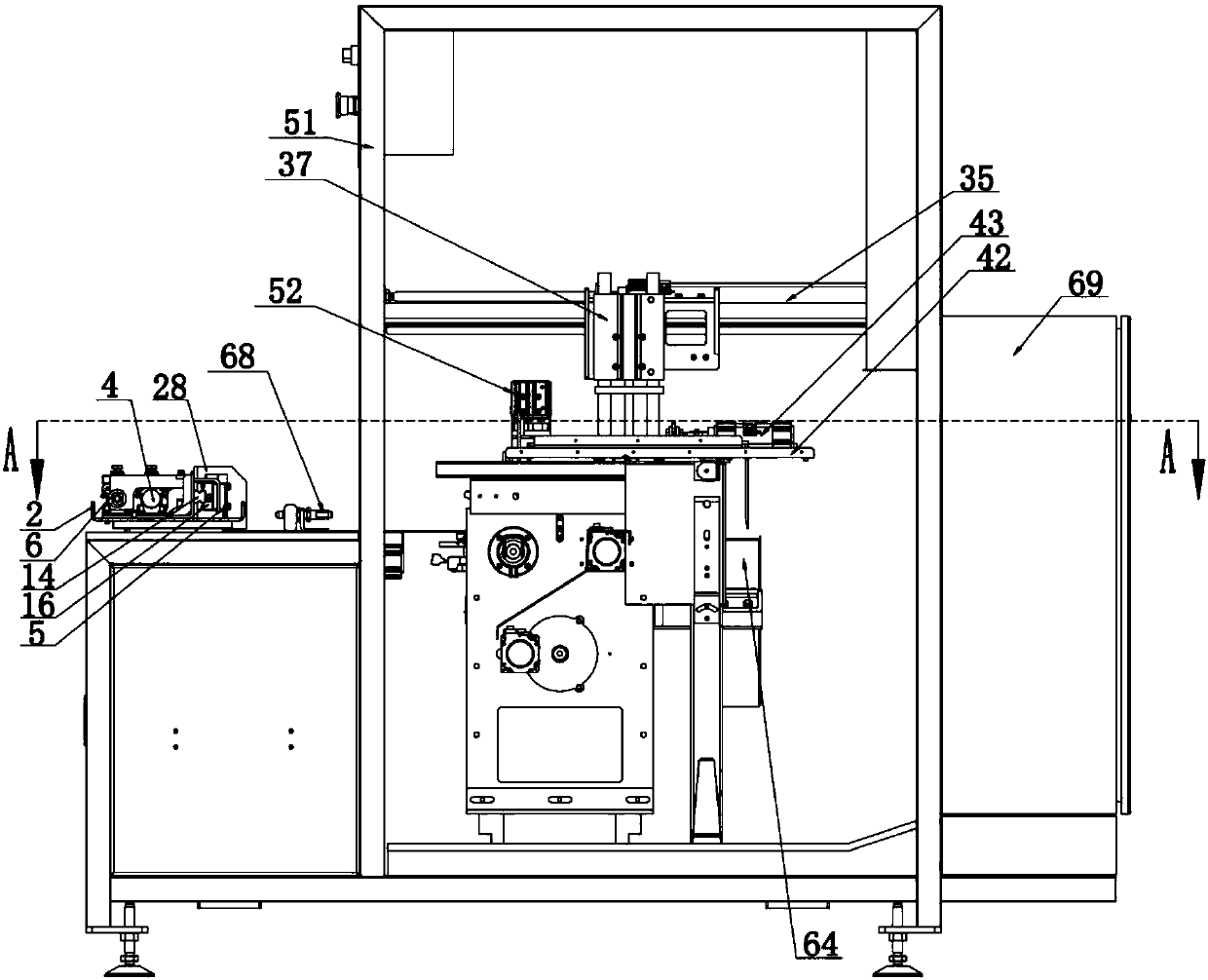

Automatic laser cleaning device used for cleaning aircraft parts

PendingCN108202052AControl spot sizeGuaranteed Surface DimensionsCleaning processes and apparatusHydraulic cylinderAutomatic control

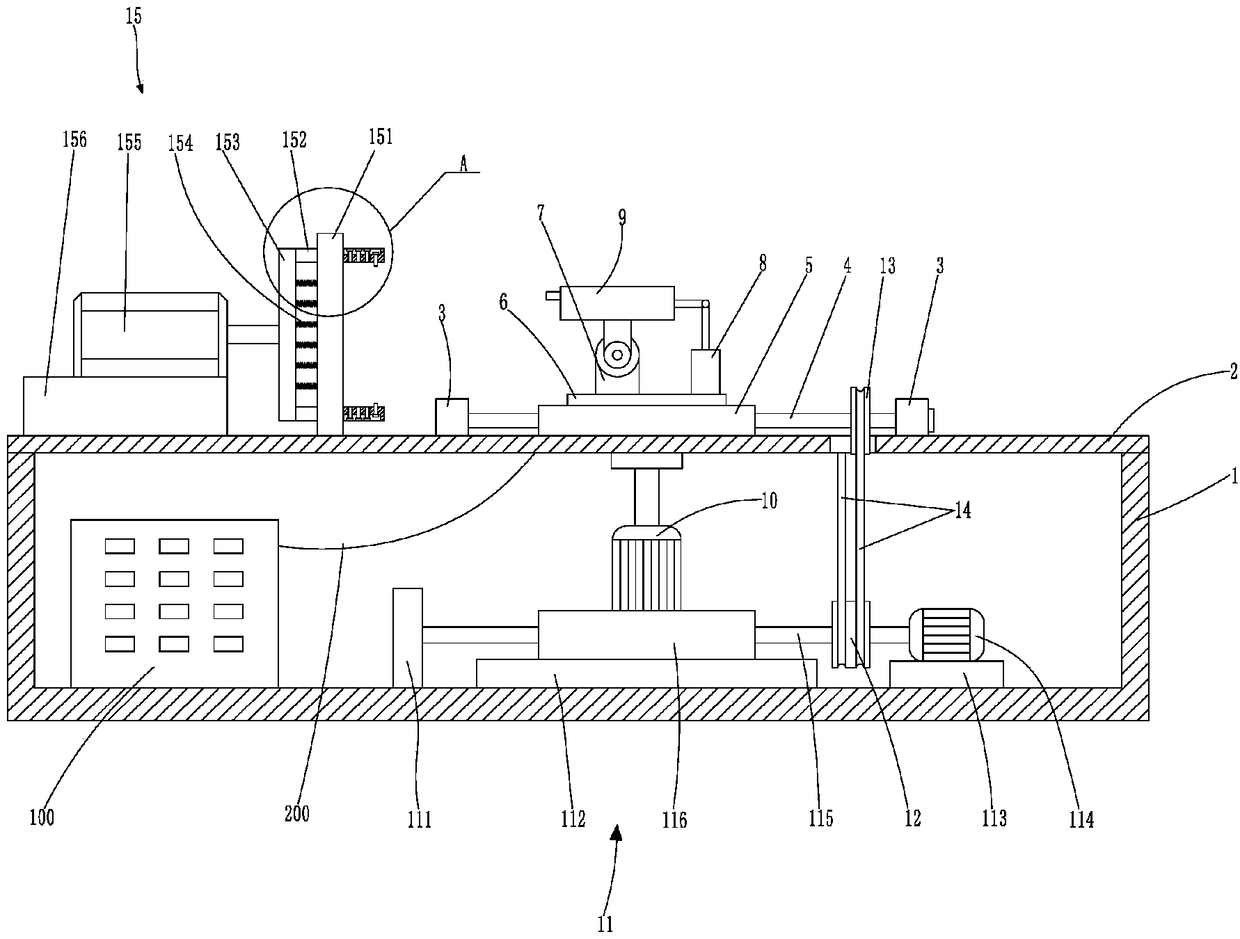

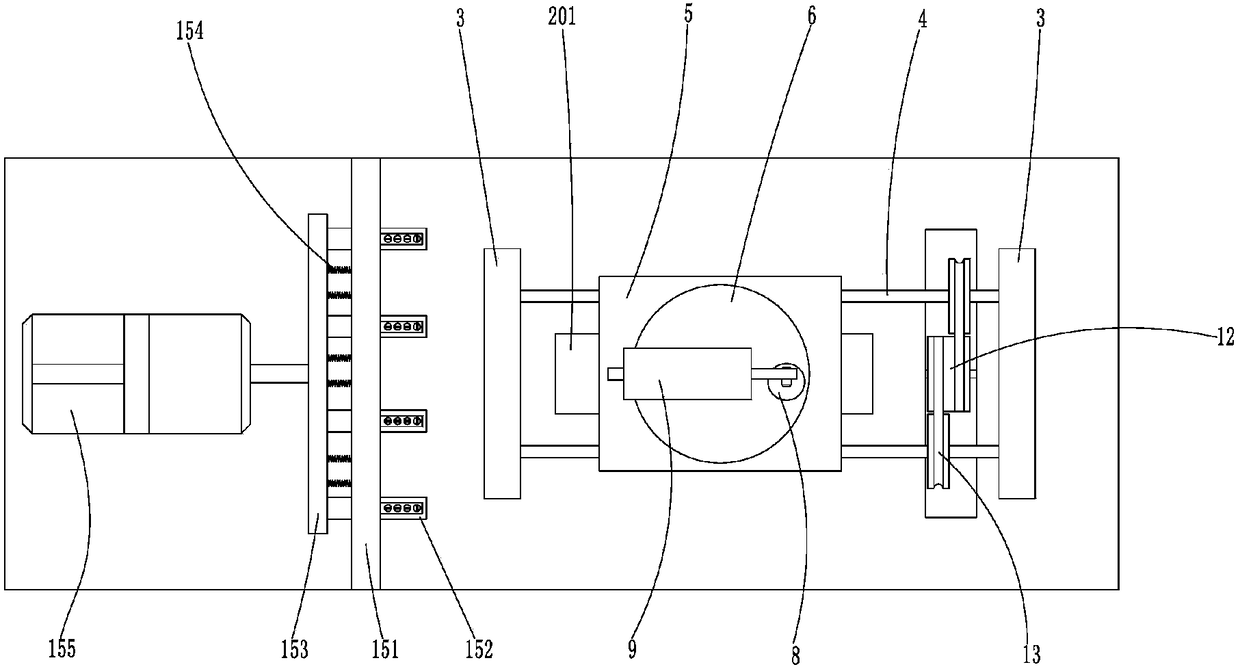

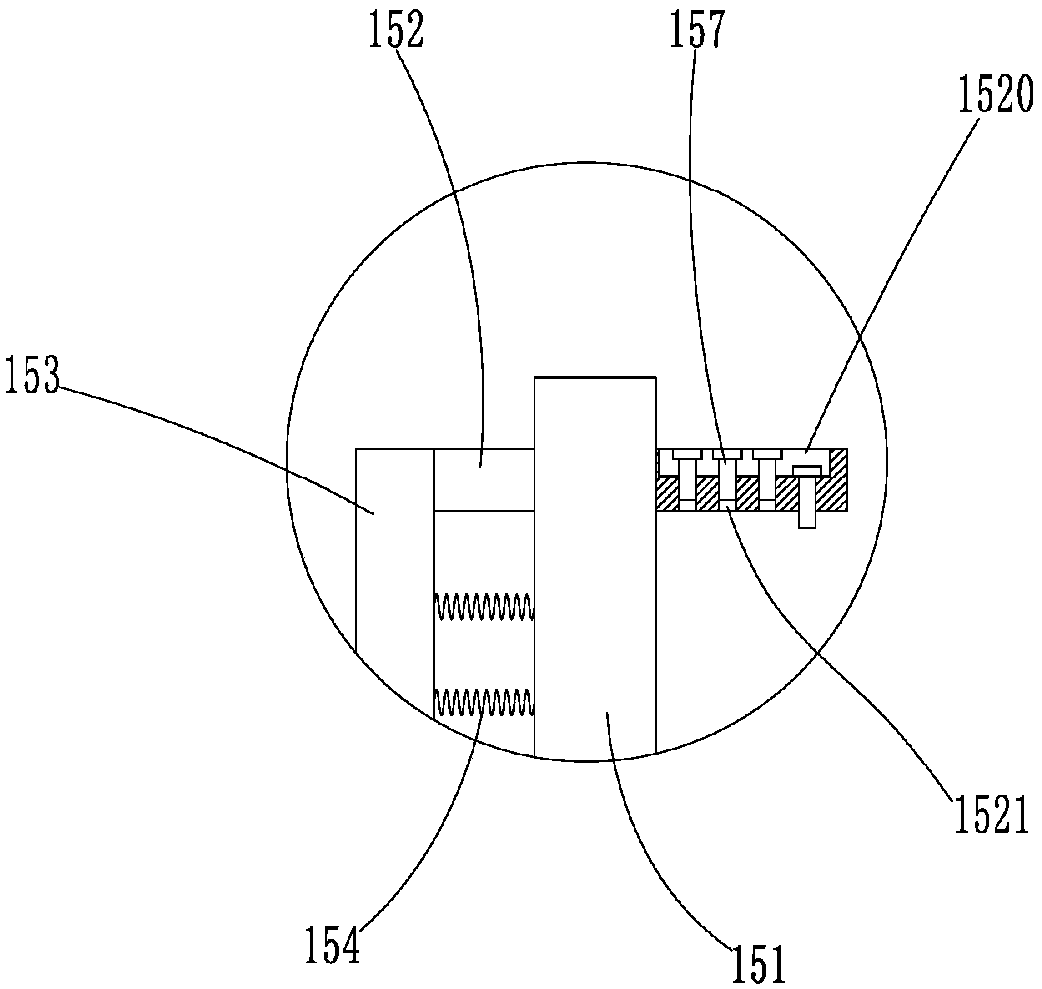

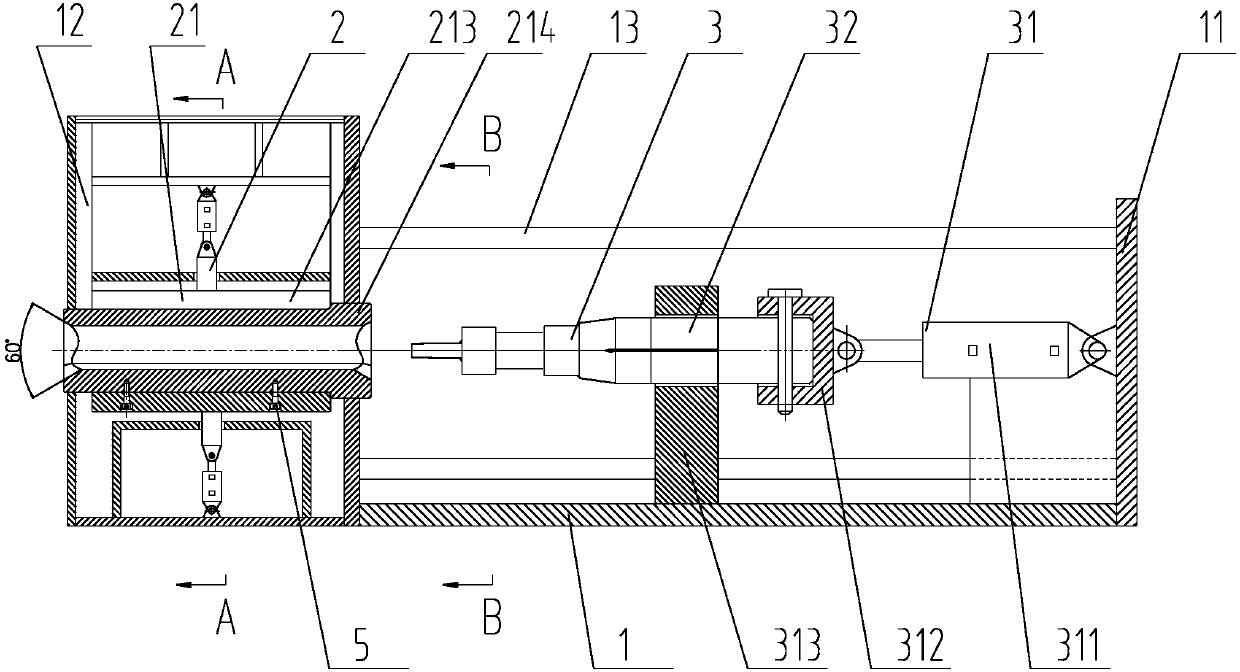

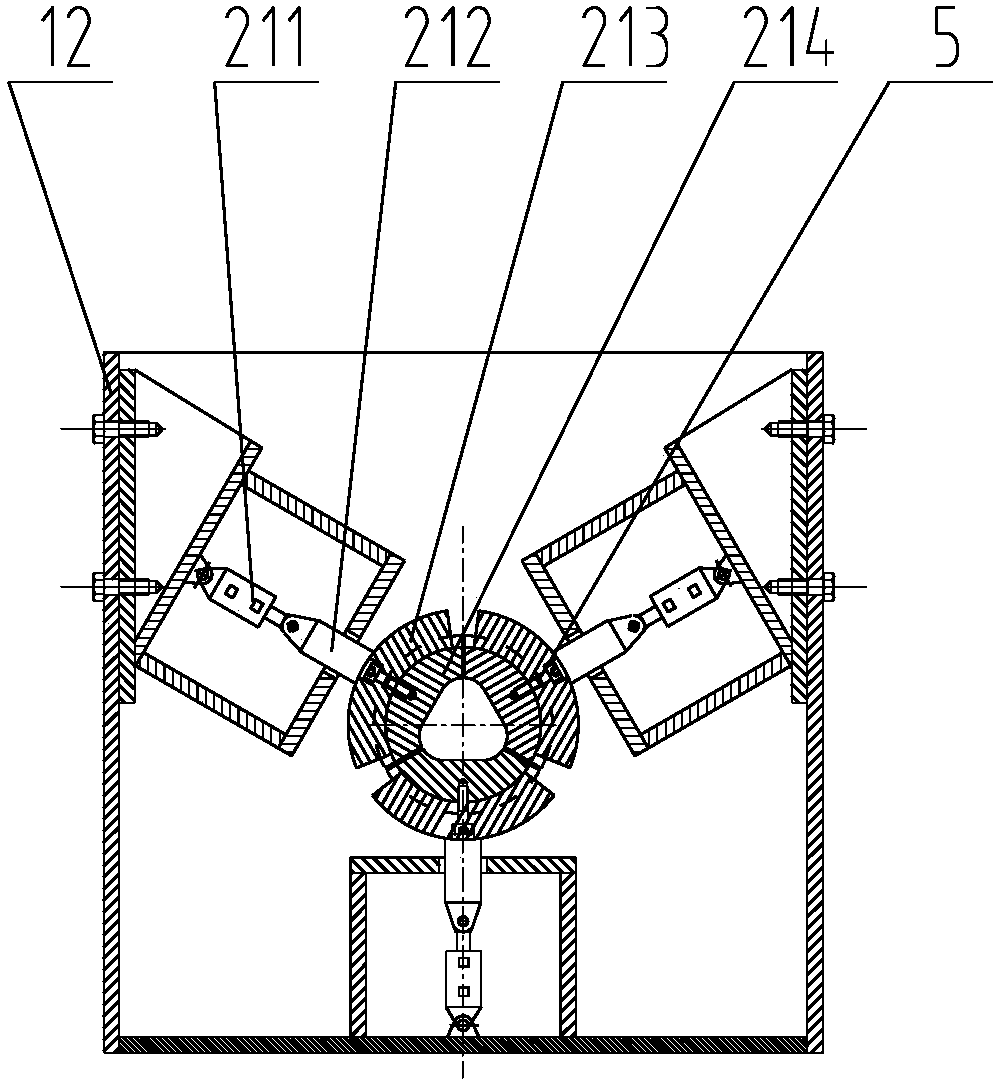

The invention provides an automatic laser cleaning device used for cleaning aircraft parts. The automatic laser cleaning device comprises an open machine base. A supporting plate is fixedly connectedto the machine base. A rectangular hole is formed in the supporting plate. Two positioning blocks located outside the rectangular hole are arranged on the supporting plate. Two parallel first lead screws are rotatably arranged between the two positioning blocks. A sliding base in sliding fit with the supporting plate is arranged on the two first lead screws in a threaded fit mode. A rotary disc isrotatably arranged on the sliding base. A rotary base and a vertical hydraulic cylinder are fixedly connected to the rotary disc. A laser cleaning head connected with a laser generator through an optical fiber is rotatably arranged on the rotary base. The tail end of the laser cleaning head is rotatably connected with a piston rod of a vertical hydraulic cylinder. The rotary disc stretches into the machine base and is connected with a first driving motor. A driving mechanism used for driving the first driving motor and the sliding base to synchronously move is arranged in the machine base. Apositioning tool is further arranged on the supporting plate. The position and swinging of the laser cleaning head are controlled automatically, and the spot size of laser irradiated on an object is controlled, so that the adjustment time is short, and the response speed is high.

Owner:彭州启光科技有限公司

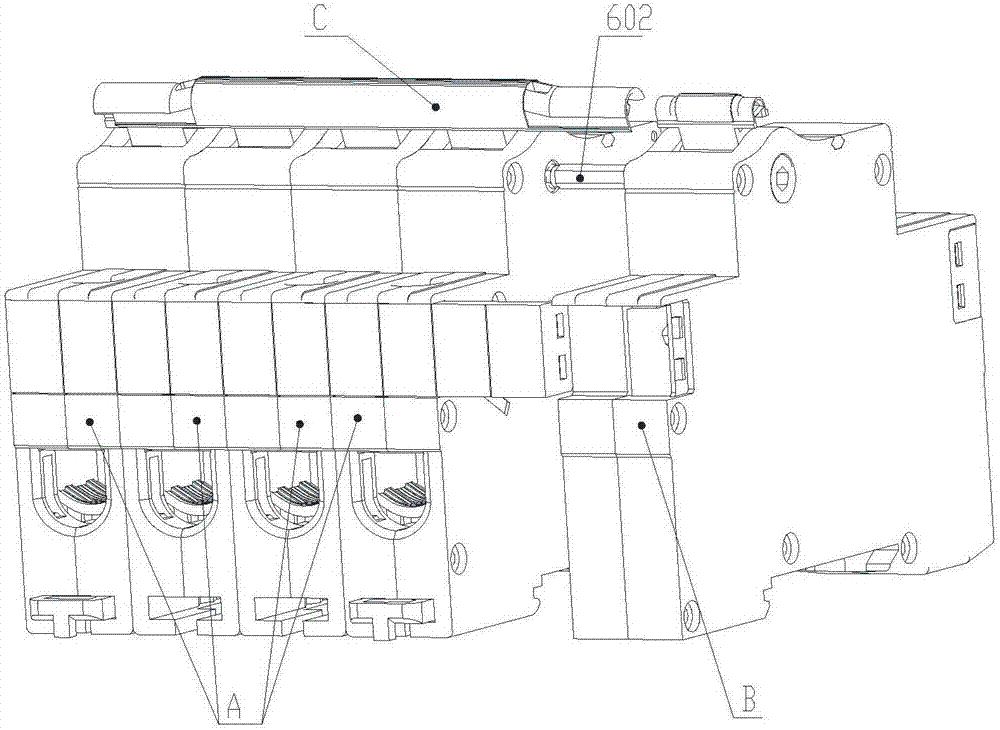

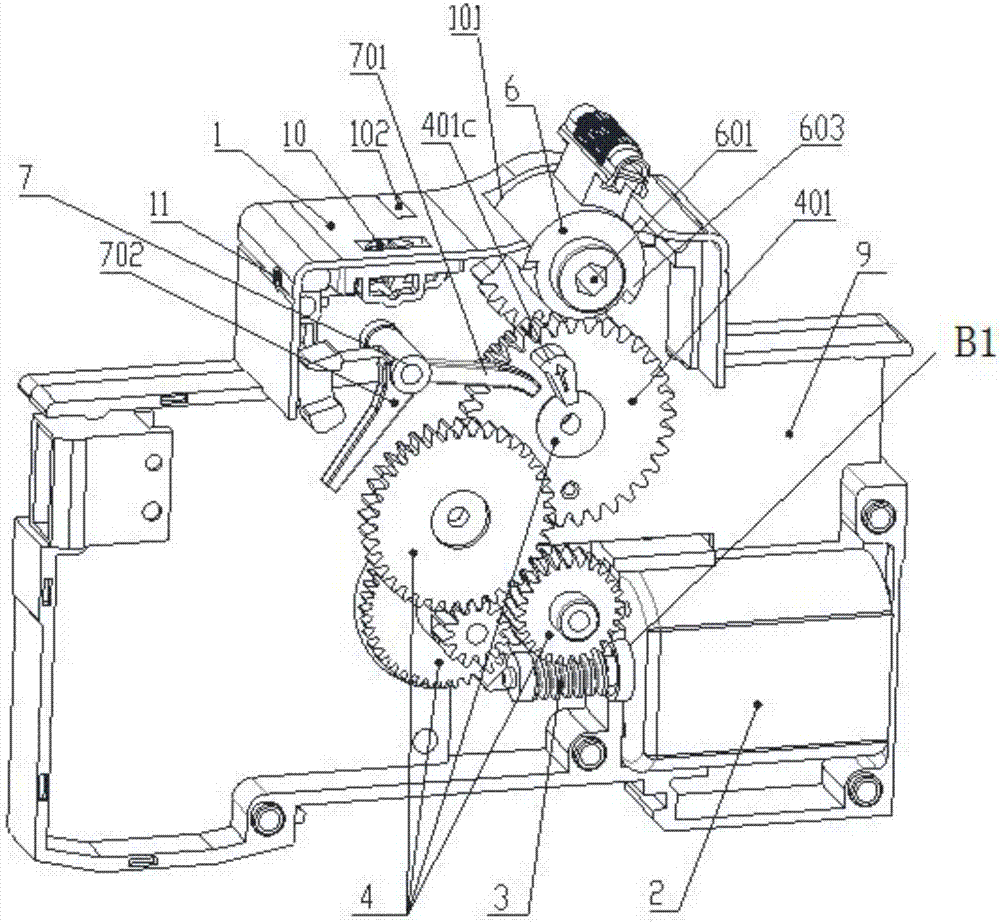

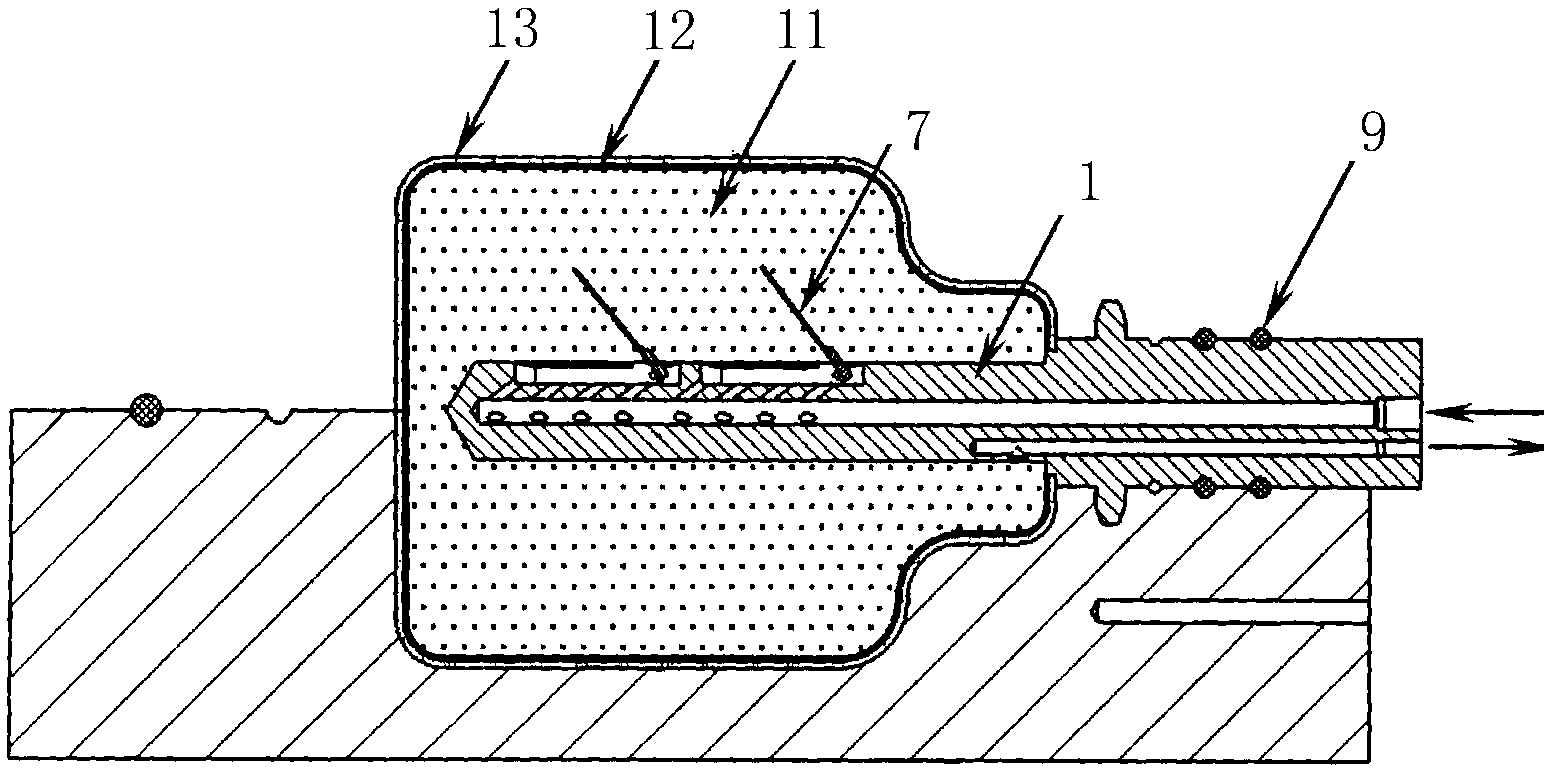

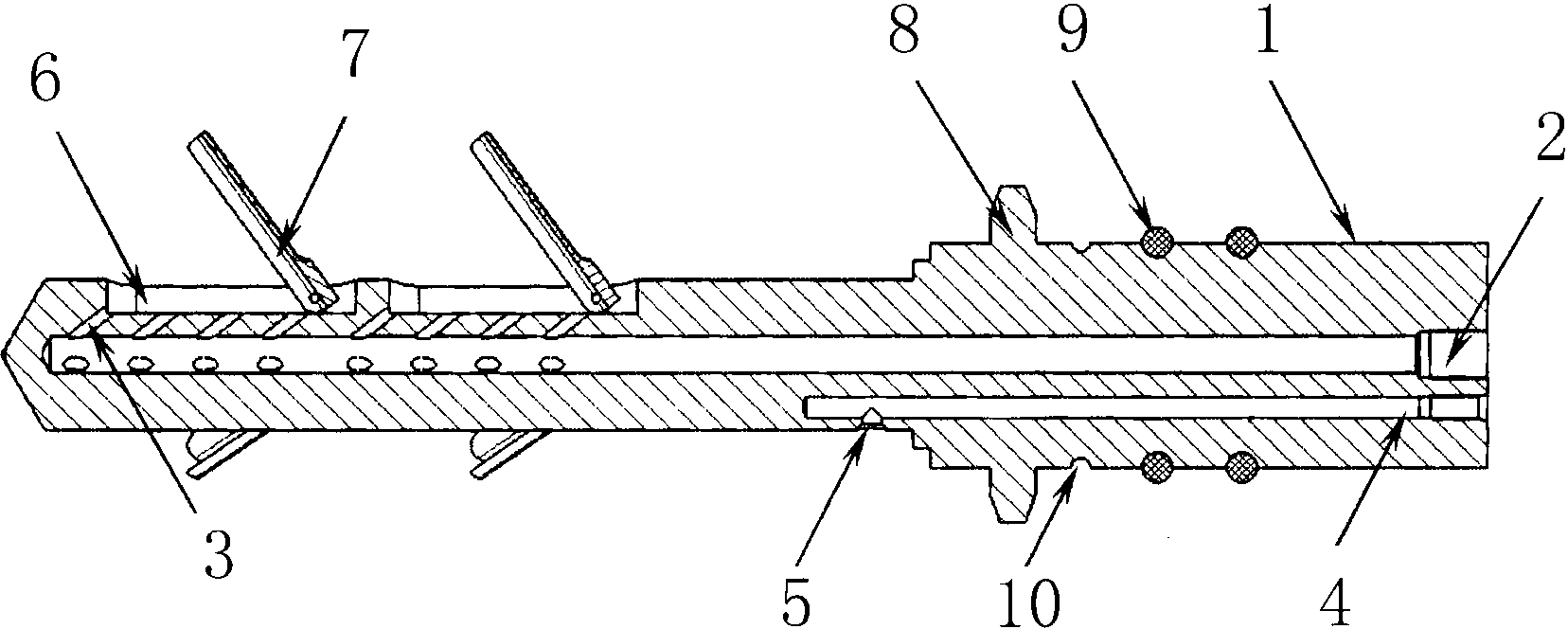

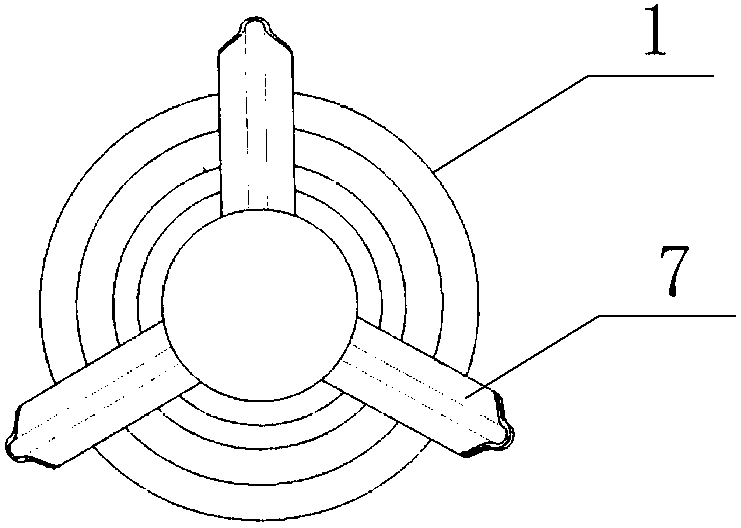

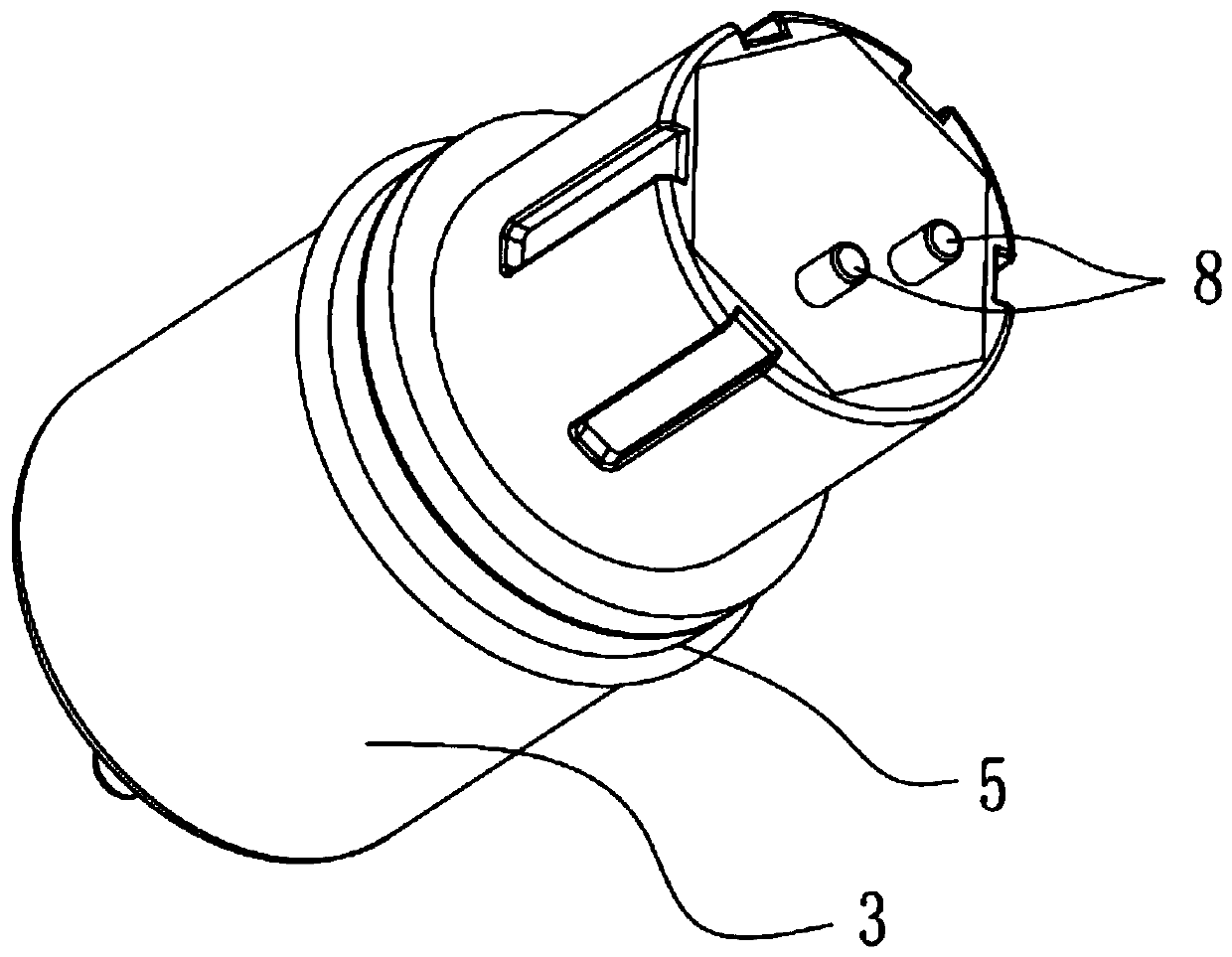

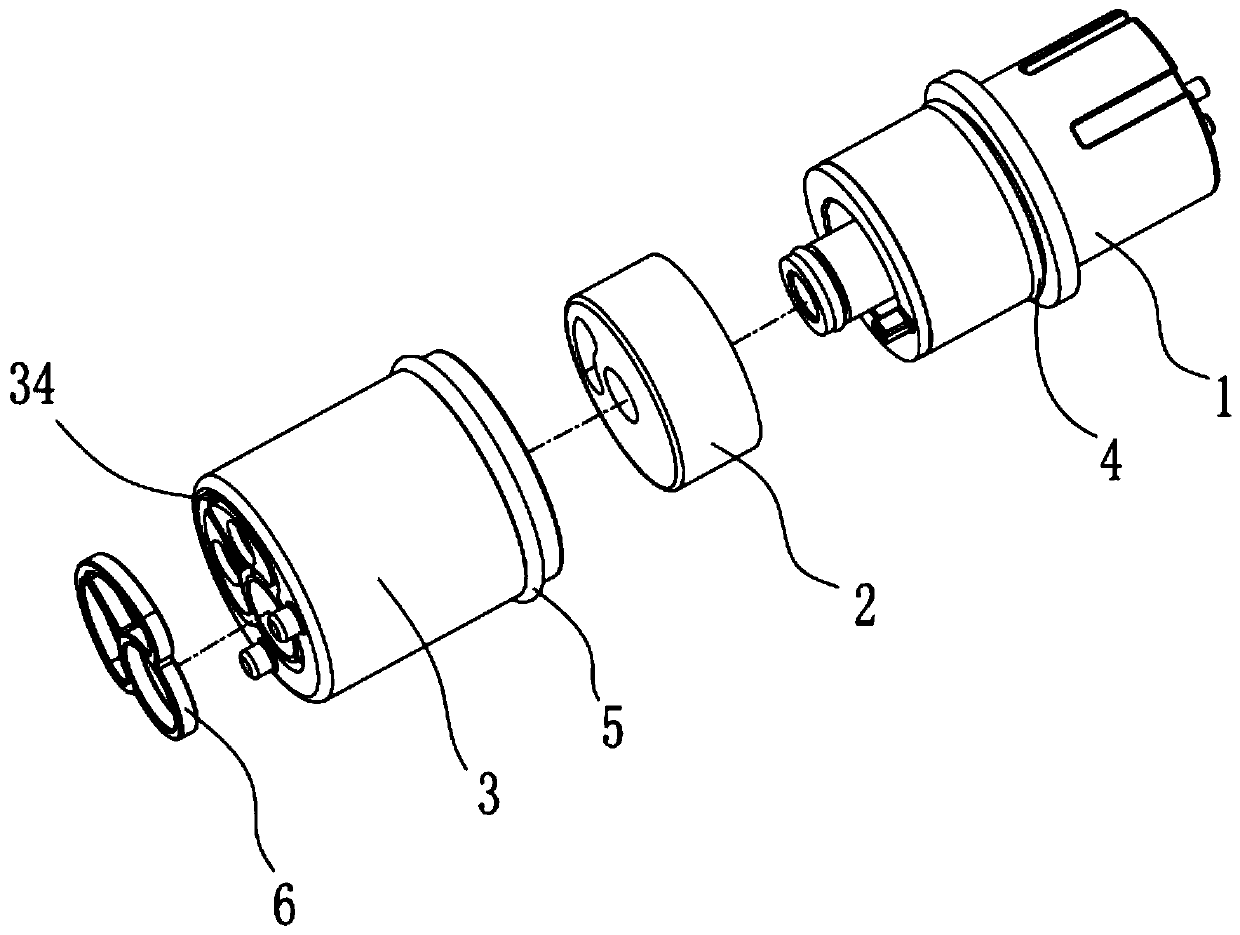

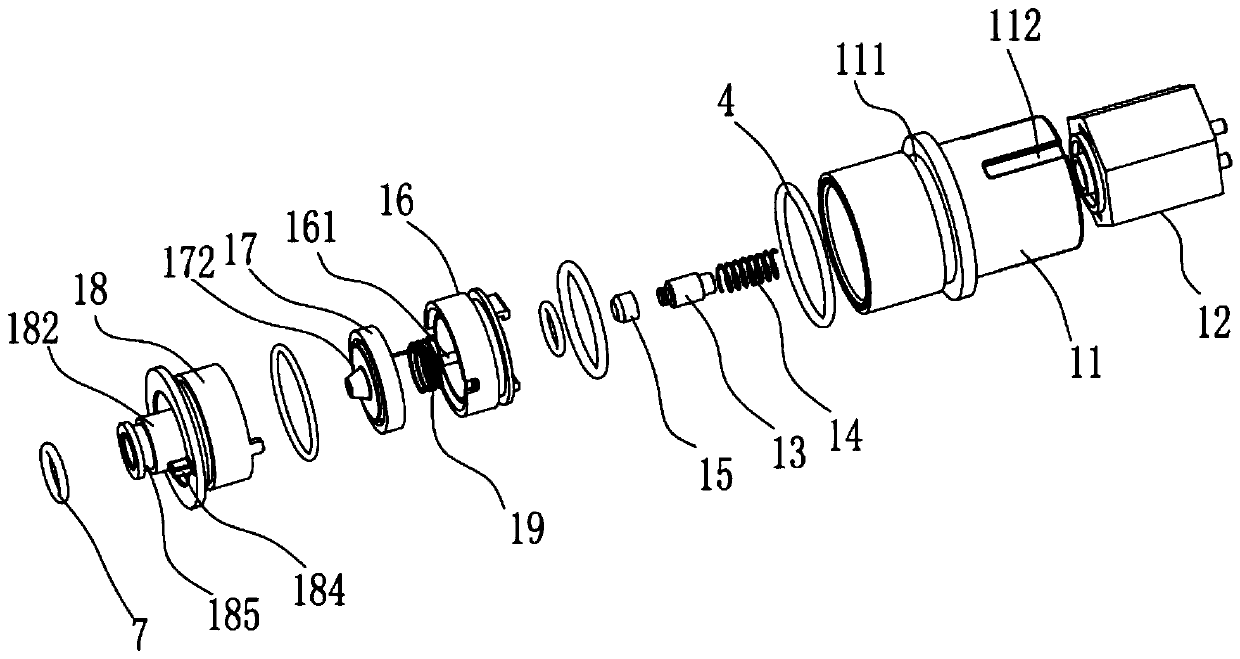

Motor-operated small-size circuit breaker with trip protection function

InactiveCN107230591AConsistent DimensionsEasy to installProtective switch terminals/connectionsProtective switch operating/release mechanismsComputer moduleCircuit breaker

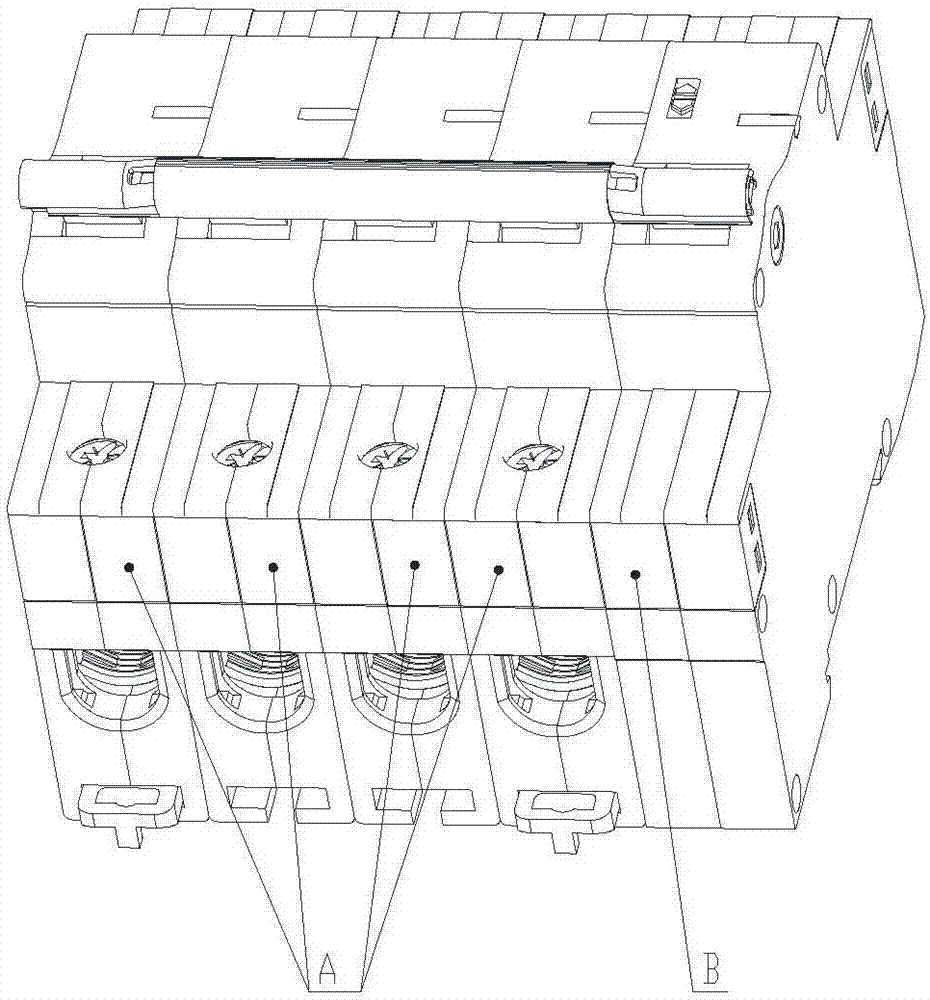

The invention relates to a motor-operated small-size circuit breaker with a trip protection function. The motor-operated small-size circuit breaker comprises at least one level of small-size circuit breaker (A) and a motor-operated device (B), wherein the small-size circuit breaker (A) and the motor-operated device (B) are connected by employing side-surface splicing, the motor-operated device (B) controls the small-size circuit breaker (A) to do breaking-closing operation, the motor-operated small-size circuit breaker is characterized in that a trip linkage piece (7) is arranged on the motor-operated device (B) and can be linked with a trip rod (8) in the small-size circuit breaker (A) so that the trip rod (8) can trip. By the motor-operated small-size circuit breaker, the reliability and the stability of a product are improved, the appearance sizes of a motor-operated device module and a small-size circuit breaker module are completely consistent, the product volume is reduced, and a user is more rapid and convenient to install and use; and meanwhile, the small-size circuit breaker is directly driven to be rapidly trip from the interior by the motor-operated device, the purposes of the small-size circuit breaker is directly locked in a trip state by the motor-operated device and closing operation cannot be performed by an external handle under the special states of user arrearage and a rear-end circuit fault are achieved.

Owner:SHANGHAI LIANGXIN ELECTRICAL

Filler used for sewage plant external whole-process deodorization system and preparation method of filler

InactiveCN105236563AMeet the load requirements of long-term processing processesMeet load requirementsSustainable biological treatmentBiological water/sewage treatmentManufacturing technologyPortland cement

The invention relates to filler used for a sewage plant external whole-process deodorization system. The deodorization filler is prepared from, by mass, 45-48% of ordinary portland cement, 48-49% of plant ash, 1-2% of compound nutrients and the balance water. The strength of the filler can meet the load requirement in the long-time processing process. The biological filler can be applied to the sewage treatment whole-process biological deodorization system and has the advantages of being simple in manufacturing technology, low in cost, convenient and fast to install, free of fault points, long in service life and the like, the using requirement can be met, and the deodorization efficiency is improved.

Owner:天津诚信环球节能环保科技有限公司

Method for hollow molding of compound material and auxiliary assembly thereof

The invention relates to a method for hollow molding of a compound material, which comprises the following steps: 1) manufacturing a tire membrane by using a low-melting-point material; 2) covering a membrane isolating layer on the surface of the tire membrane; 3) covering a pre-soaking material on the membrane isolating layer, and then placing into a hot-pressing mould coated with a release agent; 4) injecting heated inert gases and increasing the temperature and pressure in a double-layer tire body; 5) ensuring consistent inner and outer temperatures of the compound material; 6) discharging the molten low-melting-point material from a cavity of a hollow auxiliary assembly; 7) molding the compound material under the conditions of high-temperature and high-pressure inert gases and mould temperature; and 8) pulling out the hollow auxiliary assembly and taking out the final compound material product, and removing the isolating layer, thereby obtaining the end product. According to the method, the quality is stable, the overall dimension is consistent, the whole strength is high, the wall thickness is uniform, the phenomenon of easiness in cracking due to ultralow strength is avoided, and meanwhile, the auxiliary assembly is adopted so that the extraction during the processing process is more convenient.

Owner:SHENYANG AIRCRAFT CORP

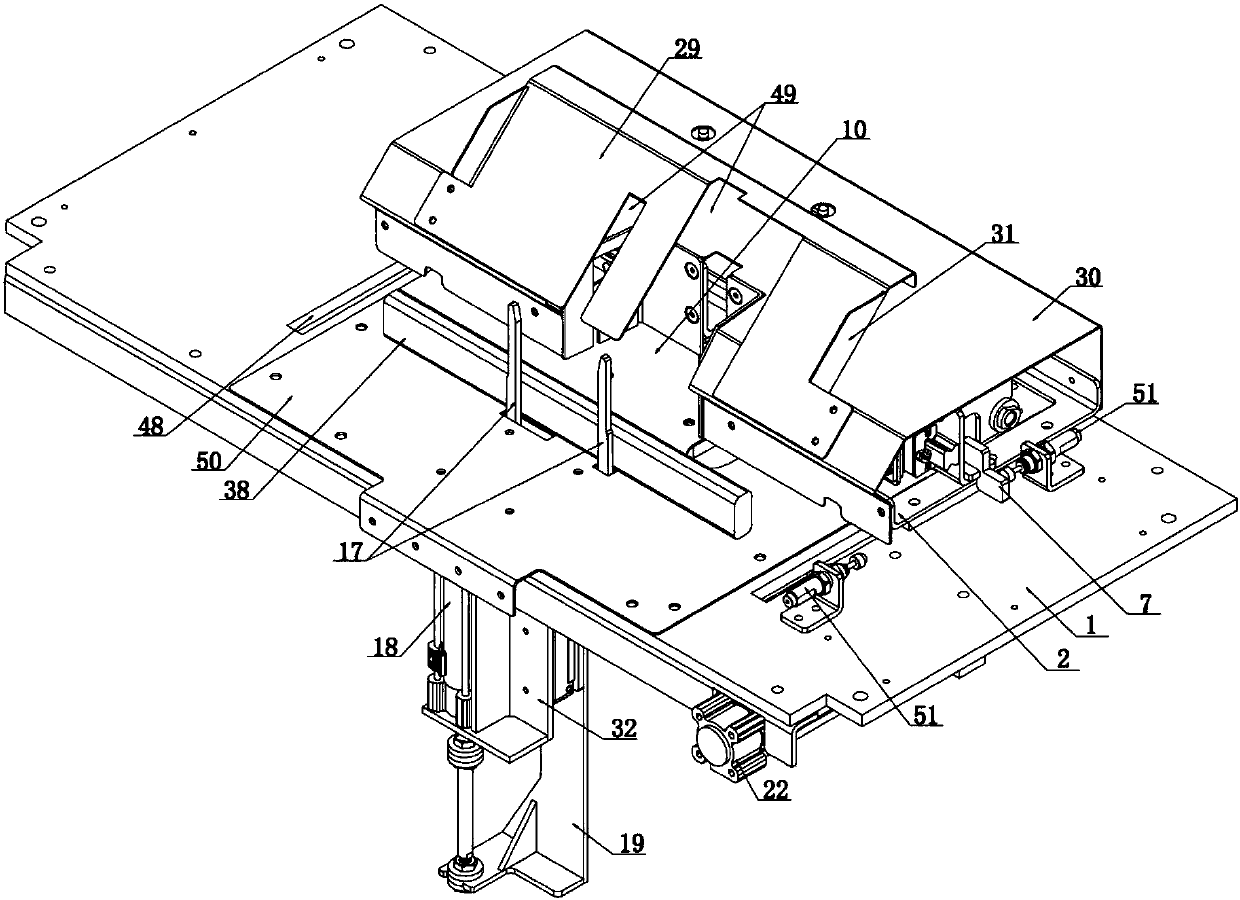

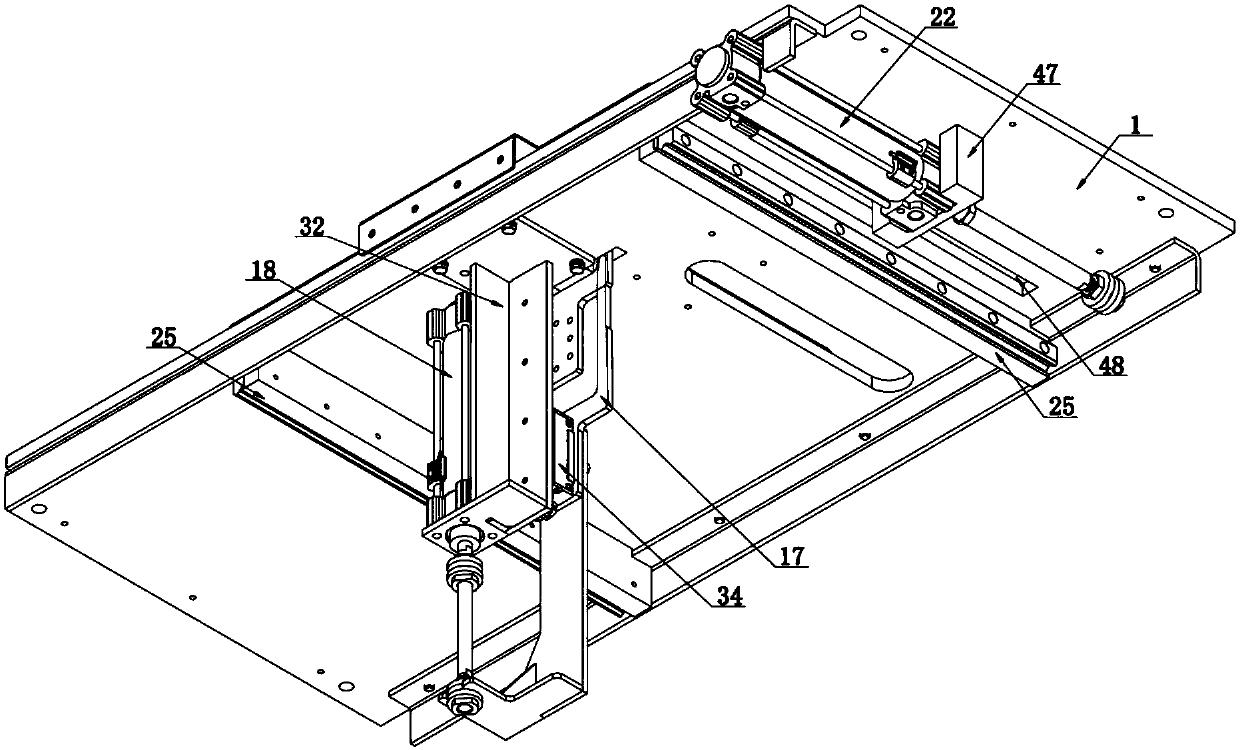

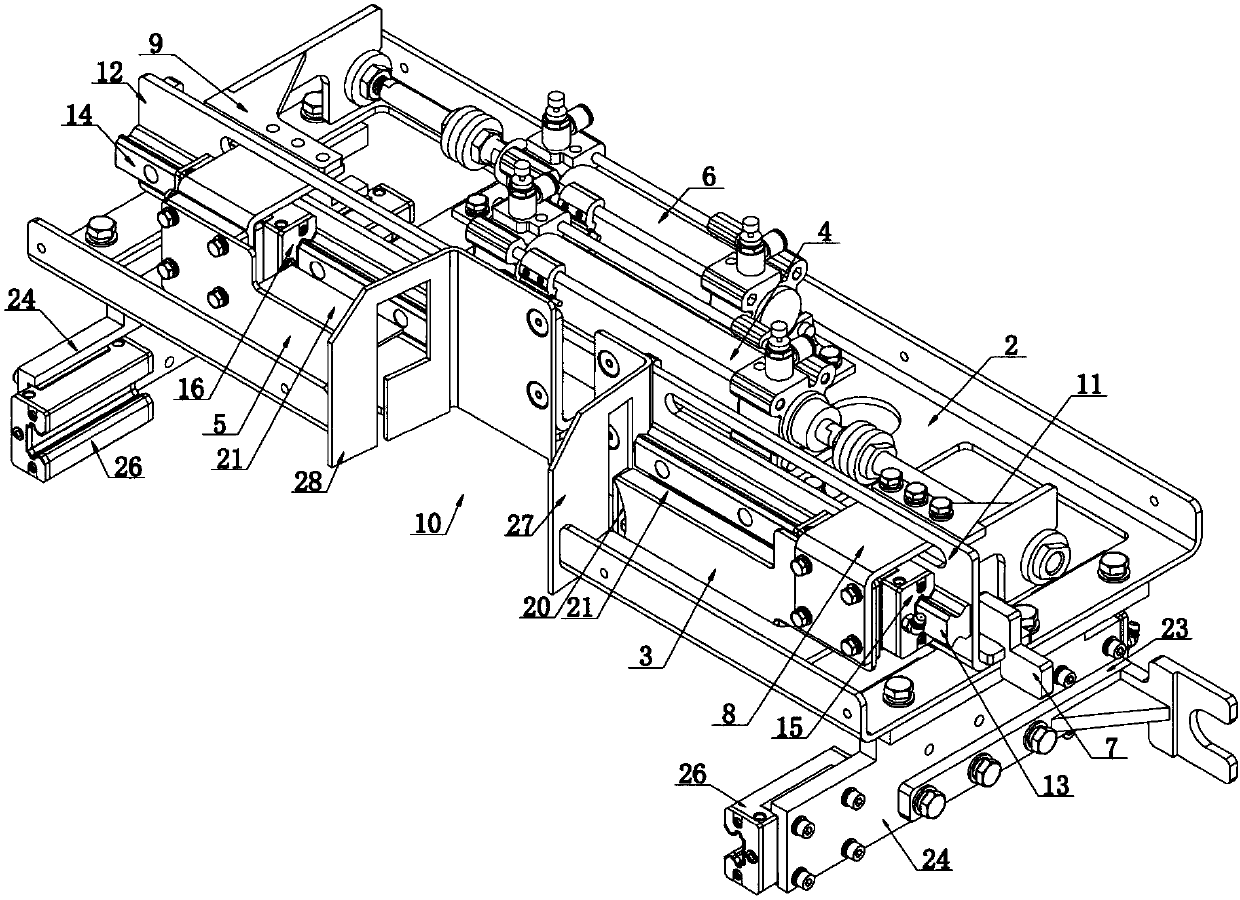

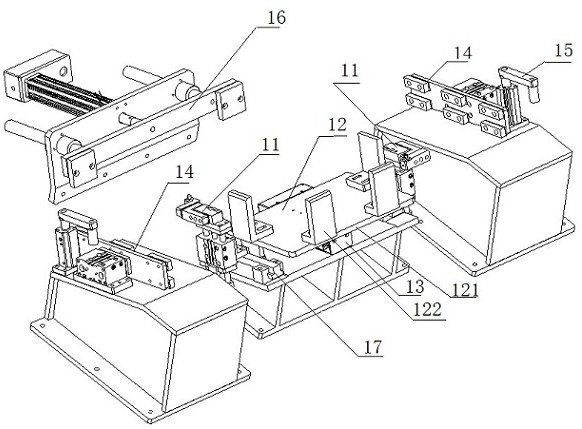

Automatic vermicelli folding device and bending method

ActiveCN105836236BSmooth slidingAchieve bendingPackaging foodstuffsFood scienceEngineeringFood packaging

Owner:YANTAI GANGYUAN MACHINERY CO LTD

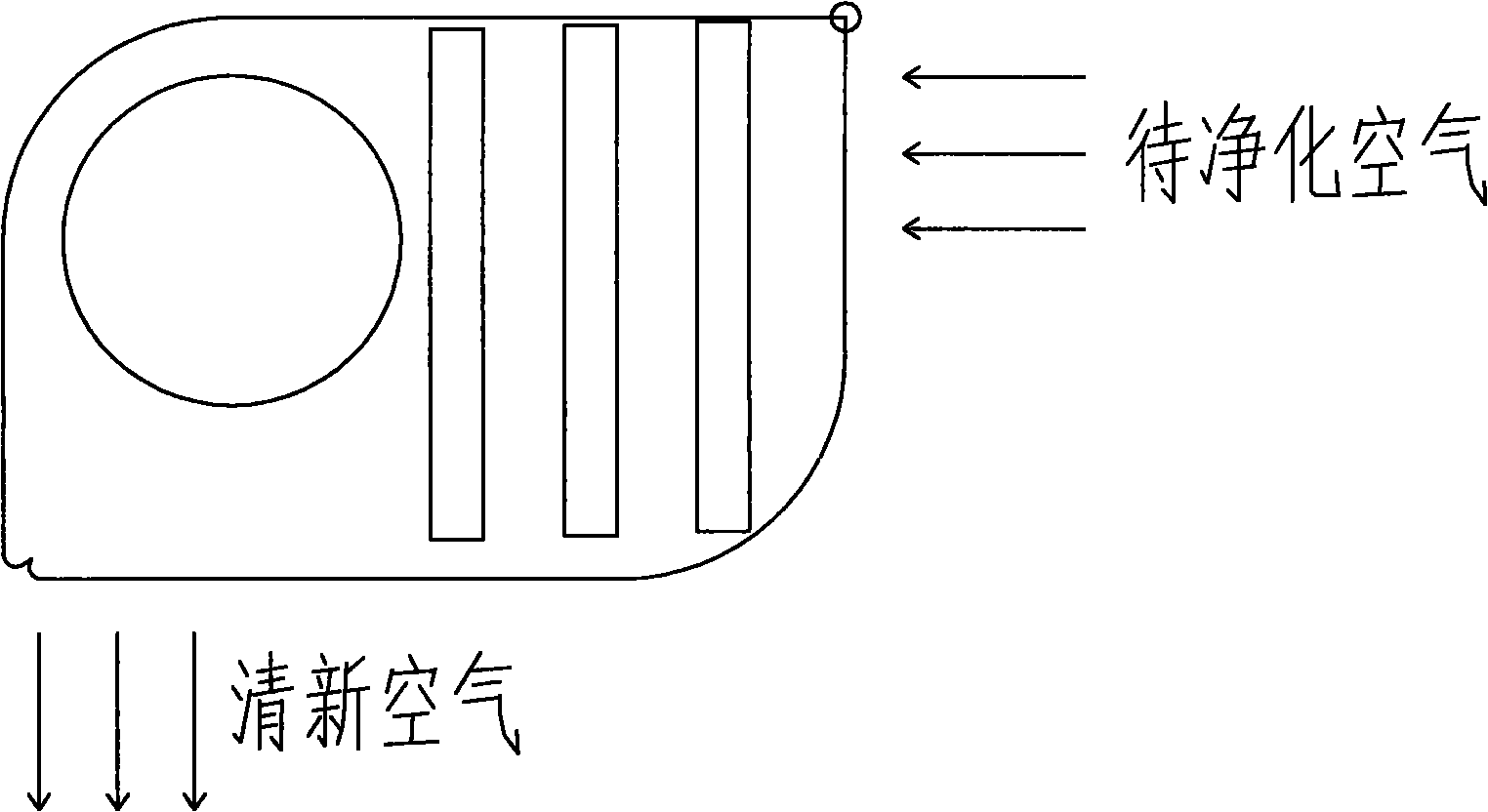

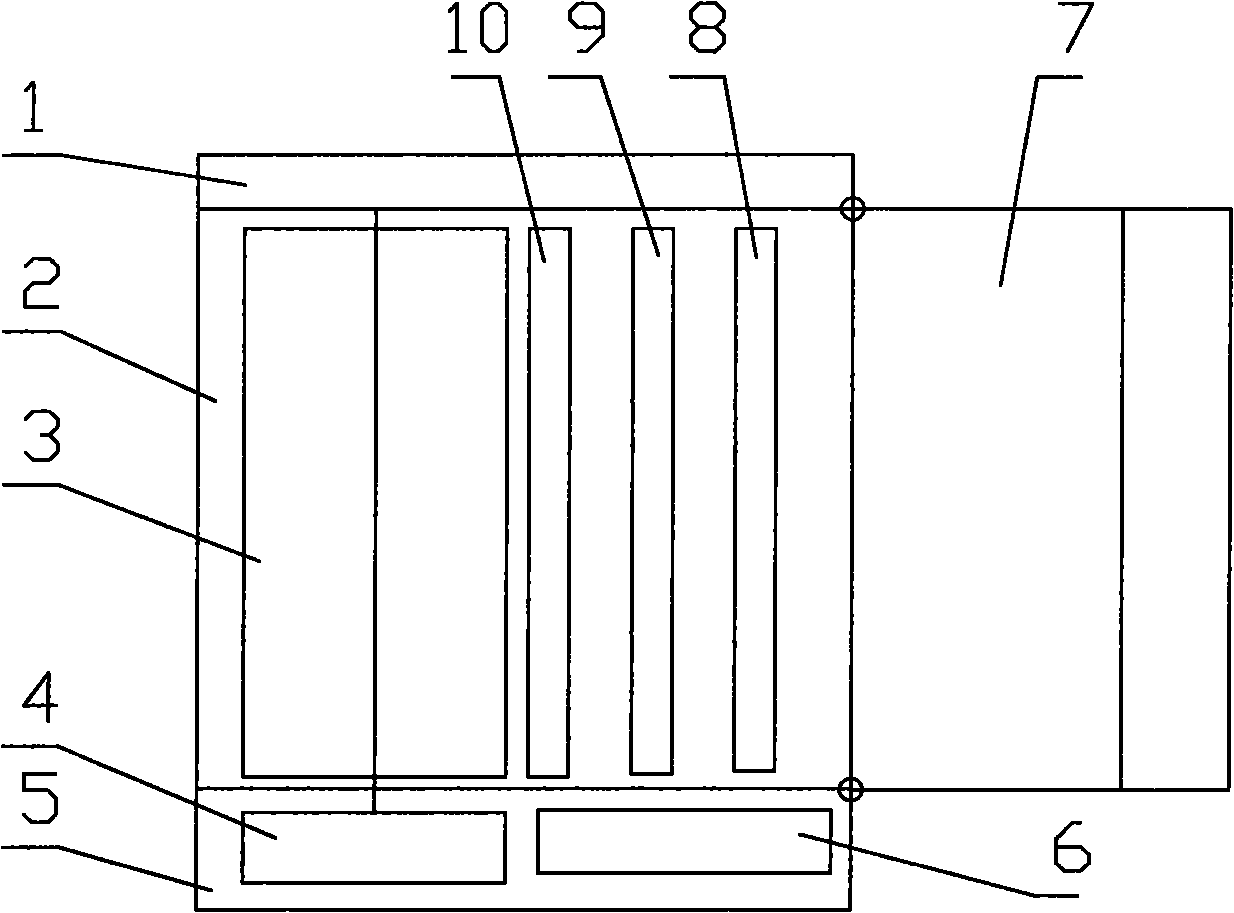

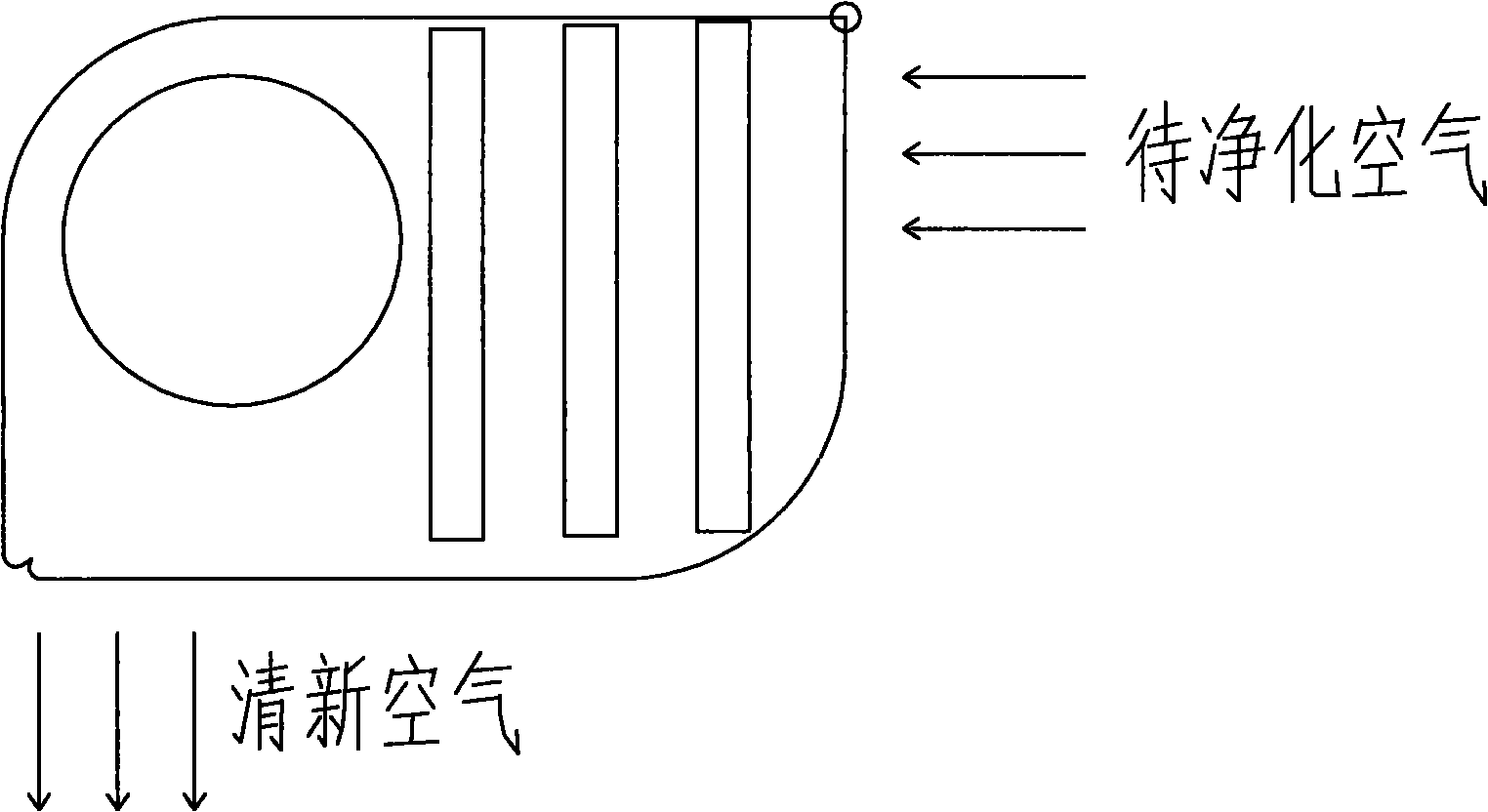

Air freshening machine

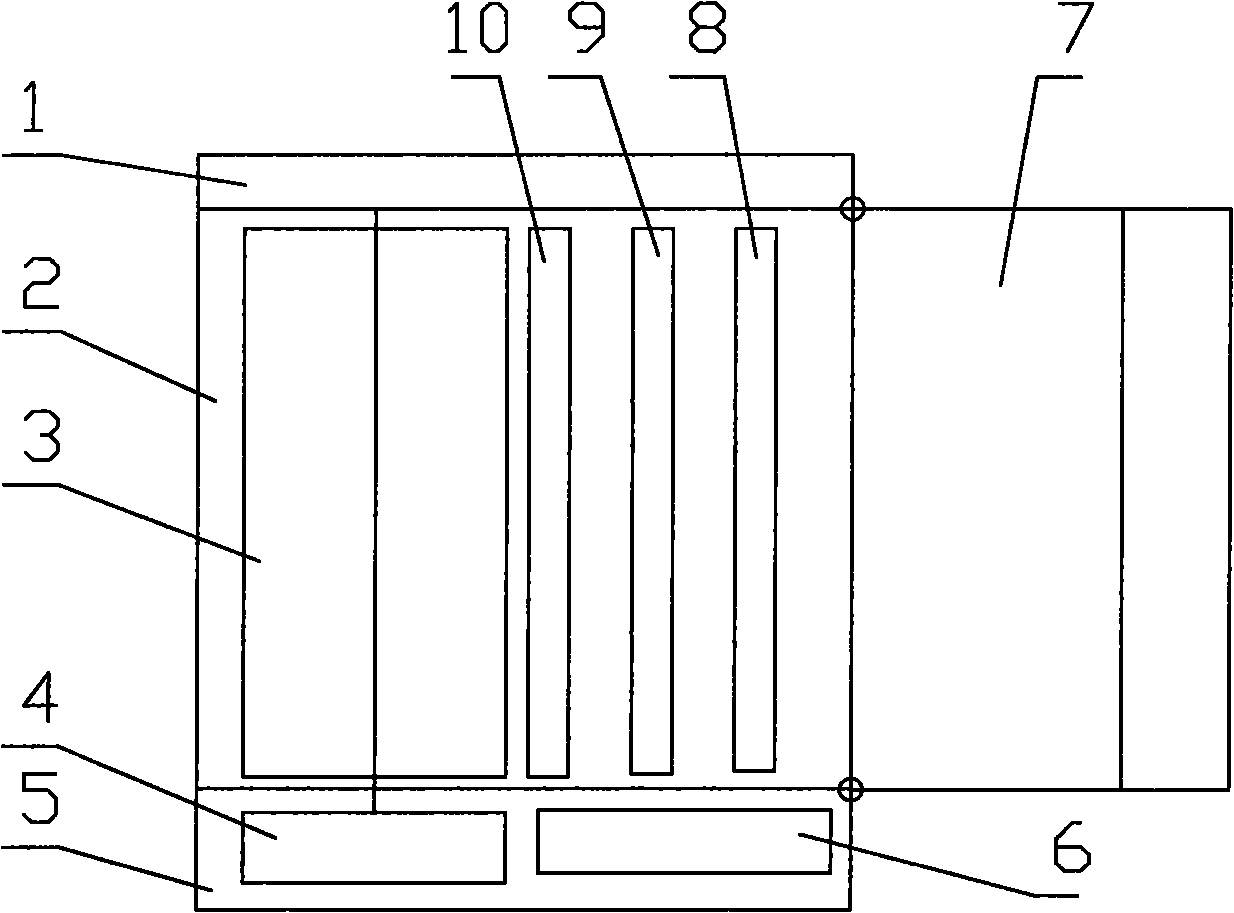

InactiveCN102188741ASimple structureSuitable for operationDeodrantsRadiationEngineeringUv disinfection

The invention relates to an air freshening machine, which comprises an upper cover (1), a shell (2), a fan (3), a motor (4), a lower cover (5), a negative-ion generator, a control circuit board (6), a door (7), a filter screen (8), an ultraviolet disinfection screen (9), a high-voltage static adsorption screen (10) and an on-off control part of an ultraviolet lamp. The air freshening machine has a simple structure and is convenient to operate, and the control of the disinfection time of ultraviolet can be realized conveniently.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

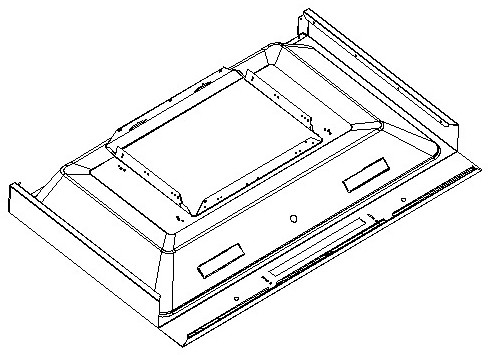

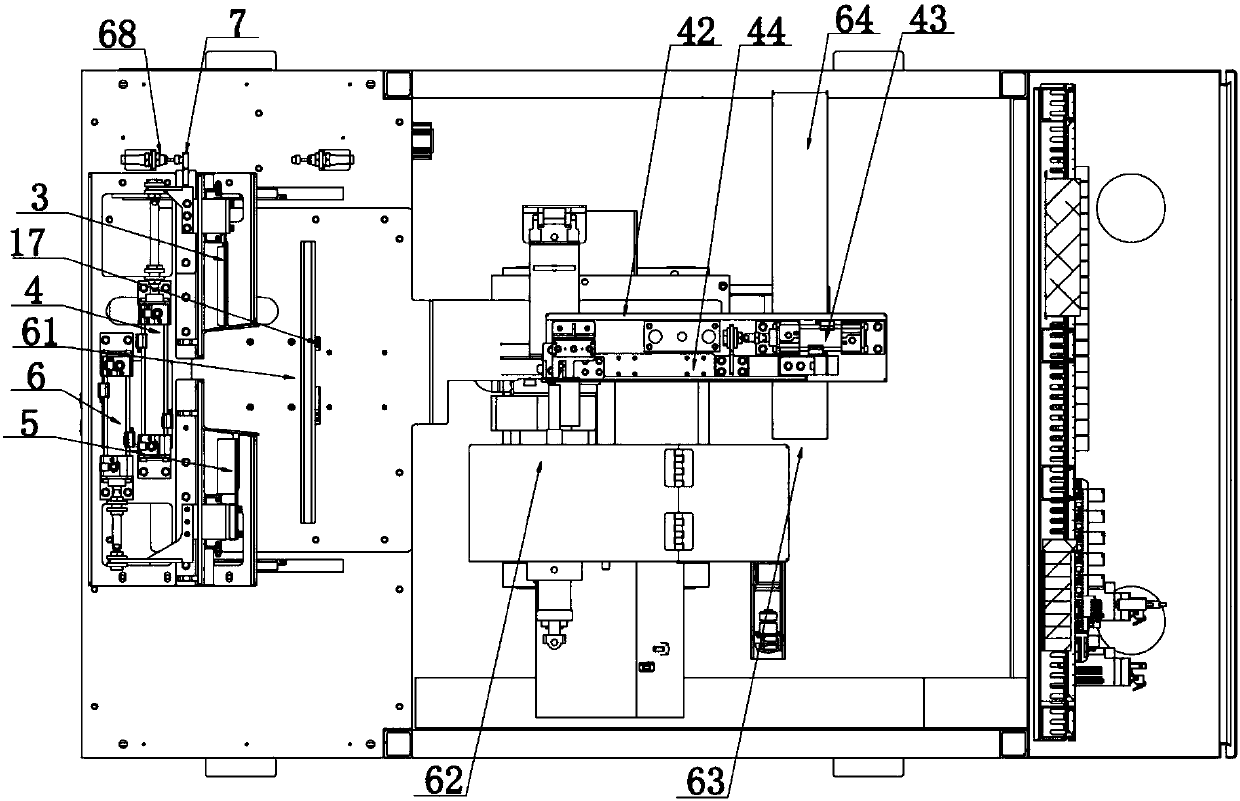

Flanging and bending equipment for metal plate shell of range hood

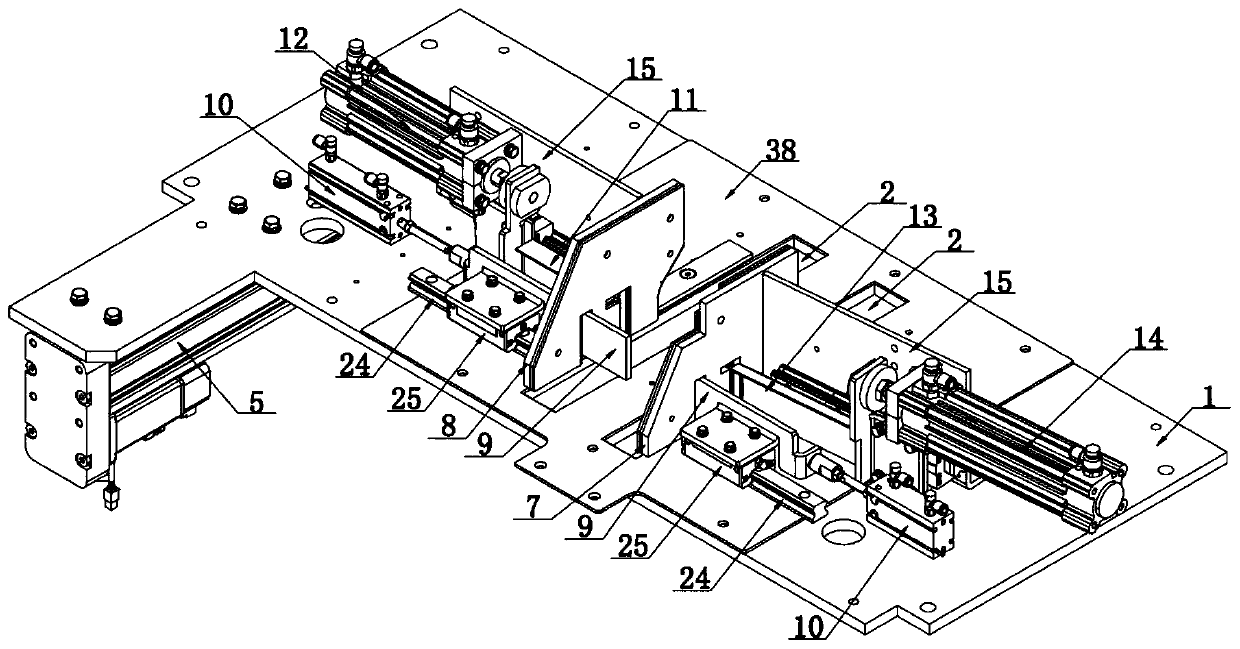

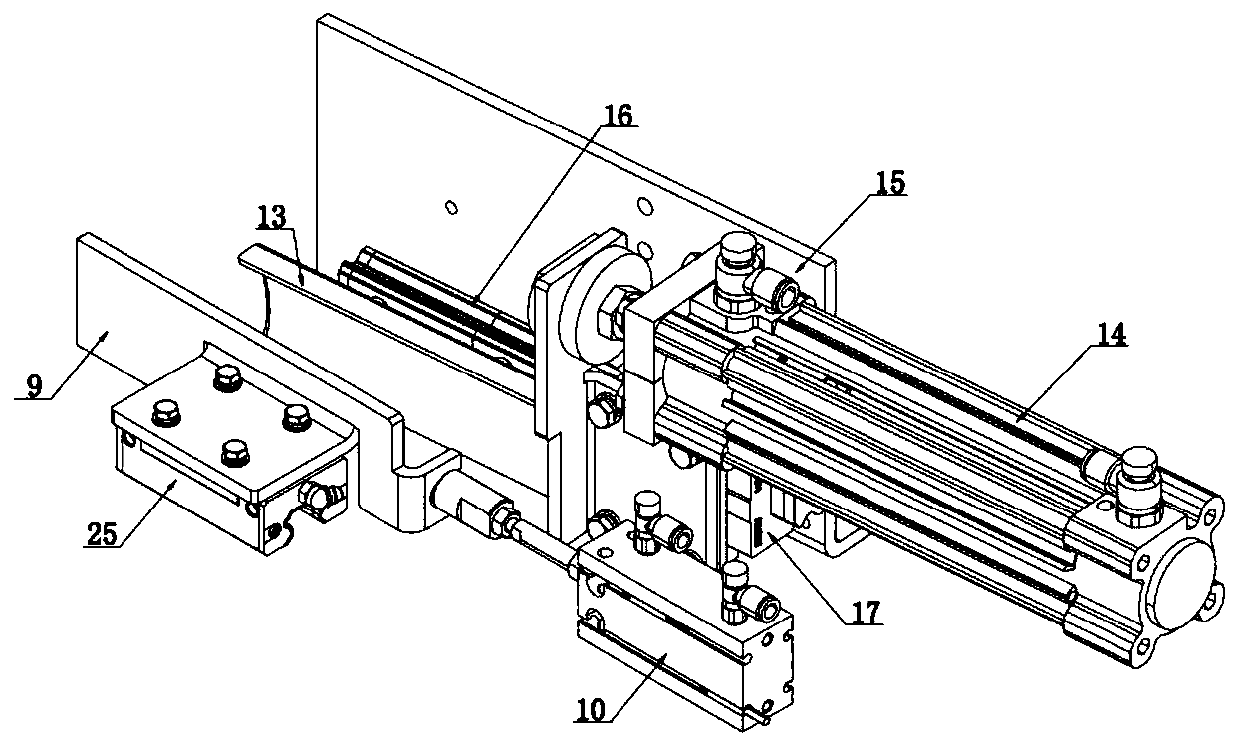

PendingCN113042629APrecise positioningGuaranteed adjustment accuracyShaping toolsMetal-working feeding devicesEngineeringStructural engineering

The invention discloses flanging and bending equipment for a metal plate shell of a range hood. The flanging and bending equipment comprises an equipment body, a product positioning tool, an upper pressing cutting die assembly, a lower pressing cutting die and a lower overturning cutting die assembly, wherein the product positioning tool, the upper pressing cutting die assembly, the lower pressing cutting die and the lower overturning cutting die assembly are mounted on the surface of the body. An auxiliary feeding assembly and a rear auxiliary feeding assembly of the product positioning tool are used for feeding and fixing. Left and right mounting supports are located on the left side and the right side of a to-be-machined metal plate and used for clamping the metal plate. A bending upper cutting die of the upper pressing cutting die assembly is located at the upper end of the bent edge of the fed to-be-machined metal plate and used for pressing the upper portion of a to-be-bent line. The lower overturning cutting die assembly rotates the to-be-bent edge upwards. According to the flanging and bending equipment for the metal plate shell of the range hood, the bending line position of the metal plate can be accurately adjusted, and the bending precision of metal plates made of different materials is guaranteed.

Owner:南京英田激光科技有限公司

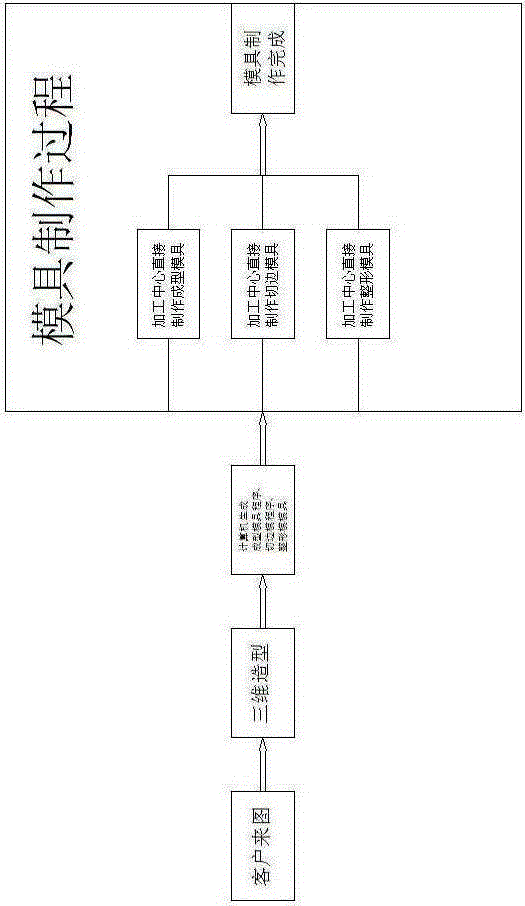

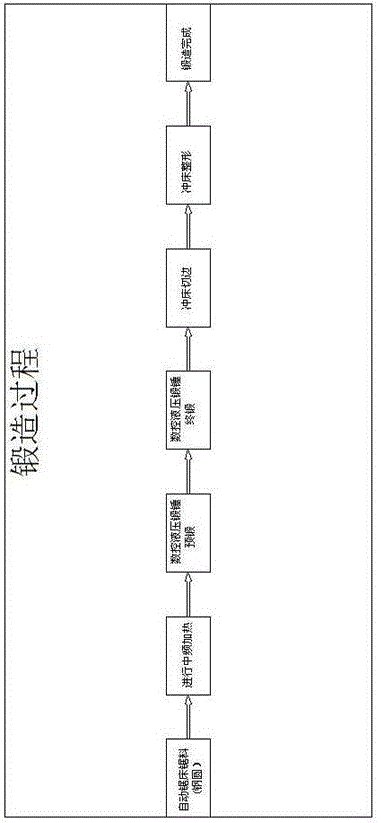

Novel forging method for manual tool

InactiveCN105108020AReduce labor intensityImprove machining accuracyMetal-working apparatusSurface finishNumerical control

A novel forging method for a manual tool comprises the following steps S1. establishing a three-dimension model after receiving a drawing from a client, generating a program of a forming die, a program of a trimming die and a program of a shaping die using a computer; S2. manufacturing dies, directly manufacturing the forming die through a machining center according to the program of the forming die, directly manufacturing the trimming die through the machining center according to the program of the trimming die, and directly manufacturing the shaping die through the machining center according to the program of the shaping die; S3. forging, heating using the intermediate frequency after an automatic sawing machine saws material, pre-forging using a numerical control hydraulic forging hammer after heating using the intermediate frequency, final-forging after using the numerical control hydraulic forging hammer after pre-forging, trimming and shaping using a punch after final-forging to complete forging. By adopting the novel forging method for manual tool, the surface smoothness, the consistency and wear resistance of a die can be improved, and the processing efficiency is raised, and the flexibility of die manufacturing can be raised.

Owner:NANTONG SHIFA SHIP MACHINERY

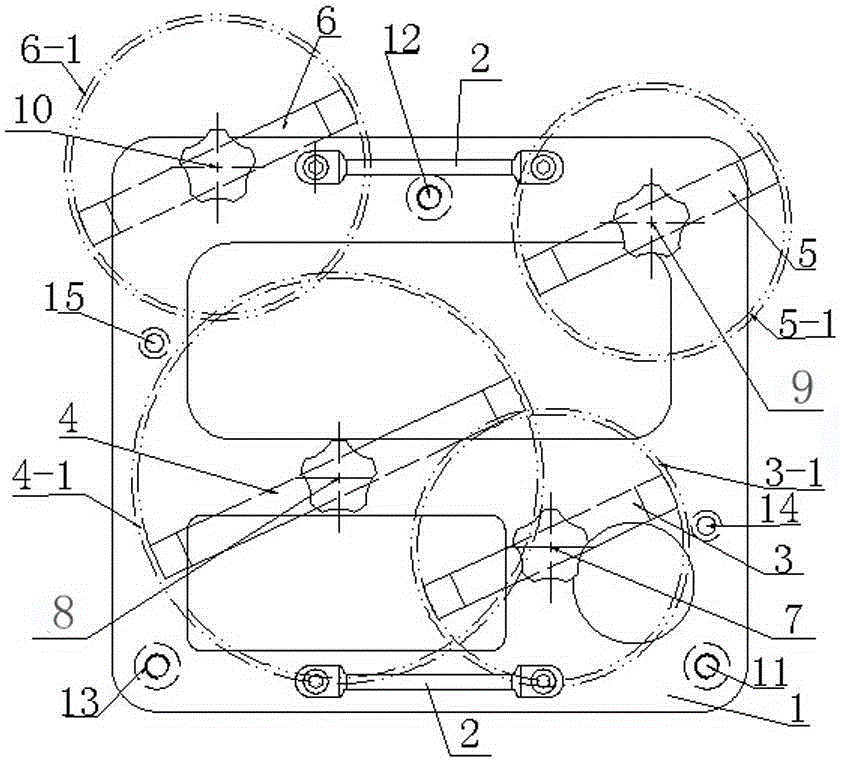

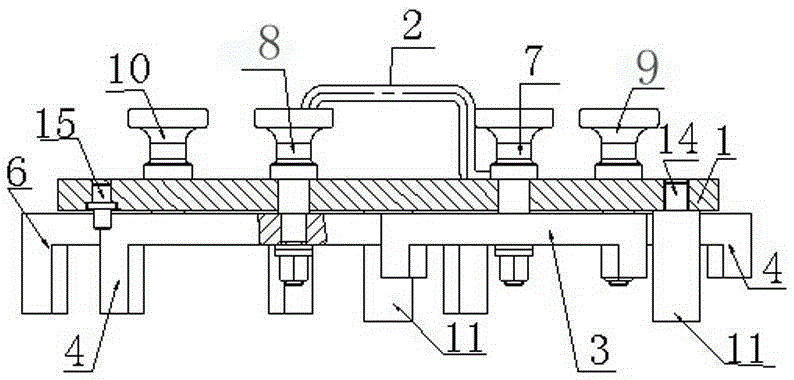

Inner chamber testing fixture for gear chamber of flywheel housing of engine

InactiveCN105277361AQuality assuranceReduce work intensityMachine gearing/transmission testingInterference problemEngineering

The invention provides an inner chamber testing fixture for a gear chamber of a flywheel housing of an engine. The inner chamber testing fixture includes a frame-shaped body, wherein the frame-shaped body is corresponding to the outer contour of a gear chamber of a flywheel housing of an engine; a positioning pin 1 and a positioning pin 2 are arranged at the lower position on two sides of the frame-shaped body; the positioning pin 1 and the positioning pin 2 are corresponding to positioning mounting holes of the flywheel housing of an engine; the frame-shaped body is corresponding to the motion trail of a gear 1, the motion trail of a gear 2, the motion trail of a gear 3 and the motion trail of a gear 4 and are provided with a detection plate 1, a detection plate 2, a detection plate 3 and a detection plate 4 downwards; and a rotation handle 1, a rotation handle 2, a rotation handle 3 and a rotation handle 4 are arranged on the frame-shaped body and are corresponding to the detection plate 1, the detection plate 2, the detection plate 3 and the detection plate 4 so that the detection plate 1, the detection plate 2, the detection plate 3 and the detection plate 4 can move along the motion trails of the gear 1, the gear 2, the gear 3 and the gear 4. The inner chamber testing fixture for a gear chamber of a flywheel housing of an engine can detect the inner chamber interference problem of a gear chamber of a flywheel housing of an engine through the simulation effect of the motion trails.

Owner:东实汽车动力零部件(湖北)有限公司

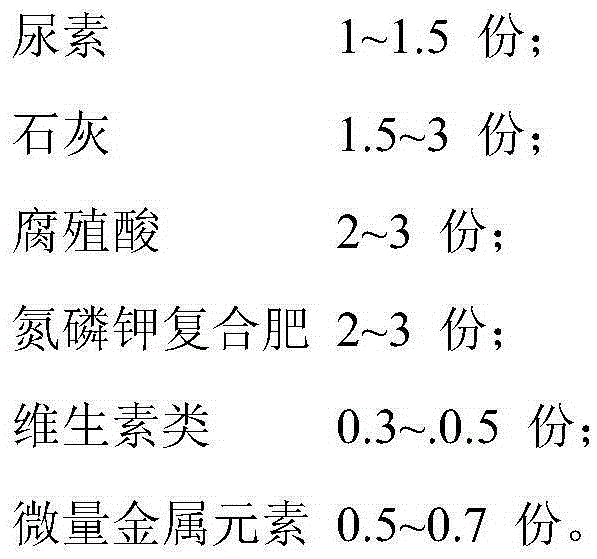

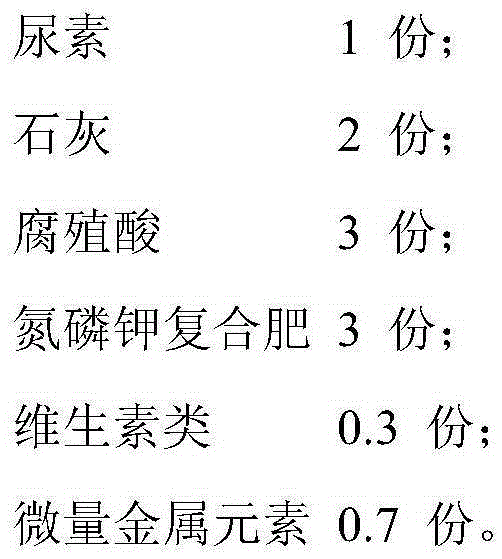

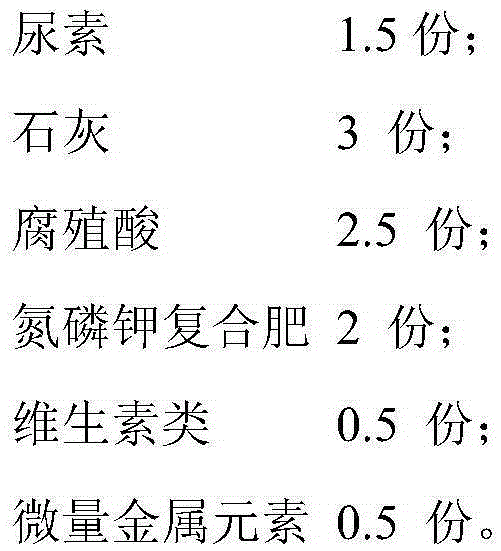

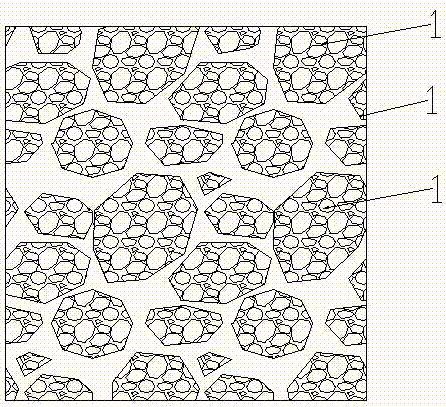

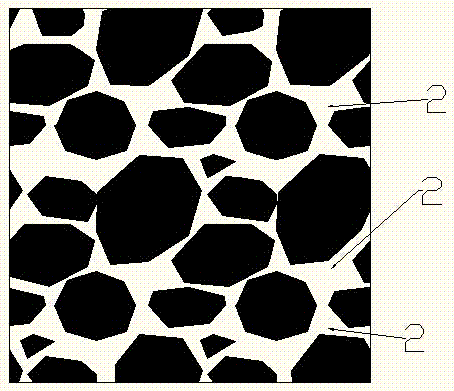

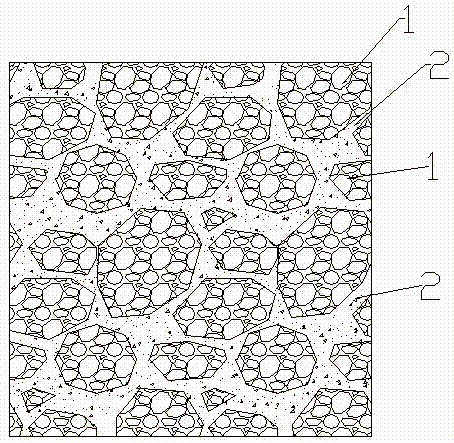

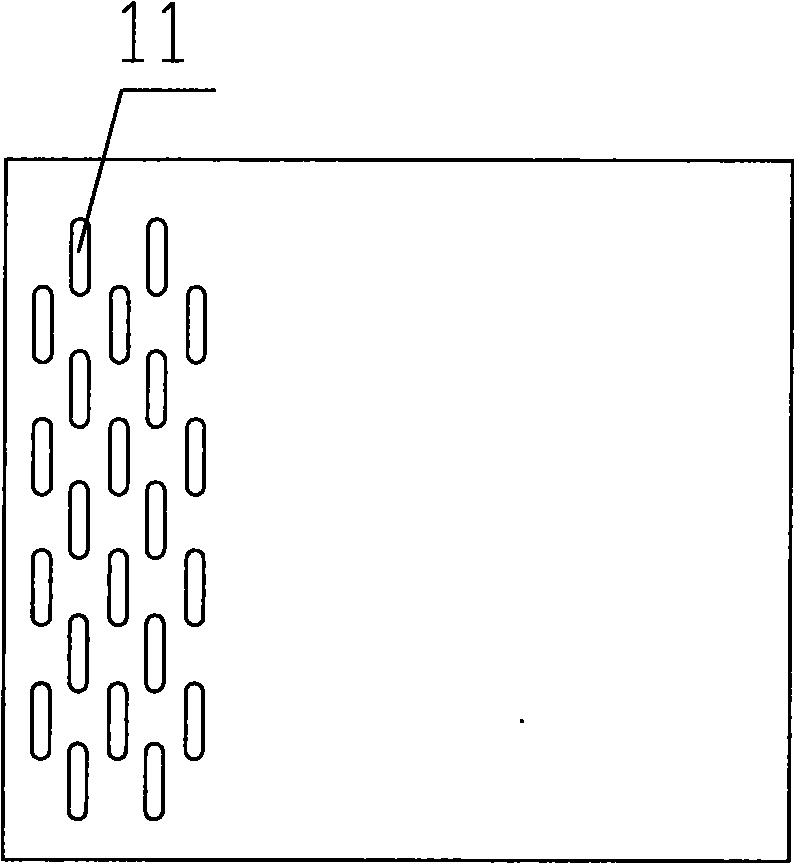

Method for making structured biological deodorizing filler and structured biological deodorizing filler

ActiveCN104524965BUniform sizeConsistent strengthDispersed particle separationAir quality improvementControllabilityBalance water

The invention discloses a method for manufacturing regular biological deodorization packing. The method is characterized in that humic acid, composite nutrients and water are doped in raw material ceramsite and straw particles forming the packing, meanwhile, acidity buffer matter is added, the packing in a regular shape is pressed through a mould, and a cellular structure body is formed after natural airing. The invention further discloses the regular biological deodorization packing. The regular biological deodorization packing is characterized in that the regular biological deodorization packing is composed of, by weight, 60 percent to 70 percent of the ceramsite, 12 percent to 15 percent of the straw particles, three percent to five percent of sodium humate, two percent to three percent of the composite nutrients (urea, carbinol, the humic acid, nitrogen-phosphorus-potassium mixed fertilizer, molasses, peptone, light ground pumice and the like), two percent to three percent of the acidity buffer matter, hydroxide, 12 percent to 15 percent of silicate and the balance water. The biological deodorization packing has the performance of controllability and self-domestication culturability, packing cost is lowered, the biological deodorization packing is high in deodorization efficiency, stable in running, long in service life and low in cost, and needed nutrition can be continuously provided for microorganism in the deodorization process.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

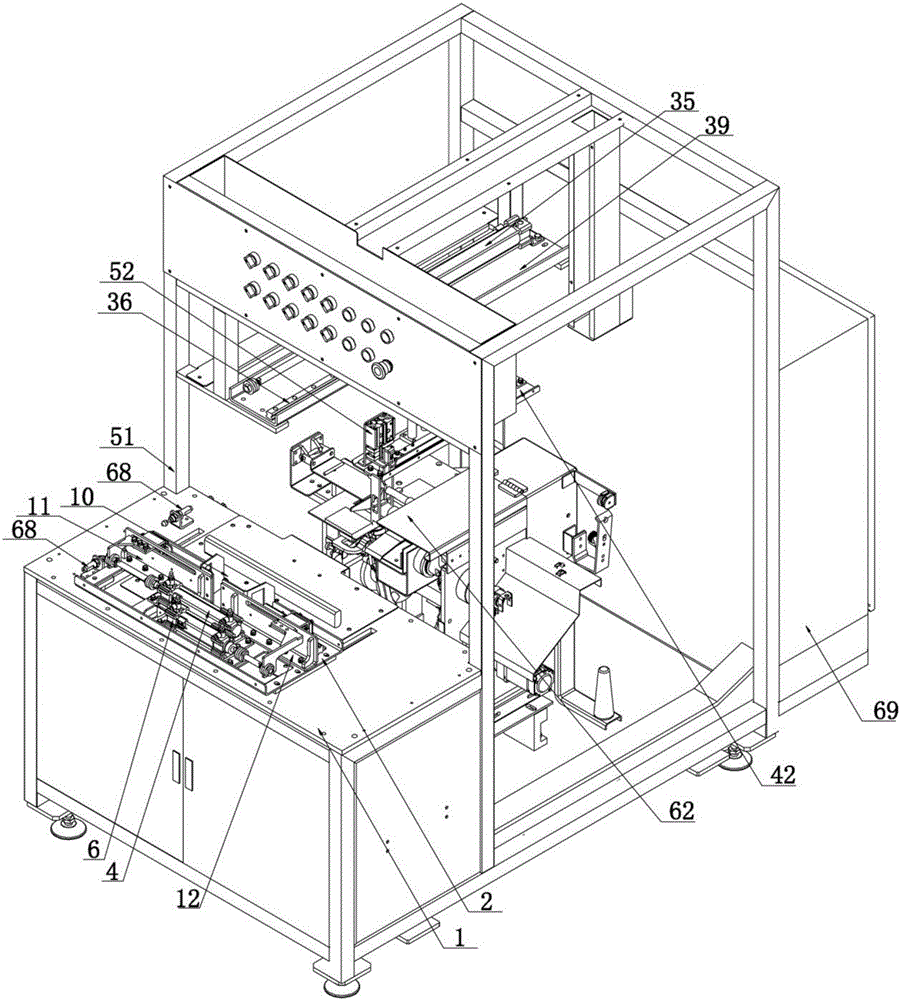

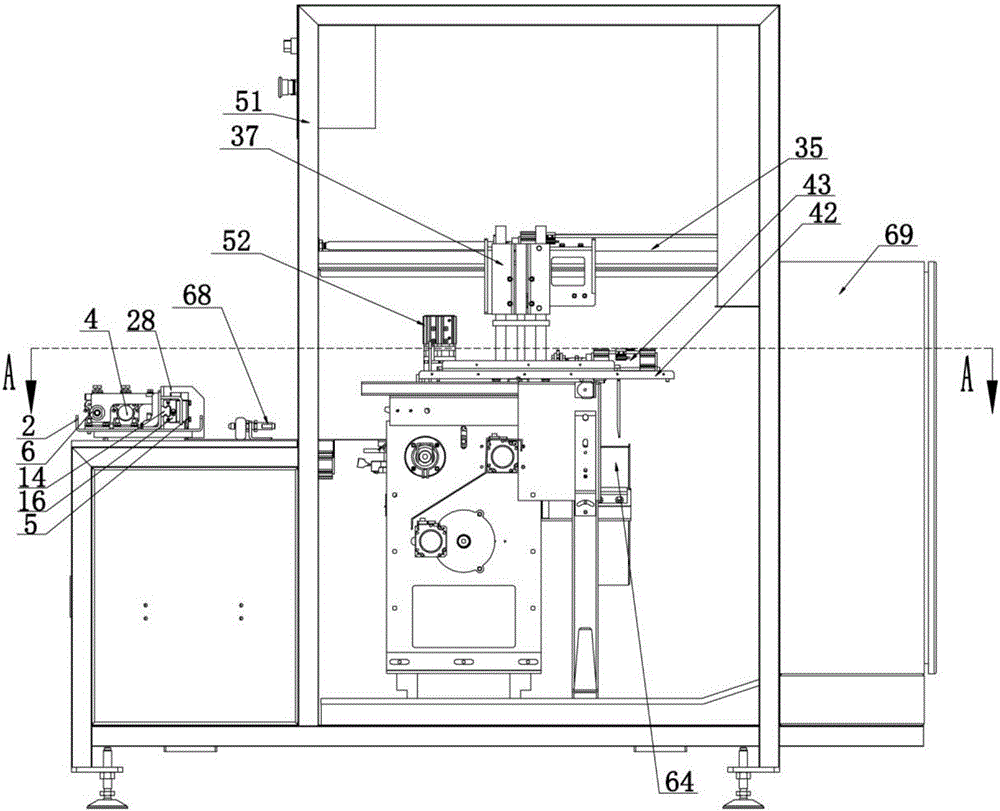

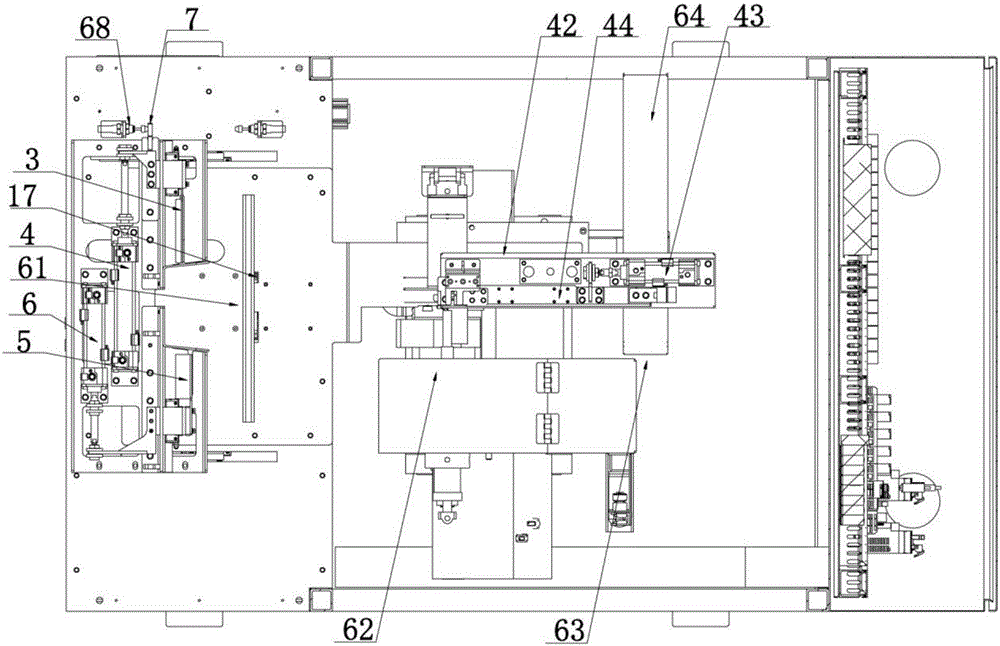

Automatic bean vermicelli folding and binding machine and bending method

ActiveCN105857706AConsistent DimensionsNice appearanceBinding material applicationEngineeringMechanical engineering

The invention discloses an automatic bean vermicelli folding and binding machine and a bending method. The binding machine comprises a rack, a folding mechanism, a clamping shift mechanism and a binding mechanism, the folding mechanism is arranged at the front end of the binding mechanism, and the clamping shift mechanism is arranged above the binding mechanism. The binding method includes that the bean vermicelli is placed between a block pressure bar and a bending push trough; the bean vermicelli is bent in the shape of 'U'; the bean vermicelli is bent to the right side; the bean vermicelli is bent to the left side; a right-bending plate is reset; the bean vermicelli is clamped through the clamping shift mechanism; a left-bending plate is reset, the block pressure bar is allowed to descend, small to-be-bound bundles of the bean vermicelli are shifted out through the clamping shift mechanism to be bound, the block pressure bar is reset, and the bending mechanism is reset as well. By the arrangement, automatic folding, shifting and binding of the bean vermicelli can be realized, folding and binding efficiency is high, overall dimensions of the bean vermicelli are identical, elastic degrees of the bean vermicelli with less burr is appropriate, binding ropes are tied on lateral sides of the small bundles of the bean vermicelli, aesthetic effect of the bean vermicelli is unaffected when the small bundles of the bean vermicelli are put into transparent bags, workers are avoided touching the bean vermicelli during the working process, and further safety and sanitation in food is realized.

Owner:YANTAI GANGYUAN MACHINERY CO LTD

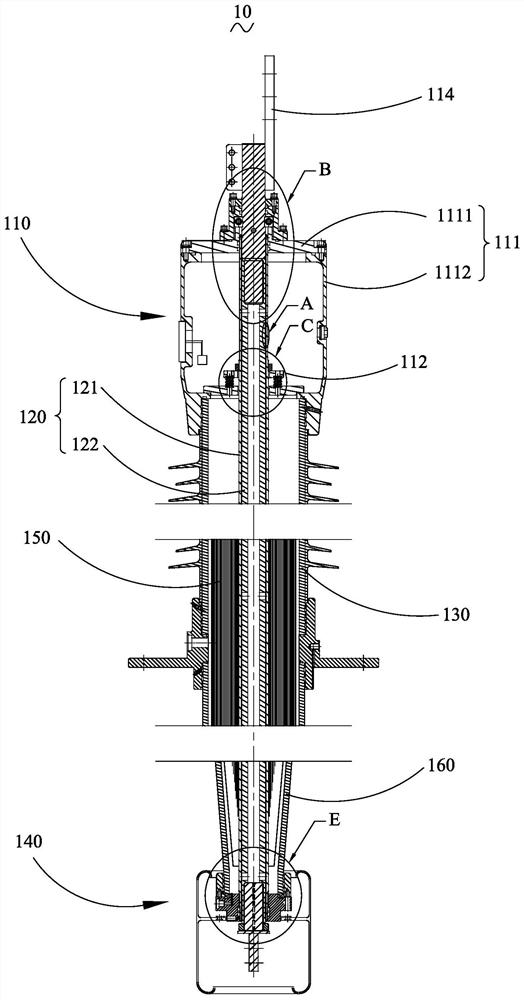

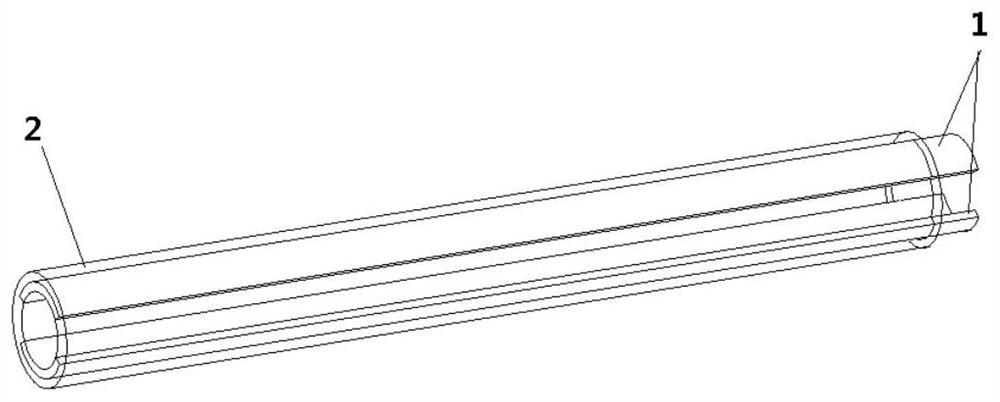

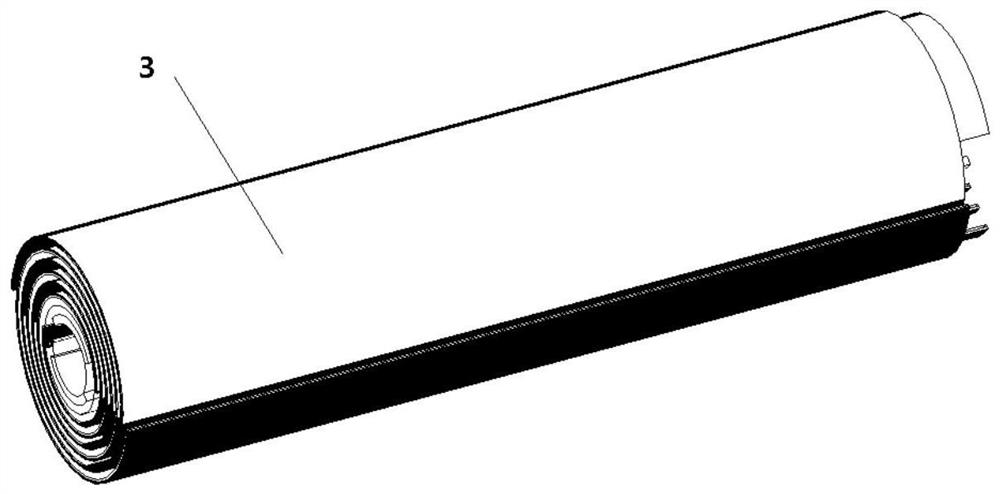

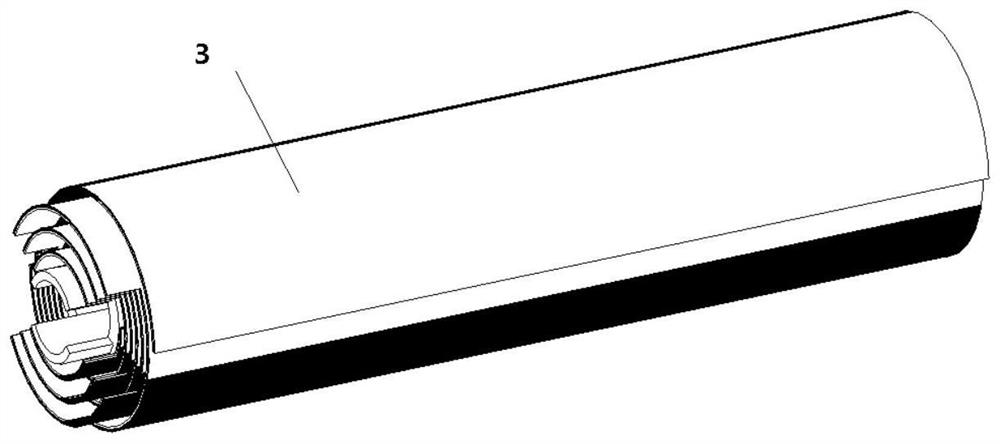

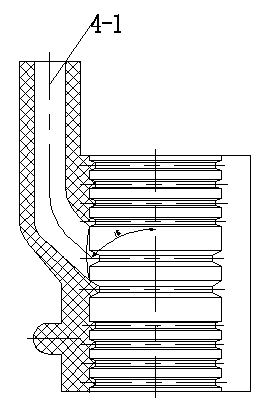

Transformer bushing

PendingCN112885566AGuaranteed reliabilityEasy to rollTransformers/inductances detailsLead-in/lead-through insulatorsCapacitanceTransformer

The invention discloses a transformer bushing, which comprises a head assembly, a central conduit, a composite jacket and a tail assembly, the central conduit sequentially penetrates through the head assembly, the composite jacket and the tail assembly, the central conduit comprises a current-carrying rod and a winding pipe, the current-carrying rod comprises a first guide rod and a second guide rod, and the first guide rod and the second guide rod are fixedly connected, the winding pipe is sleeved outside the current-carrying rod, a gap between the winding pipe and the current-carrying rod is not less than 3mm, and the length of the winding pipe is less than that of the current-carrying rod. The transformer bushing is simple in structure, reliable winding of a capacitor core and reliable current carrying of the conducting rod can be guaranteed, meanwhile, stable connection and reliable matching between parts are guaranteed, exchange of transformer bushing products of the same voltage class can be achieved, and universality is achieved.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

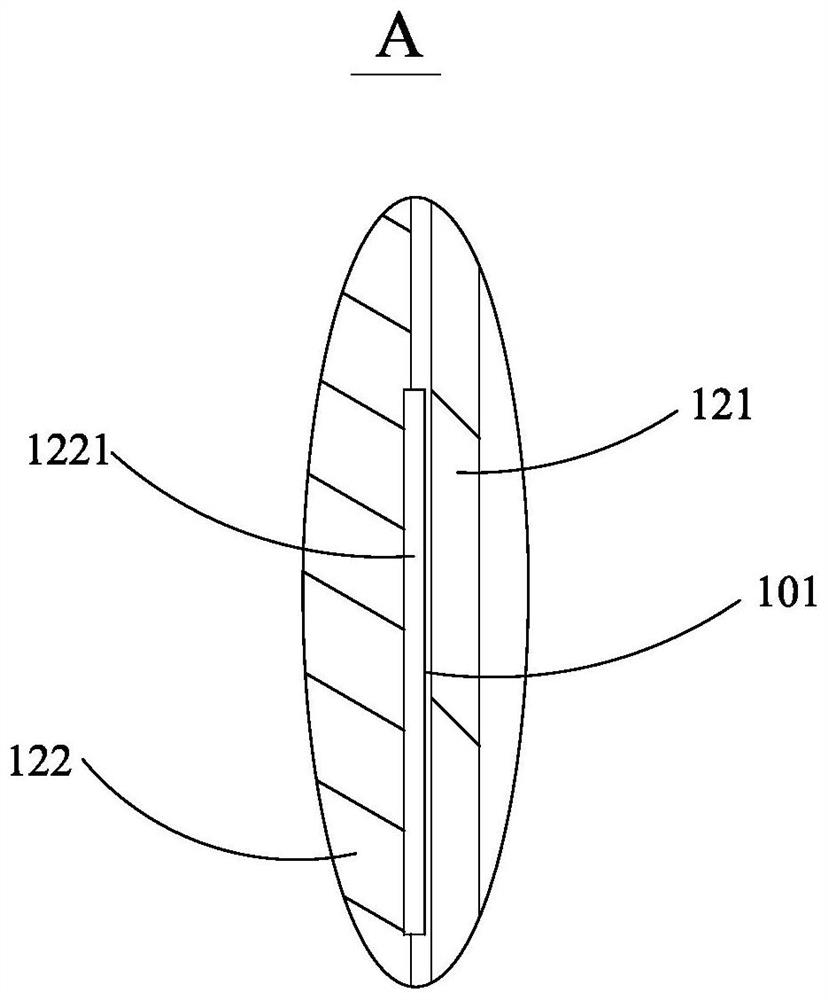

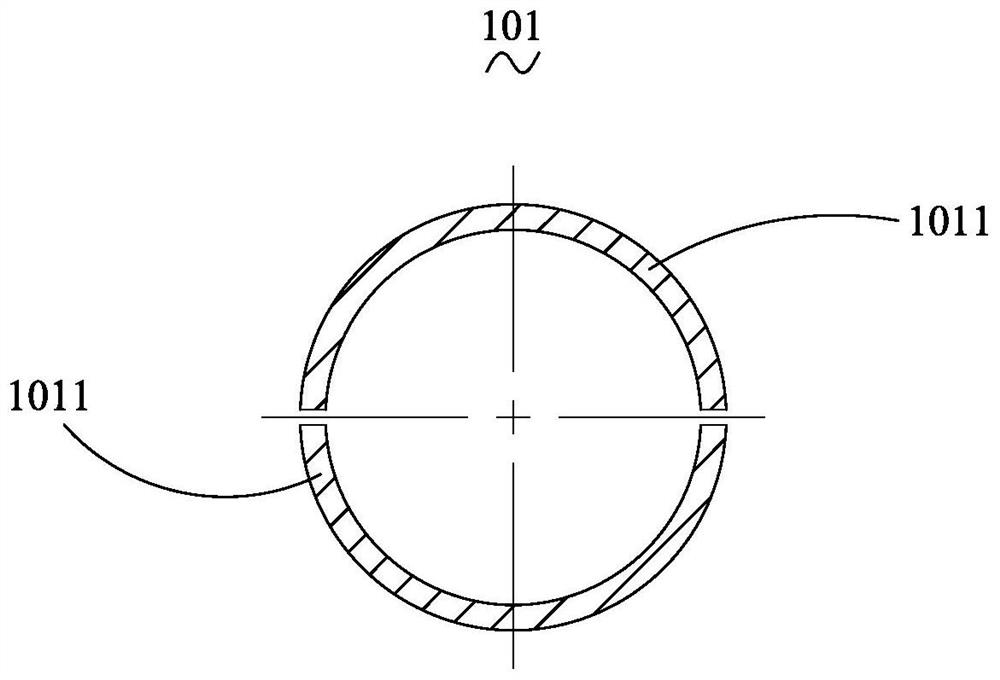

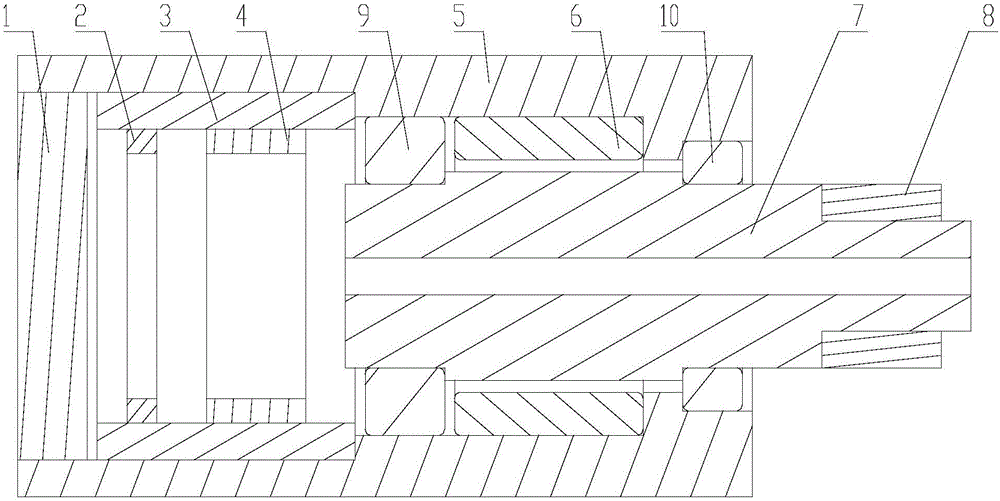

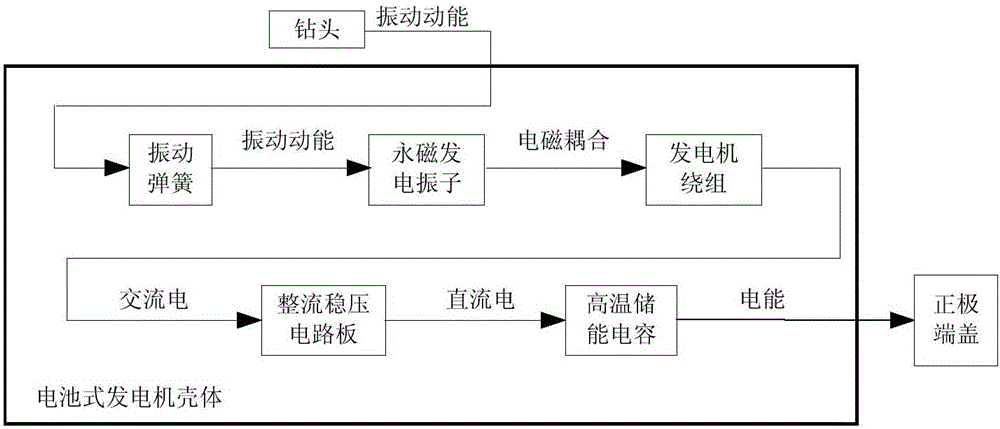

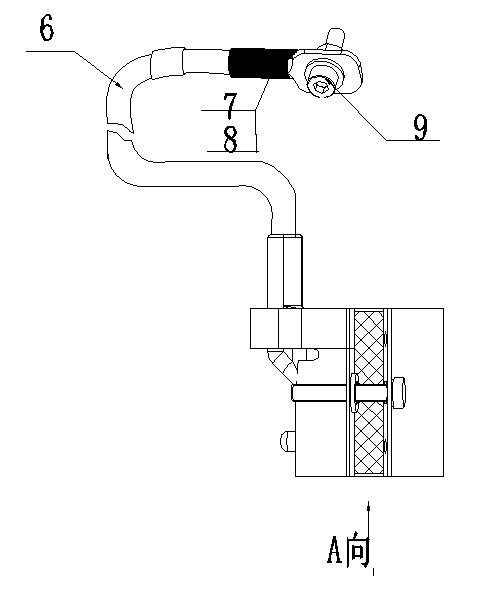

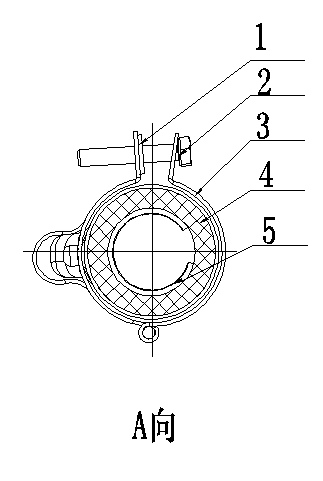

Cell-type vibration generator for oil drilling

InactiveCN106356972AConsistent DimensionsExtended service lifeBatteries circuit arrangementsElectric powerEngineeringThree-phase

A cell-type vibration generator for oil drilling comprises a positive end cover, a power exploring pipe, a commutating and voltage-stabilizing circuit plate, a cell-type generator shell, a generator winding, a permanent-magnetic power generating vibrator and a vibration spring. One end of the vibration spring is connected with a drill while the other end is connected with the permanent-magnetic power generating vibrator; the generator winding is fixed in the cell-type generator shell and is insulated with same; the permanent-magnetic power generating vibrator penetrates the generator winding with two ends connected with the cell-type generator shell through a bearing; the power exploring pipe is fixedly connected in the cell-type generator shell, and the commutating and voltage-stabilizing circuit plate is fixed in the power exploring pipe; the generator winding interacts with the permanent-magnetic power generating vibrator to generate three-phase alternating current, and the three-phase alternating current is commutated and stabilized into direct current via the commutating and voltage-stabilizing circuit plate; the positive end cover is fixedly connected to the rear end of the power exploring pipe, a lead passing hole is formed in the positive end cover, and a power exploring pipe lead extends out of the lead passing hole to serve as a positive electrode for the entire device.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

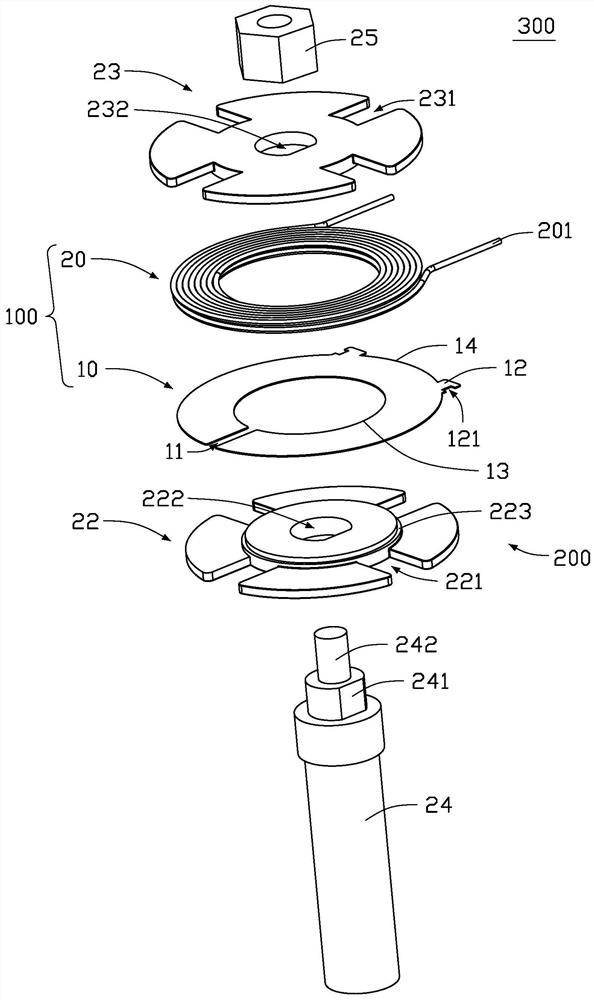

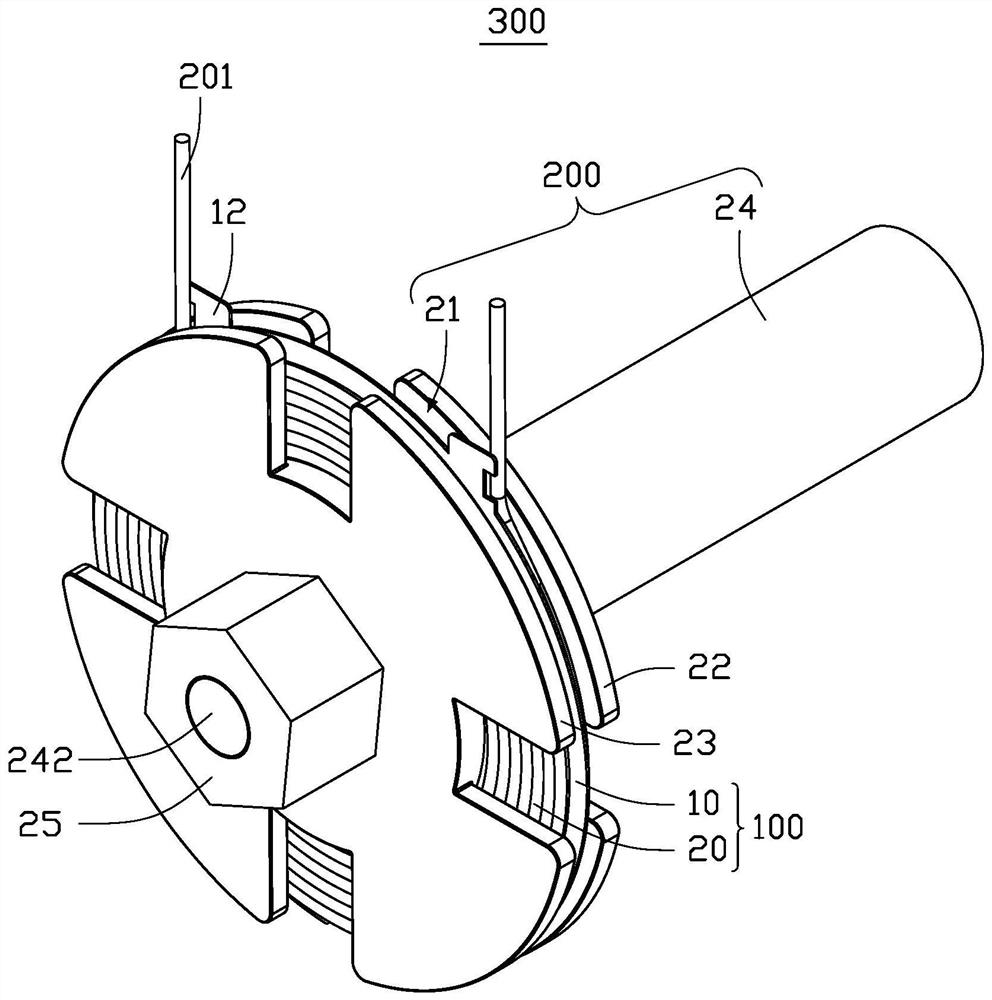

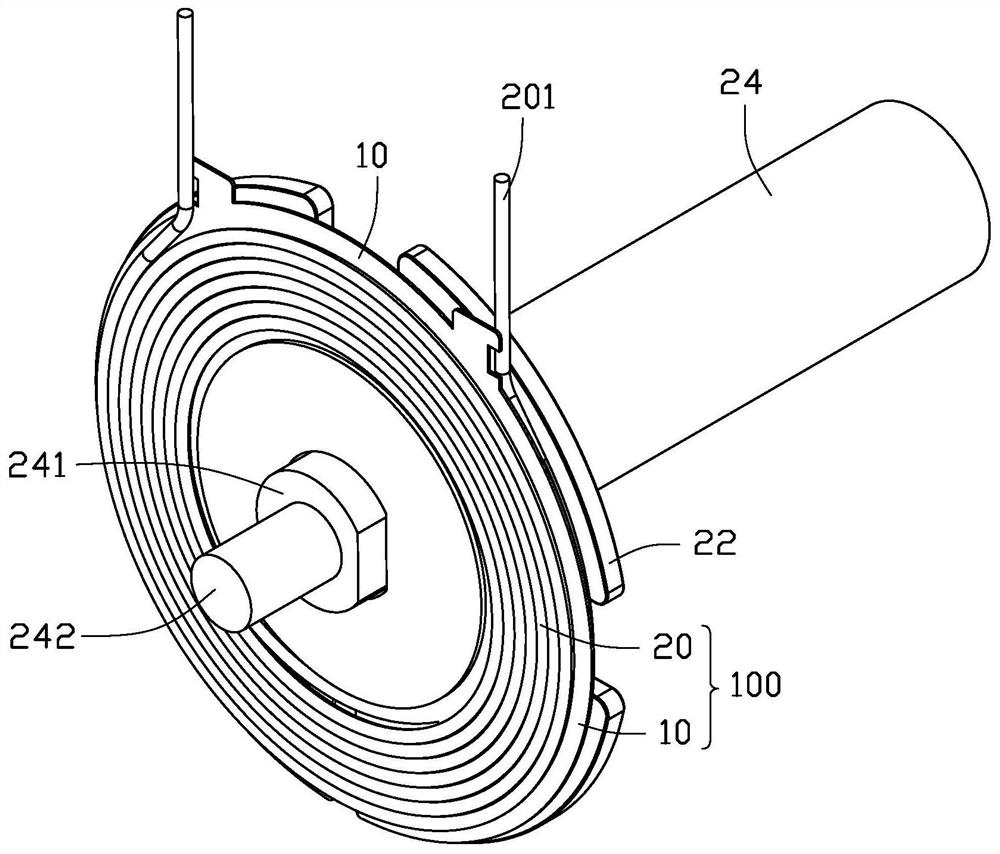

Transformer coil winding and winding device comprising transformer coil winding

ActiveCN111739716APrevent collapsing and looseningConsistent DimensionsTransformers/inductances coils/windings/connectionsCoils manufactureTransformerMechanical engineering

The invention discloses a transformer coil winding. The transformer coil winding comprises coils and an isolation piece, wherein the coils comprise a first coil and a second coil, and the first coil and the second coil are respectively formed by winding wires wound on the two sides of the isolation piece; the isolation piece is provided with an open groove, the wire is arranged in the open groovein a penetrating mode in the direction perpendicular to the isolation piece, and the open groove is used for dividing the wire into a first part and a second part; a first portion of the wire is woundon a first side of the isolation piece to form the first coil, and a second portion of the wire is wound on a second side of the isolation piece to form the second coil. According to the transformercoil winding, the coil can be prevented from collapsing and loosening, the boundary dimension of the coil is kept consistent, production and installation of the coil are facilitated, insulating materials are saved, and high-voltage short circuit between the coil and a magnetic core is avoided. The invention further provides a winding device comprising the transformer coil winding.

Owner:SHENZHEN JINGQUANHUA ELECTRONICS

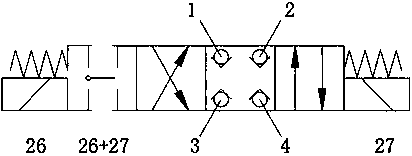

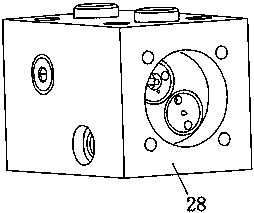

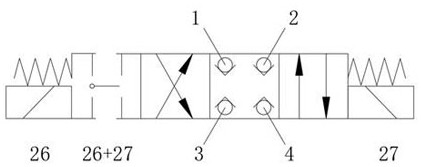

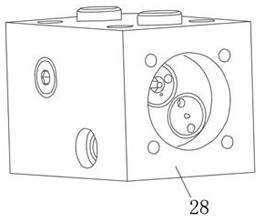

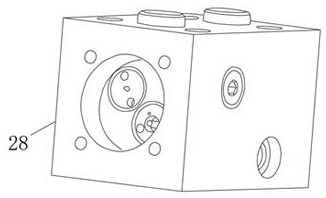

Plate-type four-position four-way cone valve direct-acting type electromagnetic reversing hydraulic valve

The invention discloses a plate-type four-position four-way cone valve direct-acting type electromagnetic reversing hydraulic valve, which comprises a valve body. The two sides of the valve body are provided with a first valve core assembly, a second valve core assembly, a third valve core assembly and a fourth valve core assembly with cone valve type structures, and other two sides of the valve body are respectively equipped with a first electromagnet and a second electromagnet; and the plate-type four-position four-way cone valve direct-acting type electromagnetic reversing hydraulic valve is different from the prior art, the two electromagnets of the plate-type four-position four-way cone valve direct-acting type electromagnetic reversing hydraulic valve can be powered on at the same time, and the one position function is added to meet special needs; the valve core assemblies are the cone valve type structures, and can realize nominal zero leakage of four oil ports, and at the sametime, the valve core assemblies are four sets of independent components; and through different oil way combinations, other valve types with no leakage function can be derived, and the external dimension is basically the same as an ordinary slide valve type.

Owner:NINGBO HAIHONG HYDRAULICS

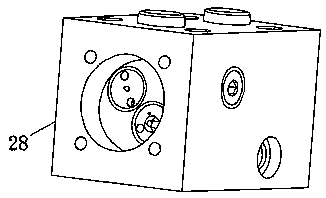

Non-ferrous metal rod variable-frequency induction gradient heating device and heating method

The invention relates to a non-ferrous metal rod variable-frequency induction gradient heating device and heating method. The device is characterized in that a variable-frequency power supply controlcabinet is powered by a variable-frequency power supply, a variable-frequency induction coil is controlled by the variable-frequency power supply control cabinet, the variable-frequency induction coilis divided into three sections of coils, the three sections of the coils refer to an A-section induction coil, a B-section induction coil and a C-section induction coil, a metal rod enters a gradientheating furnace, the induction coils which are non-uniformly wound in the furnace body are used for inputting different energy to different parts of the metal rod, so that the heated metal rod is lowin head temperature, and the temperature is gradually increased towards the tail part, therefore in the extrusion forming process of the metal rod with the temperature gradient in an extruding machine, when the middle rear end of the metal rod is extruded, the temperature reduced by the heat dissipation of the metal rod is equal to the temperature increased through the temperature gradient at therear end of the metal rod, the temperature of each section entering a die is the same, so that the temperature of the extruded metal material is ensured to be consistent, and the quality of the finished metal material is ensured; and due to the temperature gradient, the temperature reduced by heat dissipation can be made up, the rate of finished products is improved, and the production efficiencyis improved.

Owner:西安威特电力电子设备研究所

Automatic bean vermicelli bending device

PendingCN111332559ASimple structureEasy to operatePackagingAgricultural engineeringStructural engineering

The invention discloses an automatic bean vermicelli bending device. The automatic bean vermicelli bending device comprises a main panel, a push rod mechanism, a bending mechanism and a blocking and pressing mechanism, the push rod mechanism comprises a push rod, a push rod lifting air cylinder and a push rod moving electric cylinder, the bending mechanism comprises a first bending mechanism located on the left side of the main panel and a second bending mechanism located on the right side of the main panel, a left baffle is arranged on the inner side of the first bending mechanism, a right baffle is arranged on the inner side of the second bending mechanism, a push rod moving channel is formed between the left baffle and the right baffle, and the blocking and pressing mechanism comprisesa blocking and pressing bottom plate and a blocking and pressing bottom plate air cylinder. According to the automatic bean vermicelli bending device, the bean vermicelli advances along with the pushrod, the push rod mechanism is simple in structure, convenient to operate, light in weight and convenient to drive, energy consumption for bending the bean vermicelli is reduced, adjustment, maintenance and repair are facilitated, automatic bending of the bean vermicelli is achieved, the bending efficiency is high, and moreover, the automatically-bent bean vermicelli is consistent in appearance size and attractive in appearance; automatic bean vermicelli bending prevents people from making direct contact with the bean vermicelli, so that food is safer and more sanitary.

Owner:YANTAI GANGYUAN MACHINERY CO LTD

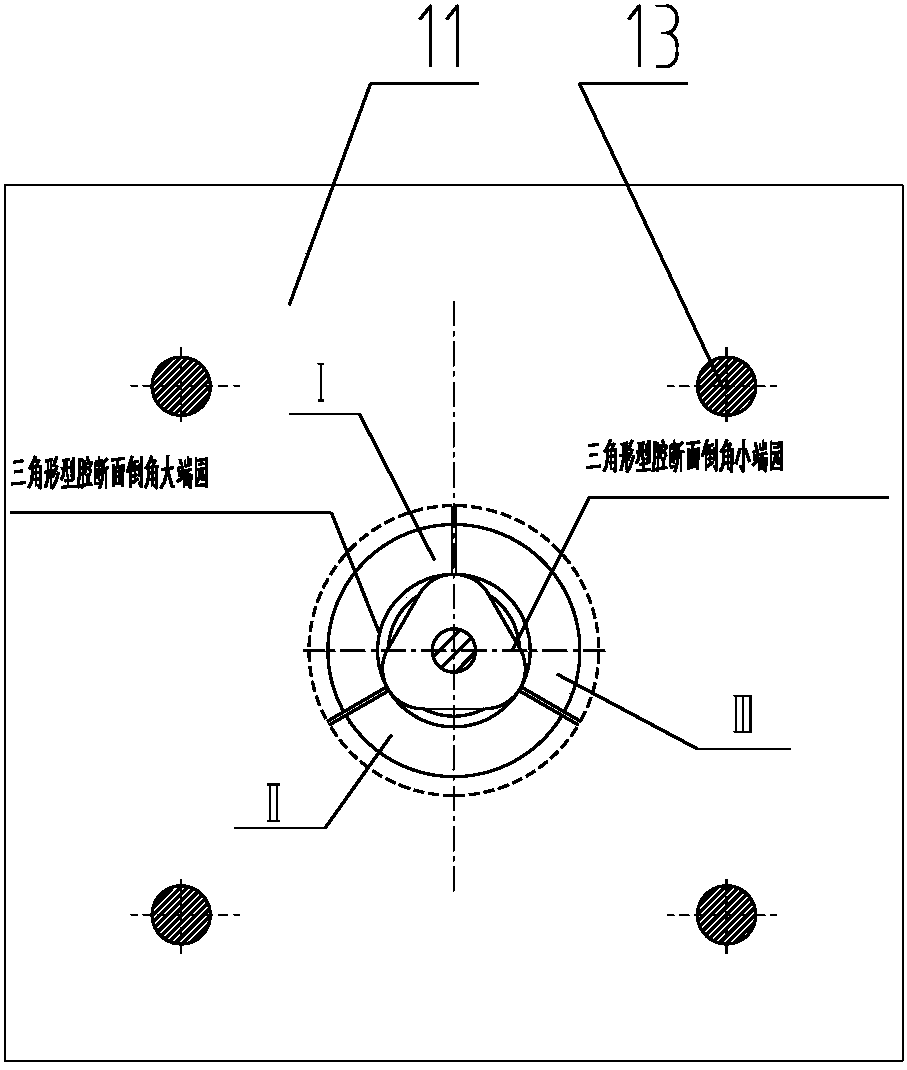

Welding-free triangular arc protruding edge integral drill rod clamping device and machining method thereof

PendingCN107891113AImprove torsion resistanceFully automatedMetal-working apparatusFriction weldingShielded metal arc welding

The invention provides a welding-free triangular arc protruding edge integral drill rod clamping device and a machining method thereof. Three clamping oil cylinders are uniformly distributed within the whole circumference 360-degree range of the outer sides of half bodies of three clamping blocks, and thus clamping in the drill rod extruding process, installing before drill rod extruding and taking out after extrusion are achieved. By means of the split type outer die extruding technology, the two ends of a triangular arc protruding edge rod body are subjected to local upsetting, a drill rod inner thread connector and a drill rod outer thread connector are machined at the two upset ends of the rod body correspondingly, and thus the drill rod body and a drill rod connector form an integralstructure without welding connection. According to the clamping device and the machining method thereof, machining and manufacturing of the triangular arc protruding edge integral drill rod are achieved, and the overall strength and torsional performance of the triangular arc protruding edge drill rod are improved greatly. Meanwhile, the quality defect due to manual arc welding or friction weldingadopted in an inserted type triangular arc protruding edge drill rod and a friction welding type triangular arc protruding edge drill rod is avoided, and the progress of the triangular arc protrudingedge machining technology and development of the pit drilling cause in China are propelled.

Owner:HUAIBEI HENGYUAN ENG BUILDING MATERIALS &EQUIP

Air freshening machine

InactiveCN102188741BAchieve disinfectionAchieving processing powerDeodrantsRadiationUv disinfectionEngineering

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

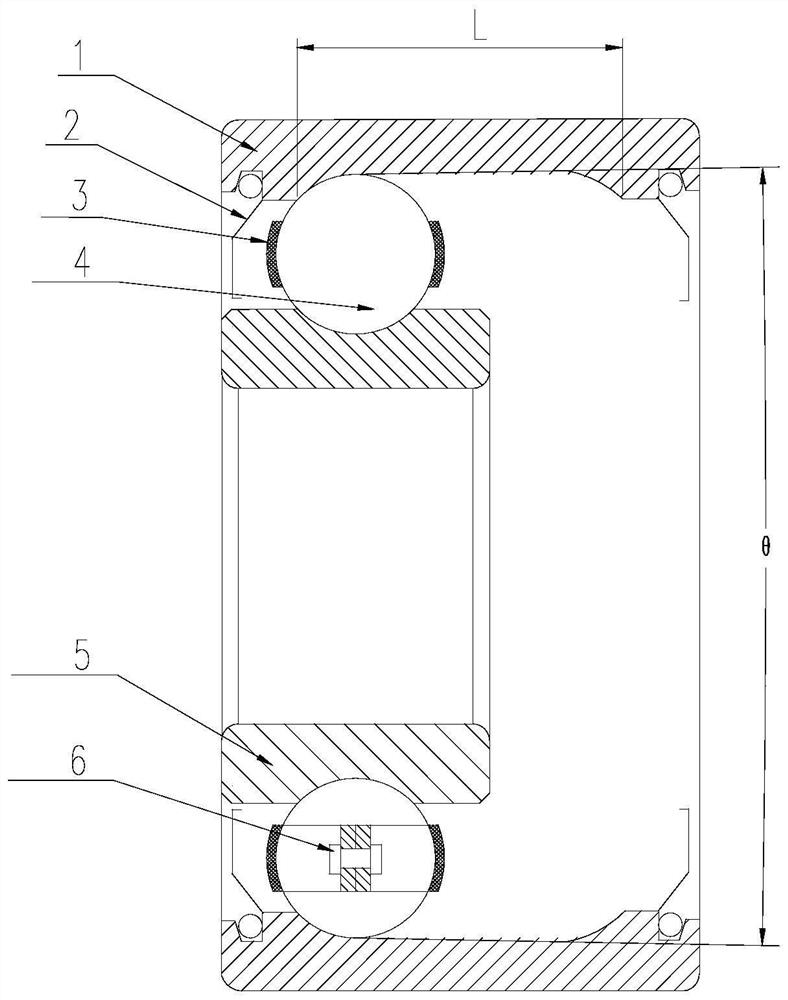

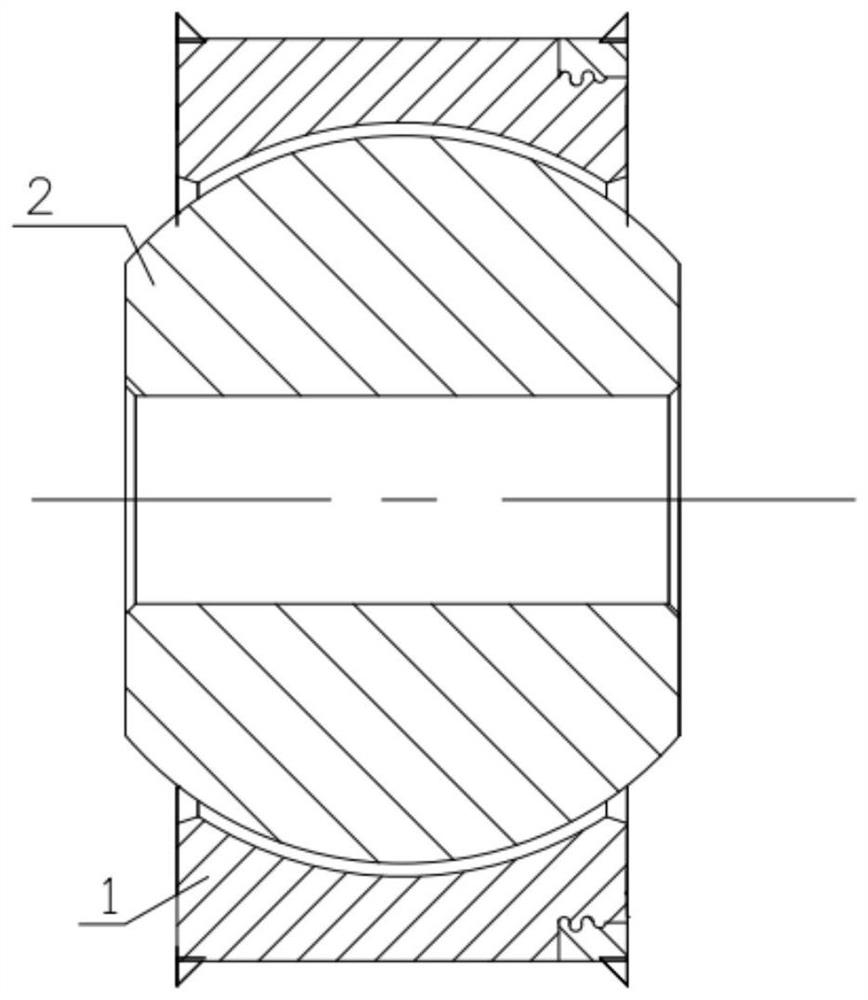

Wide-outer-ring long-service-life bearing with clearance adjusting function

PendingCN114526287AAchieve super long lifeLarge centering angleRolling contact bearingsBearing componentsAxial displacementBall bearing

The invention provides a wide-outer-ring long-service-life bearing with a clearance adjusting function, which comprises an outer ring, an inner ring and steel balls arranged between the outer ring and the inner ring, raceways corresponding to the steel balls are arranged on the inner side of the outer ring and the outer side of the inner ring, more than two raceways are arranged on the inner side of the outer ring, the more than two raceways are coaxially arranged, and the clearance adjusting function is realized between the outer ring and the inner ring. The diameters of at least two of the more than two raceways are different; the size of the bearing clearance of the bearing is adjusted by switching the raceways of the steel balls. According to the wide-outer-ring long-service-life bearing with the clearance adjusting function, the multiple outer ring raceways are arranged, and axial displacement can be achieved while rotation of the bearing inner ring is achieved; the bearing has the characteristics of a deep groove ball bearing, and meanwhile, the self-aligning angle larger than that of a common deep groove ball bearing can be achieved; a plurality of raceways are arranged, so that the ultra-long service life of the bearing can be realized.

Owner:AEROSPACE PRECISION PROD INC LTD

Electromagnetic ammunition capable of being launched by conventional gunpowder launcher

ActiveCN112833705AImprove concealmentImproved anti-armor capabilityAmmunition projectilesElectromagnetic launchersMetal stripsComposite film

The invention relates to an electromagnetic ammunition capable of being launched by a conventional gunpowder launcher, which is characterized in that two parallel tile-shaped metal strips are symmetrically inlaid on the inner wall of an insulating sleeve, and two layers of composite films made of conductive foils and insulating foil materials tightly wind outside the insulating sleeve in a lapping manner, the two composite films and the two tile-shaped metal strips are connected through two fan-shaped metal blocks respectively, and each fan-shaped metal block is provided with an electrode protruding backwards. A metal primer, bullets and a detachable holding seat are tightly pressed in a launching cavity, the metal primer is located on the outer side of the bottom of a cartridge case, the device is wrapped by the cartridge case, an insulating lining is arranged in the cartridge case and insulates the cartridge case from all internal parts, and the front end of the insulating lining is open. Before battle preparation, positive and negative electrodes of a vehicle-mounted high-voltage charger make contact with two electrodes at the tail of the electric ammunition for several seconds, the electric ammunition is disconnected after voltage balance is achieved, the electric ammunition is loaded into an artillery bore, like a traditional artillery, a firing pin is used for firing the metal primer, electric energy stored in the ammunition is instantly released, and the bullets and the detachable holding seat are pushed out at a high speed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

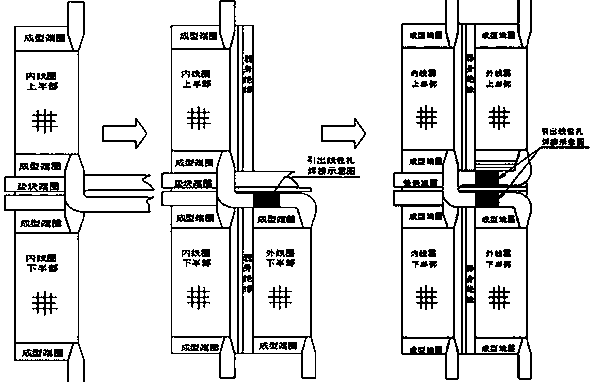

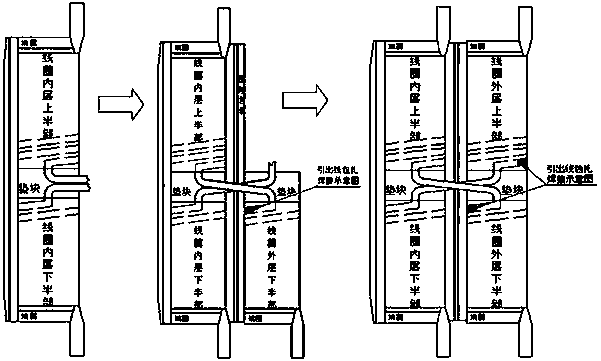

Manufacturing method of balance transformer compensation coil

PendingCN111009411AReduce difficultySolve welding difficultiesCoils manufactureTransformerWhole body

The invention discloses a manufacturing method of a balance transformer compensation coil. The method comprises a process I, a process II, a process III, a process IV and a process V. In the process I, an upper half part of an inner coil, a lower half part of the inner coil, an upper half part of an outer coil and a lower half part of the outer coil are simultaneously wound into a whole body; in the process II, the upper half part and the lower half part of the inner coil complete sleeving work, and outgoing lines of the upper half part and the lower half part of the inner coil are in S-bend transition to a middle position of the outer coil; in the process III, the outgoing lines of the upper half part of the inner coil and the lower half part of the outer coil are welded and bound; in theprocess IV, the upper half portion of the outer coil and the lower half portion of the inner coil are welded and bound; and in the process V, integral sleeving of the upper half part of the inner coil, the lower half part of the inner coil, the upper half part of the outer coil and the lower half part of the outer coil is completed. According to the manufacturing method of the balance transformercompensation coil, under a condition that mechanical performance and electrical performance of a transformer product are guaranteed, barrier-free operation of all procedures is ensured.

Owner:CHINA RAILWAY ELECTRICAL IND CO LTD

Grounding clamping piece for bellows signal cable

InactiveCN103579836AConsistent DimensionsMeet the requirements of lightning protection and grounding protectionCouplings bases/casesConnections effected by permanent deformationMicrowaveCopper

A grounding clamping piece for a bellows signal cable includes a seal gasket, an inside hexagonal bolt and a hinge. An inside-contact piece is arranged in the middle of an inner cavity of a sealing element, and the outer ring of the sealing element is provided with the hinge. The inside-contact piece is a contact copper piece processed through high-temperature copper brazing on a pressing-connecting pipe, it is guaranteed that the included angle between the contact copper piece and the pressing-connecting pipe is 45 degrees through a clamp, and the shape of ripples in the outer ring of the pressing-connecting pipe and the shape of the bellows signal cable are consistent in size; inner corrugated grooves are formed in the two ends of the inner cavity of the sealing element, the middle portion of the inner cavity and the pressing-connecting pipe in the inside-contact piece are consistent in shape and structure, and a cable is inserted in an inner cavity of a grounding wire outlet tail pipe on the sealing element. According to the grounding clamping piece for the bellows signal cable, the defects that an original grounding clamp of a mobile base station main signal cable and an original grounding clamp of a microwave communication signal cable are large in contact resistance, unreliable in long-term work, poor in waterproof performance, large in mounting randomness and incapable of being used repeatedly are overcome.

Owner:JIANGSU RONGLIAN TECH DEV

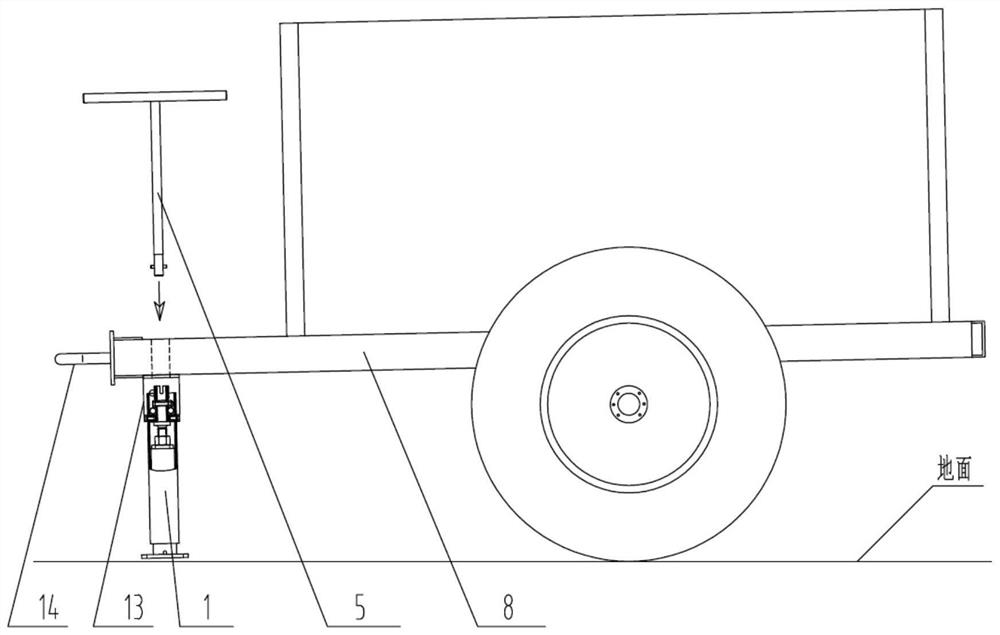

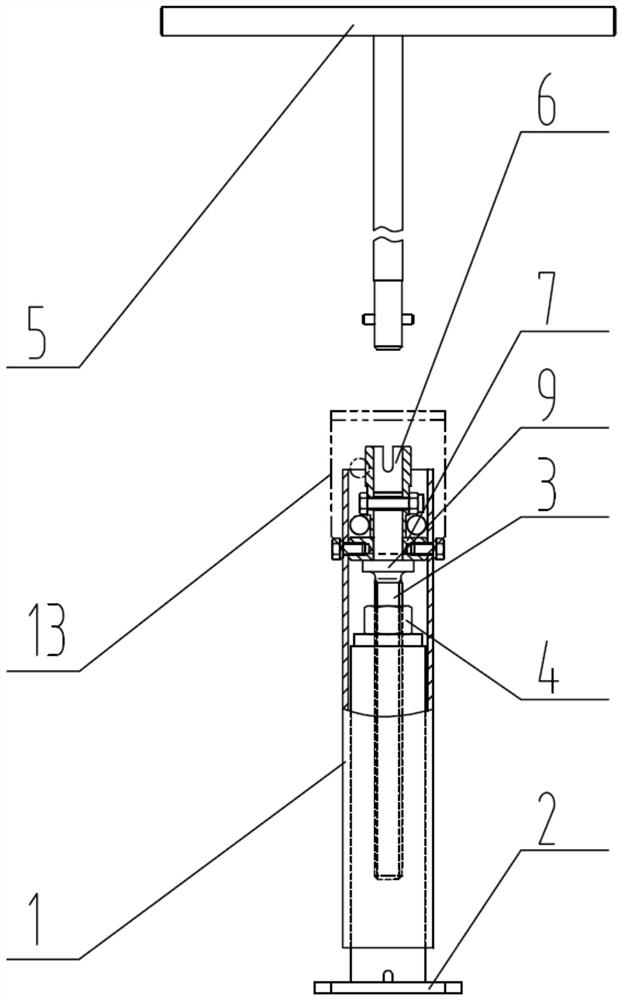

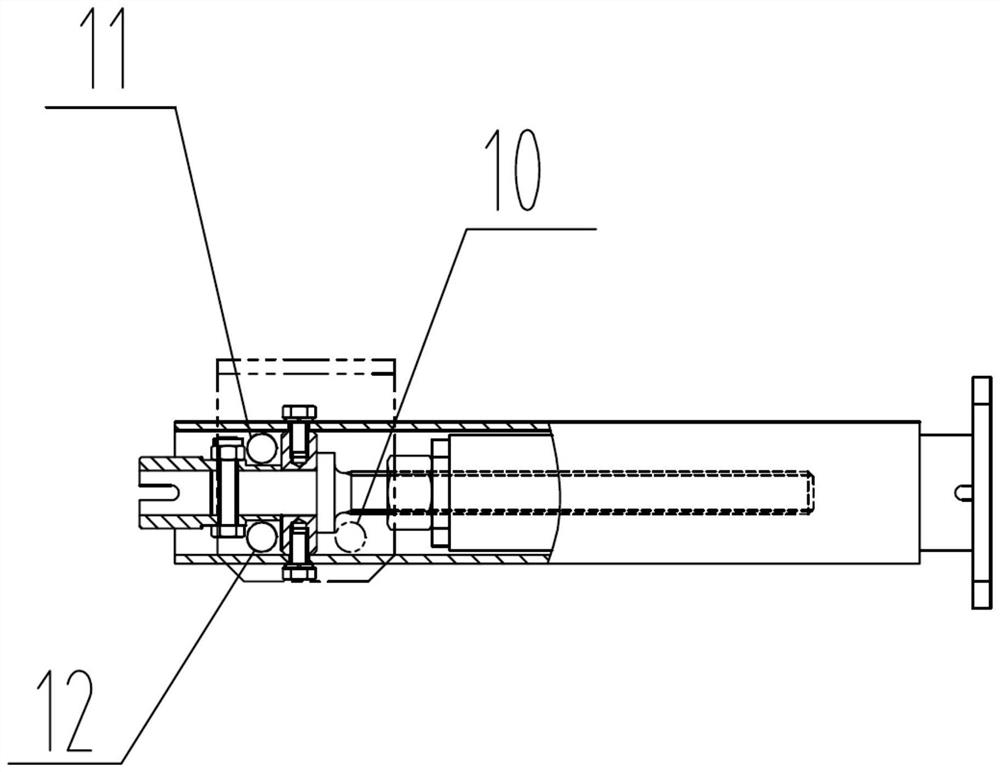

Trailer supporting leg mechanism

InactiveCN113348860AAchieve elongationImprove versatilityAgricultural machinesLoadersAgricultural engineeringJackscrew

The invention relates to the technical field of agricultural machinery, in particular to a trailer supporting leg mechanism. The trailer supporting leg mechanism comprises a square outer sleeve, an adjusting screw and a square inner supporting leg arranged in the outer sleeve in a sliding mode, wherein one end of the inner supporting leg is fixedly connected with a nut top plate, and the other end of the inner supporting leg is a supporting foot; the adjusting screw penetrates through the outer sleeve and the inner supporting leg and is in threaded fit with the nut top plate to adjust the up-down telescopic amount of the inner supporting leg. According to the trailer supporting leg mechanism, the problem that a trailer supporting leg can be installed and disassembled only by means of a jack and other external auxiliary tools in the actual use process in the prior art can be solved.

Owner:JIANGSU WORLD AGRI MACHINERY

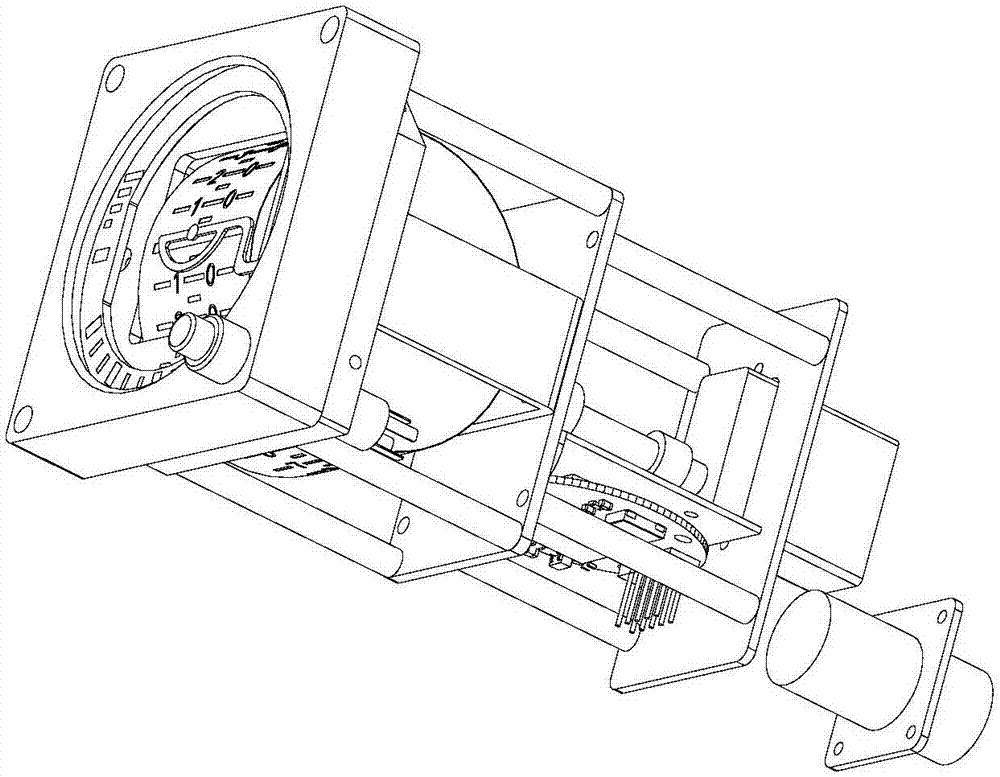

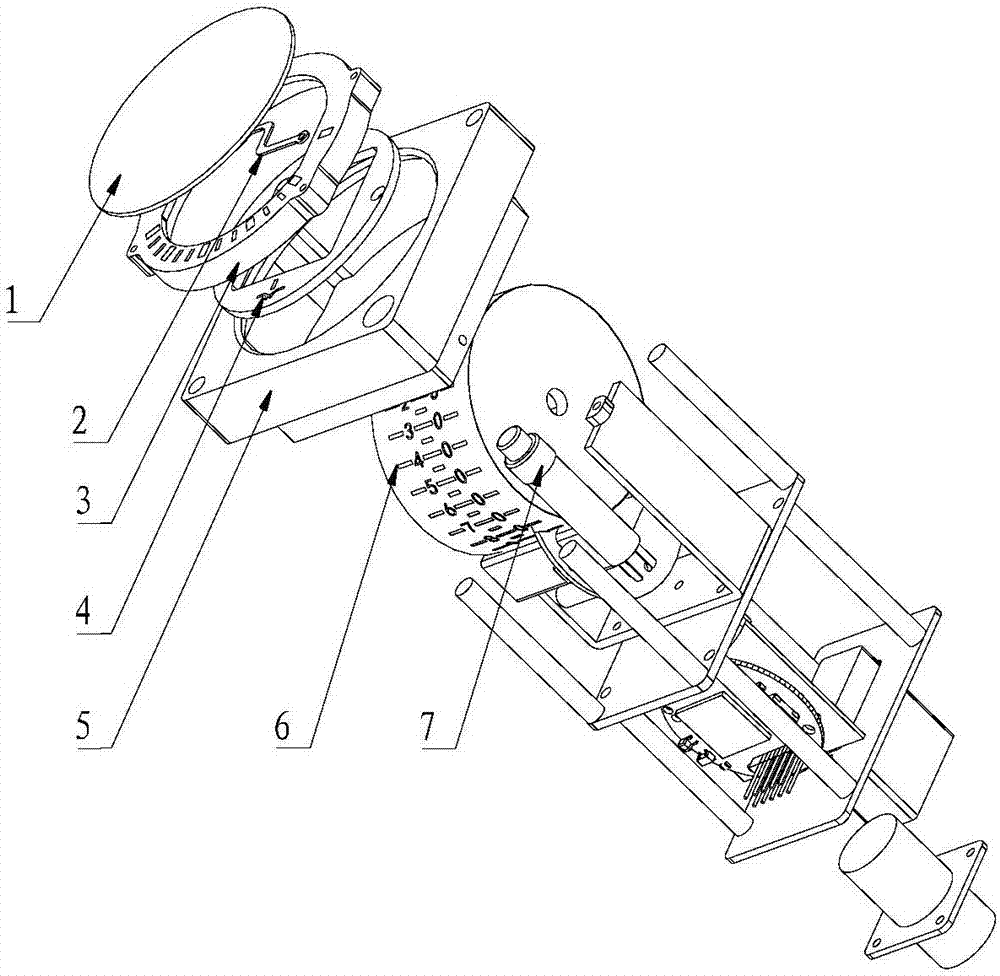

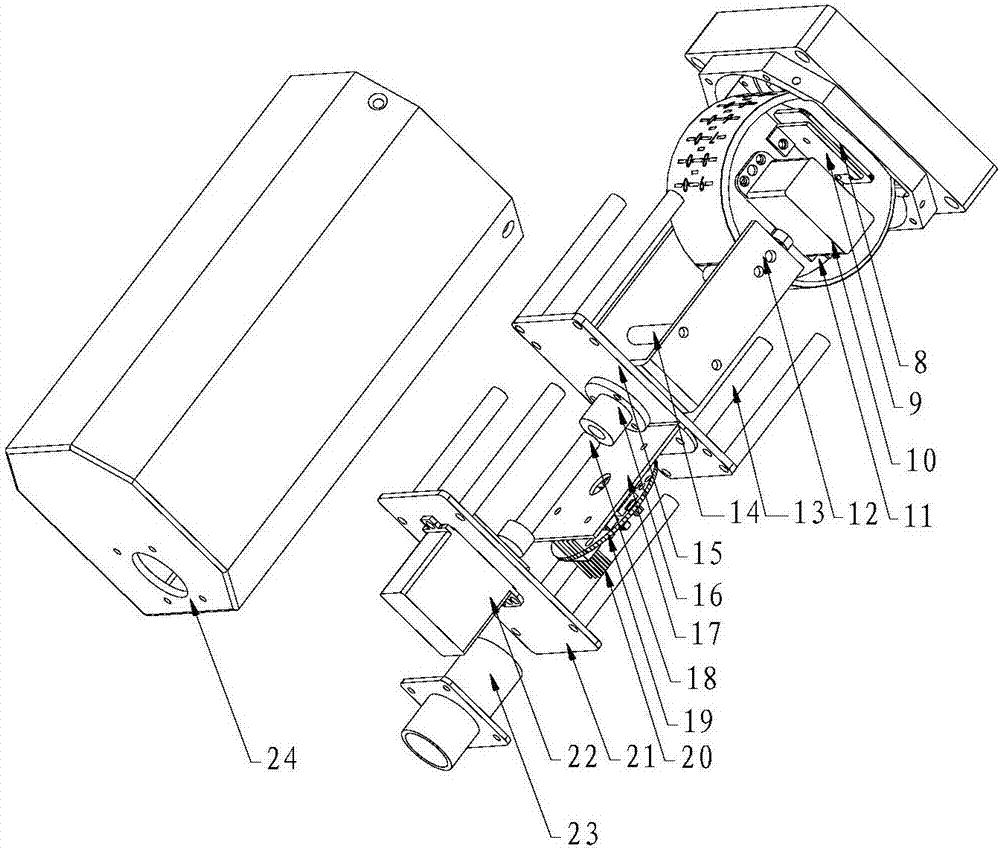

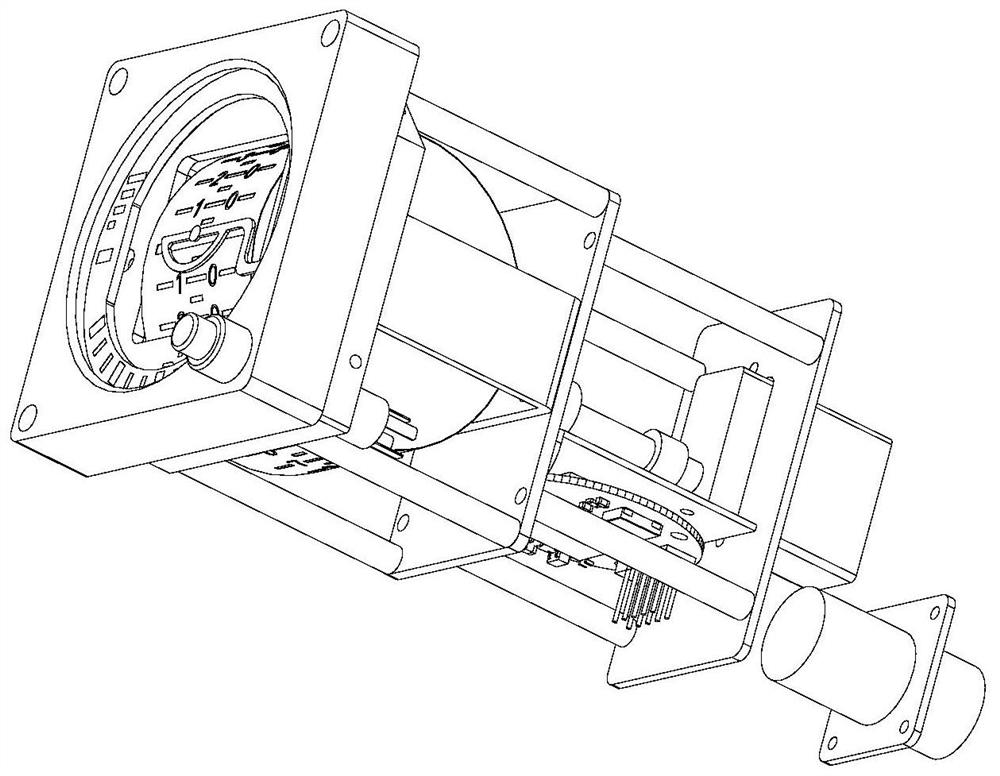

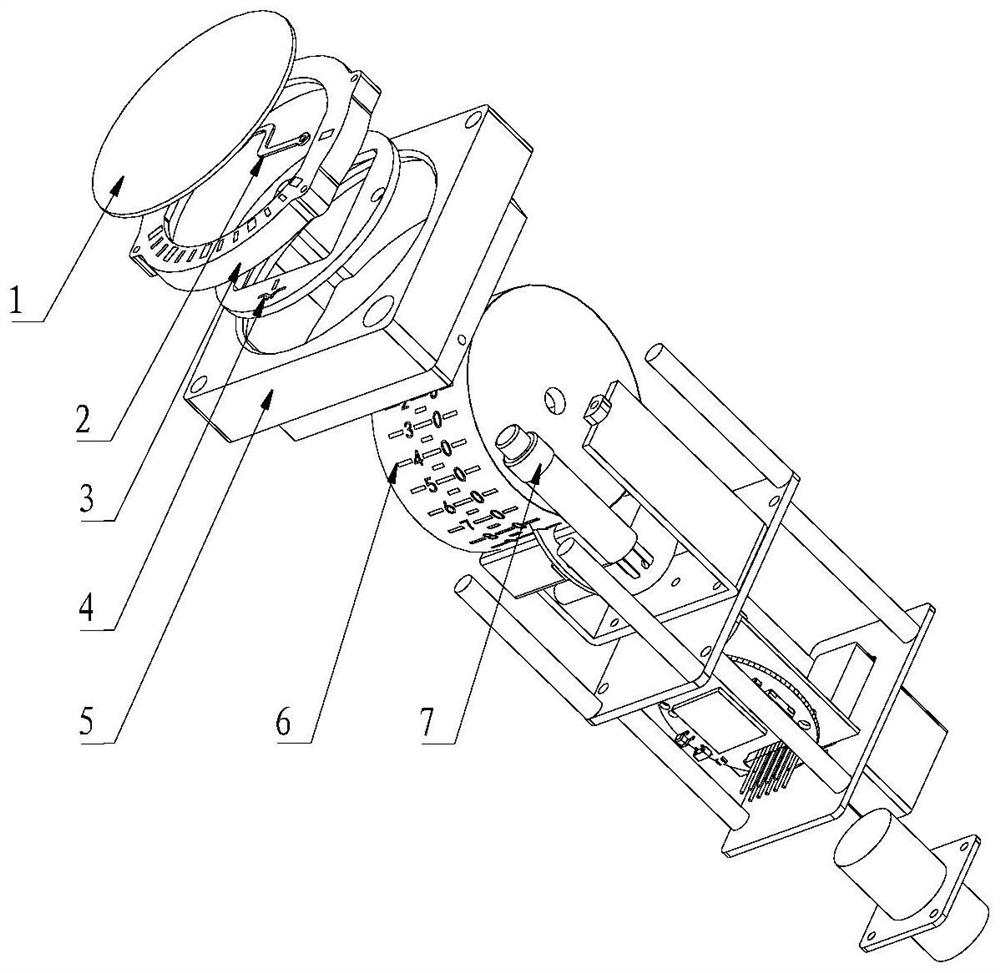

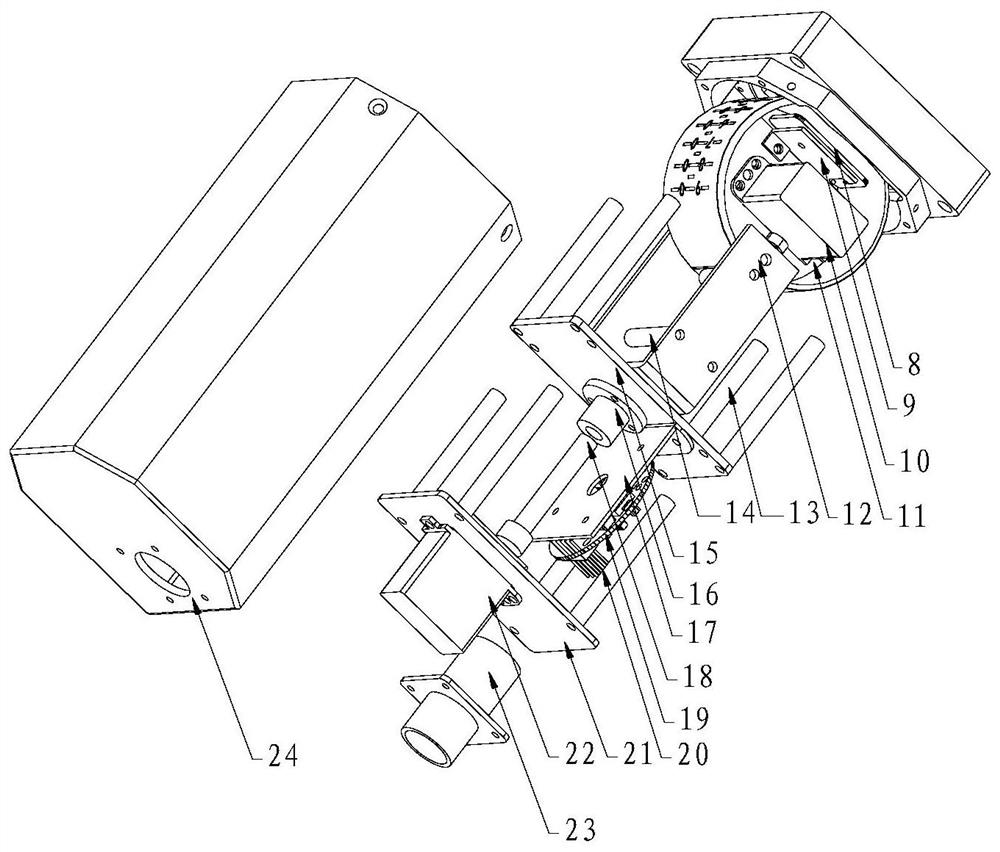

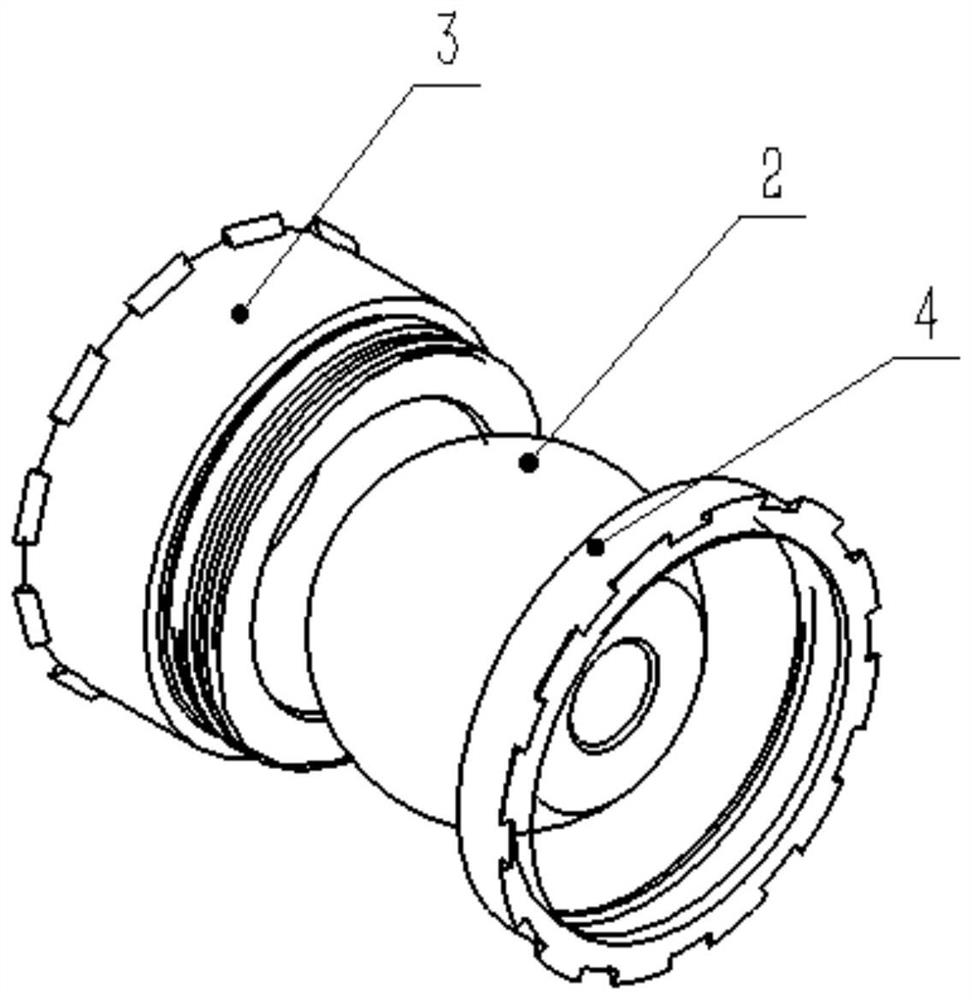

Flight simulation horizon based on CAN bus control

ActiveCN107067873AConsistent DimensionsCompact structureCosmonautic condition simulationsSimulatorsAviationHorizon

The invention belongs to the technology of flight simulation, and particularly provides a flight simulation horizon based on CAN bus control. The flight simulation horizon based on CAN bus control comprises protective glass, a pitch angle rotating mechanism, a horizontal angle rotating mechanism, a fixed mounting plate, a drive-controlled printed circuit board, a controlled printed circuit board support, a surface shell for packaging the above components and a rear cover, wherein the protective glass is arranged on the surface shell and is located above the horizontal angle rotating mechanism; the pitch angle rotating mechanism is embedded in the horizontal angle rotating mechanism; and the drive-controlled printed circuit board is arranged on the fixed mounting plate through the controlled printed circuit board support. The flight simulation horizon based on CAN bus control has the following advantages that the structure is compact; the data transmission rate is high; the response speed is quick; the reliability is high; light emission is uniform; the display effects are good; independent configuration as a function unit for the whole can be realized; and application requirements of simulation aircrafts with different models can be met.

Owner:SHANGHAI AVIATION ELECTRIC

A plate-type four-position four-way cone valve direct-acting electromagnetic reversing hydraulic valve

Owner:NINGBO HAIHONG HYDRAULICS

Automatic folding and binding machine and bending method for vermicelli

ActiveCN105857706BSmooth slidingAchieve bendingBinding material applicationMechanical engineeringBinding efficiency

The invention discloses an automatic bean vermicelli folding and binding machine and a bending method. The binding machine comprises a rack, a folding mechanism, a clamping shift mechanism and a binding mechanism, the folding mechanism is arranged at the front end of the binding mechanism, and the clamping shift mechanism is arranged above the binding mechanism. The binding method includes that the bean vermicelli is placed between a block pressure bar and a bending push trough; the bean vermicelli is bent in the shape of 'U'; the bean vermicelli is bent to the right side; the bean vermicelli is bent to the left side; a right-bending plate is reset; the bean vermicelli is clamped through the clamping shift mechanism; a left-bending plate is reset, the block pressure bar is allowed to descend, small to-be-bound bundles of the bean vermicelli are shifted out through the clamping shift mechanism to be bound, the block pressure bar is reset, and the bending mechanism is reset as well. By the arrangement, automatic folding, shifting and binding of the bean vermicelli can be realized, folding and binding efficiency is high, overall dimensions of the bean vermicelli are identical, elastic degrees of the bean vermicelli with less burr is appropriate, binding ropes are tied on lateral sides of the small bundles of the bean vermicelli, aesthetic effect of the bean vermicelli is unaffected when the small bundles of the bean vermicelli are put into transparent bags, workers are avoided touching the bean vermicelli during the working process, and further safety and sanitation in food is realized.

Owner:YANTAI GANGYUAN MACHINERY CO LTD

Adjustable electric control valve element

PendingCN111350846AMixing Ratio AdjustmentSimple structureOperating means/releasing devices for valvesMultiple way valvesEngineeringElectric control

The invention discloses an adjustable electric control valve element. The adjustable electric control valve element comprises a pulse valve, a water diversion rotary disc and a body sleeve; a valve body water inlet and a valve body water outlet are formed in one end of the pulse valve, and a butt joint terminal is arranged at the other end of the pulse valve; the water diversion rotary disc is fixedly arranged on the pulse valve, a water diversion opening and a rotary disc water outlet are formed in the water diversion rotary disc, the water diversion opening communicates with the valve body water inlet in a sealed mode, and the rotary disc water outlet communicates with the valve body water outlet in a sealed mode; and the body sleeve is arranged on the water diversion rotary disc in a sleeving mode and is rotationally connected with the water diversion rotary disc in a sealed mode, a plurality of body water inlets and a body water outlet are formed in the body sleeve, the body wateroutlet communicates with the rotary disc water outlet, and in the relative rotation process of the water diversion rotary disc and the body sleeve, the water diversion opening at least partially communicates with the water inlets. The adjustable electric control valve element is small in size, can be matched with a mechanical ceramic valve element, and can adjust the flow or the cold and hot watermixing proportion.

Owner:GULI (XIAMEN) TECH CO LTD

Aviation simulation flight ground level meter based on can bus control

ActiveCN107067873BConsistent DimensionsCompact structureCosmonautic condition simulationsSimulatorsAviationFlight vehicle

The invention belongs to aviation simulation technology, and specifically provides an aviation simulation flight horizon meter based on CAN bus control. The aviation simulation flight horizon table based on CAN bus control includes a protective glass, a pitch angle rotation mechanism, a horizontal angle rotation mechanism, a fixed mounting plate, a drive control printed circuit board, a control printed circuit board bracket, and a package for packaging the above-mentioned components. The watch case and the back cover, wherein the protective glass is installed on the watch case and is located above the horizontal angle rotation mechanism, the pitch angle rotation mechanism is embedded in the horizontal angle rotation mechanism, and the drive control printed circuit board passes through the control printed circuit board The bracket is arranged on the fixed mounting plate. The aviation simulation flight horizon table based on CAN bus provided by the invention has the following advantages: compact structure, high data transmission rate, fast response speed, high reliability, uniform luminescence, good display effect, as a whole functional unit, independent configuration, can Meet the application requirements of different models of simulated aircraft.

Owner:SHANGHAI AVIATION ELECTRIC

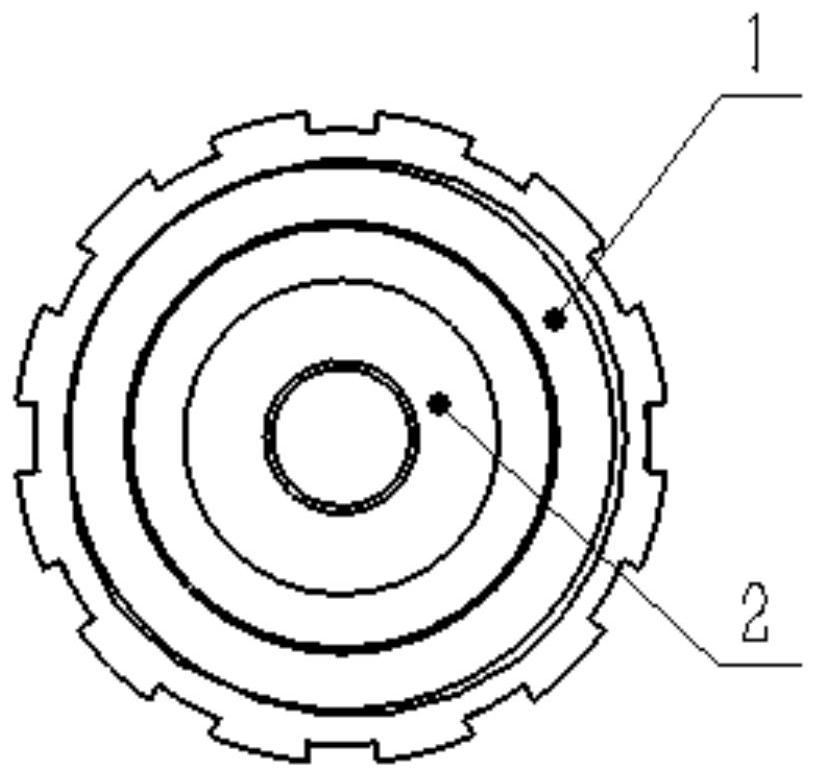

Novel knuckle bearing convenient to mount and replace

PendingCN112178050AEasy to installEasy to replaceSliding contact bearingsBearing unit rigid supportFixed bearingEngineering

The invention provides a novel knuckle bearing convenient to mount and replace. The knuckle bearing comprises a bearing outer ring and an inner ring; the inner ring is located in the bearing outer ring; the bearing outer ring comprises an outer ring body and a fixing ring; a first flange is arranged at one end of the outer ring body; an outer thread is arranged at the other end of the outer ring body; an inner thread is arranged on the inner surface of the fixing ring; a second flange is arranged at one end of the outer surface; and the outer ring is in threaded connection with the fixing ring. According to the novel knuckle bearing convenient to mount and replace, the appearance structure of a traditional knuckle bearing is changed, the bearing outer ring is divided into two parts including the outer ring body and the fixing ring, and the outer ring body and the fixing ring are connected in a threaded manner to fix the bearing, so that the bearing can be mounted and dismounted conveniently, and the bearing can be screwed down after being normally mounted; and the bearing is consistent with the traditional bearing in outline dimension, service life and bearing capacity, and is convenient to popularize and apply.

Owner:AEROSPACE PRECISION PROD INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com