Automatic laser cleaning device used for cleaning aircraft parts

A technology for laser cleaning and parts, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of low efficiency, long processing time, etc., achieve short adjustment time, fast response, and avoid repeated cleaning processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

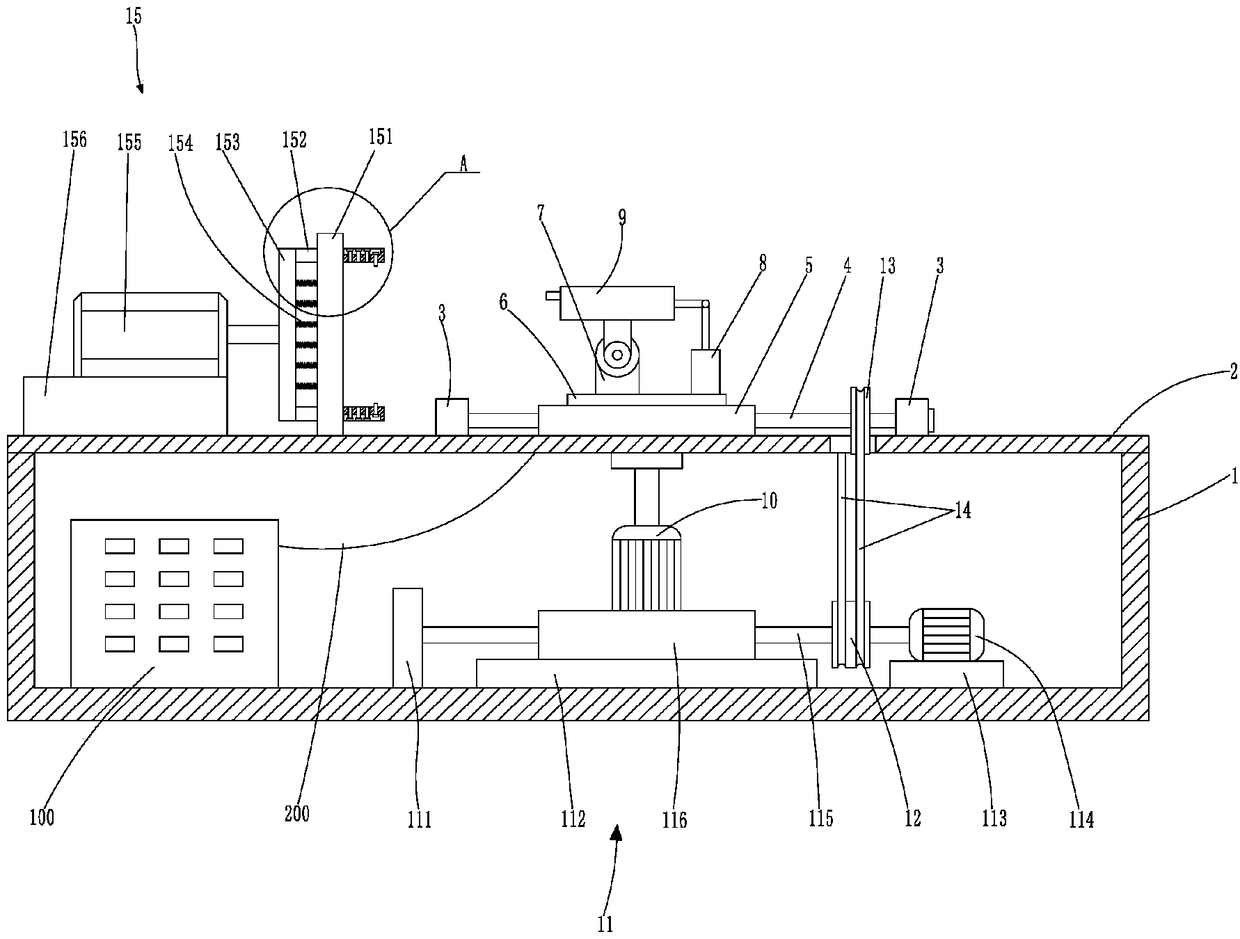

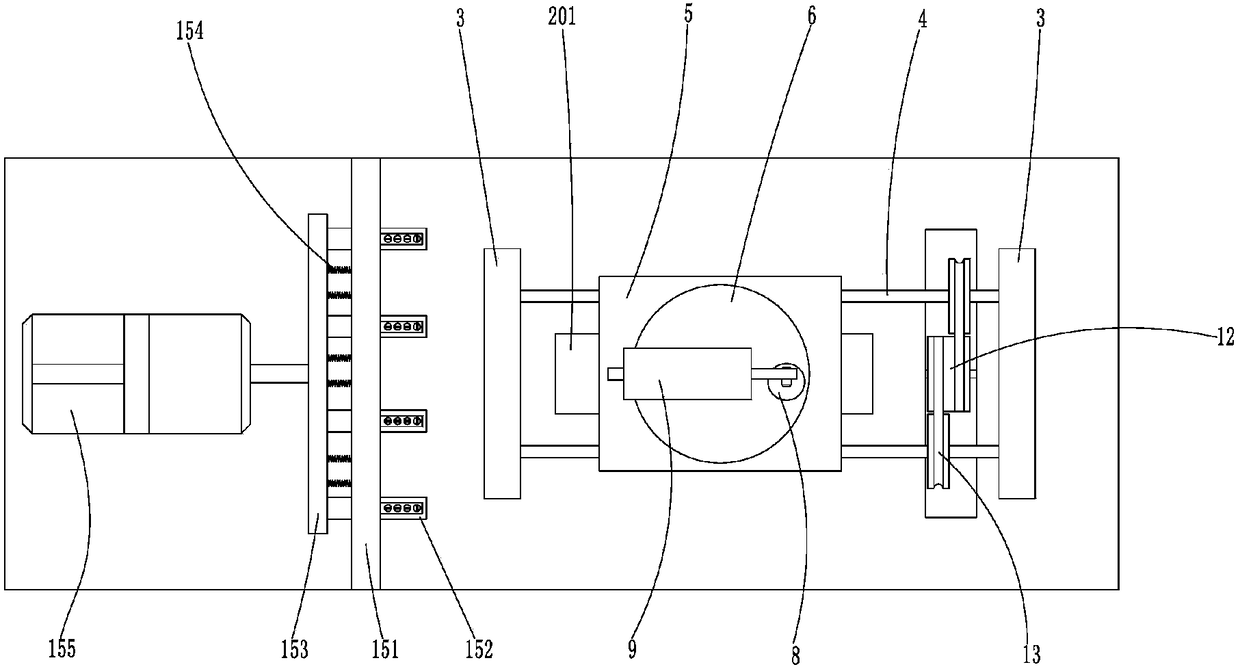

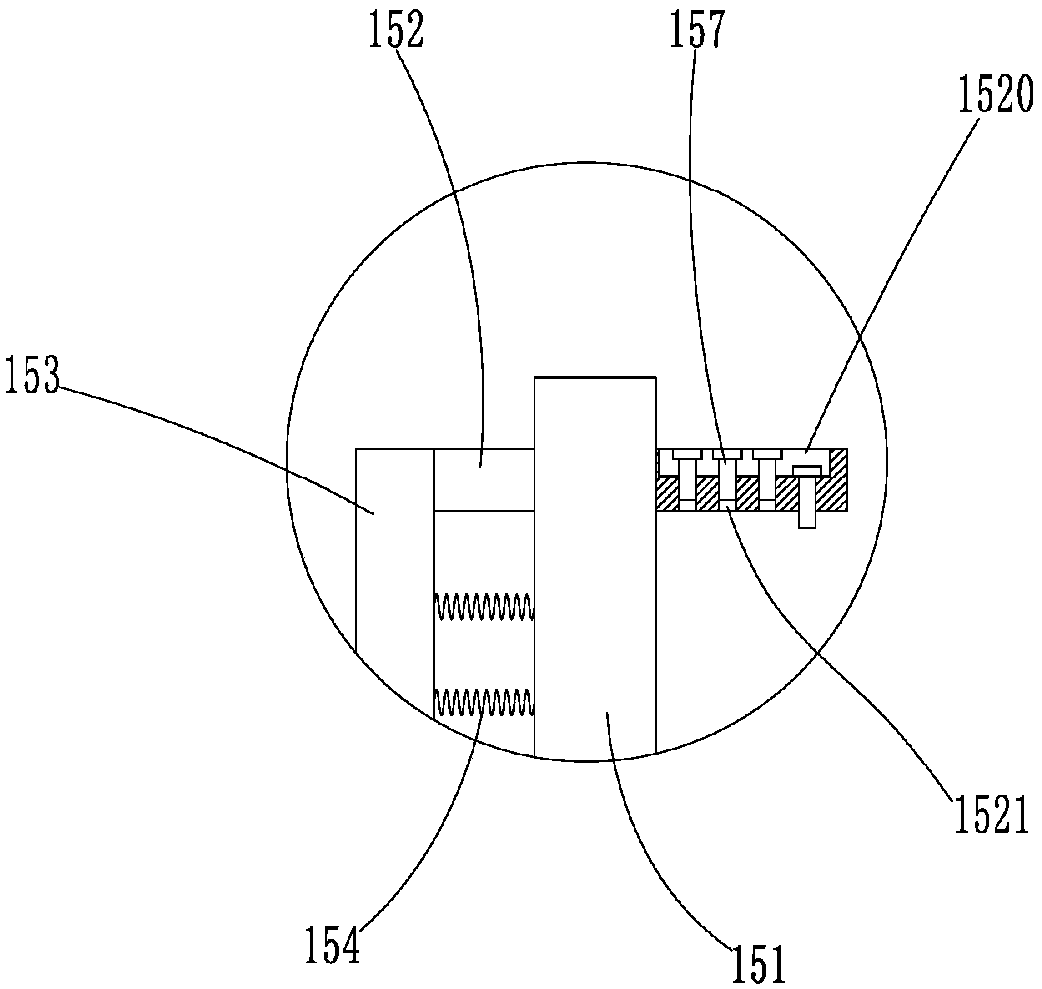

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] like Figure 1 ~ Figure 3 As shown, a kind of automatic laser cleaning device for aircraft parts cleaning according to the present invention includes an open base 1, the base 1 is a cuboid structure and the support plate 2 is fixed on the base 1, the base 1 1 is equipped with a laser generator 100, a rectangular hole 201 is opened on the support plate 2 along its length direction, two positioning blocks 3 are respectively located outside the short sides of the rectangular hole 201 on the support plate 2, and the two positioning blocks 3 There are two parallel first screw rods 4 for rotation between them. The two first screw rods 4 are threaded with a sliding seat 5 that is slidingly matched with the support plate 2. Through the rotation of the two first screw rods 4, the sliding The seat 5 moves laterally on the support plate 2 . A rotating disk 6 with a "T" s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com