Large-format array femtosecond laser micro-fluidic chip direct printing method and equipment thereof

A microfluidic chip and femtosecond laser technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low technical efficiency and low intelligence in the preparation of microfluidic chips, and achieve the benefits of mass production. The effect of high preparation and processing stability and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The following examples will further illustrate the present invention in conjunction with the accompanying drawings. This example is based on the method of femtosecond laser interference to realize the preparation technology of large-format array femtosecond laser direct printing microfluidic chips, but this example cannot be used to limit the present invention , all the similar methods of the present invention and similar changes thereof should be included in the protection scope of the present invention.

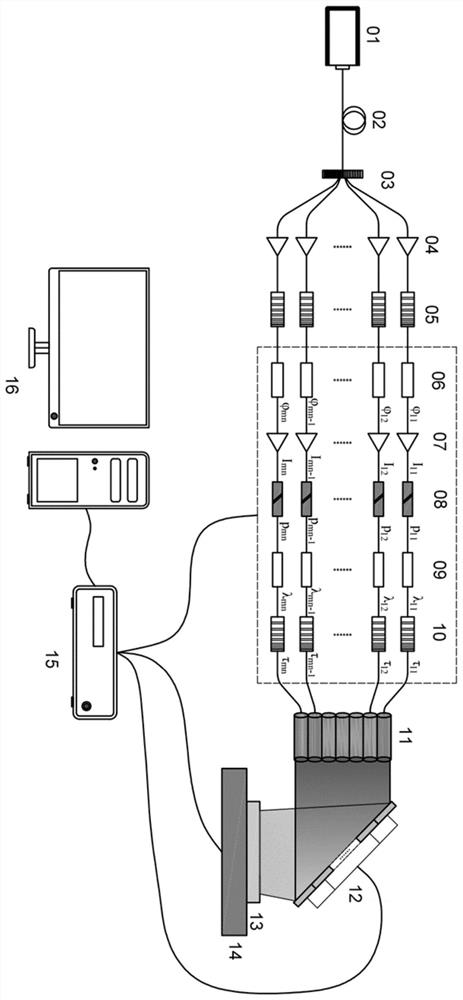

[0083] figure 1 The computer system (16) implements the phase modulator (06), the light intensity modulator (07), the polarization controller (08), the frequency multiplier (09), and the pulse compressor (10) through the integrated controller (15). control the phase φ, light intensity I, polarization p, center wavelength λ, and pulse width τ of each split laser beam, and realize the signal control of each mirror unit in the mirror array element device (12), and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com