Method for hollow molding of compound material and auxiliary assembly thereof

A composite material and auxiliary tooling technology, applied in the field of processing technology, can solve the problems of easy cracking at the joints, poor surface quality, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

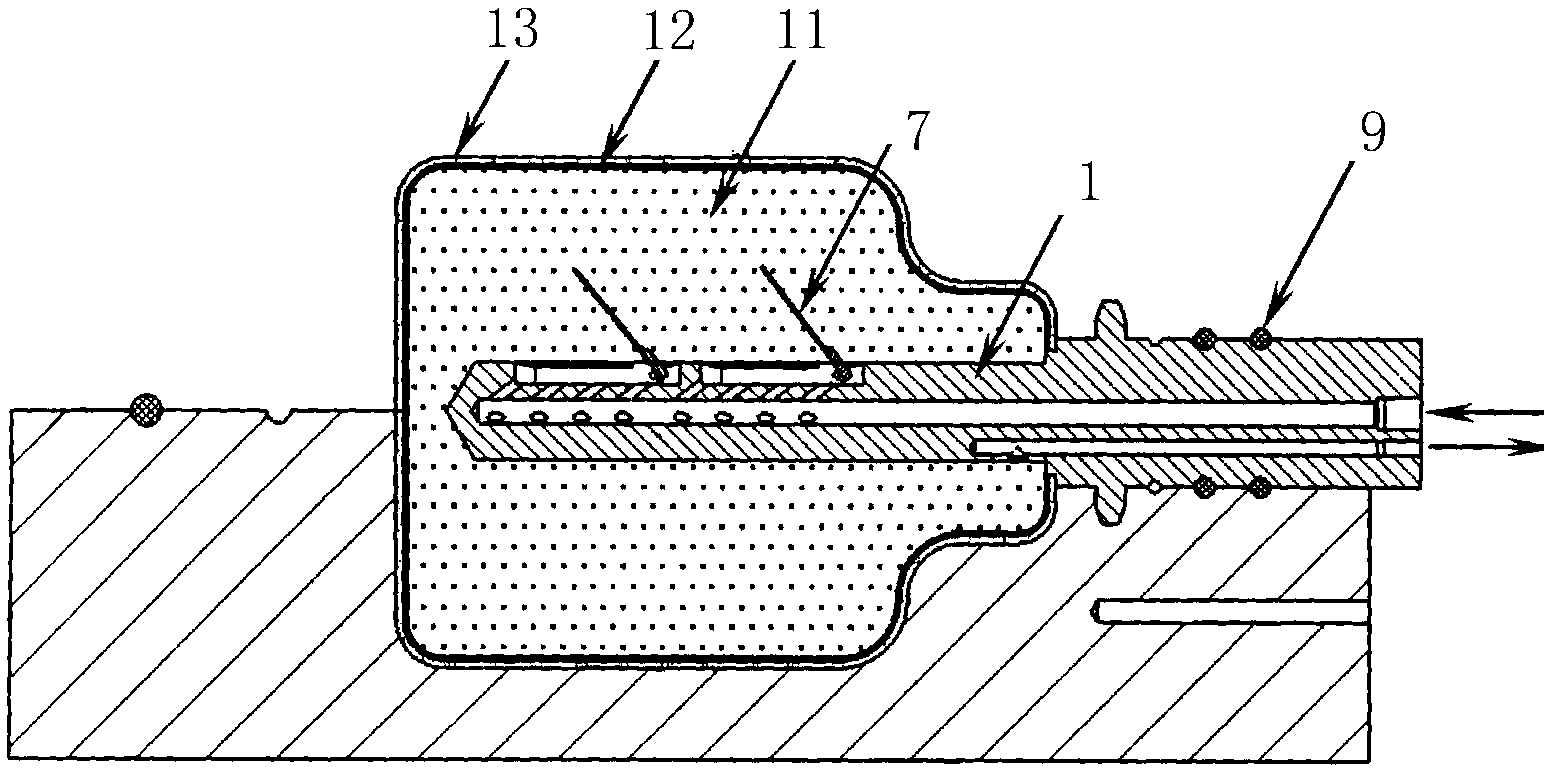

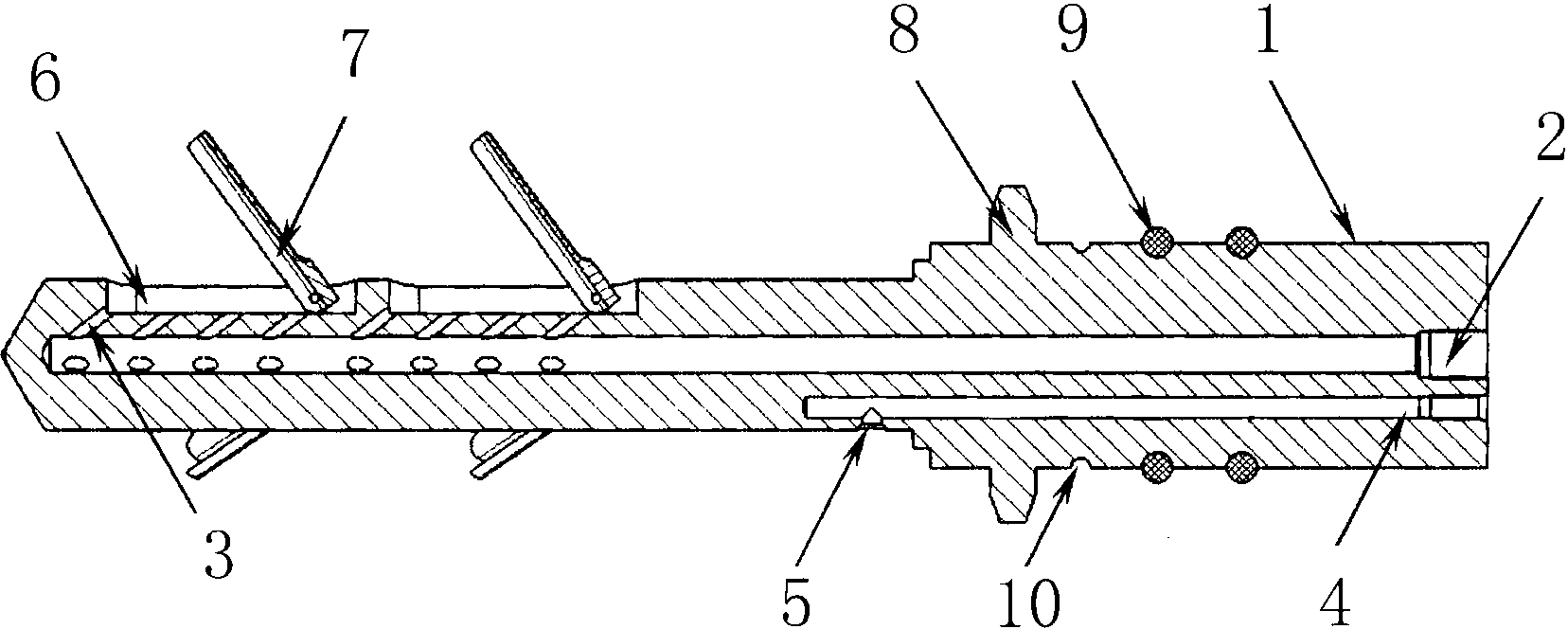

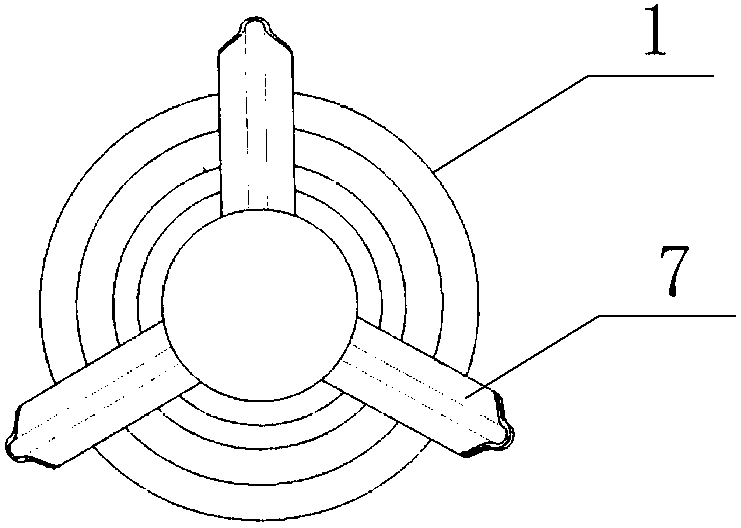

[0023] Such as figure 1 Shown, a kind of composite hollow molding method comprises the following steps:

[0024] 1) Use the hollow auxiliary tooling as the center, and use the casting method to make a fetal membrane 11 with low melting point materials;

[0025] 2) Wrap a layer of film isolation layer 12 on the surface of the fetal membrane to form a double-layer carcass, and apply a release agent;

[0026] 3) Wrap the prepreg 13 outside the film isolation layer, and then put it into a hot press mold coated with a release agent;

[0027] 4) Inject heated inert gas through the hollow auxiliary tooling to increase the temperature and pressure in the double-layer carcass to melt the low melting point embryo body;

[0028] 5) Heat up the external hot-pressing mold to ensure that the internal and external temperatures of the composite material are consistent;

[0029] 6) Under the condition of ensuring the specified pressure in the inner cavity of the composite material, the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com