Method for making structured biological deodorizing filler and structured biological deodorizing filler

A technology of biological deodorization and production method, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of increased initial operation of the project, inconsistent pores, and increased system resistance, reducing load requirements and equipment cost. Low, low pressure drop across the filter bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

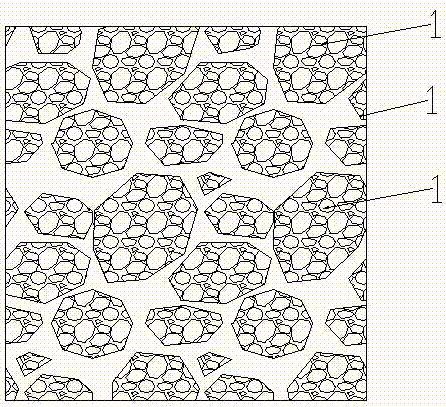

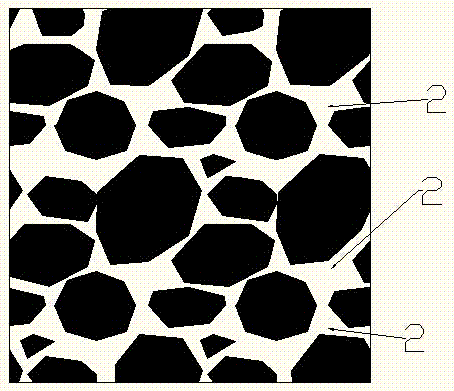

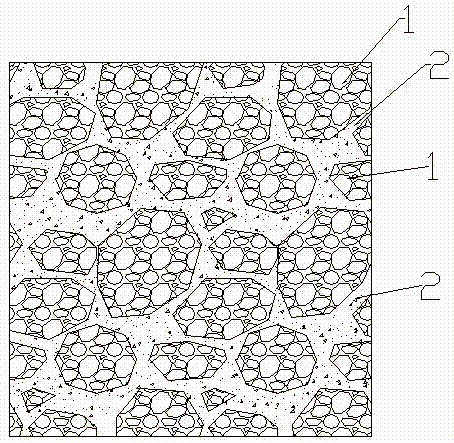

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] The preparation method of the regular biological deodorizing filler of the present invention is based on light ceramsite, calcium hydroxide, silicate, sodium humate, straw particles, compound nutrients (urea, methanol, humic acid, nitrogen, phosphorus and potassium compound fertilizer, molasses) , peptone, light pumice powder and other components) as raw materials, add about 20% of water, through ordinary production equipment, press into a regular biological filler with a fixed shape, and pack it into bags after natural drying. In addition to calcium hydroxide, it can also be strongly alkaline hydroxides such as potassium hydroxide.

[0047] Among them, according to the weight ratio of raw materials: 60-70% of light ceramsite, 2-3% of calcium hydroxide, 12-15% of silicate, 3-5% of sodium humate, 12-15% of straw particles, and compound nutrients (urea,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com