Filler used for sewage plant external whole-process deodorization system and preparation method of filler

A production method and external technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the effect of biological deodorization process is not particularly ideal, the installation is time-consuming and laborious, and the production Complicated process and other issues, to achieve the effect of improving the deodorization effect, simple production process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of packing used for the external full-process deodorization system of sewage plant, the composition mass percentage of described deodorizing packing is as follows:

[0033] 45% of ordinary Portland cement, 48% of plant ash, 1% of compound nutrients, and the balance is water.

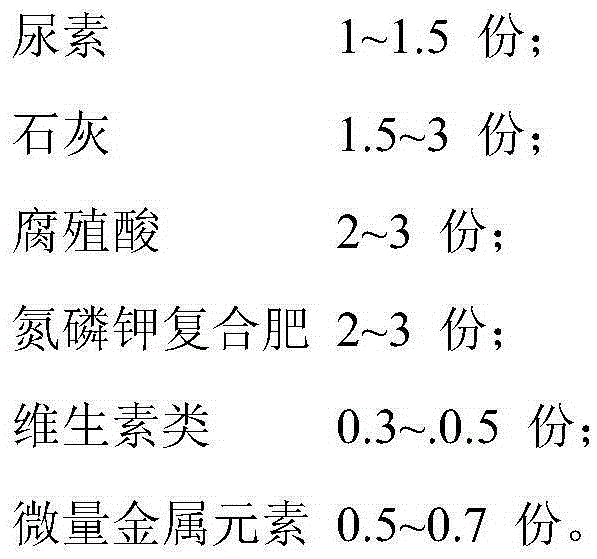

[0034] Wherein, the composition and parts by weight of the compound nutrients are as follows:

[0035]

[0036] The above-mentioned method for making the filler for the external full-process deodorization system of the sewage plant, the steps are as follows:

[0037] Ordinary Portland cement and plant ash are ground into powder respectively, weighed so that the weight meets the requirements of the filler ratio, and then the weighed ordinary Portland cement and plant ash powder are fully mixed and stirred repeatedly to remove the When the air bubbles reach the conditions before molding, compound nutrients and water are added to the mixture, and the regular shape of the filler is pressed ...

Embodiment 2

[0042] A kind of packing used for the external full-process deodorization system of sewage plant, the composition mass percentage of described deodorizing packing is as follows:

[0043] 46-47% of ordinary Portland cement, 48.5% of plant ash, 1.5% of compound nutrients, and the balance is water.

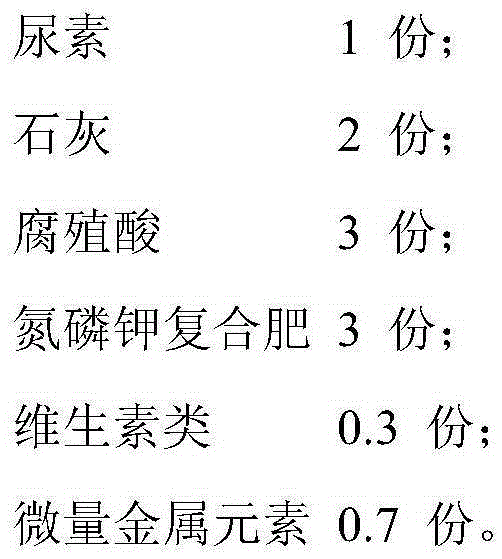

[0044] Wherein, the composition and parts by weight of the compound nutrients are as follows:

[0045]

[0046] The above-mentioned method for making the filler for the external full-process deodorization system of the sewage plant, the steps are as follows:

[0047] Ordinary Portland cement and plant ash are ground into powder respectively, weighed so that the weight meets the requirements of the filler ratio, and then the weighed ordinary Portland cement and plant ash powder are fully mixed and stirred repeatedly to remove the When the air bubbles reach the conditions before molding, compound nutrients and water are added to the mixture, and the regular shape of the filler is p...

Embodiment 3

[0052] A kind of packing used for the external full-process deodorization system of sewage plant, the composition mass percentage of described deodorizing packing is as follows:

[0053] 48% of ordinary Portland cement, 49% of plant ash, 2% of compound nutrients, and the balance is water.

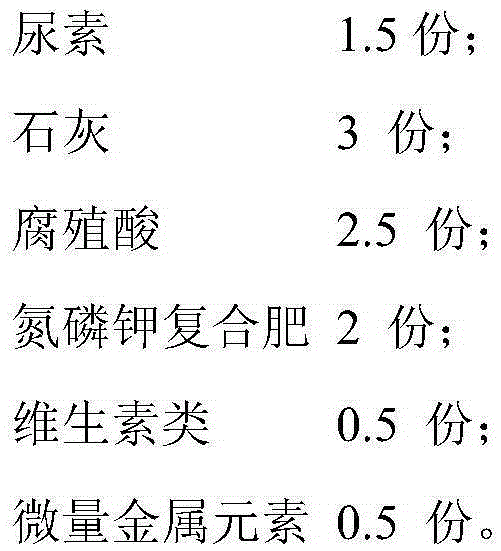

[0054] Wherein, the composition and parts by weight of the compound nutrients are as follows:

[0055]

[0056] The above-mentioned method for making the filler for the external full-process deodorization system of the sewage plant, the steps are as follows:

[0057] Ordinary Portland cement and plant ash are ground into powder respectively, weighed so that the weight meets the requirements of the filler ratio, and then the weighed ordinary Portland cement and plant ash powder are fully mixed and stirred repeatedly to remove the When the air bubbles reach the conditions before molding, compound nutrients and water are added to the mixture, and the regular shape of the filler is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com