Manufacturing method of balance transformer compensation coil

A technology of balancing transformers and compensating coils, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of easily damaged insulating parts, difficult operation of the overall process, and difficulty in lead welding, so as to reduce the difficulty and solve the problems. If the distance is too close, the effect of bandaging work is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

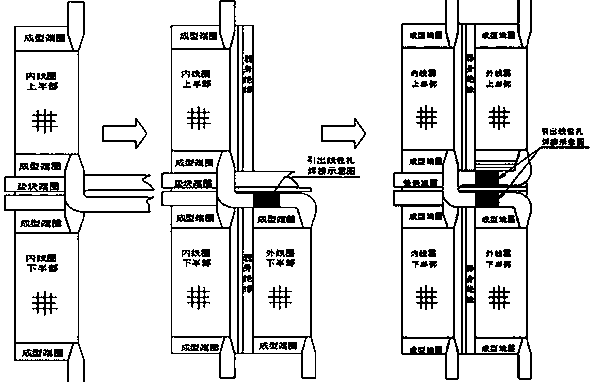

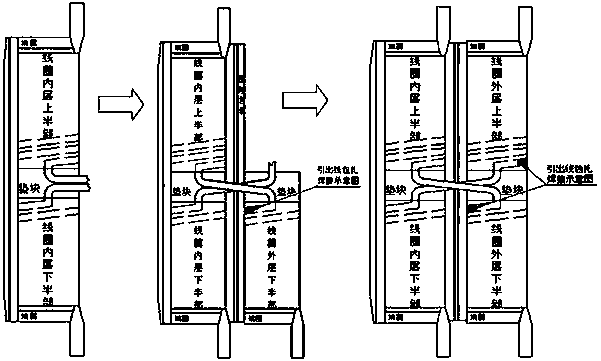

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] Such as figure 1 , figure 2 As shown, the present embodiment contrasts the difference between the original production method and the present invention,

[0014] It includes a method for making a compensation coil of a balance transformer, including process one, process two, process three, process four and process five, process one is to make the upper half of the inner coil, the lower half of the inner coil, the upper half of the outer coil and the outer The lower half of the coil is wound into a whole at the same time; the second process is to complete the assembly work of the upper half of the inner coil and the lower half of the inner coil, and the lead-out wires of the upper half of the coil and the lower half of the inner coil transition to the middle position of the outer coil , the S bend is a slow bend transition, and a 2-meter margin is reserved for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com