Novel forging method for manual tool

A hand tool, a new type of technology, applied in the forging field of mechanical tools, can solve the problems of low strike frequency and strike energy of friction presses, inconsistent product size, thickness and shape, and difficulty in ensuring product processing and production, so as to reduce the failure rate and maintenance costs, ensure product consistency, and precisely control the effect of striking energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

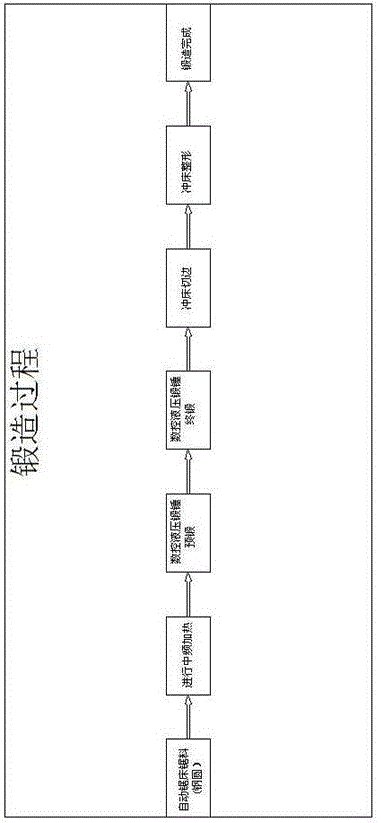

[0011] Such as figure 1 , figure 2 , a new type of forging process for hand tools, including the following steps:

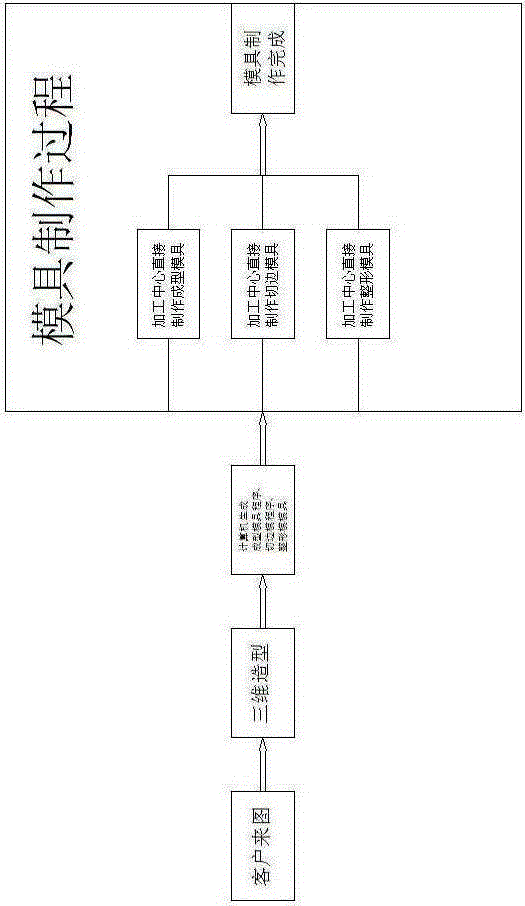

[0012] Step 1: Carry out three-dimensional modeling after the customer submits the drawing; and then obtain the forming mold program, trimming mold program and shaping mold mold through computer generation;

[0013] Step 2: mold manufacturing process; according to the forming mold program, the machining center directly makes the forming mold; according to the trimming mold program, the machining center directly makes the trimming mold; according to the shaping mold mold, the machining center directly makes the shaping mold;

[0014] Advantages: The machining center directly processes and forms, one step in place, saving trouble and labor, high processing precision, and the overall dimensions are exactly the same. The mold does not need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com