Inner chamber testing fixture for gear chamber of flywheel housing of engine

A technology of engine flywheel housing and gear chamber, which is applied in the testing of machine gears/transmission mechanisms, etc. It can solve problems such as high work intensity, installation interference, and forced off-line of parts, so as to improve production efficiency, reduce work intensity, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

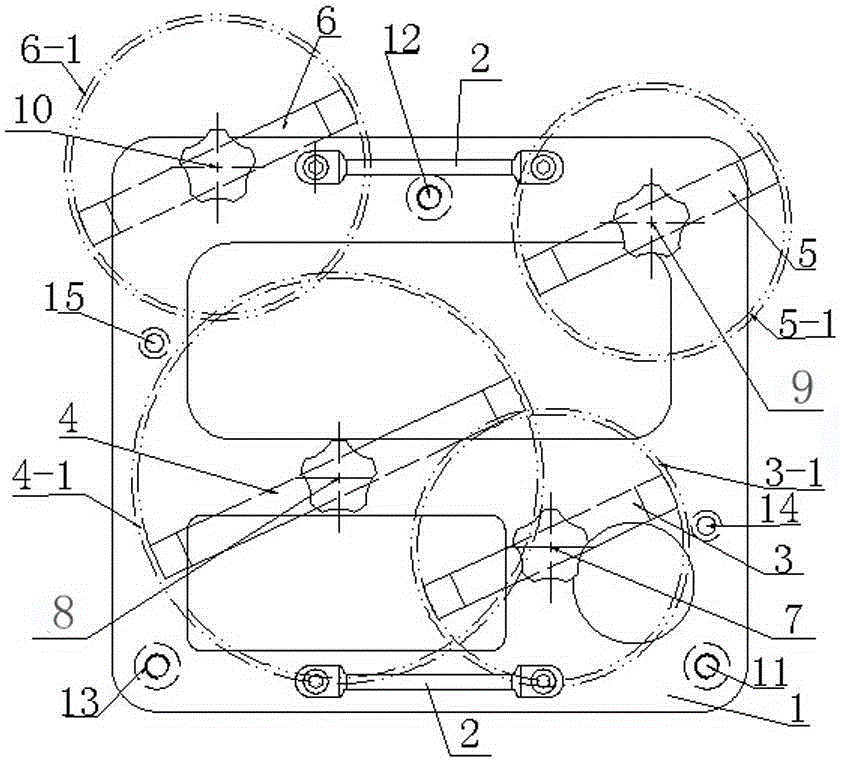

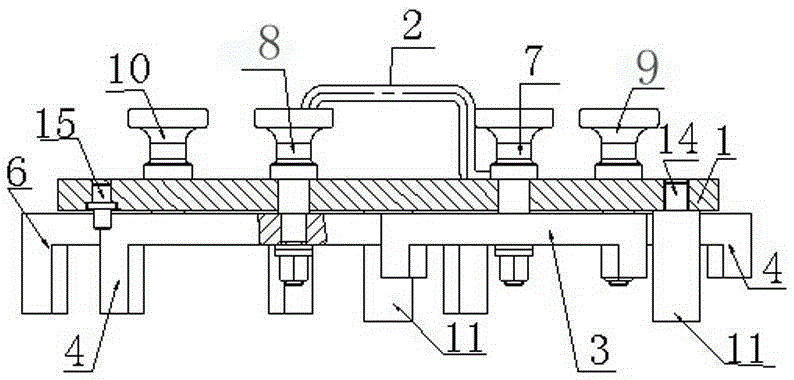

[0015] The present invention as figure 1 / 2 shown.

[0016] The inspection tool for the inner cavity of the gear chamber of the engine flywheel housing includes a frame-shaped body 1 hollowed out in the middle. The frame-shaped body 1 corresponds to the outer contour of the gear chamber of the engine flywheel housing. The two sides of shape body 1 are provided with positioning pin one 14 and positioning pin two 15 downwards, and positioning pin one 14 and positioning pin two 15 are correspondingly positioned at the outer contour side of engine flywheel housing gear room; Frame shape body 1 is downward Corresponding to the motion track 3-1 of gear one, the motion track 4-1 of gear two, the motion track 5-1 of gear three, and the motion track 6-1 of gear four, respectively, there are detection board one 3, detection board two 4, detection board three 5, Detection board four 6, frame-shaped body 1 corresponding to detection board one 3, detection board two 4, detection board thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com