Patents

Literature

59results about How to "Consistent trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

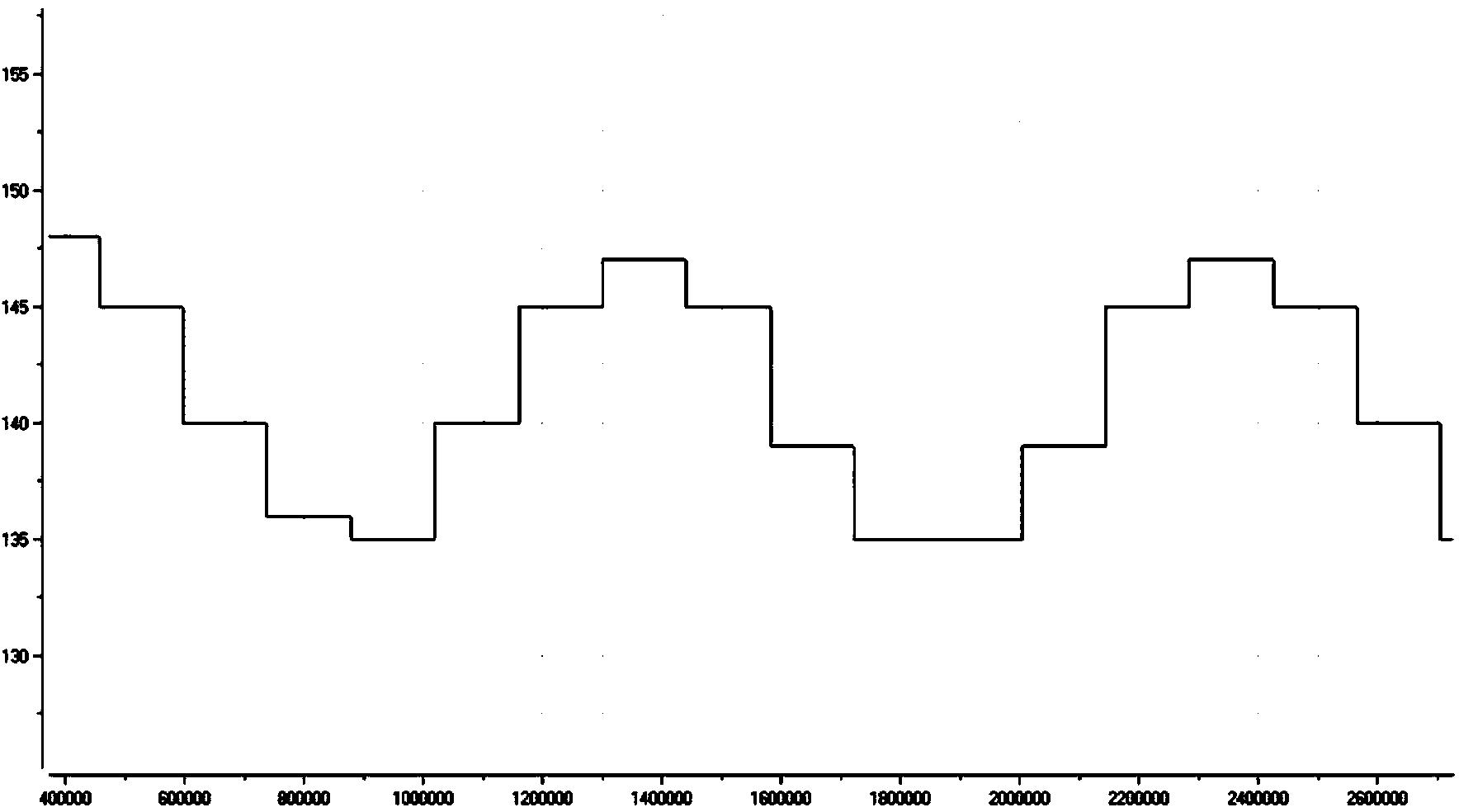

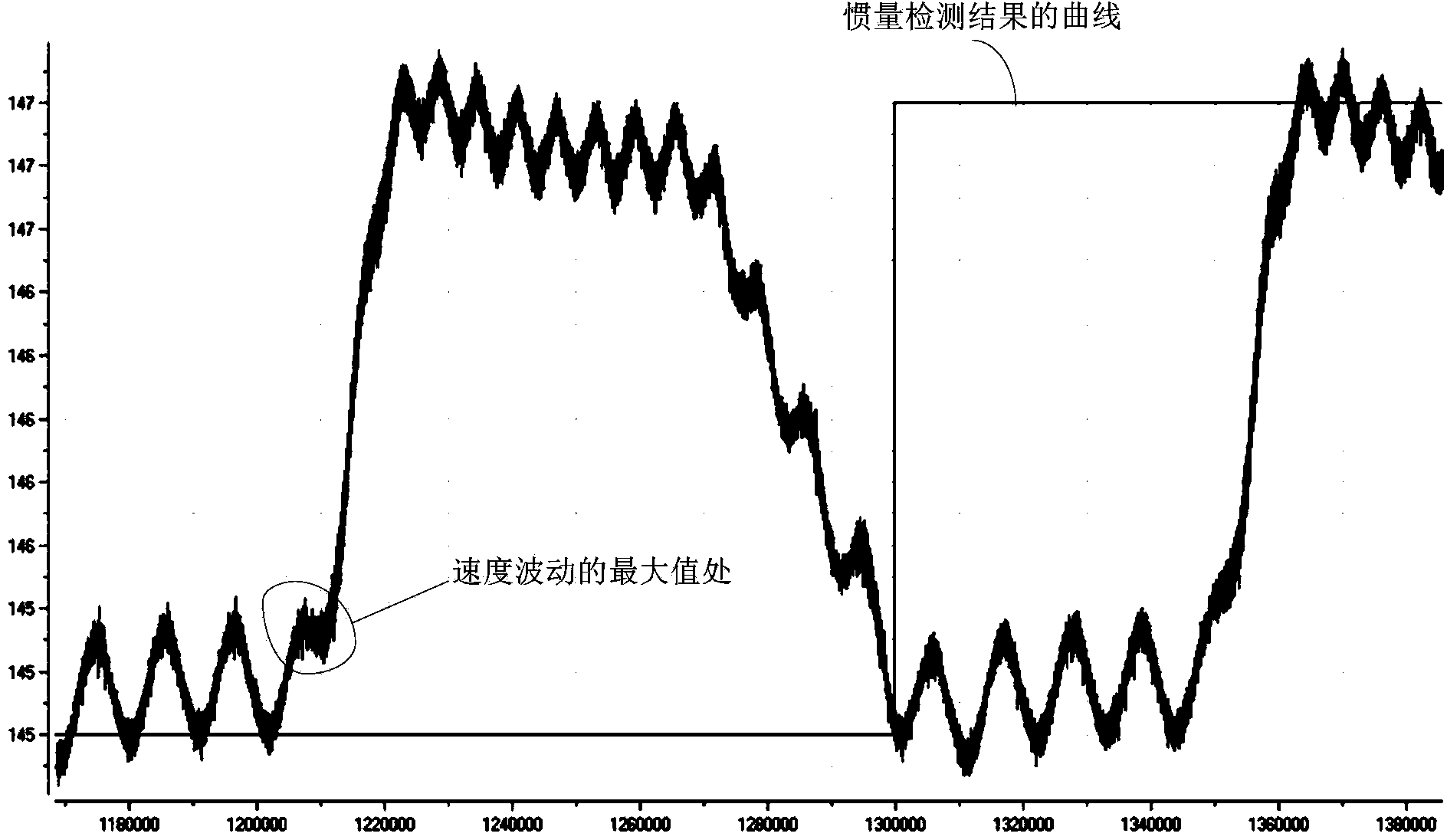

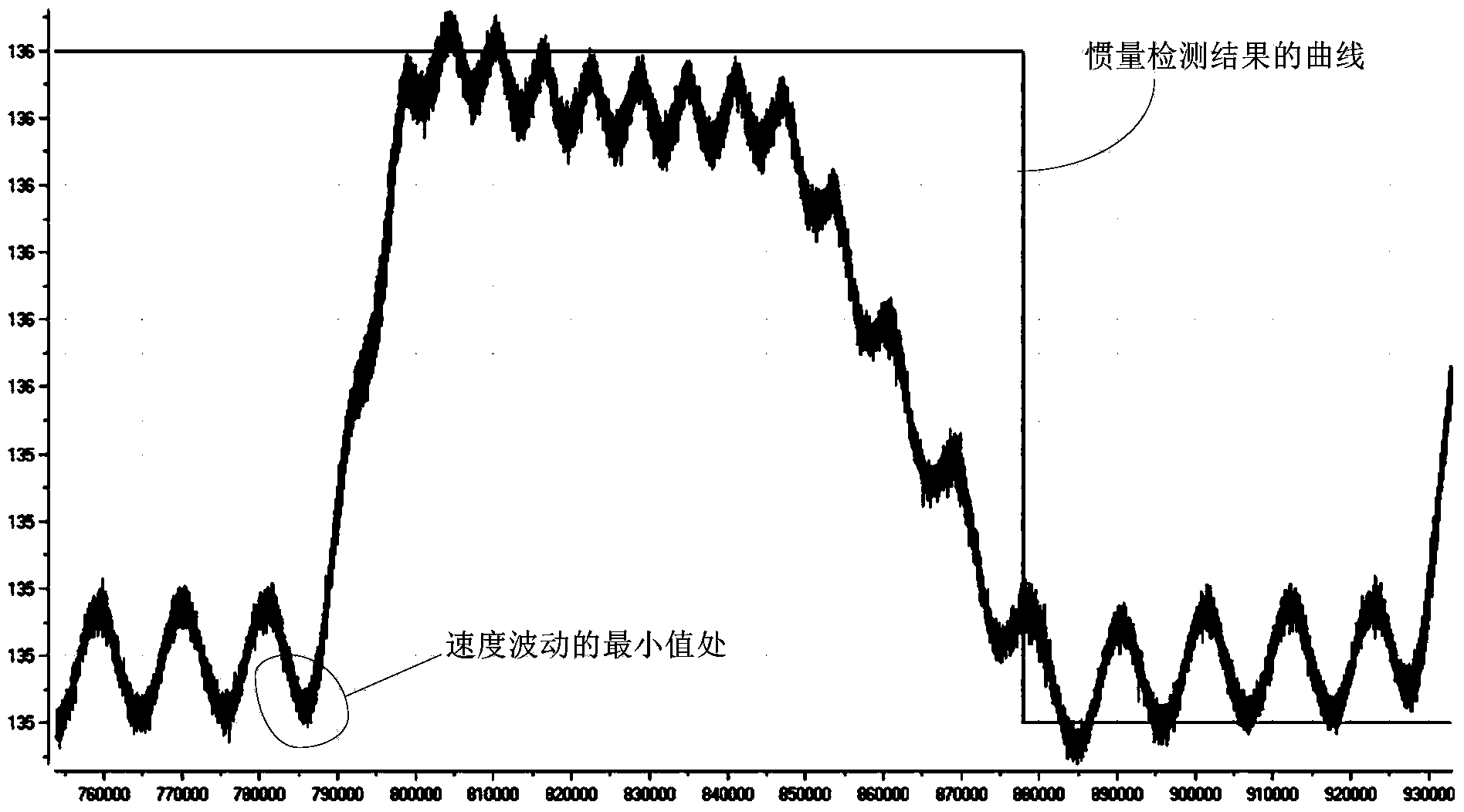

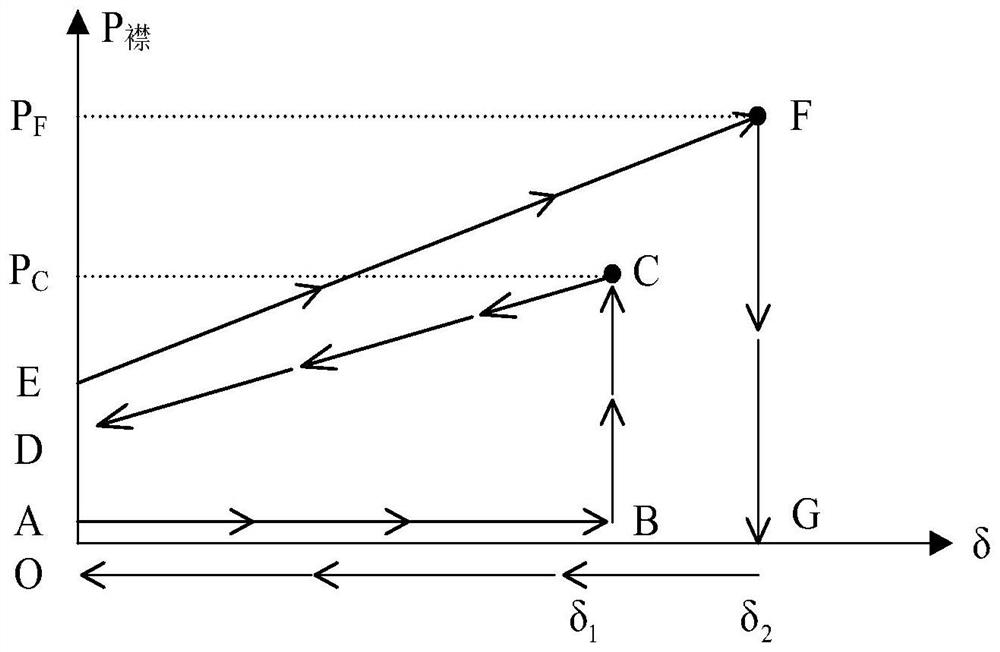

Roller washing machine and inertia detection method and device thereof

ActiveCN103966799AReduce detection errorEliminate detection errorsOther washing machinesControl devices for washing apparatusControl theoryElectromagnetic torque

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

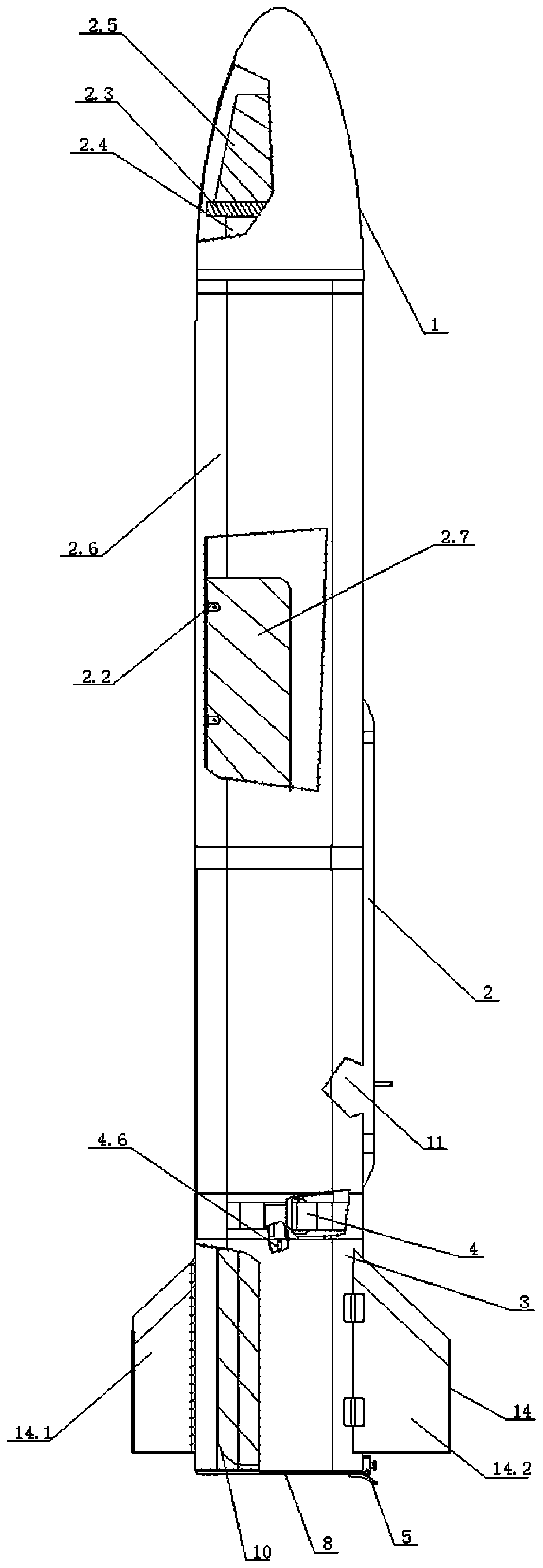

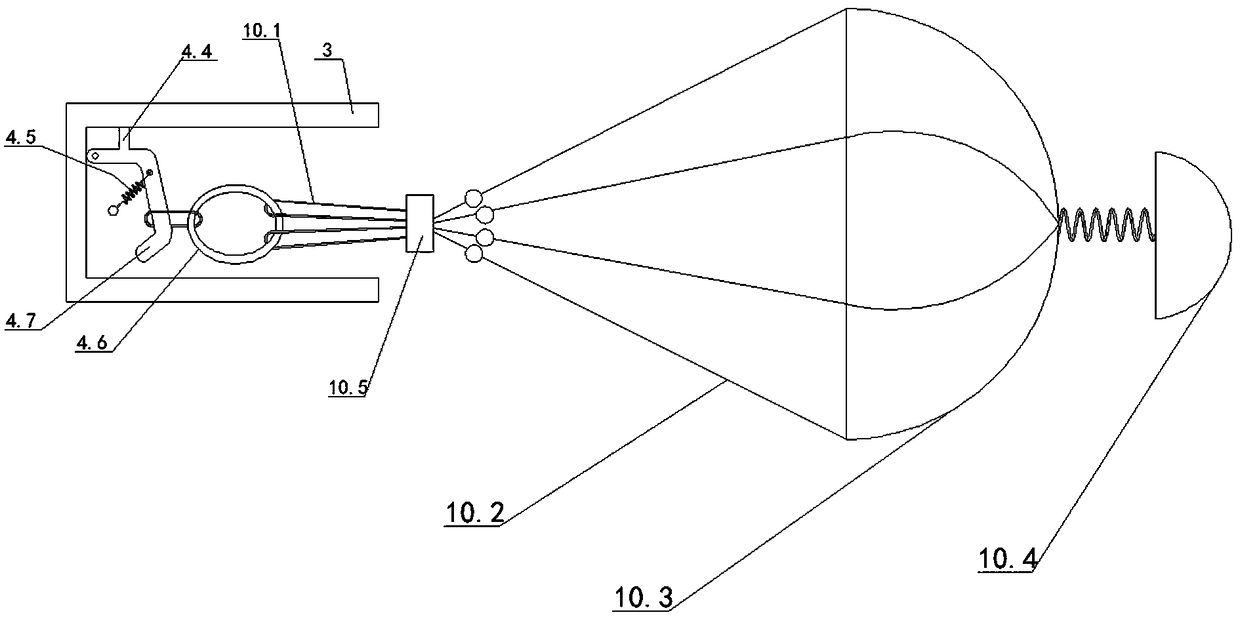

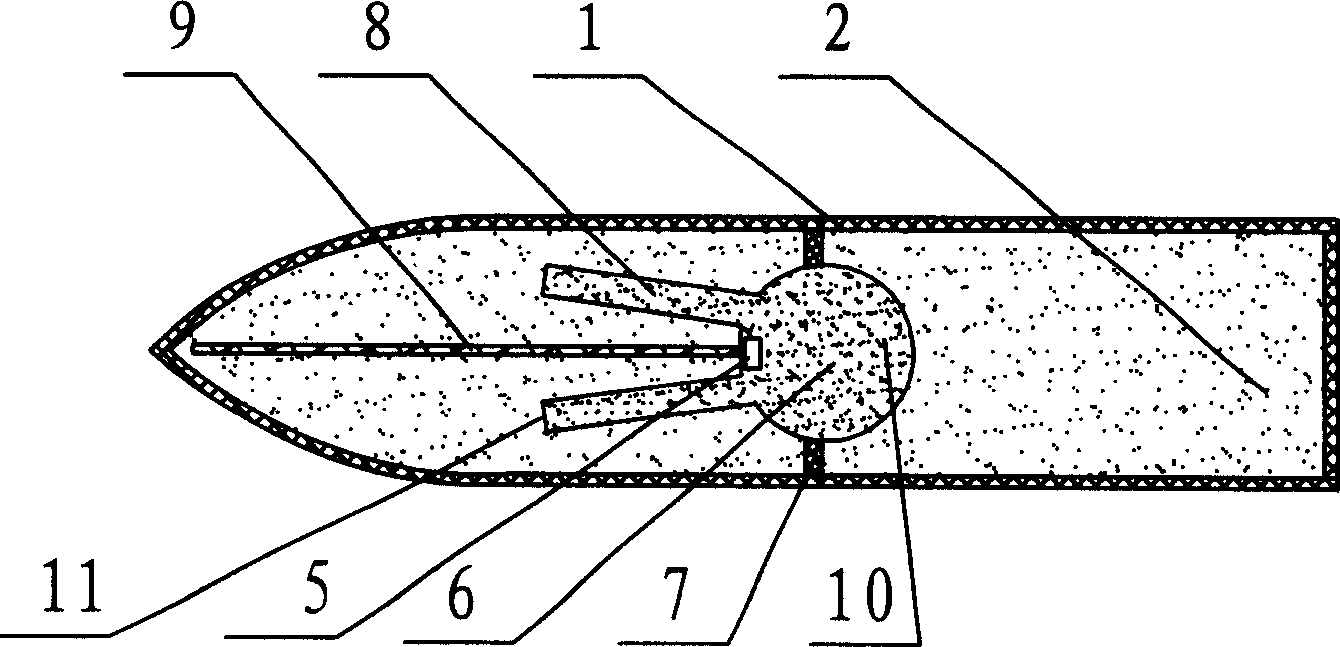

Material delivery nacelle with parachute

PendingCN108438226AImplement the airdrop jobImprove airdrop efficiencyParachutesFreight handlingNacelleAerospace engineering

The invention discloses a material delivery nacelle with parachutes, which comprises a hood (1), a cargo hold (2) and a parachute bay (3), wherein the front end of the cargo hold (2) is connected withthe hood (1), and the rear end of the cargo hold (2) is connected with the parachute bay (3); The parachutes (10) are arranged in the parachute bay (3). The parachute bay for parachutes is arranged on the material delivery nacelle, the parachutes are arranged in the parachute bay, the airdropping of the cargo is achieved without manual operation of the parachutes, and the airdropping efficiency is effectively improved.

Owner:四川众联航泰科技有限公司

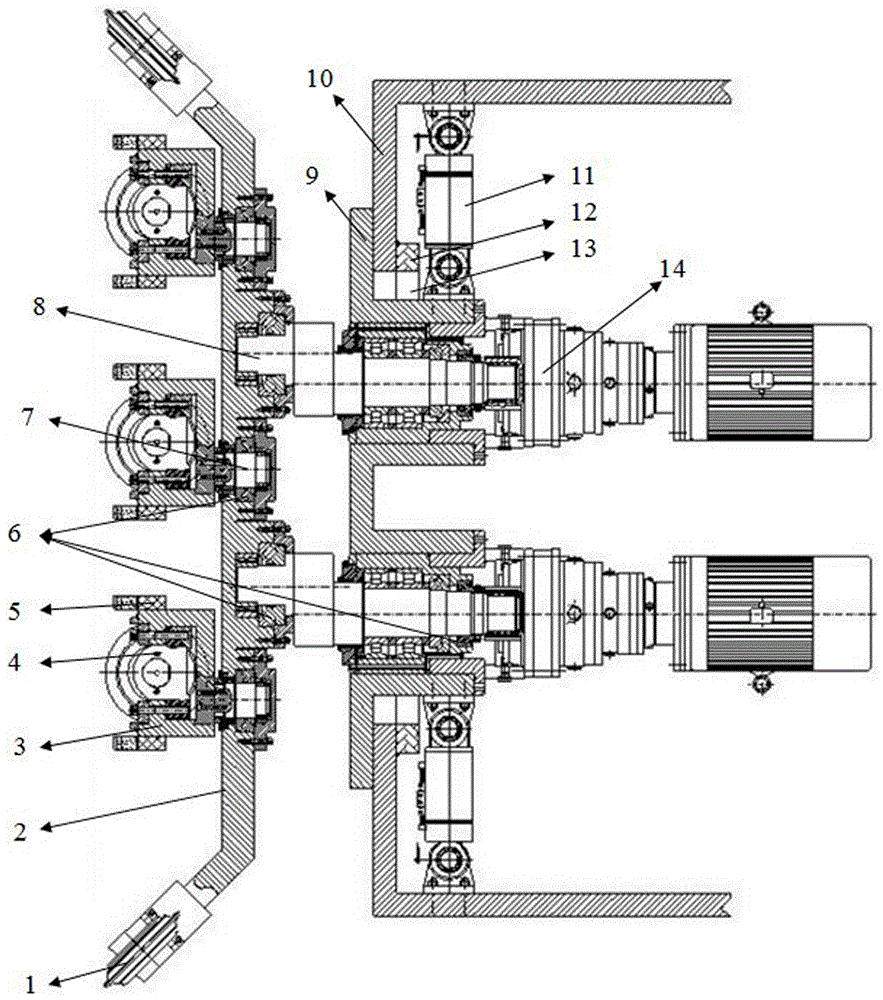

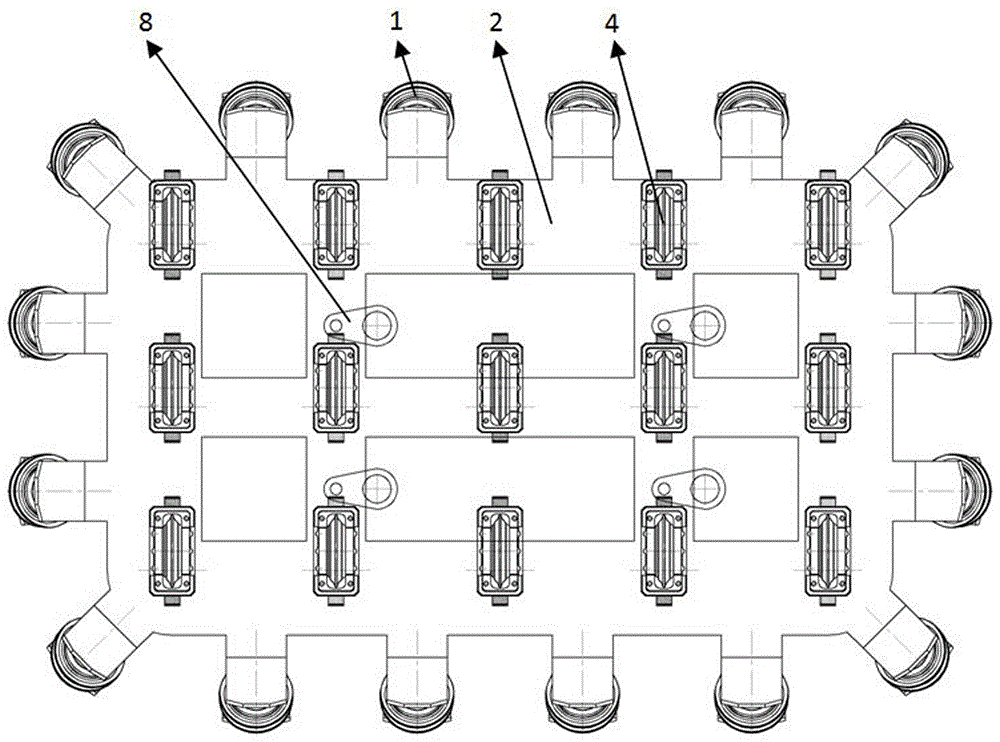

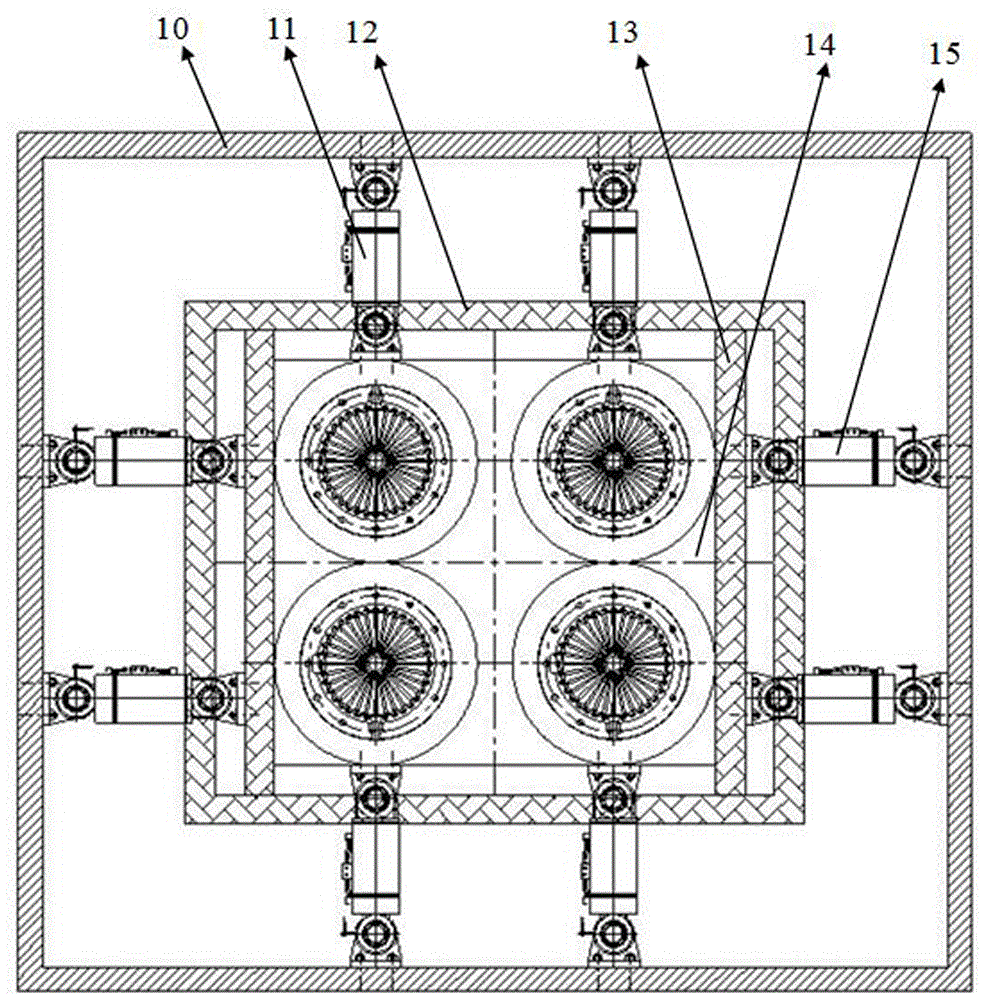

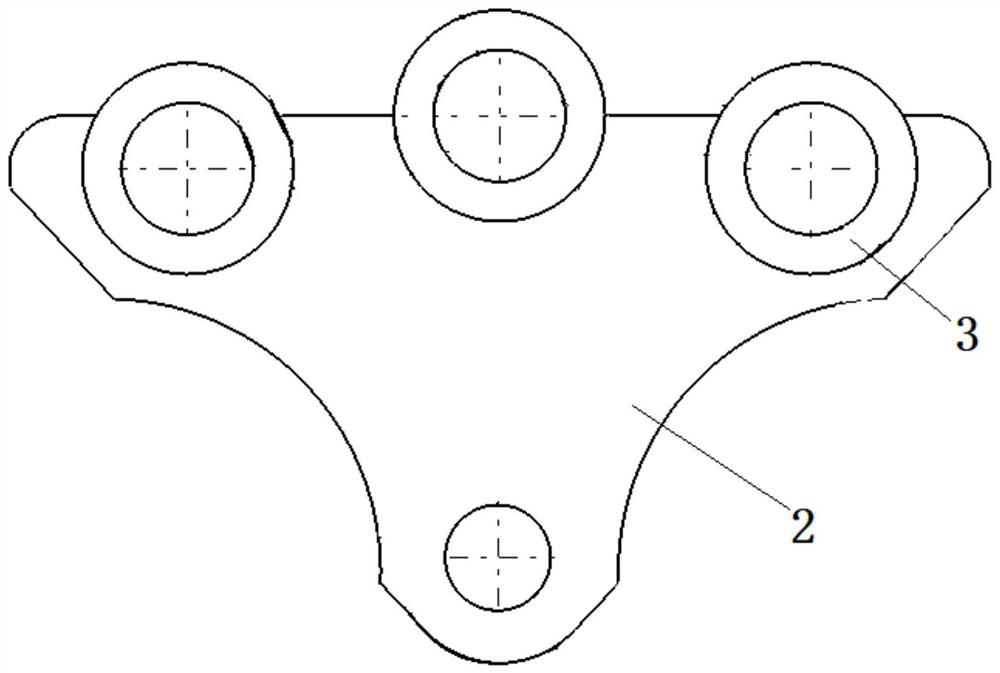

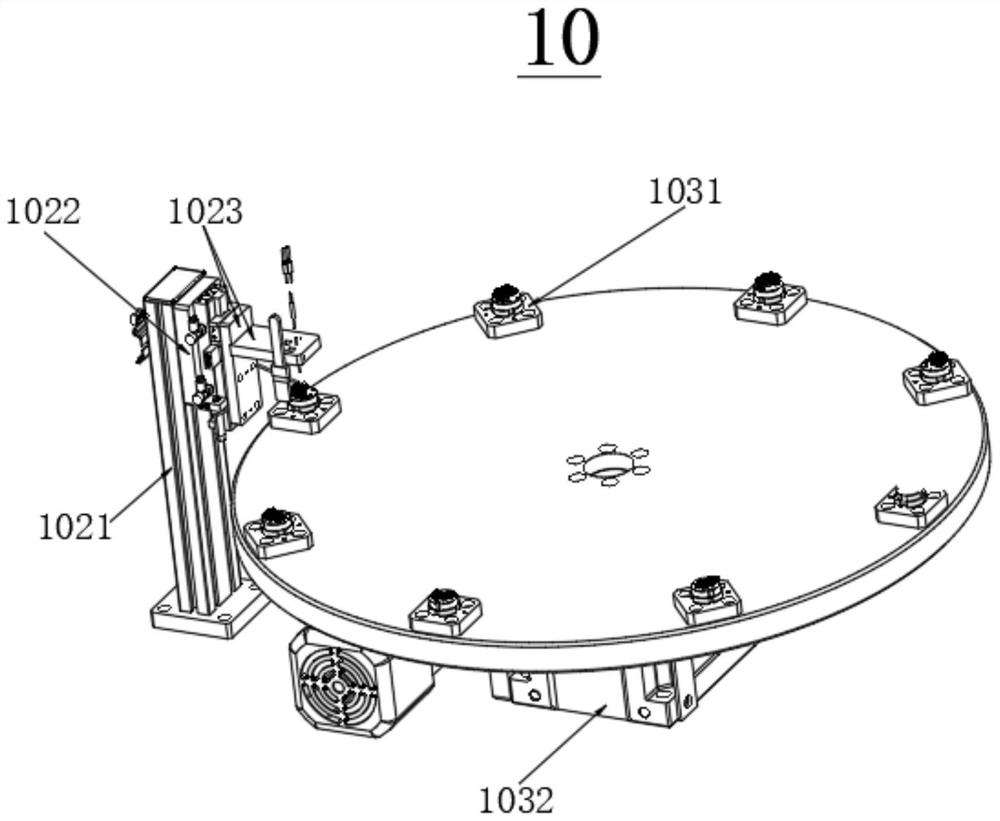

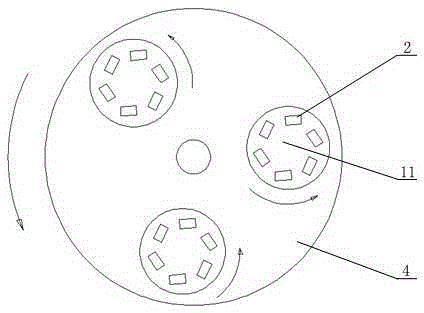

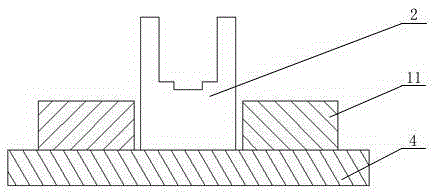

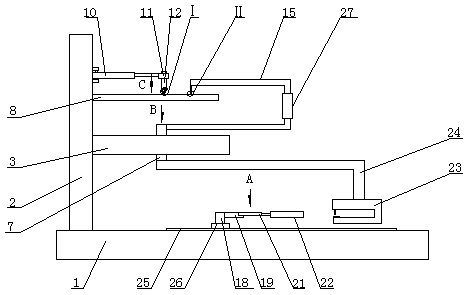

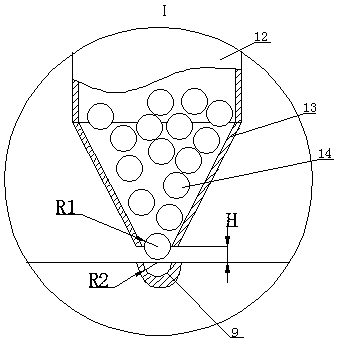

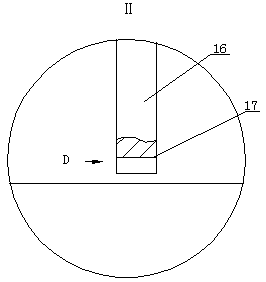

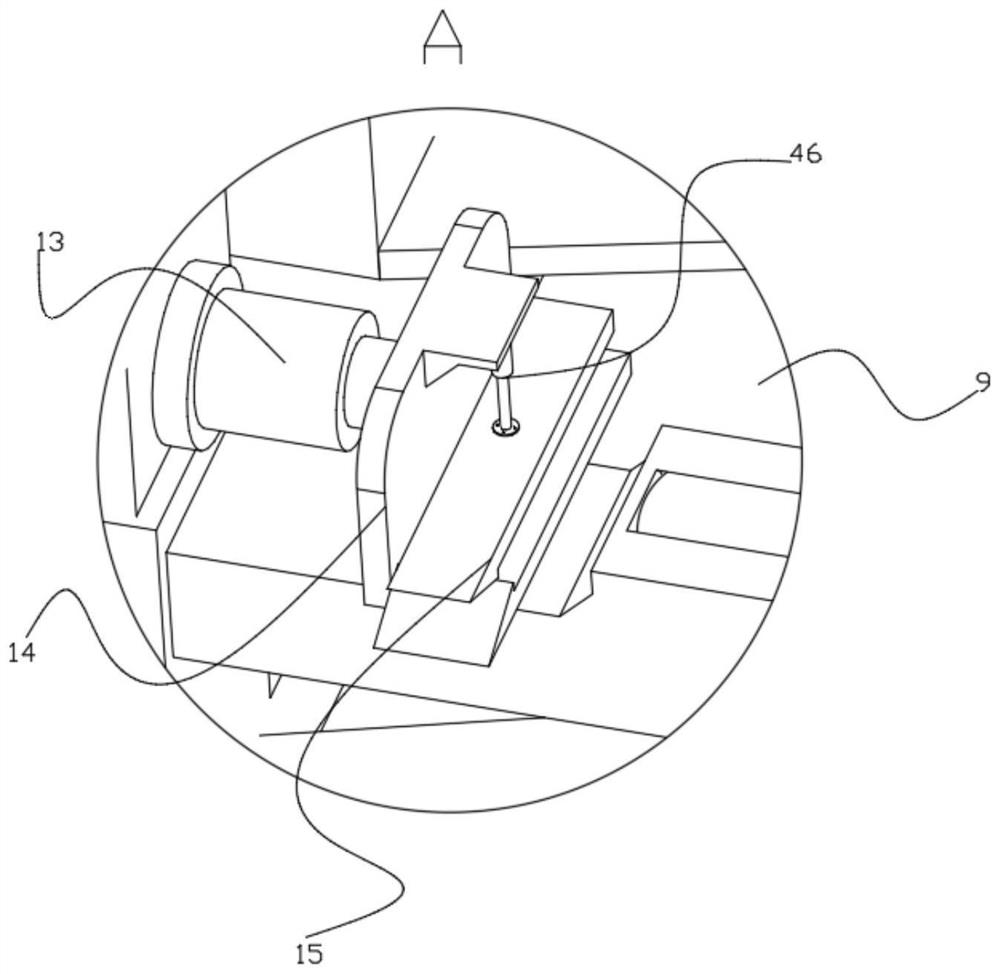

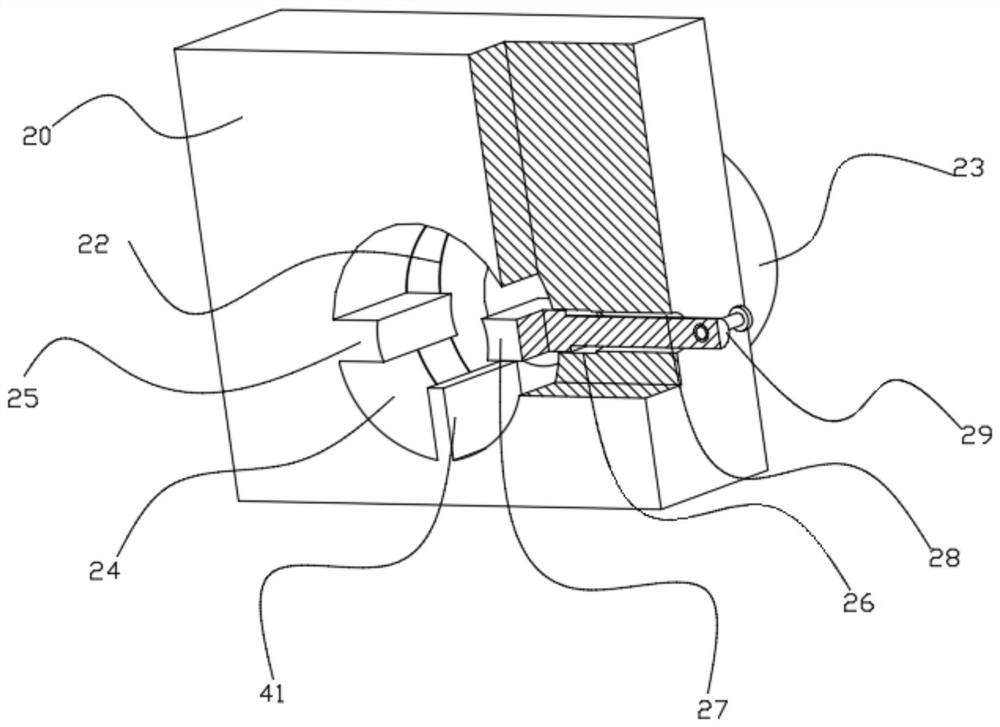

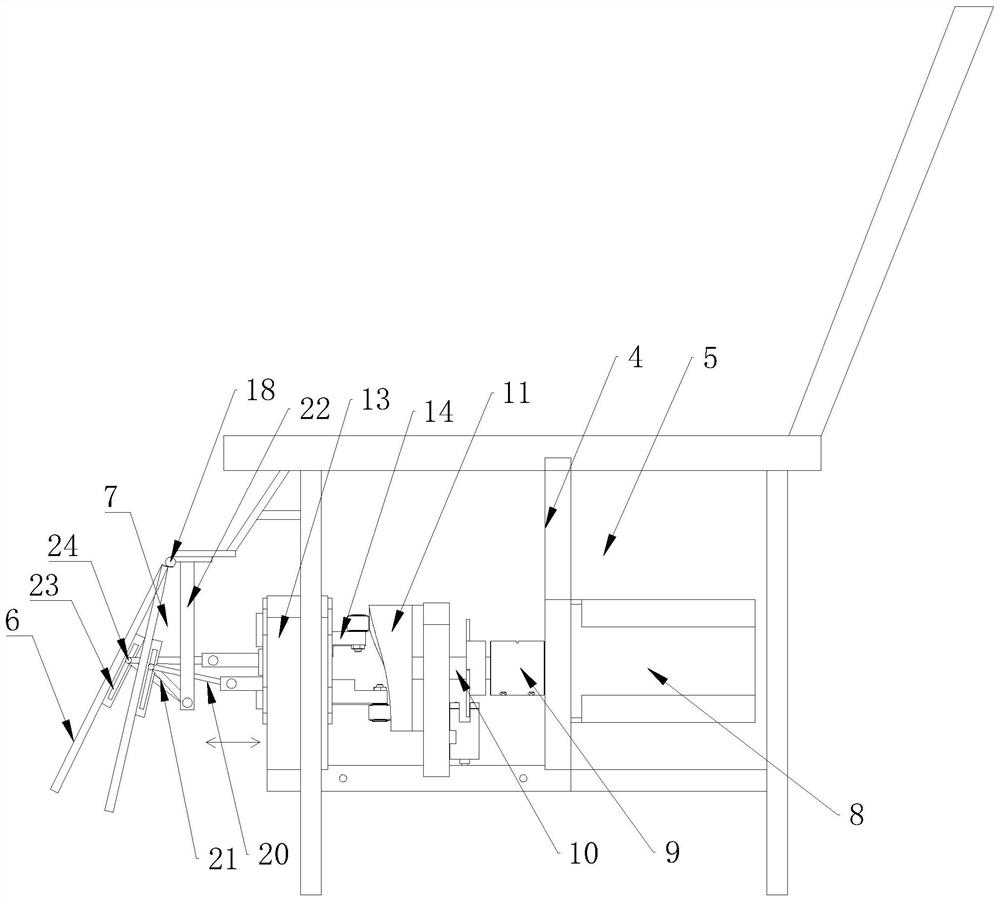

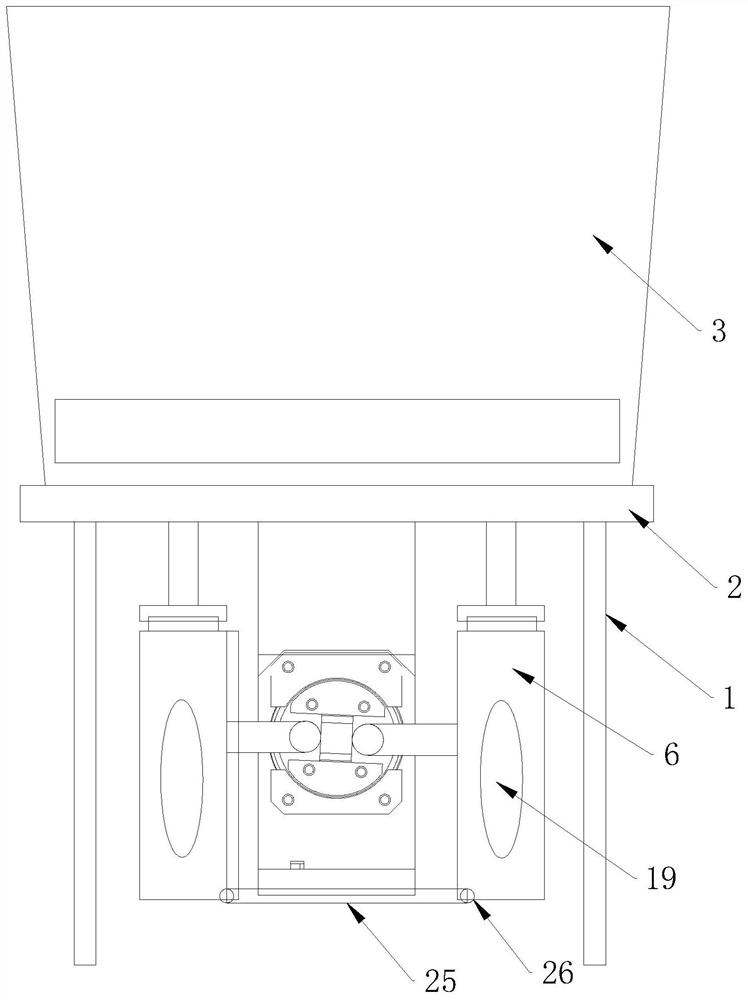

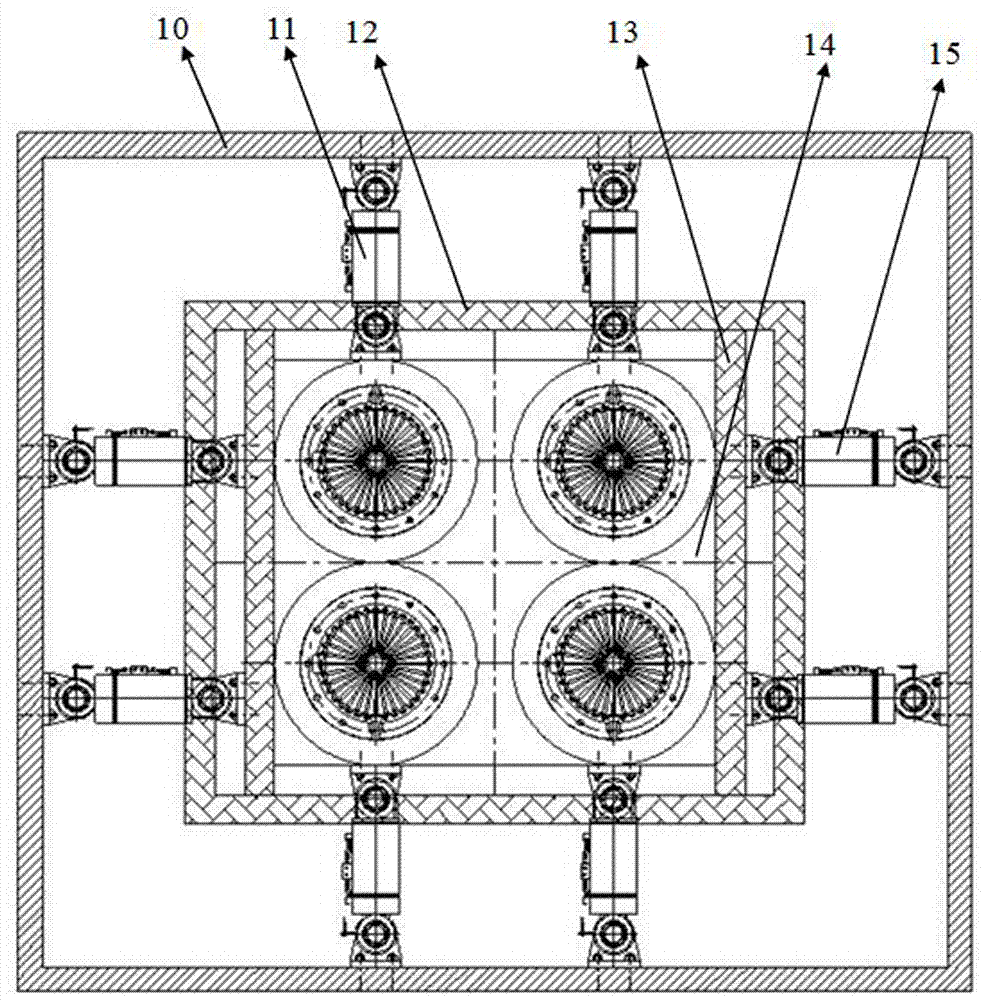

Eccentric hob horizontal-moving cutterhead used for hard rock rectangular cutting section

ActiveCN106285709ASolve the problem of blind excavationConsistent trajectoryTunnelsBlind zoneEngineering

The invention provides an eccentric hob horizontal-moving cutterhead used for a hard rock rectangular cutting section. The application of an eccentric multi-shaft hob cutterhead in the prior art to hard rock stratums is achieved. The eccentric hob horizontal-moving cutterhead comprises a cutterhead body, hobs and a driving system. The cutterhead body is driven by the driving system and is a spoke type rectangular cutterhead body; the hobs comprise positive hobs which are mounted on positive hob holders, and the positive hob holders are connected with hob holder rotating shafts into a whole in a fastened mode through bolts; and the hob holder rotating shafts are connected to the cutterhead body through bearings, and the center of each hob holder and the center of the corresponding hob holder rotating shaft are eccentric. The eccentric hob horizontal-moving cutterhead is driven by multiple eccentric driving shafts to make horizontal-connecting-rod movement, and thus the abrasion loss of the hobs is not affected by mounting positions; the positive hobs are eccentrically arranged and have the characteristics that the hobs can horizontally move along with the cutterhead and automatically rotate, and the problem that excavation dead zones exist when hobs and other crushing type tools are used for excavation in an eccentric multi-shaft movement mode is solved; and the cutterhead can conduct excavation in a multi-cutterhead combined mode, and can adapt to special-shaped excavated faces with different sizes.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

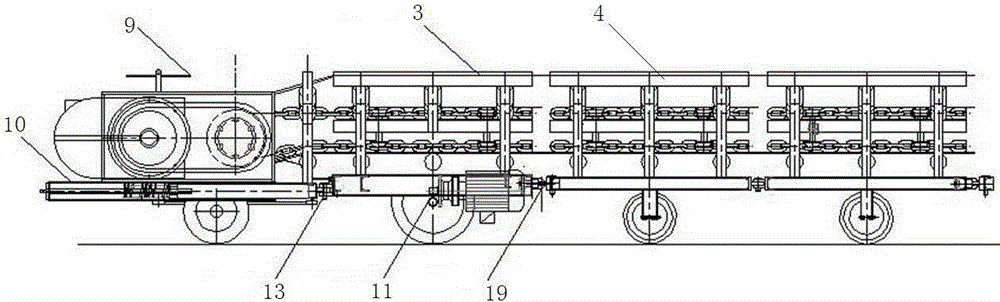

Phosphor block belt conveyor capable of performing curved running and curved operation

The invention belongs to the technical field of underground coal mine transportation facilities and particularly relates to a phosphor block belt conveyor capable of performing curved running and curved operation. The problem that an existing transportation device strictly restricts the efficiency of a united coal mining machine is solved. The phosphor block belt conveyor comprises a movable dragging assembly, a rubber belt, a round-link chain fixing the rubber belt, an rubber belt supporting structure and a rubber belt driving device, wherein the movable dragging assembly comprises a driving gun carrier and a plurality of common gun carriers which are sequentially hinged, hinge seats for hinge include one-degree-of-freedom hinge seats and three-degrees-of-freedom hinge seats which are consistent in length and width size, the driving gun carrier and the common gun carriers are two-wheeled vehicles, are consistent in length and width size and have the mass centers located at the centers of corresponding gun carrier frames, a wheel axle and wheels are installed in the middles of two sides of each gun carrier frame, and the distances from the centers of the wheel axles to the centers of the front and rear hinge seats are equal. The movable dragging assembly of the phosphor block belt conveyor capable of performing curved running and curved operation can be organically assembled and can be configured according to different road conditions and transfer requirements, electricity is saved, stable starting is also achieved, the driving gun carrier is independently braked and controlled in a centralized mode, and parking is stable.

Owner:原平市丰汇机械制造有限公司

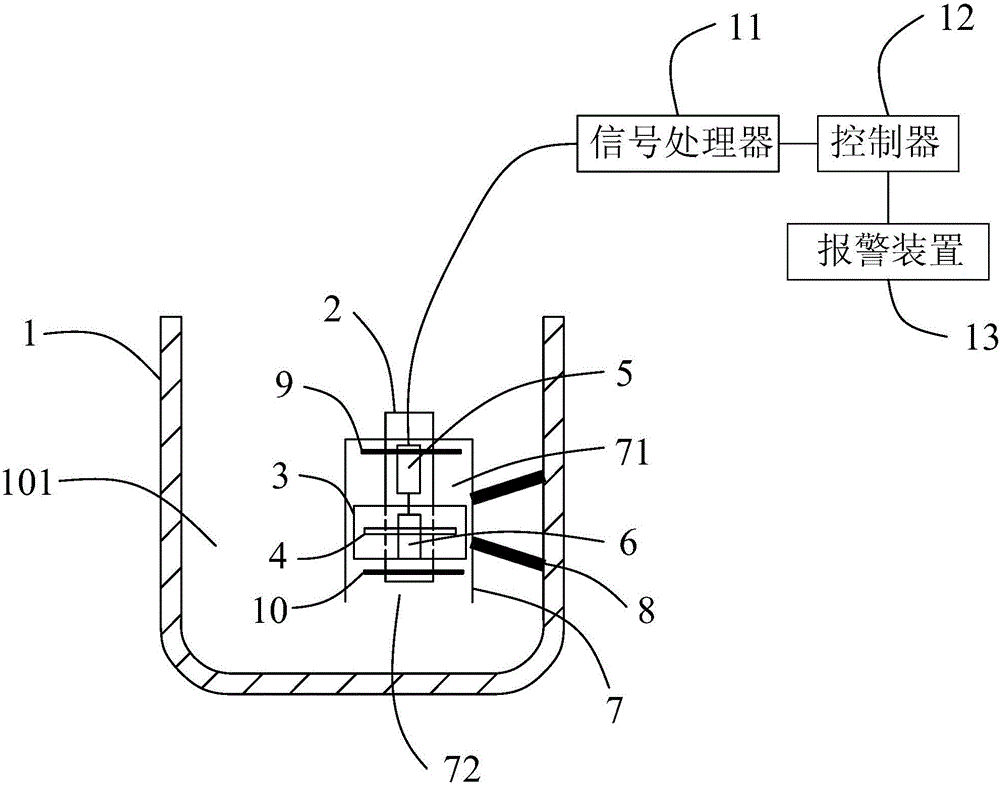

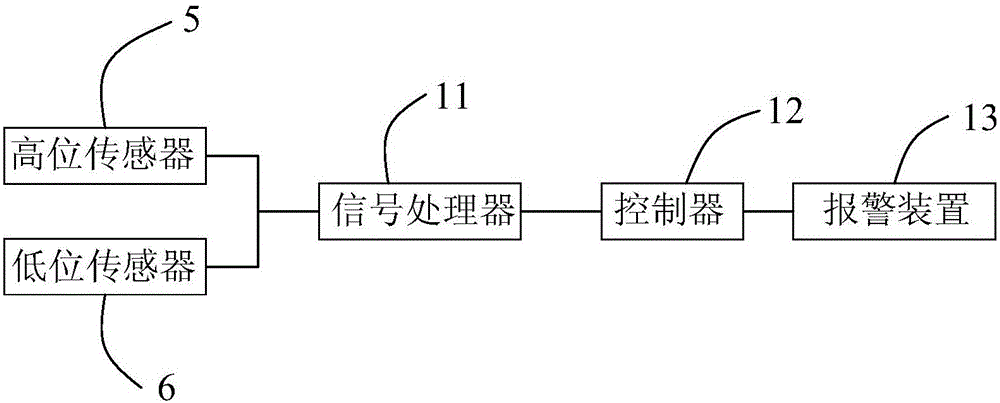

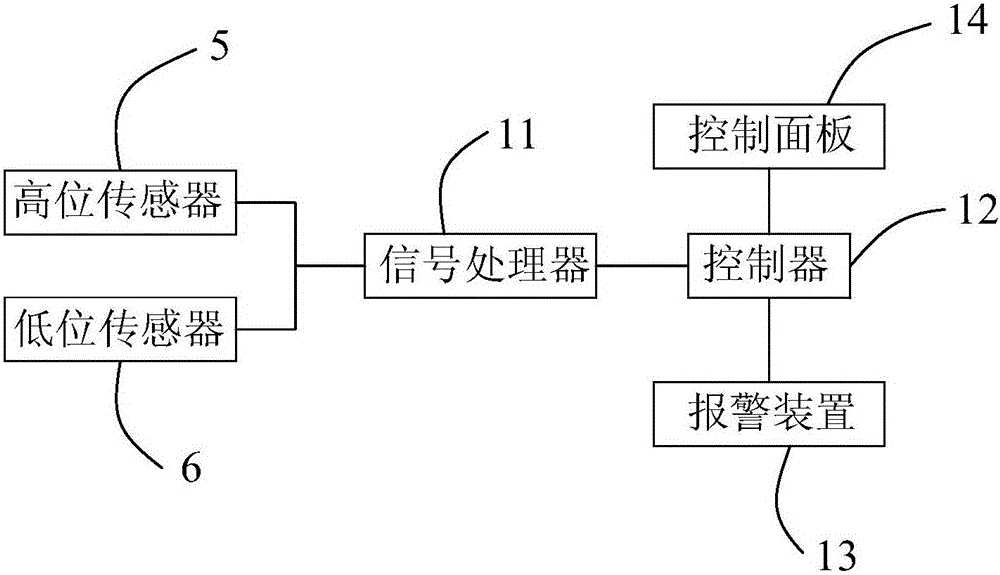

Oil quantity detection device for oil disc of sewing machine and sewing machine

ActiveCN105714488APrevent leakageImprove detection accuracyLubrication/cooling devicesPetroleum engineeringSewing machine

The invention provides an oil quantity detection device for an oil disc of a sewing machine. The oil quantity detection device comprises the oil disc provided with an oil cavity, and further comprises a support which is fixedly arranged in the oil cavity, a floater which is located in the oil cavity and can float up and down along the height change of an oil level in the oil cavity, and an element to be induced, which is fixedly arranged on the floater, wherein the support is internally provided with a sealing cavity; and the sealing cavity is internally and fixedly provided with sensors for inducing the element to be induced. According to the oil quantity detection device, the sensors are arranged at the positions with different heights in the oil cavity of the oil disc, so that when the floater drives the element to be induced to float up and down along the height change of the oil level of lubricating oil in the oil cavity, the sensors can induce the element to be induced, and furthermore, high-level oil quantity information or low-level oil quantity information in the oil disc is detected; and a maximum value and a minimum value of the oil quantity in the oil disc can be measured at the same time, so that a phenomenon that the oil quantity in the oil disc is excessive or too less is prevented, the normal work of the sewing machine can be guaranteed, and oil is prevented from leaking when the sewing machine turns on one side.

Owner:JACK SEWING MASCH CO LTD

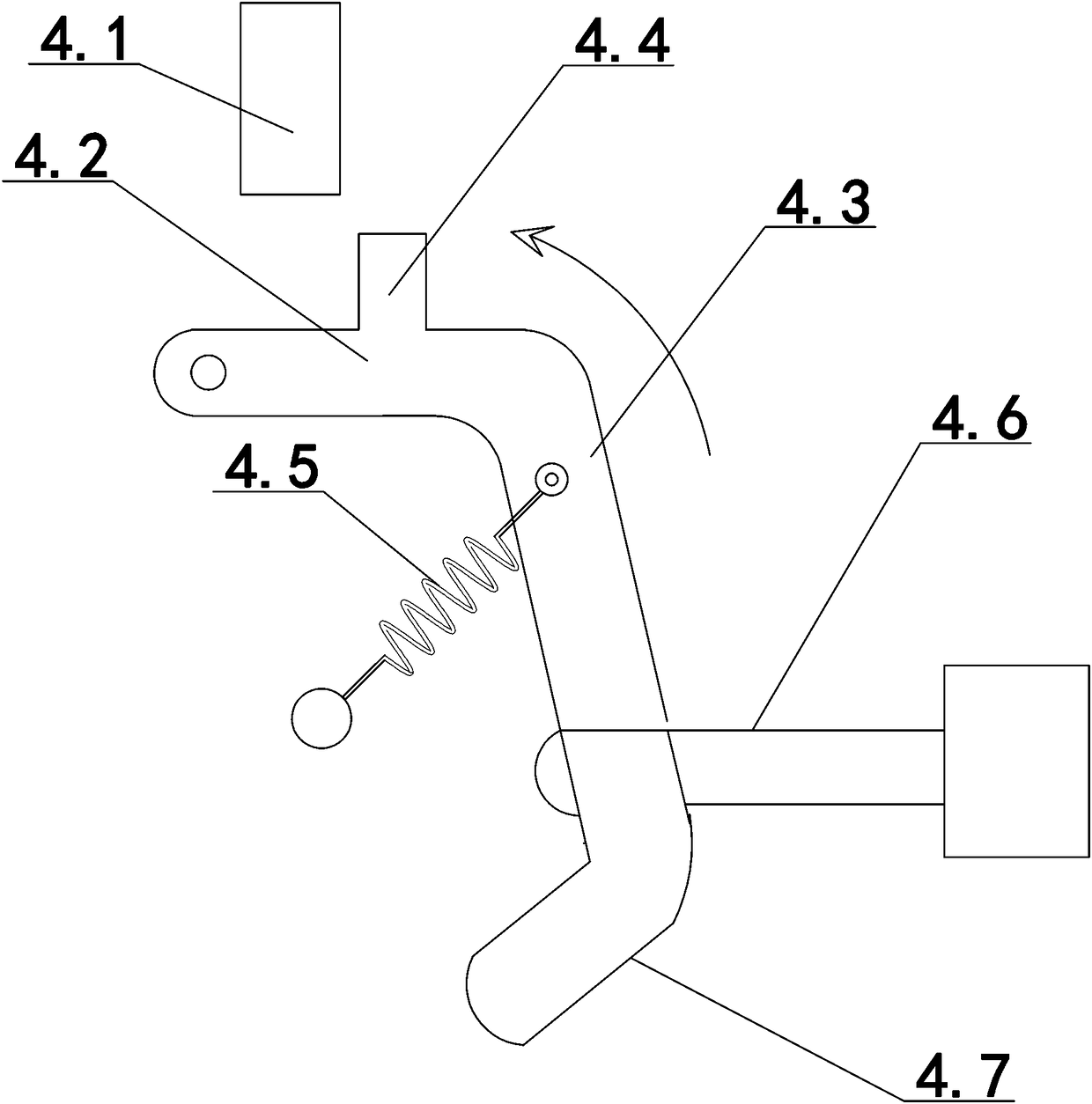

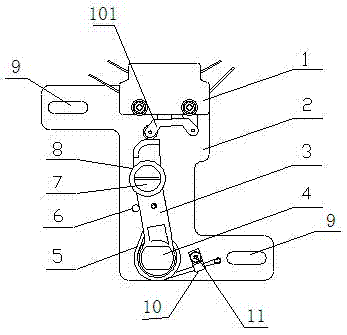

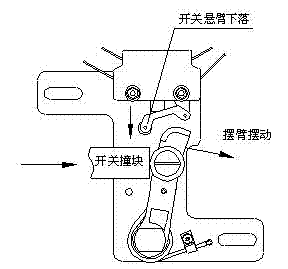

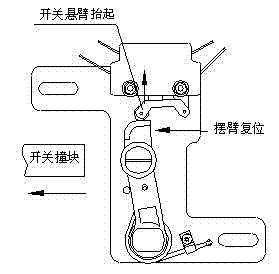

Switch assembly of urban rail vehicle sliding door

ActiveCN103670109AEliminates the potential for stickingSimple structureWing accessoriesContact operating partsLine of actionEngineering

The invention discloses a switch assembly of an urban rail vehicle sliding door. The switch assembly of the urban rail vehicle sliding door comprises a microswitch, an installation base board, a swing arm, a rotation shaft, a torsion spring, a stop pin and an idler wheel. The switch assembly of the urban rail vehicle sliding door swings under the impact of a switch impacting block of the sliding door, a switch cantilever falls down, the microswitch acts, and a door in-place signal or a lock in-place signal is sent out. In a reset state, the switch impacting block is disengaged, the cantilever resets through the torsion spring, the switch cantilever is lifted, and the microswitch recovers to an initial state. According to the switch assembly of the urban rail vehicle sliding door, a complicated stretchy guiding rod part is removed, the structure is simplified, hidden danger caused by the clamping phenomenon generated by the spring is removed, and the torsion spring replaces a compression spring to be reset, so that an line of action of force is identical with the movement track of a stressed object. The switch assembly of the urban rail vehicle sliding door has the advantages of being high in reliability, long in service life, novel in structure, ingenious in design and good in application prospect.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

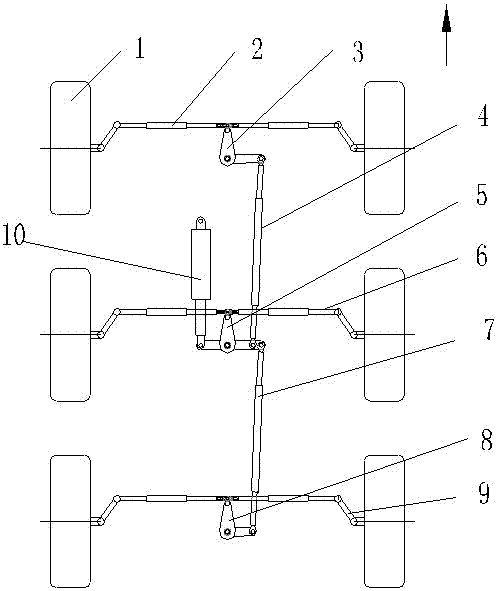

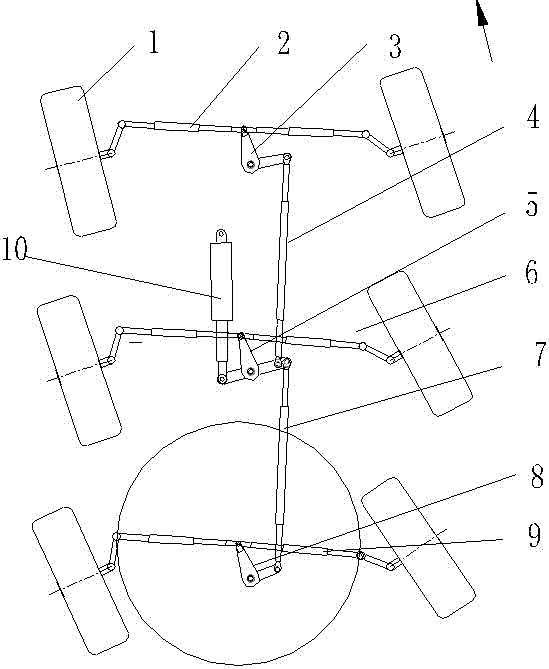

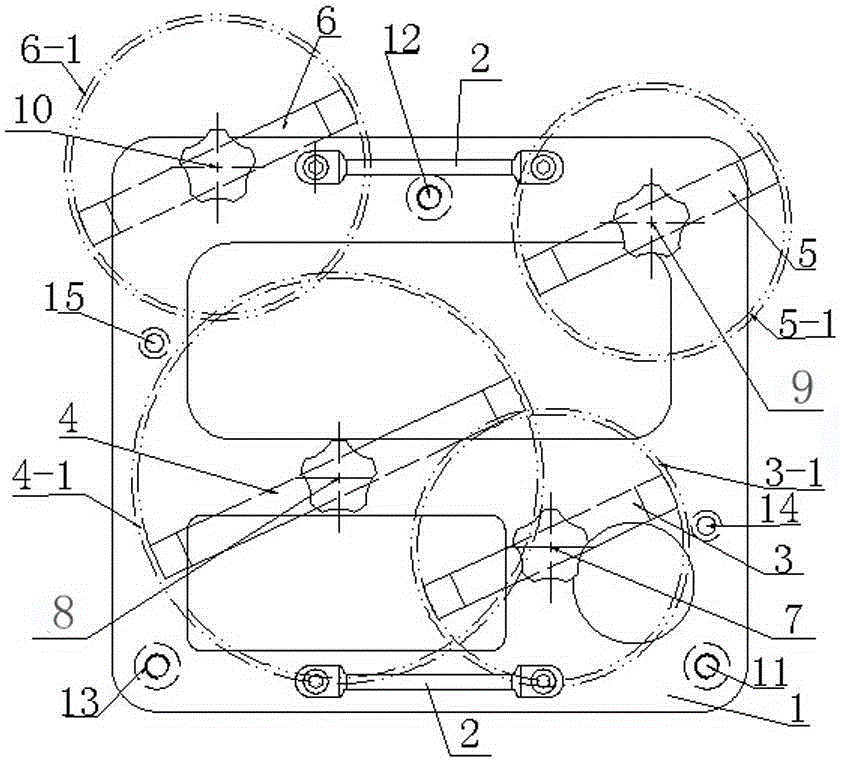

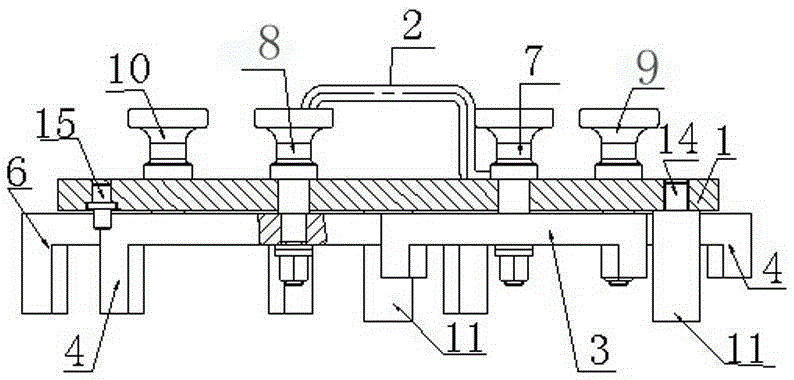

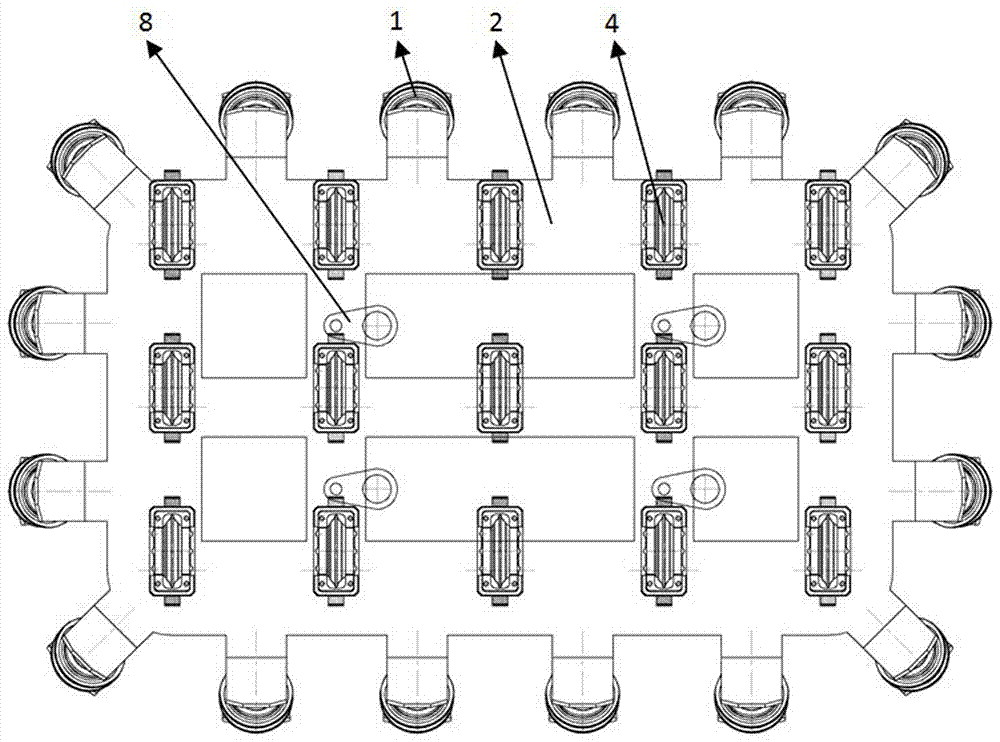

Rear wheel adjustable steering mechanism suitable for semi-trailer launching vehicle

InactiveCN107128361AImprove passabilityExtended service lifeSteering linkagesFluid steeringSemi-trailerLaunch vehicle

The invention discloses a rear wheel adjustable steering mechanism suitable for a semi-trailer launching vehicle. The rear wheel adjustable steering mechanism suitable for the semi-trailer launching vehicle comprises wheels (1), a rear first axle steering trapezoidal part (2), a rear first axle pull arm (3), a pull rod A (4), a rear second axle pull arm (5), a rear second axle steering trapezoidal part (6), a pull rod B (7), a rear third axle pull arm (8), a rear third axle steering trapezoidal part (9) and a driving oil cylinder (10). The driving oil cylinder (10) drives the rear second axle pull arm (5) to rotate around a fixed hinge pin; through the pull rod A (4) and the pull rod B (7), the rear first axle pull arm (3) and the rear third axle pull arm (8) rotate around corresponding shafts, therefore, positions of the rear first axle steering trapezoidal part (2), the rear second axle steering trapezoidal part (6) and the rear third axle steering trapezoidal part (9) are changed, the rear three-axle vehicle wheels steer according to a certain angle, the minimum passing radius of the vehicle is reduced, and the passing ability of the vehicle is improved; and meanwhile, friction between the wheels and the ground is reduced during steering, and the reliability of the wheels is improved.

Owner:BEIJING MECHANICAL EQUIP INST

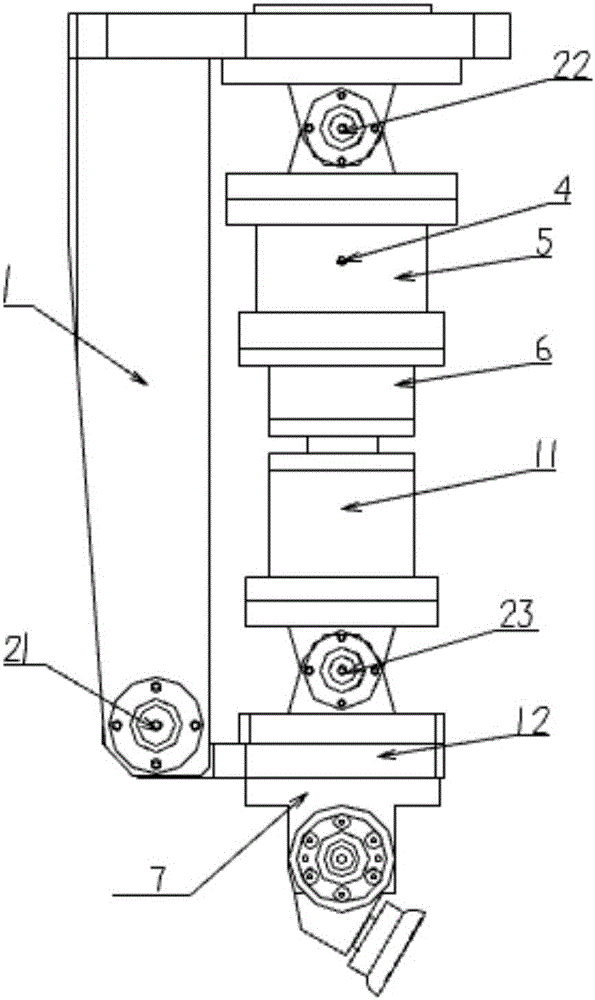

Vacuum coating equipment for processing metallic films

InactiveCN106435513AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEvaporationEngineering

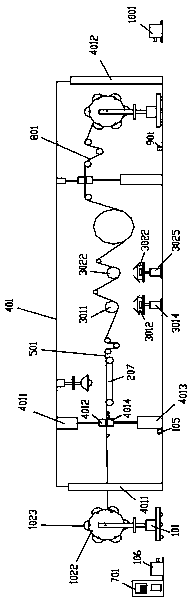

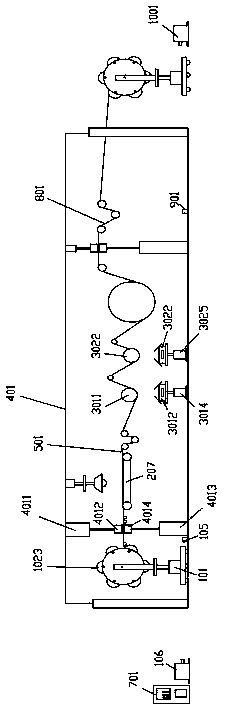

The invention discloses vacuum coating equipment for processing metallic films. The vacuum coating equipment comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism, wherein the feeding mechanism, the coating mechanism and the winding mechanism are arranged inside the vacuum chamber; the feeding mechanism comprises a first lifting mechanism and a feeding device; a preheating mechanism is arranged between the feeding mechanism and the coating mechanism; a first movable plate assembly adjusting an opening of a first evaporation boat is arranged in the opening area of the top of the first evaporation boat; a second movable plate assembly adjusting an opening of a second first evaporation boat is arranged in the opening area of the top of the second evaporation boat; film limiting devices are arranged between the feeding mechanism and the coating mechanism as well as between the coating mechanism and the winding mechanism; the winding mechanism comprises a fifth lifting mechanism and a winding device; and an extension end of the fifth lifting mechanism is matched with the winding device to drive the winding device to move up and down. The vacuum coating equipment has the advantages that the automation degree is high, supplementing and collecting are convenient and timely, preheating is uniform, the preheating degree can be adjusted, the processing requirements of the films of various models can be met and the coating thickness can be adjusted.

Owner:铜陵市铜创电子科技有限公司

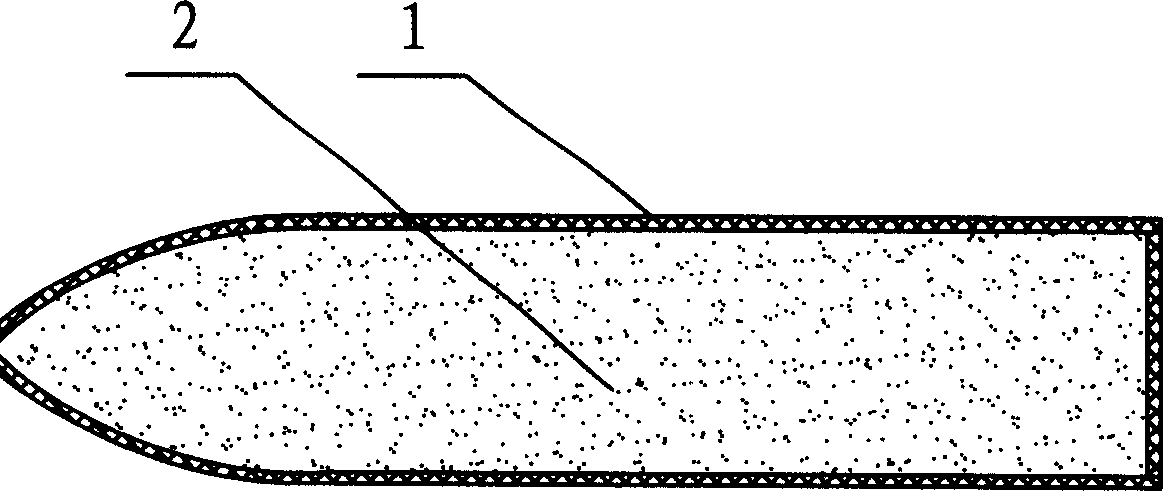

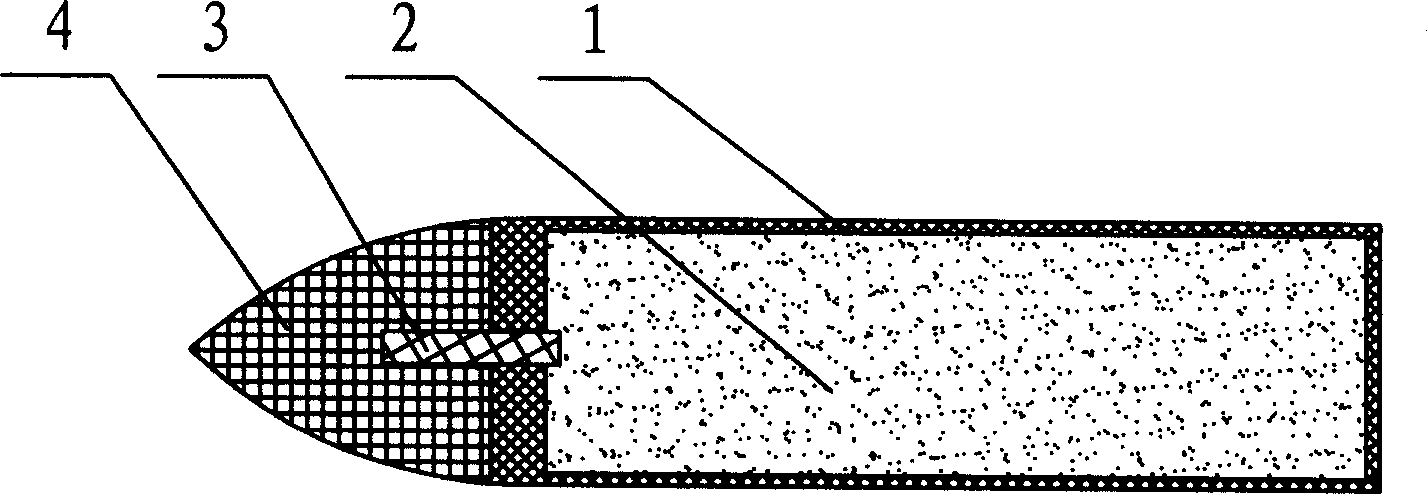

Bullets in use for training and manufacturing method

InactiveCN1696599AReduce destructive powerFree from harmTraining ammunitionElastomerMetallic materials

The present invention relates to a training bullet adopting inert filling material and its making method. Said training bullet includes hollow bullet body which can be matched with standard cartridge case and inert filling material which can be filled in the hollow bullet body, in the front end elastic body a front end elastic body is fixed, said front end elastic body can be fixedly connected with said hollow bullet body, in the interior of hollow bullet body a buffer device is set. Said hollow bullet body is made up by using non-metal material through a die-moulding process.

Owner:王宝山

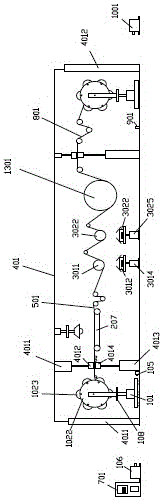

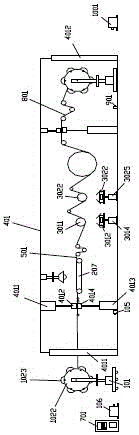

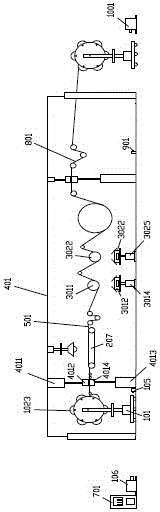

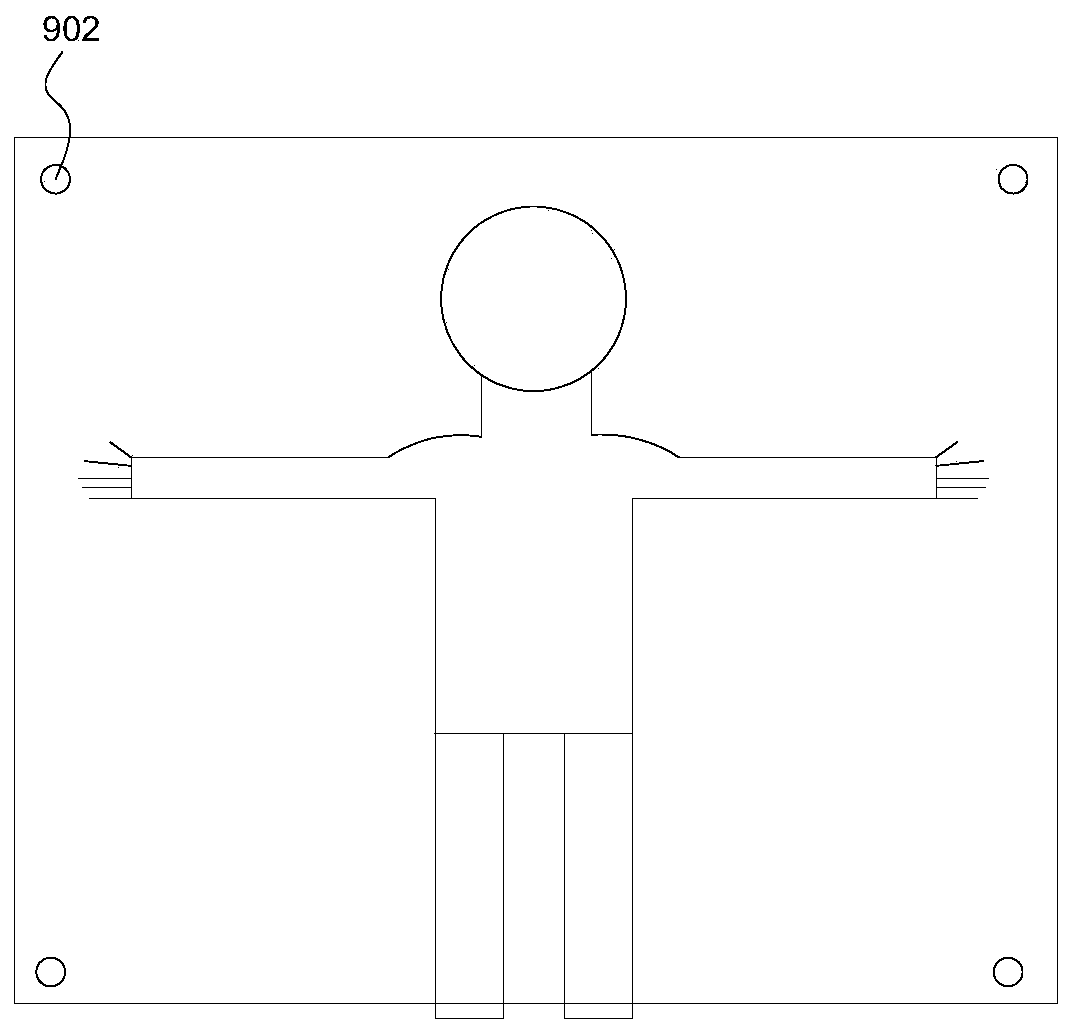

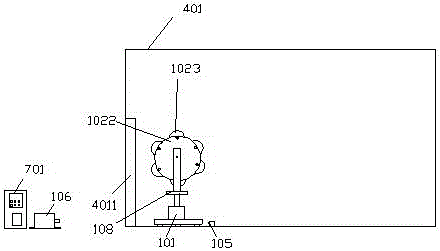

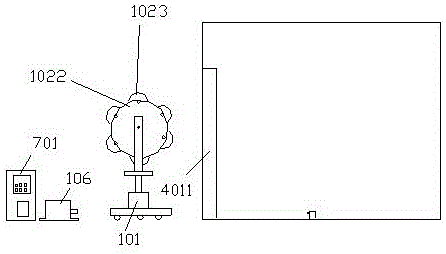

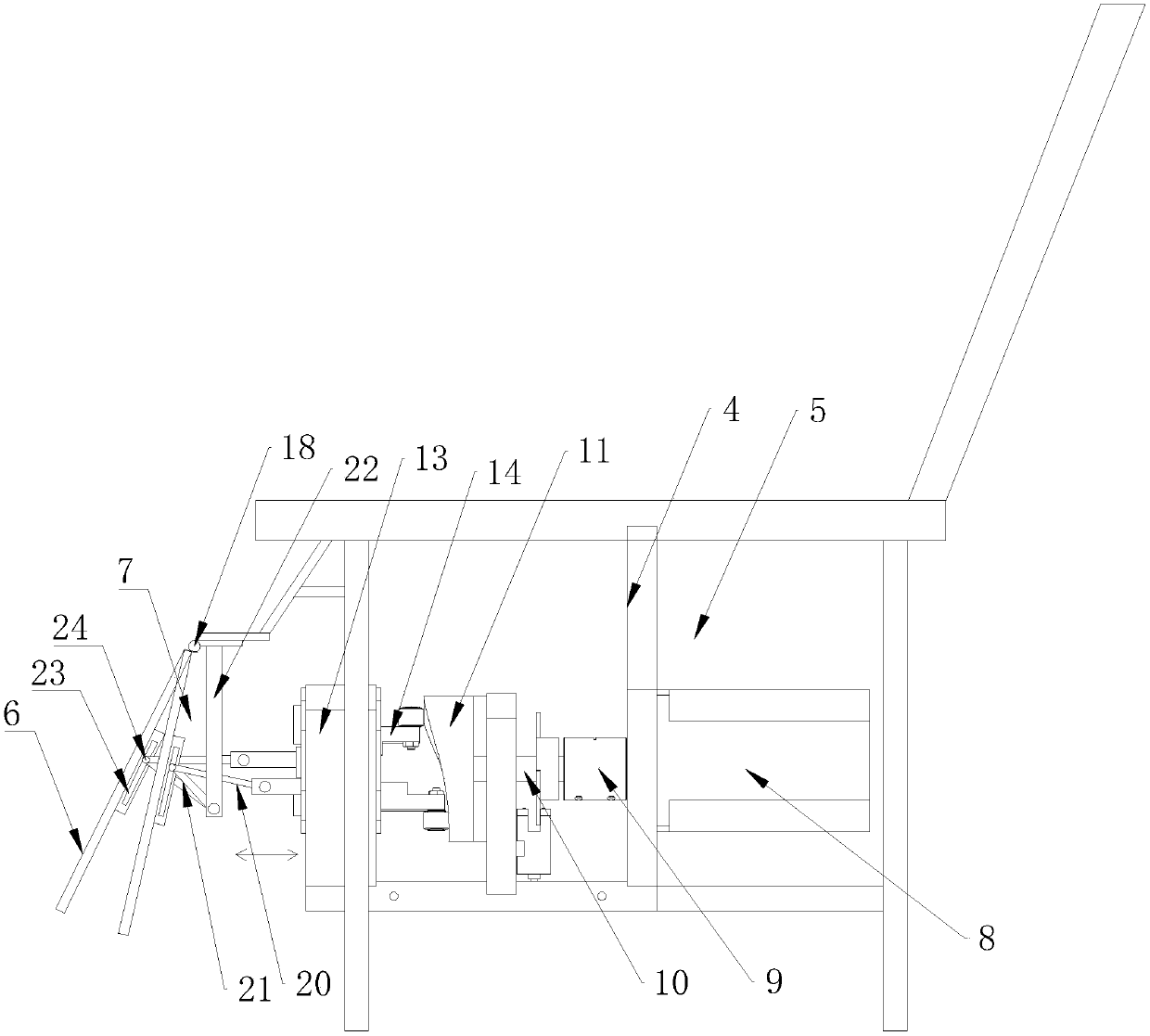

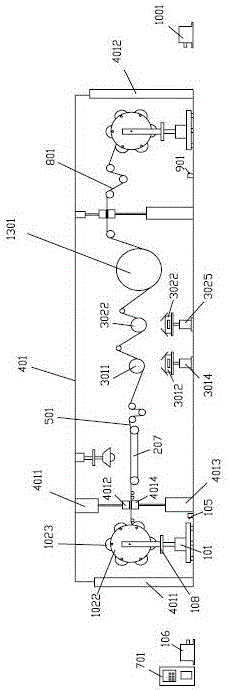

Medical protective clothing on-site making wearable equipment and method thereof

InactiveCN111150164AConsistent trajectoryAvoid pollutionSevering textilesClothes making applicancesHuman bodyBiomedical engineering

The invention discloses medical protective clothing on-site making wearable equipment, which comprises a box body, a first storage cavity, a wearing cavity and a second storage cavity are formed in the box body, the top of the first storage cavity and the top of the second storage cavity communicate with the wearing cavity through material holes, and a feeding mechanism, a shearing mechanism and apositioning mechanism are arranged below the material holes; a human body size measuring assembly is arranged in the wearing cavity; a glue pressing head is arranged in the wearing cavity and is mounted on a driving mechanism capable of driving the glue pressing head to move; the human body size measuring assembly, the feeding mechanism, the shearing mechanism, the positioning mechanism and the driving mechanism are all electrically connected with a controller. The invention further discloses an on-site making and wearing method of the medical protective clothing. The protective fabric can befolded and stored in a first material storage cavity and a second material storage cavity, more fabric can be stored in a small space, and the warehouse space does not need to be occupied. In use, on-site manufacturing is carried out, manufacturing and wearing are synchronously carried out, and the equipment is fast and convenient and especially suitable for epidemic situations.

Owner:高玉龙

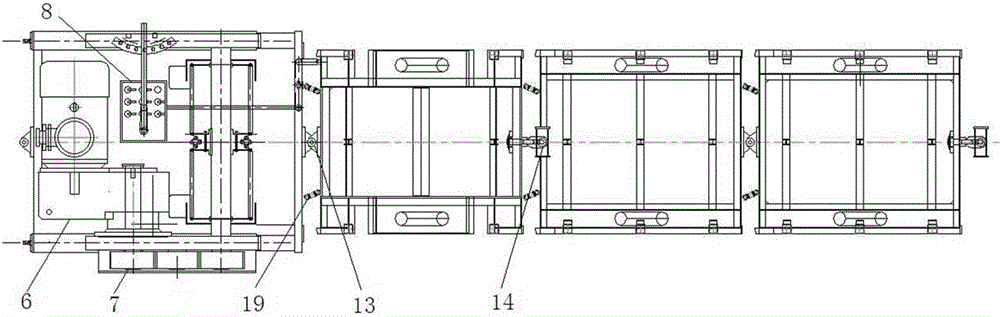

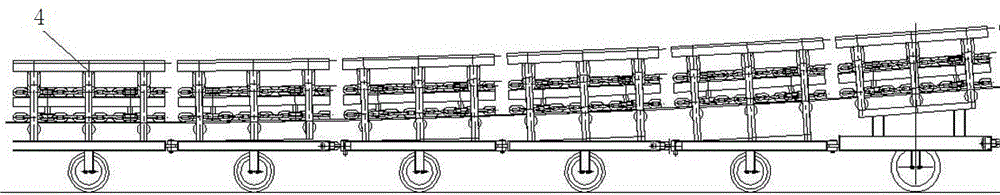

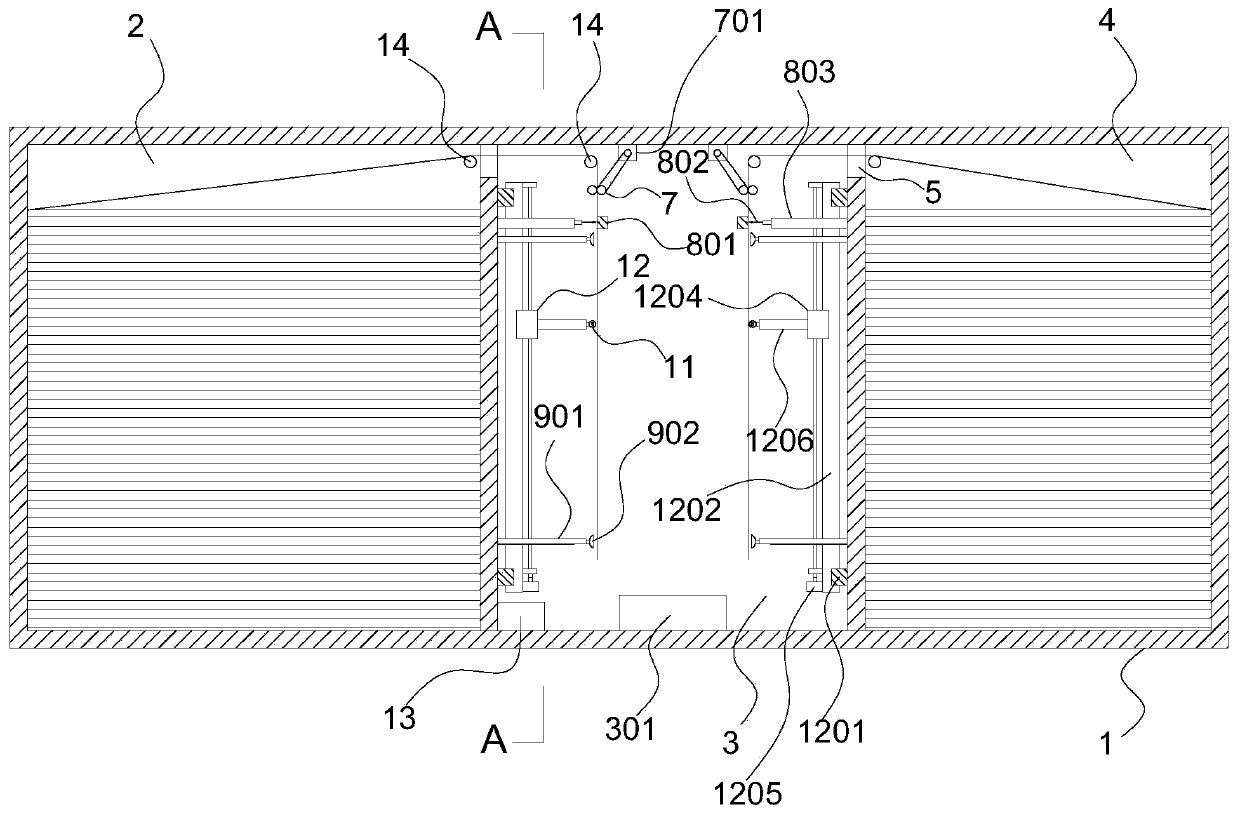

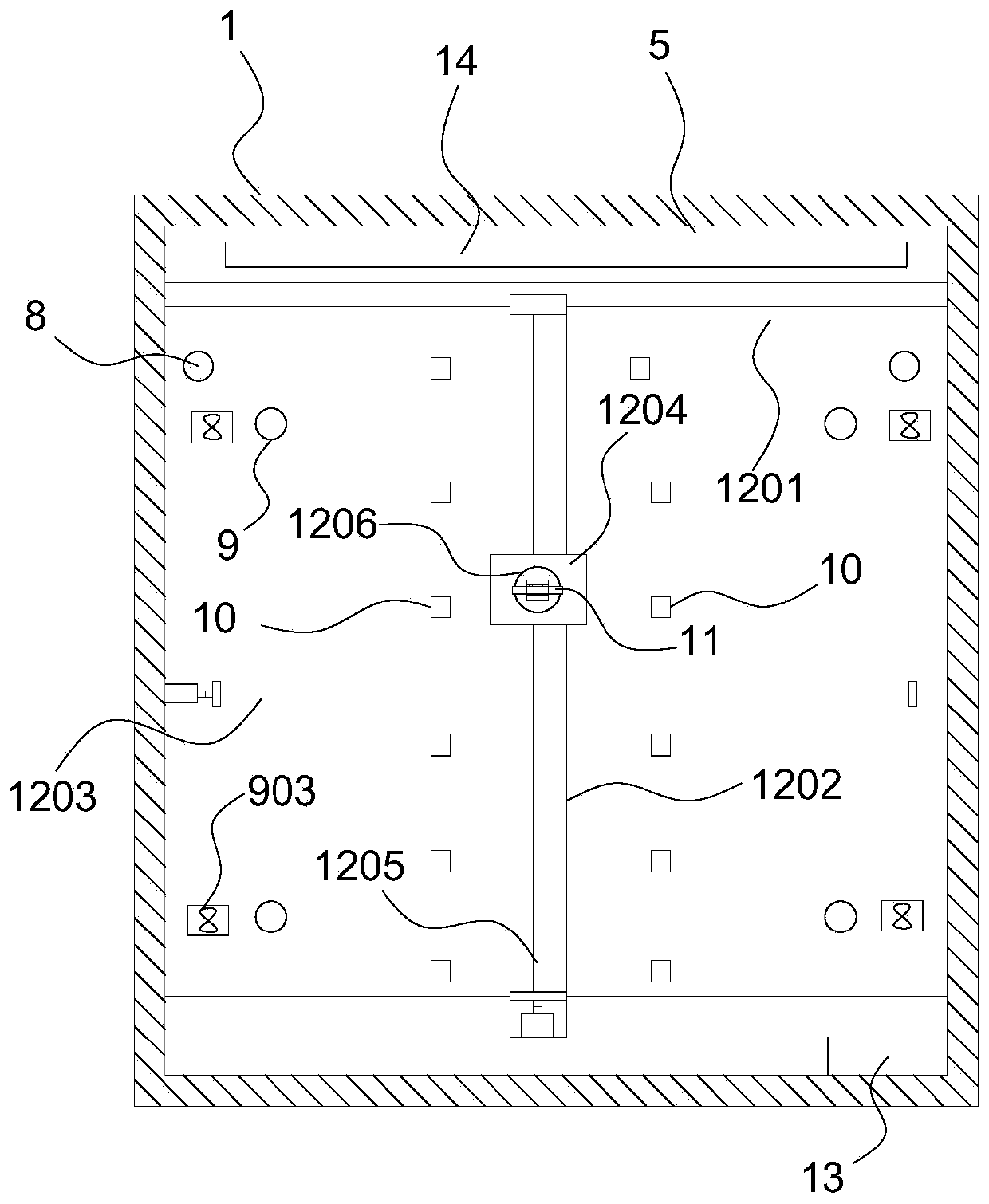

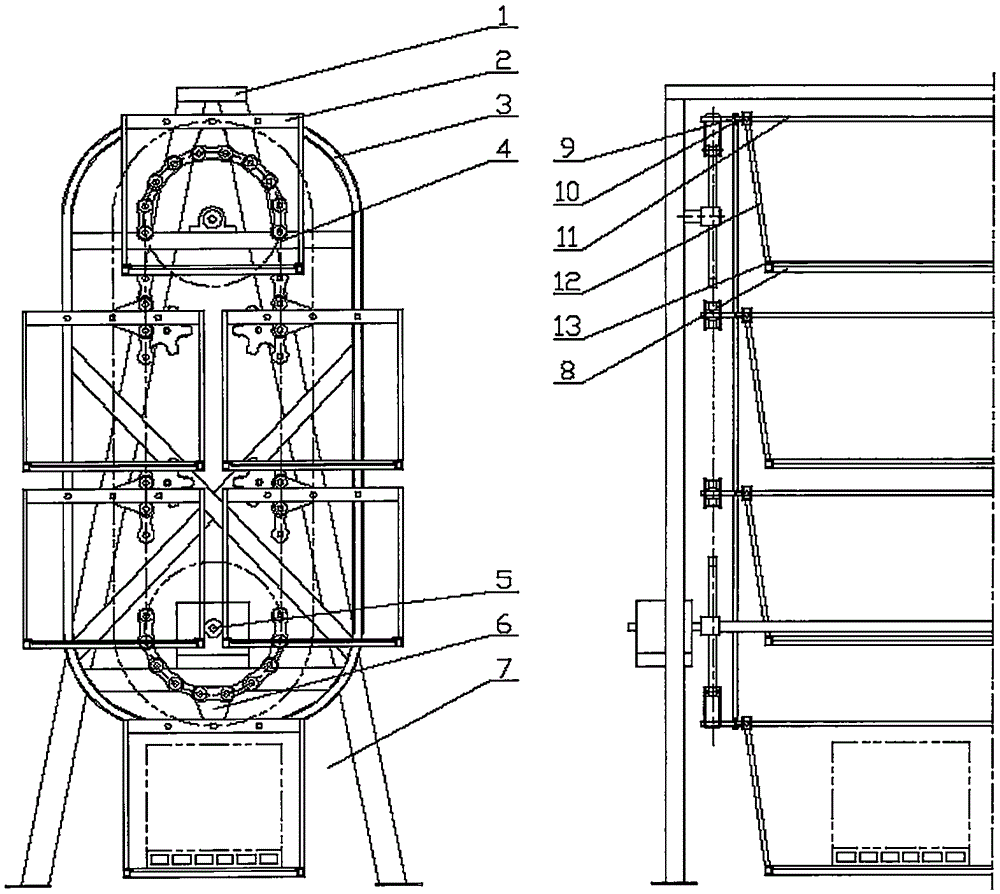

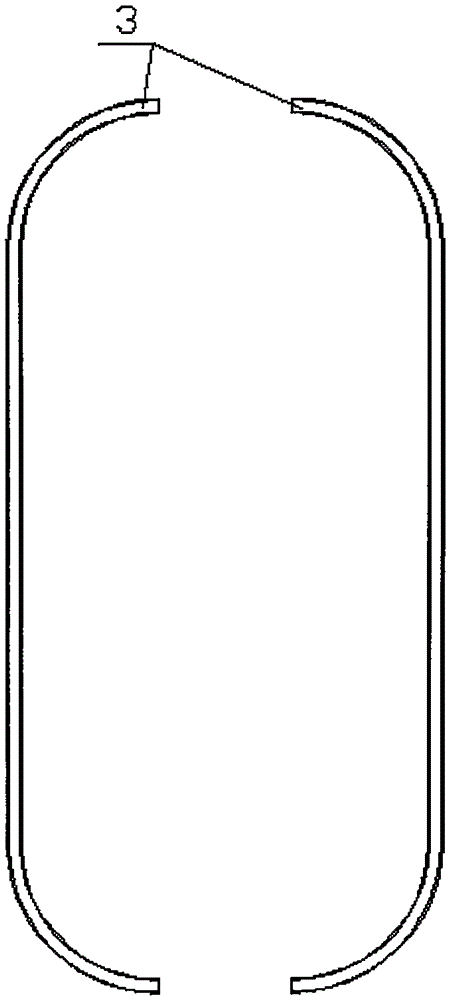

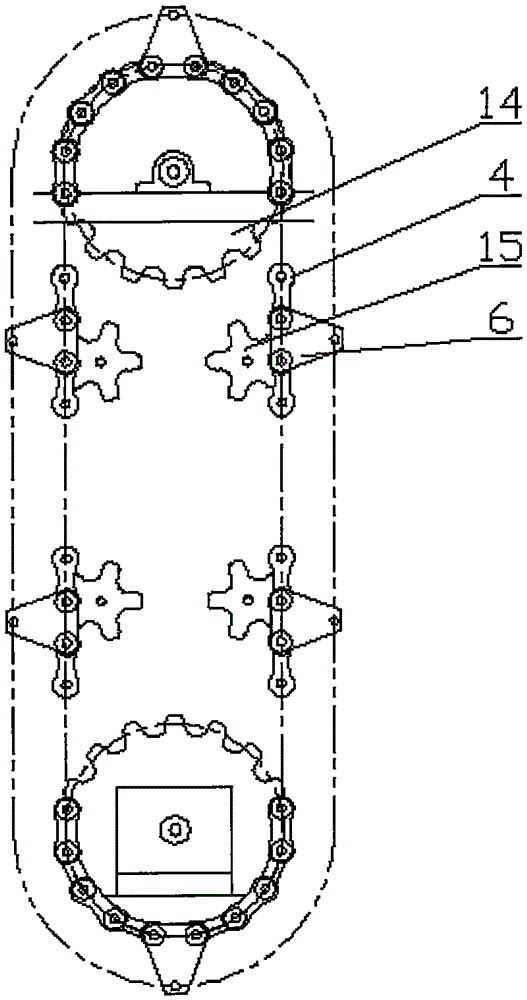

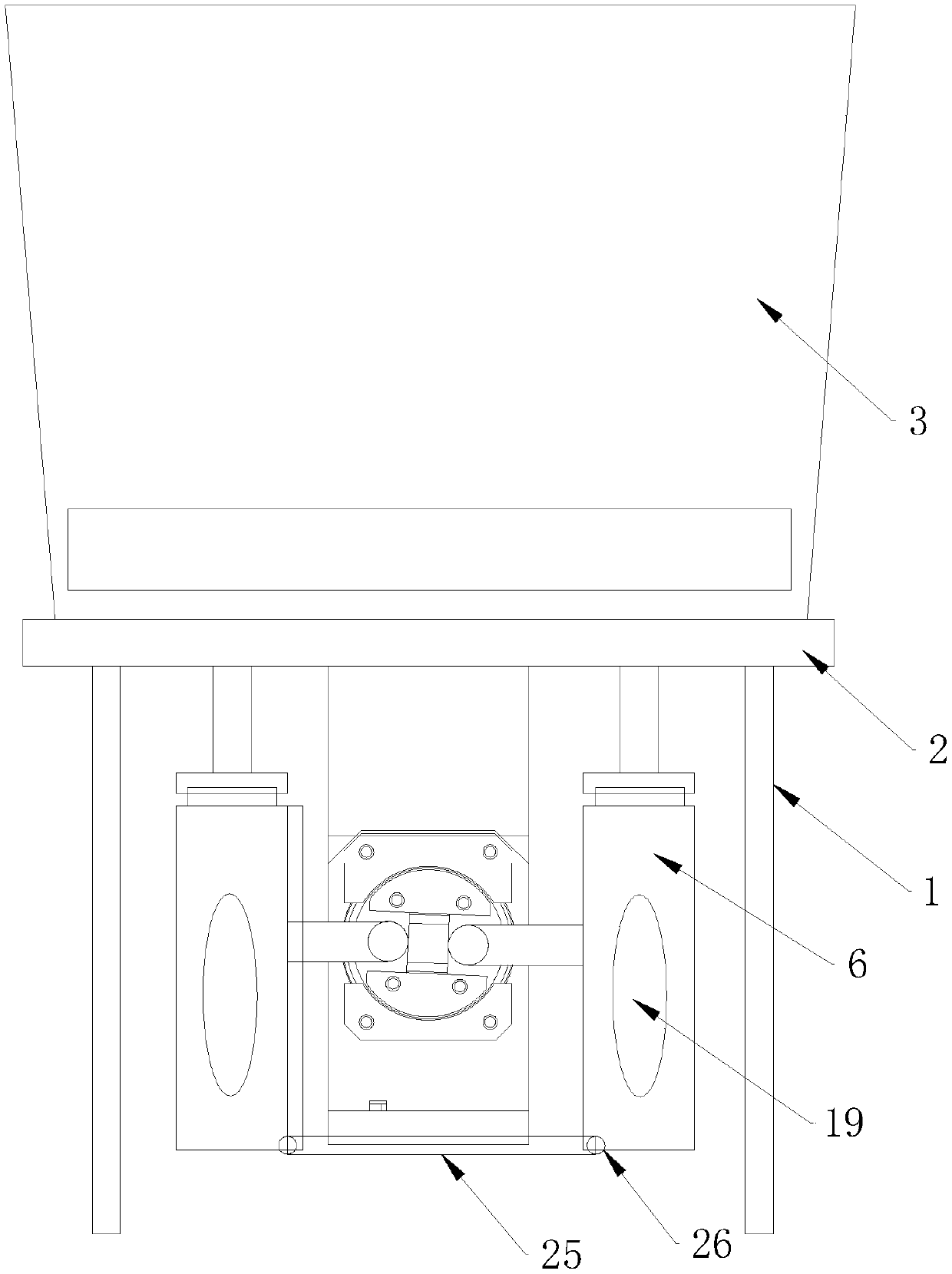

Circulation three-dimensional storage device capable of operating in bi-direction

The invention relates to a circulation three-dimensional storage device capable of operating in bi-direction. The circulation three-dimensional storage device capable of operating in bi-direction comprises two support frames (1), a plurality of bearing hanging baskets (2), left and right slide rails (3), a driving chain (4), a power shaft (5), a chain plate (6), a gateway (7), a supporting platform (8), a spindle sleeve (9), a siding column (10), an articulated shaft (11), a hanging arm (12), a limiting ridge (13), and a driven sprocket wheel (15) and the like. The three-dimensional storage device has the storage capability 2 to 14 times of that of the area of land occupation, the utilization rate of space can be effectively raised. The three-dimensional storage device can be applied to an area of population aggregation or an area of logistics concentration such as a district, a supermarket and a square so that cargos and vehicles can be quickly stored and taken away in an area having large logistics volume and passenger flow volume, so jam caused by place problems and inconvenient logistics turnover can be avoided, a neat, high-efficiency and convenient cultural environment can be provided to the public place, so the three-dimensional storage device has wide prospect of market application.

Owner:宁波科创制造技术开发有限公司

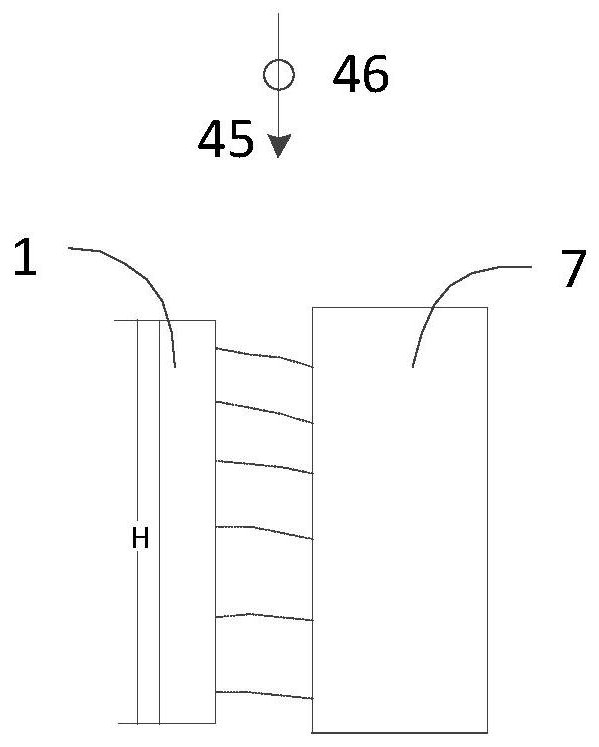

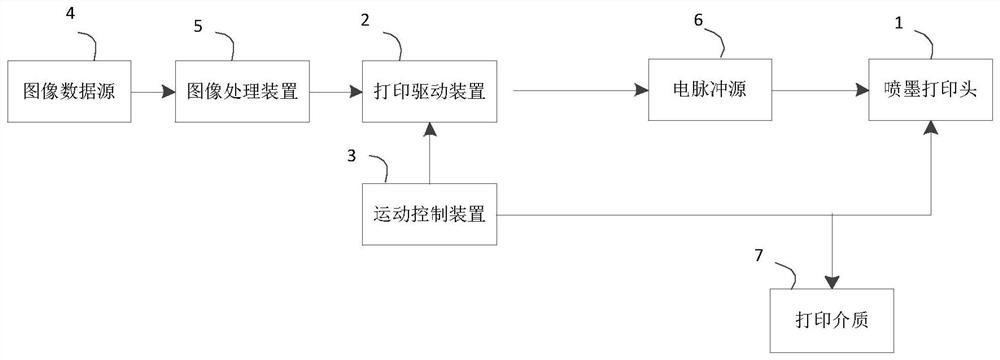

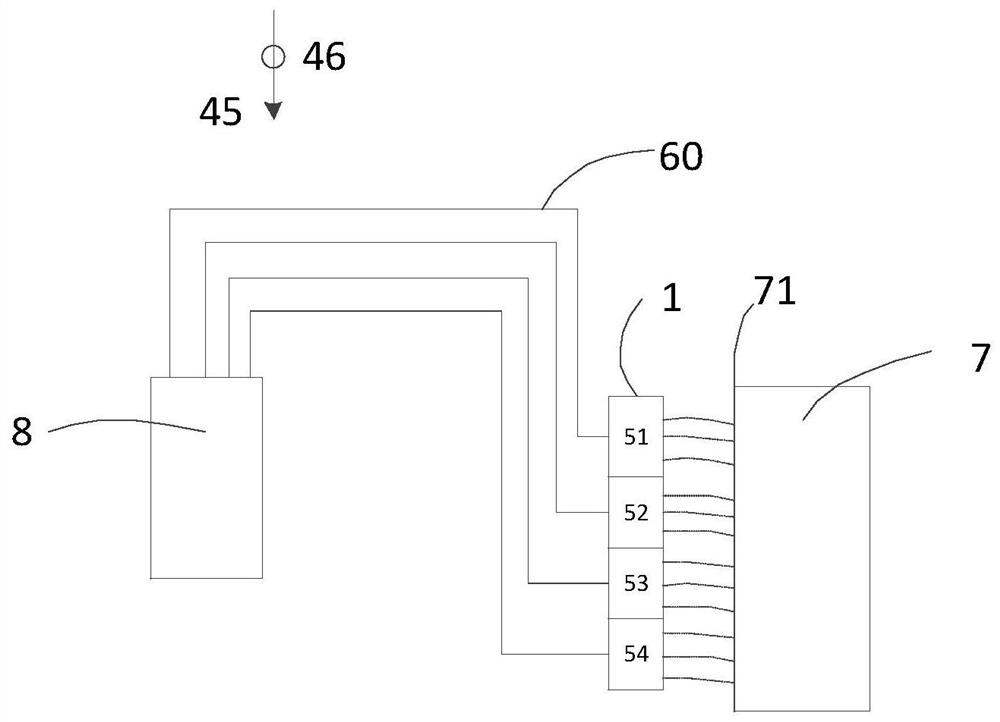

Printing device and method

The invention provides a printing device. The printing device comprises an ink box for providing ink, at least one ink jet print head, a printing medium, a printing driving device, a motion control device and an image processing device, wherein each ink jet print head at least comprises two printing units, the printing units are arranged in a first direction, and each printing unit is connected with the ink box through a channel; the printing medium is disposed opposite to the ink jet print heads; the printing driving device for controlling the ink jet printing heads to print on the printing medium; the motion control device controls relative motion of the ink jet print heads and the print medium in a horizontal direction; and the image processing device transmits image information to be printed to the print driving device. According to the printing device provided by the invention, the ink jet print heads are divided into the multiple printing units, each printing unit is independently supplied with ink, so that the pressure of the ink received by each printing unit is basically consistent, the tracks of the ink during side-jet printing are basically consistent, and the printing quality is improved.

Owner:SHANGHAI REALFAST DIGITAL TECH CO LTD

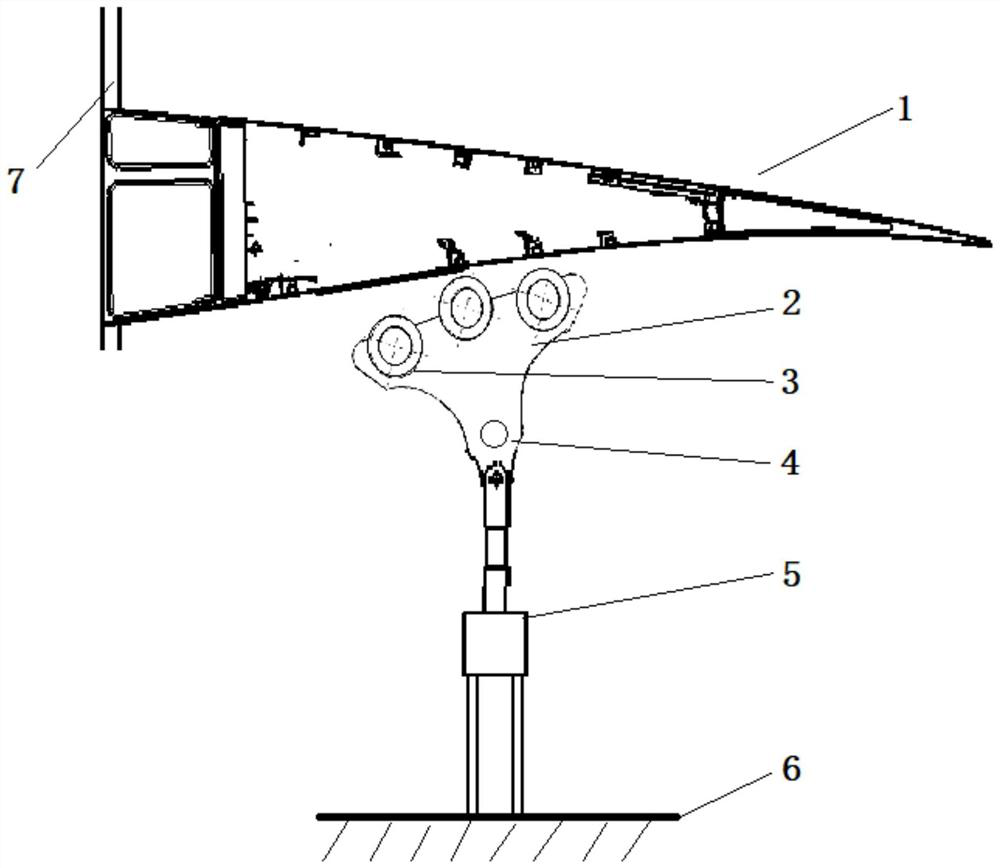

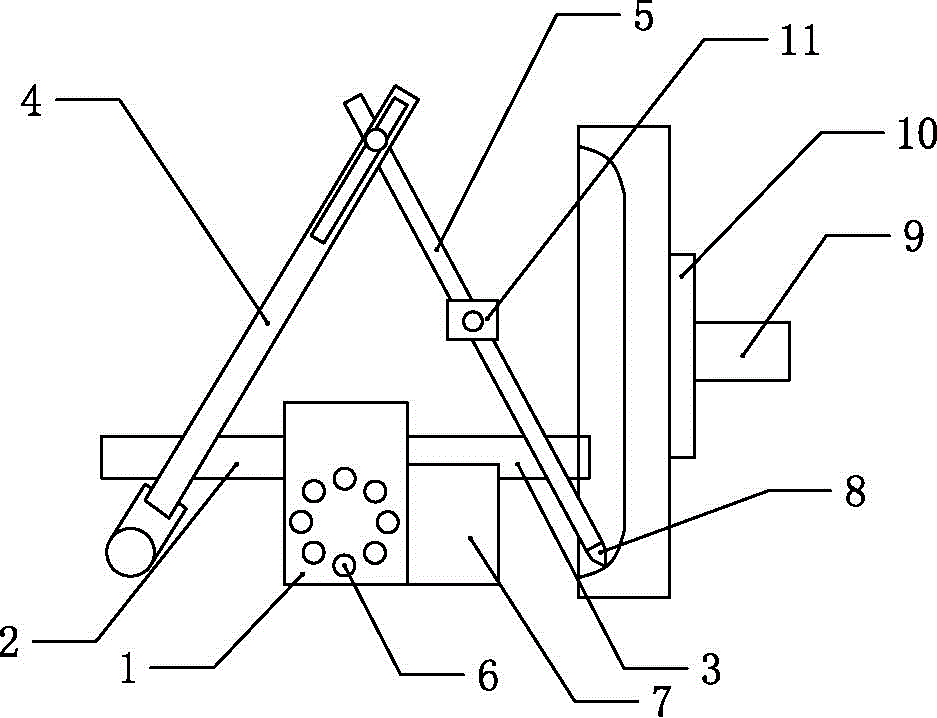

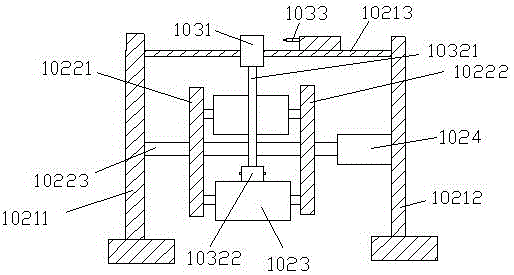

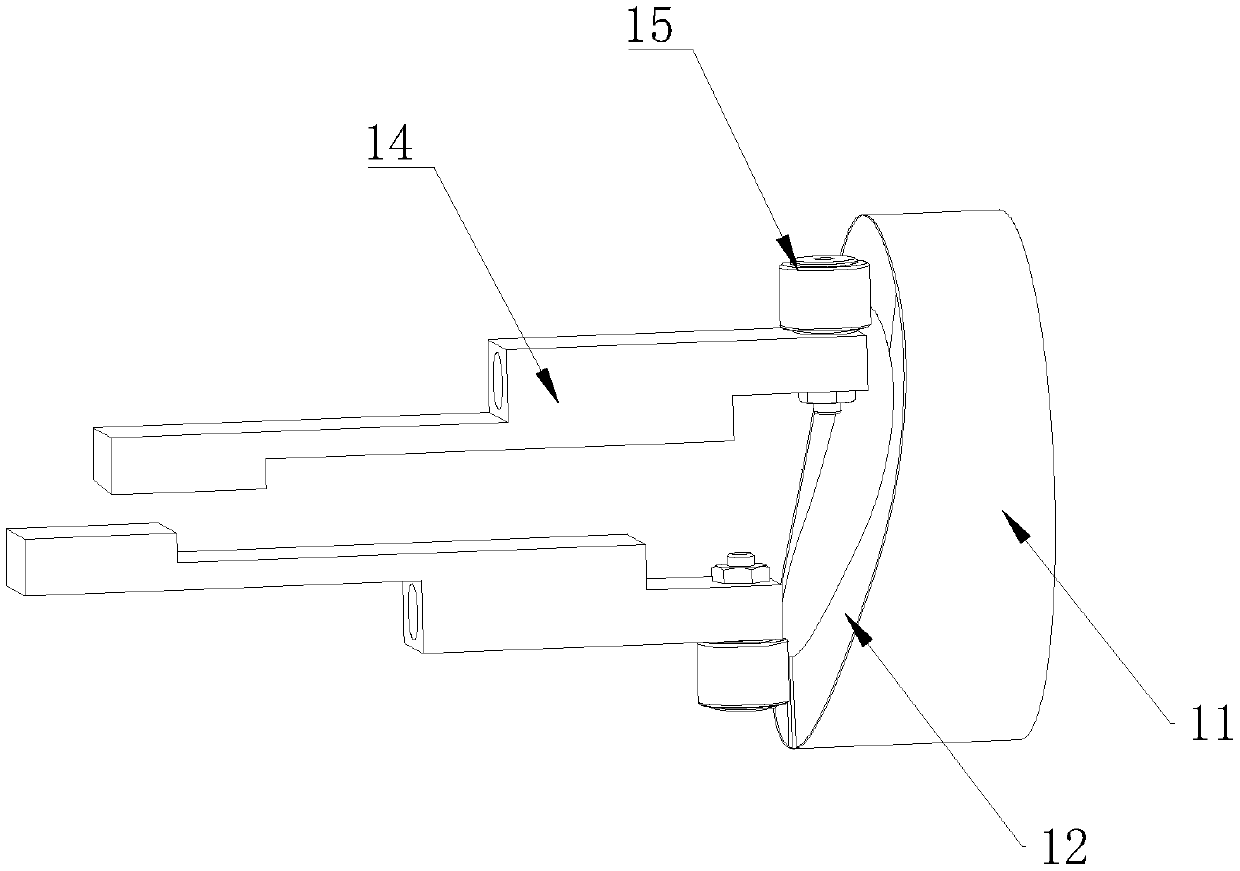

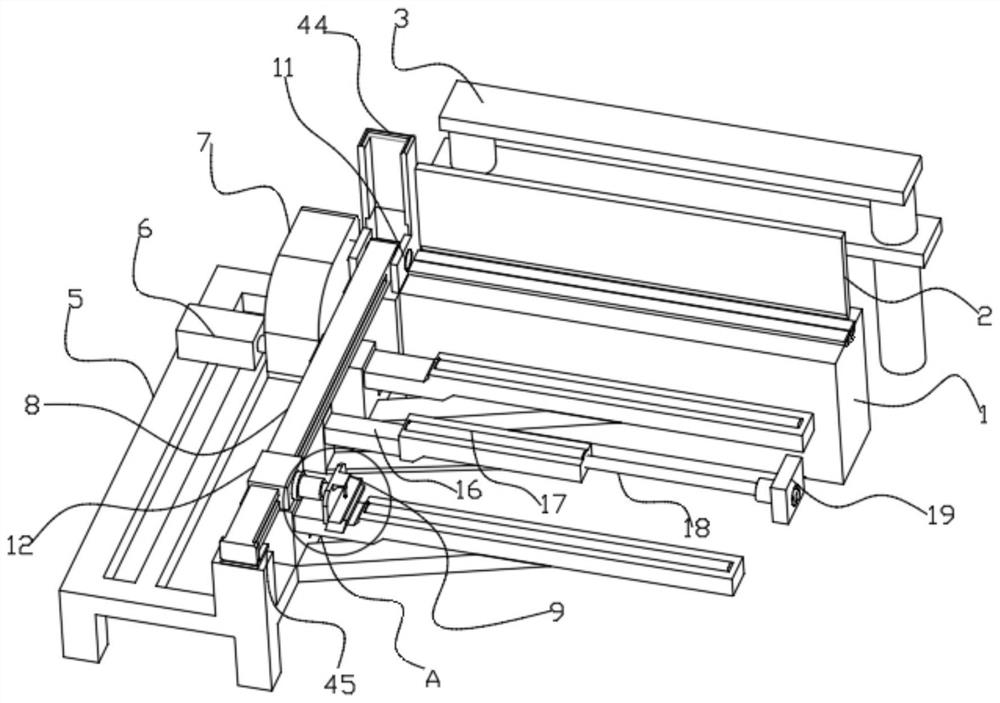

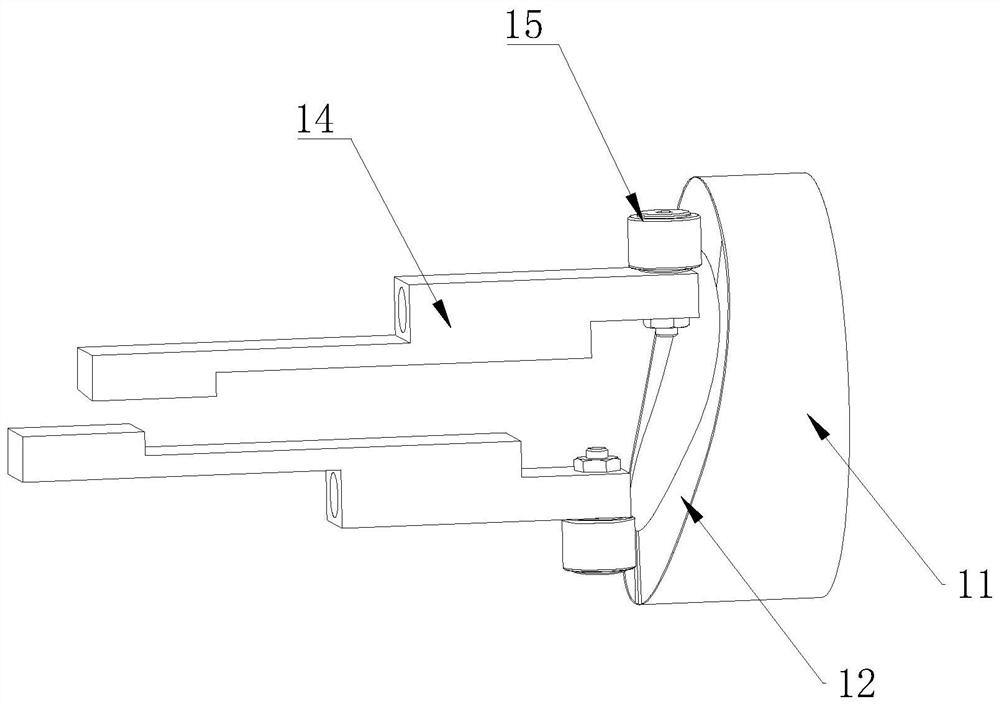

Follow-up loading device for movable airfoil of aircraft

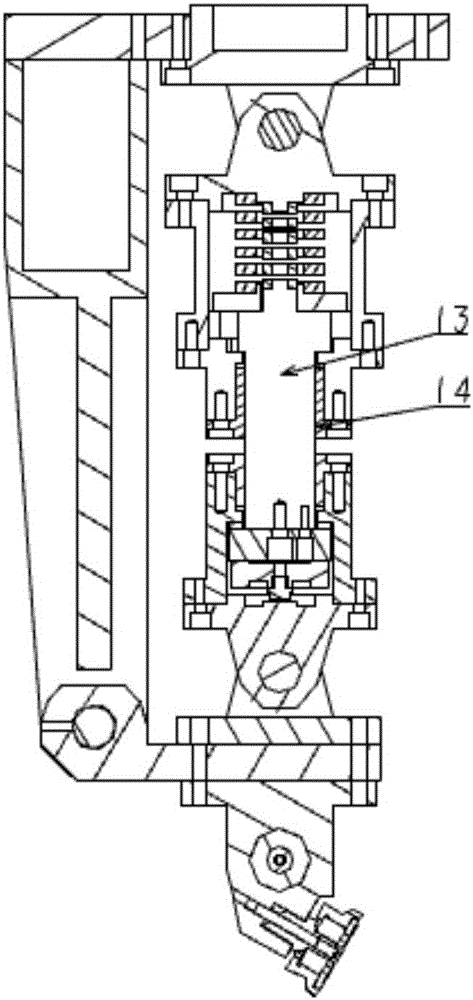

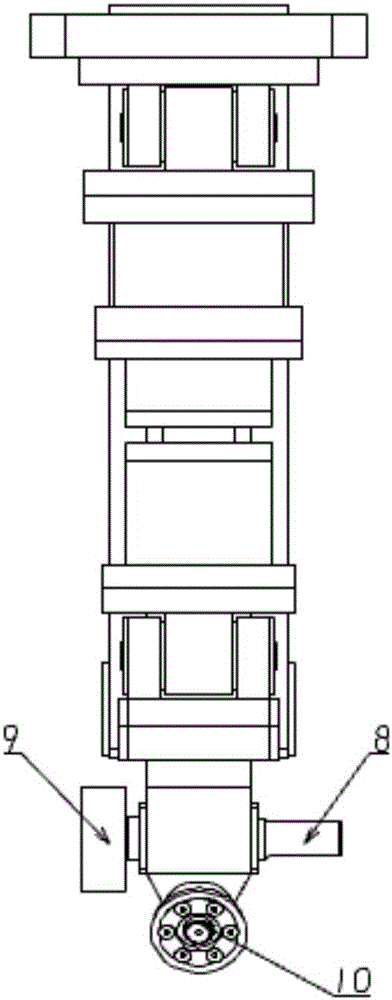

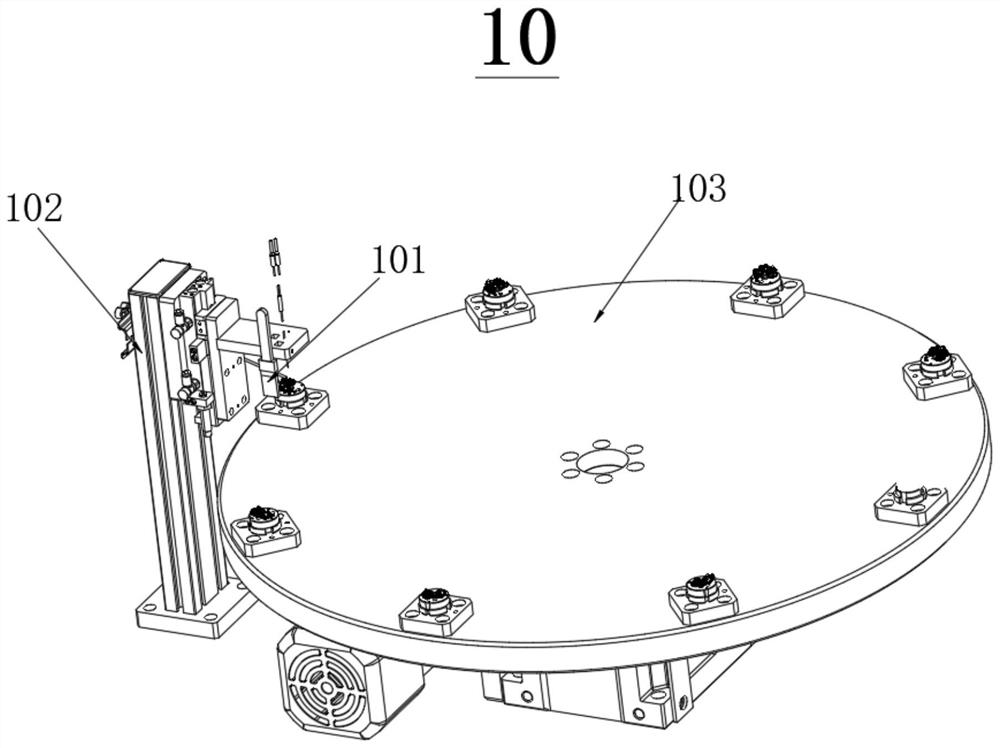

ActiveCN114509251AFollow-up loading implementationAccurately reflect loading problemsMachine part testingFlight vehicleControl system

The invention belongs to the technical field of aircraft motion mechanism tests, and particularly relates to a follow-up loading device for a movable airfoil of an aircraft, and the device comprises a test piece fixing device which is used for fixing the movable airfoil; the loading actuating cylinder is fixed on the terrace and is positioned at the bottom of the movable wing surface; the follow-up loading head is hinged with a loading rod of the loading actuating cylinder and can rotate around a hinged joint, in addition, at least three loading rollers are embedded at the top end of the follow-up loading head, and the outer wheel surfaces of the loading rollers are in linear contact with the movable wing surface; the driving device is used for driving the movable airfoil to deflect; the angle sensor is used for detecting the deflection angle of the movable airfoil in real time; and the control system is used for controlling the movable wing surface and the loading actuating cylinder. According to the follow-up loading device for the movable airfoil of the aircraft, follow-up loading of the movable airfoil movement mechanism is achieved by adjusting the self-adaptive follow-up loading head, and the loading problem of a flap and slat structure system in all flight attitudes can be accurately reflected.

Owner:CHINA AIRPLANT STRENGTH RES INST

Turning device for machining end covers with inner arcs

InactiveCN104439286AImprove stabilityEasy to operateLarge fixed membersTurning machinesEngineeringMechanical engineering

The invention discloses a turning device for machining end covers with inner arcs. The turning device comprises a tool positioning frame and a workpiece positioning frame. The tool positioning frame comprises a base, a transverse support rod, an oblique support rod and a toolbar, a group of tool fixing grooves is formed in a side surface of the base, and a slide cover is arranged on the tool fixing grooves; the transverse support rod comprises a first support rod and a second support rod, one end of the oblique support rod is obliquely slidably connected with the second support rod, the front end of the toolbar is hinged to the first support rod, and the rear end of the toolbar is detachably connected with the other end of the oblique support rod; the workpiece positioning frame comprises a fixing shaft, a positioning disc and positioning rods, the positioning disc is fixed to an end of the fixing shaft, workpieces can be connected with the inner side of the positioning disc, and a tool bit is arranged at the front end of the toolbar and can be butted to the inner walls of the workpieces. The turning device for machining the end covers with the inner arcs has the advantage that the shortcoming of poor smoothness of machined arc-shaped surfaces due to poor firmness of existing tools for machining inner arcs can be overcome by the aid of the turning device; a tool for machined arc-shaped surfaces can be firmly fixed, and the machined arc-shaped surfaces are good in smoothness.

Owner:ZUNYI JINHUI MACHINERY MFG

Passive spring roller hemming component

InactiveCN105728528ASolve the problem of hemming pressure controlSimple structureMetal working apparatusEngineeringFlange

The invention discloses a passive spring hemming assembly, which is in contact with the plate body to be hemmed of the automobile, and includes a bracket, the upper part of which is provided with a flange top cover connected with a mechanical arm, and the lower part is hinged with the bottom plate through a first hinge; a spring buffer , which is arranged between the flange top cover and the bottom plate; a cylinder, which is arranged between the spring buffer and the bottom plate, and the upper part of the cylinder is connected with the lower part of the spring buffer , the cylinder has an inner space for accommodating the guide rod, the upper end of the guide rod is in conflict with the spring buffer; the first rolling body is arranged on the lower part of the bottom plate, and the first rolling body includes multiple rollers of different shapes. The invention has the advantages of stable rolling force, simple debugging, low cost and the like.

Owner:WUHAN DEBAO EQUIP CO LTD

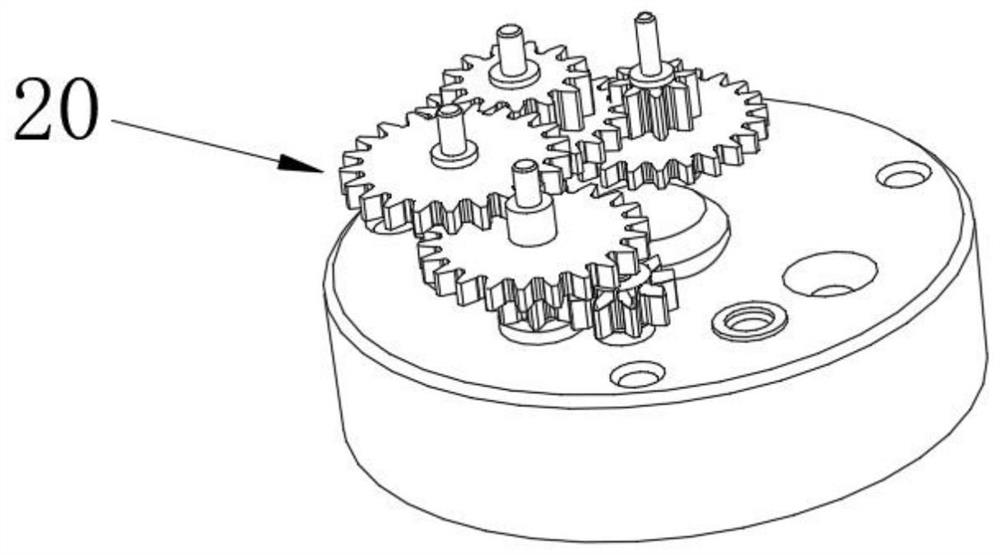

Gear set meshing detection auxiliary device for intelligent production of electromechanical valve of gas meter

PendingCN113639994AEnsure contact and contact positionGuaranteed accuracyMachine part testingPhysicsGear tooth

The invention discloses a gear set meshing detection auxiliary device for intelligent production of an electromechanical valve of a gas meter, and the device is characterized in that a self-resetting deformation part is arranged on a transmission gear set conveying track, and is used for making contact with a conveyed transmission gear set for deformation; and gears in the gearbox gear set are driven to rotate and mesh based on friction force generated by contact of the two and / or self-resetting deformation force generated by deformation of the self-resetting deformation piece. The self-resetting deformation piece makes contact with the gearbox gear set in the conveying process and then makes contact with the gearbox gear set in the conveying process to deform, and the self-resetting deformation piece and the gearbox gear set generate contact friction force and resetting deformation force; and the gears in the gearbox gear set can be driven to generate slight actions such as shaking, floating, fluctuating or rotating based on the friction force and / or the deformation force, when the gears which are not meshed or not completely meshed conduct the actions, mutual tooth grooves and gear teeth are meshed more easily, and then auxiliary meshing in the gearbox gear set is achieved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

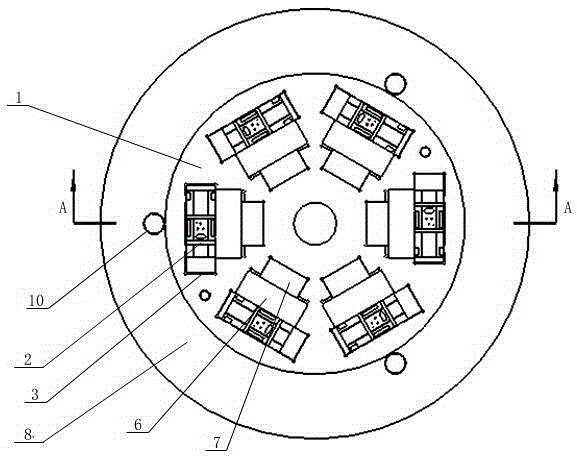

Slide valve grinding clamp used for disc grinder and clamping method for slide valves

The invention discloses a slide valve grinding clamp used for a disc grinder and a clamping method for slide valves. The slide valve grinding clamp comprises a slide valve clamping disc. A plurality of clamping cavities used for clamping the slide valves are arranged on the slide valve clamping disc. The slide valves are arranged in the corresponding clamping cavities and pressed tightly on and fixed to the slide valve clamping disc through a pressing mechanism. The multiple slide valves form an integral structure after being clamped on the slide valve clamping disc. The surfaces to be ground of the multiple slide valves are located on the same horizontal plane. The slide valve grinding clamp clamping the multiple slide valves is arranged on a grinding disc of the disc grinder, the surfaces to be ground of the slide valves are in contact with the grinding disc, and a gap exists between the slide valve clamping disc and the grinding disc. After the slide valves are clamped through the slide valve grinding clamp, the clamp can be effectively prevented from being in contact with the grinding disc, displacement of the slide valves in the self-rotation process of the clamp is eliminated, and meanwhile the grinding efficiency can be improved.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Inner chamber testing fixture for gear chamber of flywheel housing of engine

InactiveCN105277361AQuality assuranceReduce work intensityMachine gearing/transmission testingInterference problemEngineering

The invention provides an inner chamber testing fixture for a gear chamber of a flywheel housing of an engine. The inner chamber testing fixture includes a frame-shaped body, wherein the frame-shaped body is corresponding to the outer contour of a gear chamber of a flywheel housing of an engine; a positioning pin 1 and a positioning pin 2 are arranged at the lower position on two sides of the frame-shaped body; the positioning pin 1 and the positioning pin 2 are corresponding to positioning mounting holes of the flywheel housing of an engine; the frame-shaped body is corresponding to the motion trail of a gear 1, the motion trail of a gear 2, the motion trail of a gear 3 and the motion trail of a gear 4 and are provided with a detection plate 1, a detection plate 2, a detection plate 3 and a detection plate 4 downwards; and a rotation handle 1, a rotation handle 2, a rotation handle 3 and a rotation handle 4 are arranged on the frame-shaped body and are corresponding to the detection plate 1, the detection plate 2, the detection plate 3 and the detection plate 4 so that the detection plate 1, the detection plate 2, the detection plate 3 and the detection plate 4 can move along the motion trails of the gear 1, the gear 2, the gear 3 and the gear 4. The inner chamber testing fixture for a gear chamber of a flywheel housing of an engine can detect the inner chamber interference problem of a gear chamber of a flywheel housing of an engine through the simulation effect of the motion trails.

Owner:东实汽车动力零部件(湖北)有限公司

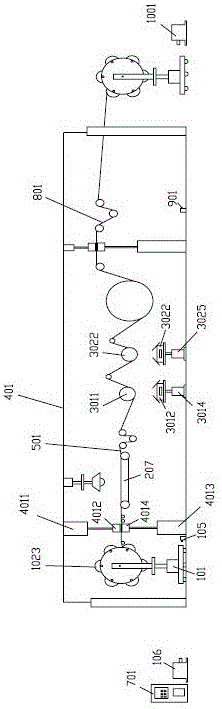

Feeding mechanism for metallized film processing

InactiveCN106244997AHigh degree of automationEasy refillVacuum evaporation coatingSputtering coatingEngineeringProximity sensing

The invention discloses a feeding mechanism for metallized film processing. The feeding mechanism comprises a first ascending and descending mechanism and a feeding device, wherein the telescopic end of the first ascending and descending mechanism is matched with the feeding device and is used for driving the feeding device to vertically move; a first proximity sensing mechanism comprises a first baffle plate and a first contact element; one end, with a higher position, in the first baffle plate sleeves a fixed transverse rod arranged at the upper end of a first support frame in a rotationally matching way; one end, with a lower position, in the first baffle plate is connected with the end, with the higher position, in the first contact element; one end, with the lower position, in the first contact element can be in contact with the outermost layer of an insulation film of a feeding roller in a feeding state; the first proximity switch is arranged on the fixed transverse rod relative to the baffle plate. The feeding mechanism has the advantages that the automation degree is high; the material supplementation is convenient and timely.

Owner:铜陵市铜创电子科技有限公司

Thread-patching device for clothes

Provided is a thread-patching device for clothes. The device comprises a base. The left side at the top of the base is equipped with a column. The right side of the middle position of the column is fixedly provided with a horizontal square framework. Four inside edges of the square framework are all fixedly equipped with first guide rails, on which first sliding blocks are installed. The first sliding blocks are fixedly provided with transverse first telescopic rods. Two adjacent first telescopic rods are mutually vertical to each other. A vertical rod is arranged in the middle of the square framework. The inner end of each first telescopic rod is fixedly connected with the side part of the vertical rod. The upper part of the vertical rod is provided with a transverse board. The left end of the transverse board is fixedly connected with the side part of the column. The top surface of the transverse board is equipped with multiple hemispherical grooves distributed in a matrix. The thread-patching device for clothes has the traditional function of patching threads for clothes. Additionally, a user can tap into his design potential and draw patterns he wants on the clothes. Through the device, a small-sized electric sewing machine is controlled to go between threads along patterns drawn by the user. As a result, self-designed patterns can be sewn on cloth of the clothes. The thread-patching device for clothes is simple in structure and low in cost.

Owner:重庆天天牛服饰有限公司

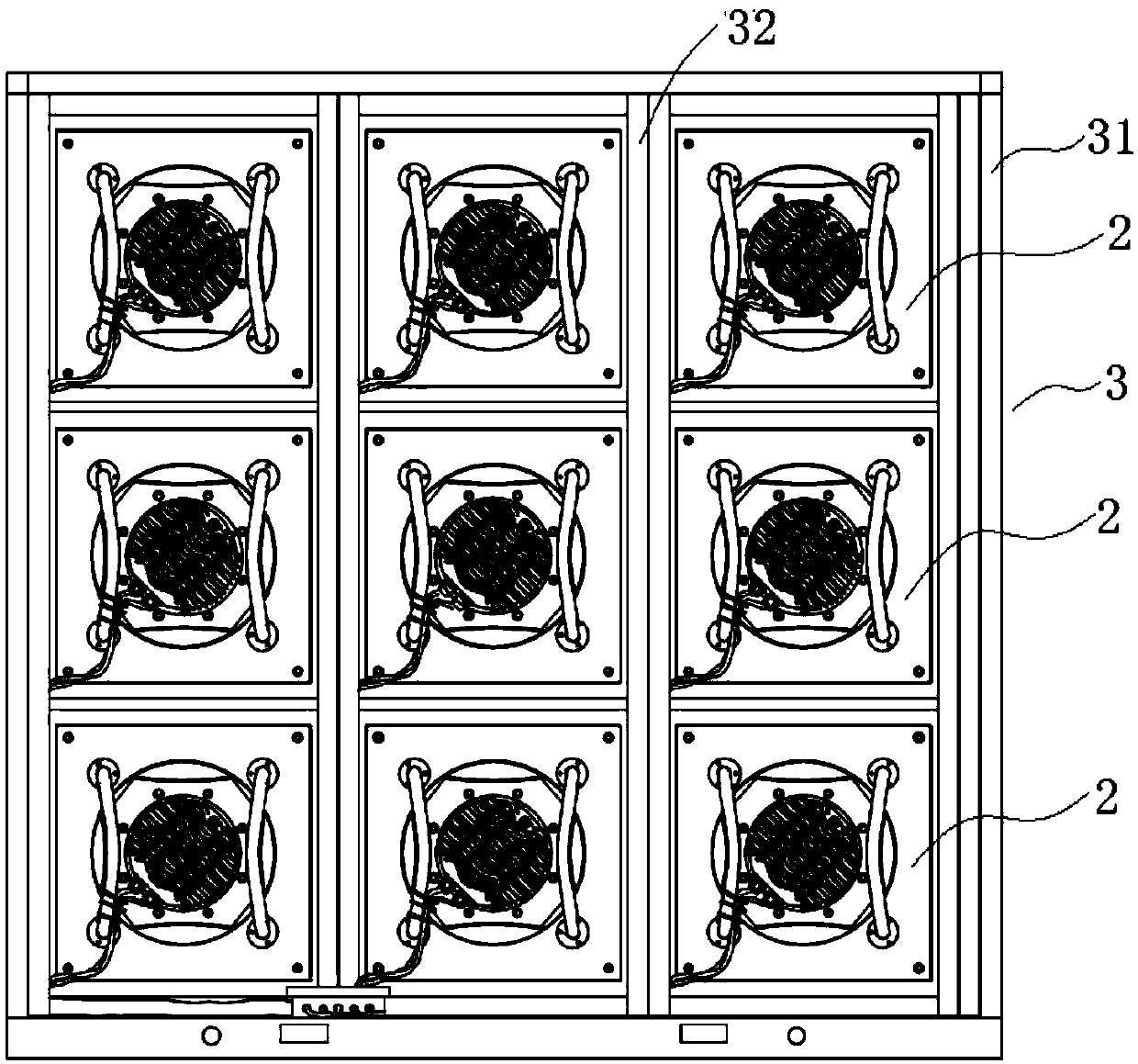

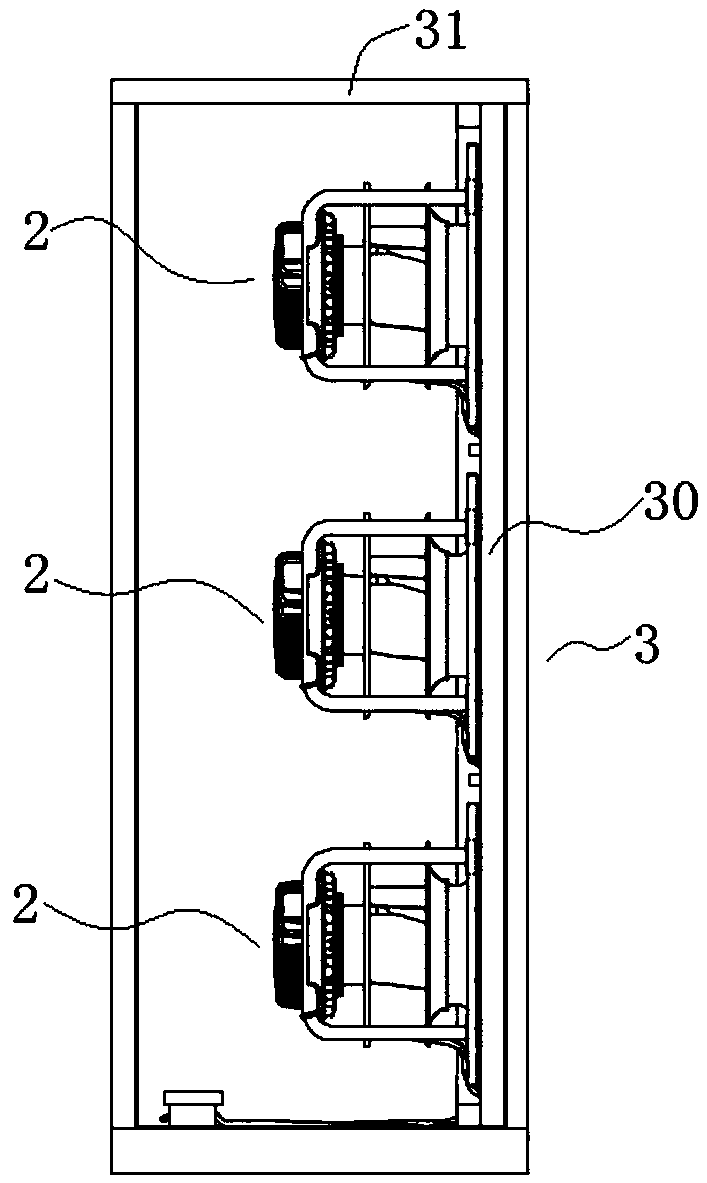

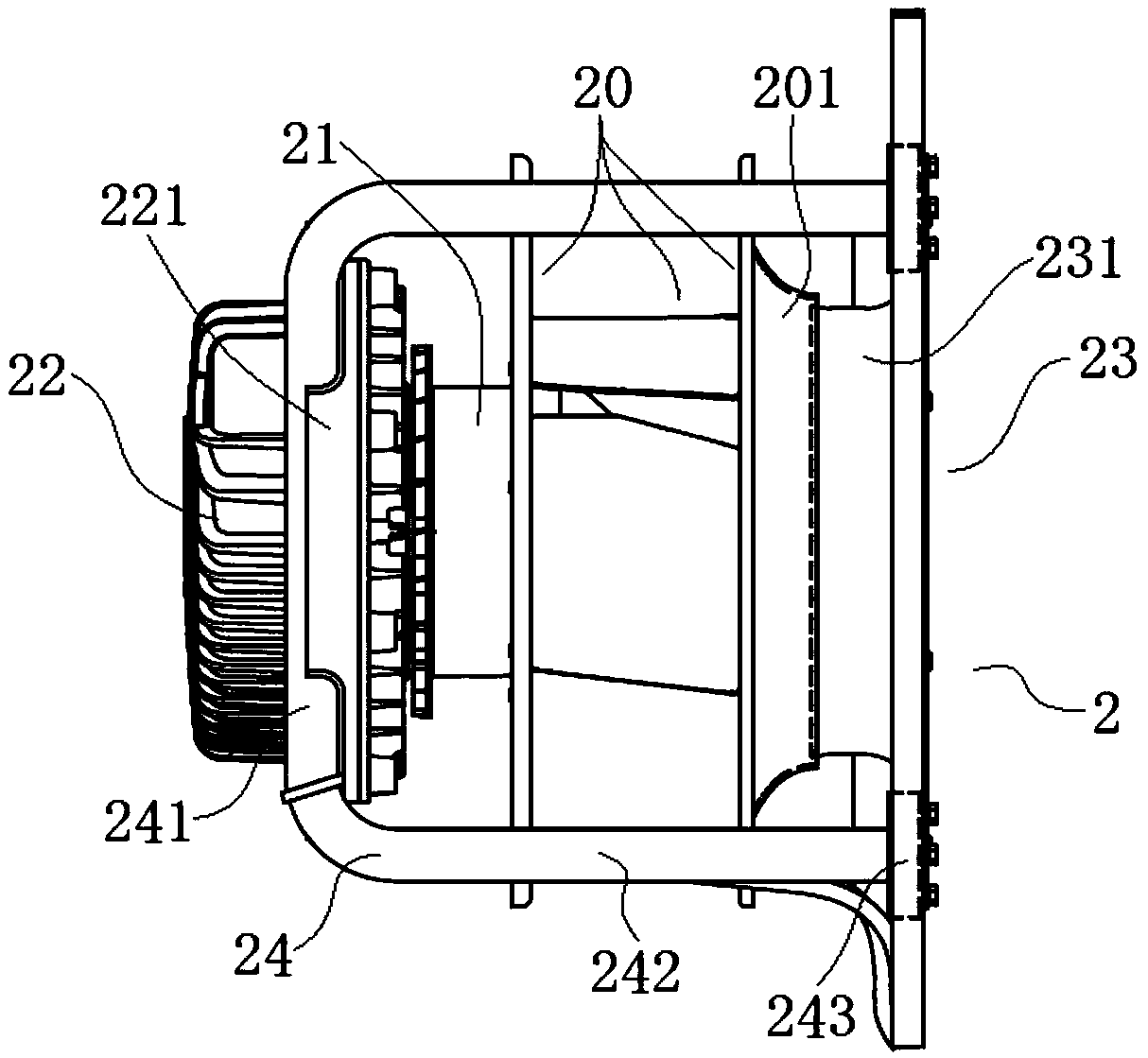

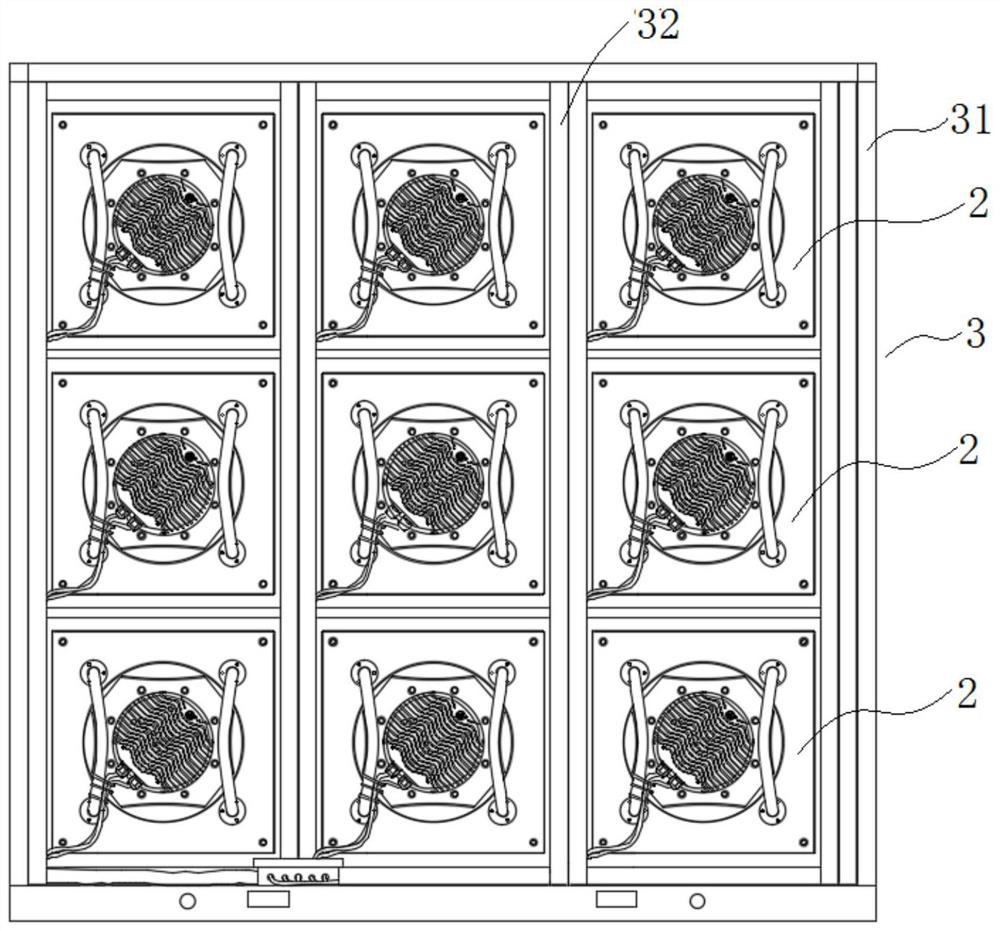

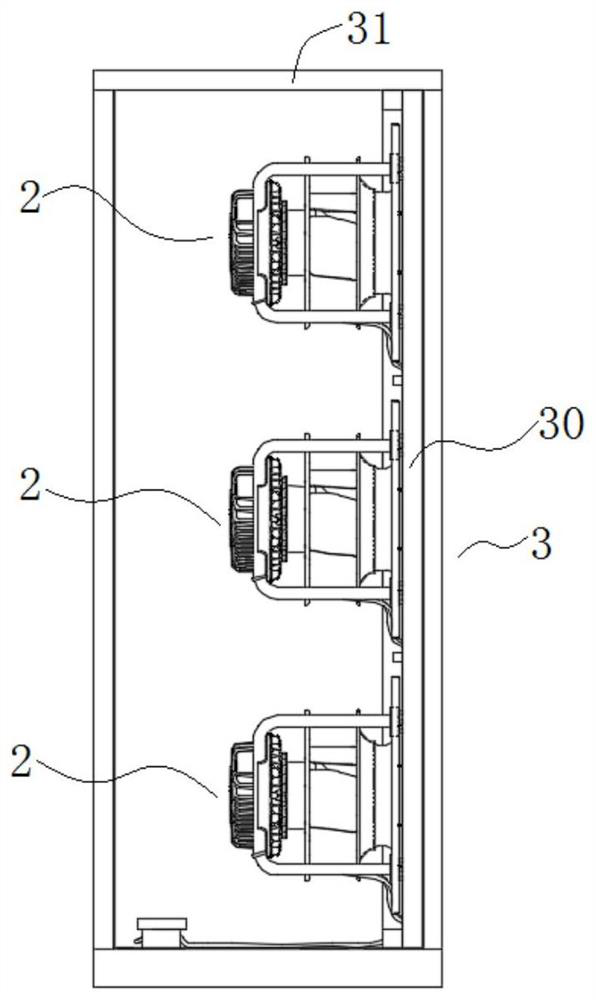

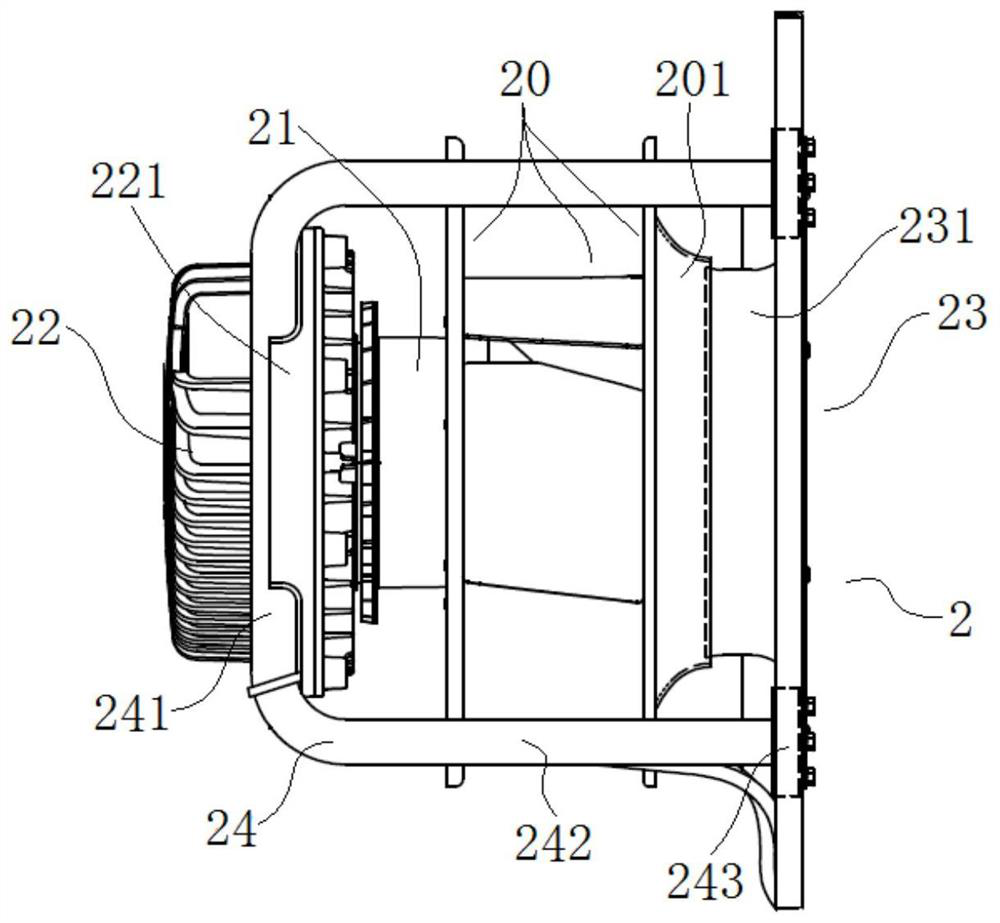

Control method of fan wall and fan wall

ActiveCN109630447AReduce mutual interferenceStable speedEngine controlPump controlAir volumeEngineering

The invention provides a control method of a fan wall. The control method comprises the following steps that S1, a main engine is controlled to collect the air pressure of an air opening of any fan through an air pressure sensor, the air pressure is compared with barometric pressure, and a first pressure difference delta P1 is equal to P<air opening>-P<barometric pressure>; S2, the main engine iscontrolled to obtain a second pressure difference delta P2 equal to (Q / (n*k)^2), wherein Q is the set fan air volume, n is the number of the fans of the fan wall, and k is the fan attribute coefficients; and S3, the main engine is controlled to adjust the air openings P by controlling the rotating speed of the fans, the rotating speed of all the fans is consistent, and the condition that delta P1-delta P2 is kept. According to the control method, the fans are controlled in a control manner of controlling the torque, all the fans stably operate together, and interference between the fans is reduced.

Owner:ZHEJIANG MINGZHEN ELECTRIC&ELECTRONICS CO LTD +1

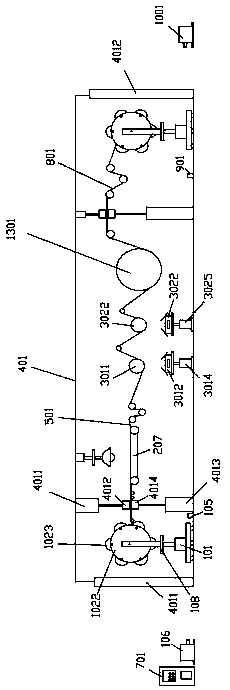

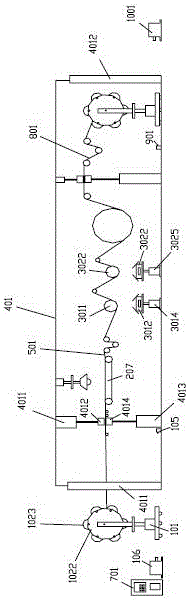

A metallized film vacuum coating machine

InactiveCN106222627BHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention discloses a metallized film vacuum coating machine. The metallized film vacuum coating machine comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism. The feeding mechanism, the coating mechanism and the winding mechanism are arranged in the vacuum chamber. The feeding mechanism comprises a first lifting mechanism and a feeding device. A preheating mechanism is arranged between the feeding mechanism and the coating mechanism. A first movable plate assembly adjusting the size of an opening of a first evaporator boat is arranged in the top opening area of the first evaporator boat. A second movable plate assembly adjusting the size of an opening of a second evaporator boat is arranged in the top opening area of the second evaporator boat. A film clamping device is arranged between the feeding mechanism and the coating mechanism. A film clamping device is arranged between the coating mechanism and the winding mechanism. The winding mechanism comprises a fifth lifting mechanism and a winding device. The telescopic end of the fifth lifting mechanism is matched with the winding device and used for driving the winding device to move up and down. The metallized film vacuum coating machine has the advantages that the automation degree is high, material supplementary / material receiving is convenient and in time, preheating is uniform, preheating quantity is adjustable, the metallized film vacuum coating machine is suitable for machining of various models of films, and the coating thickness is adjustable.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Intelligent chair with knee joint healthcare function

InactiveCN111012093AConsistent trajectoryChiropractic devicesStoolsPhysical medicine and rehabilitationEngineering

The invention discloses an intelligent chair with a knee joint healthcare function. According to the technical scheme, the chair comprises chair legs, a chair surface and a chair back, wherein a supporting frame is arranged below the chair surface, a power device is arranged on the supporting frame, two movable plates used for supporting shanks are movably arranged on the front portion of the chair surface, and the power device is connected with a linkage mechanism capable of driving the two movable plates to move forward and backward in a crossed mode. According to the scheme provided by theinvention, a driving mechanism is driven by the power device arranged below the chair surface; the driving mechanism can drive the two movable plates to move forward and backward in a crossed manner;the two movable plates respectively correspond to two shanks of a user; the movable plates are driven by the driving mechanism to enable the shanks to make postures when a person walks, the shanks andthe knee joints do not have any load, force does not need to be exerted, a healthcare function on the knee joints is achieved, and the healthcare effect especially for older people or people after long-time exercise is good.

Owner:袁一烜

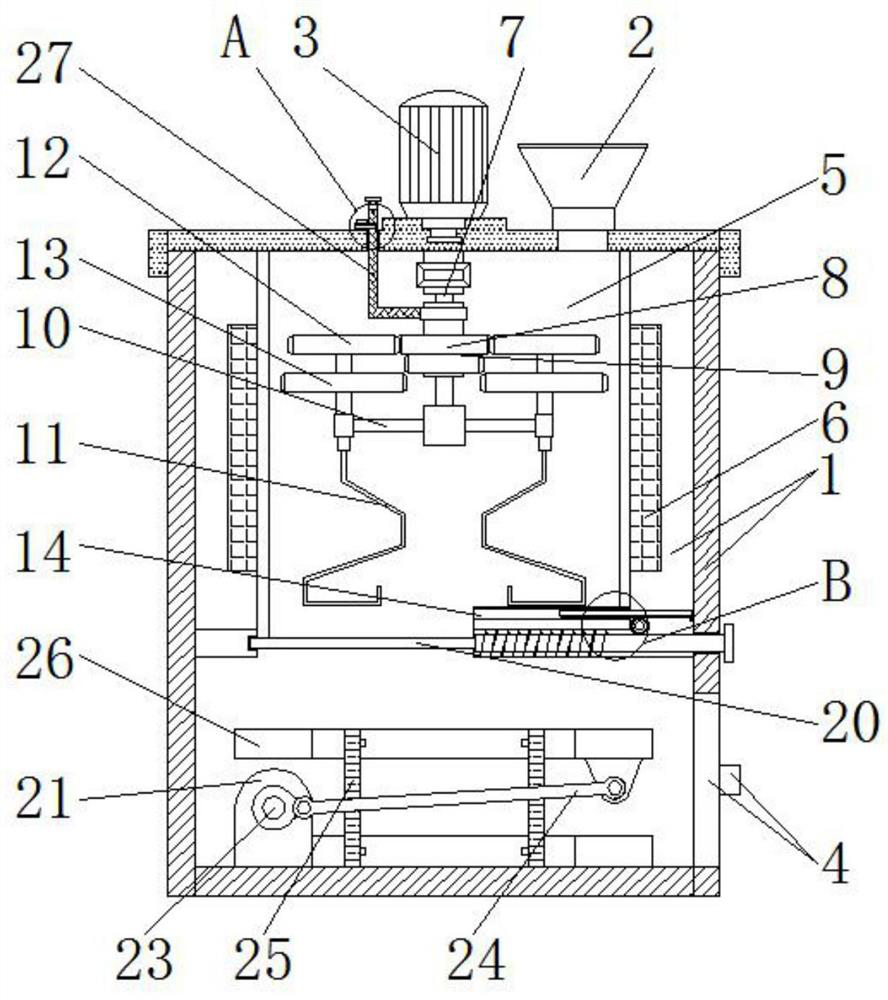

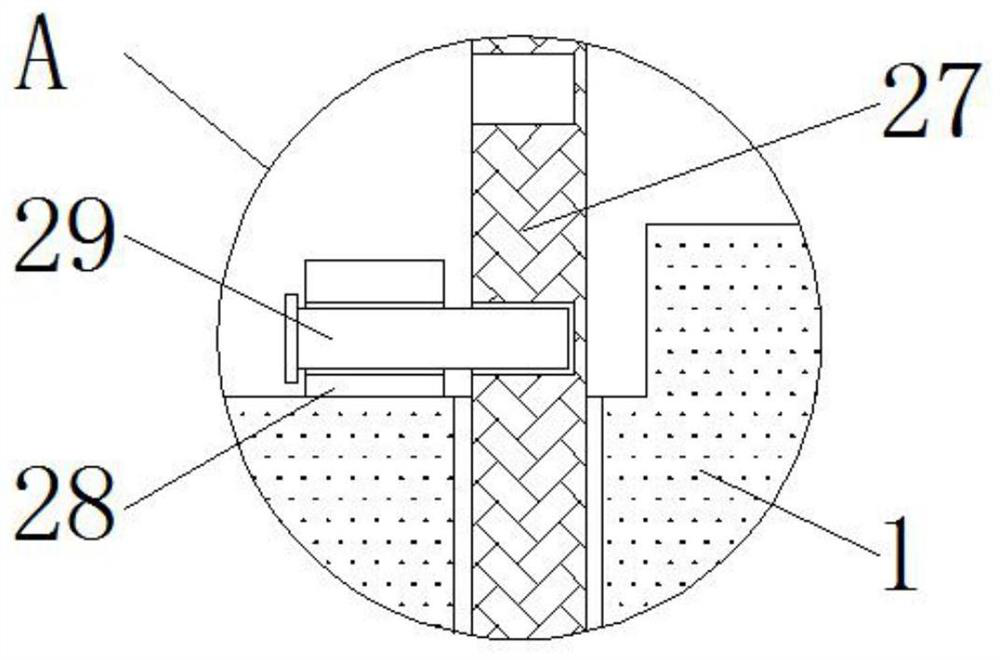

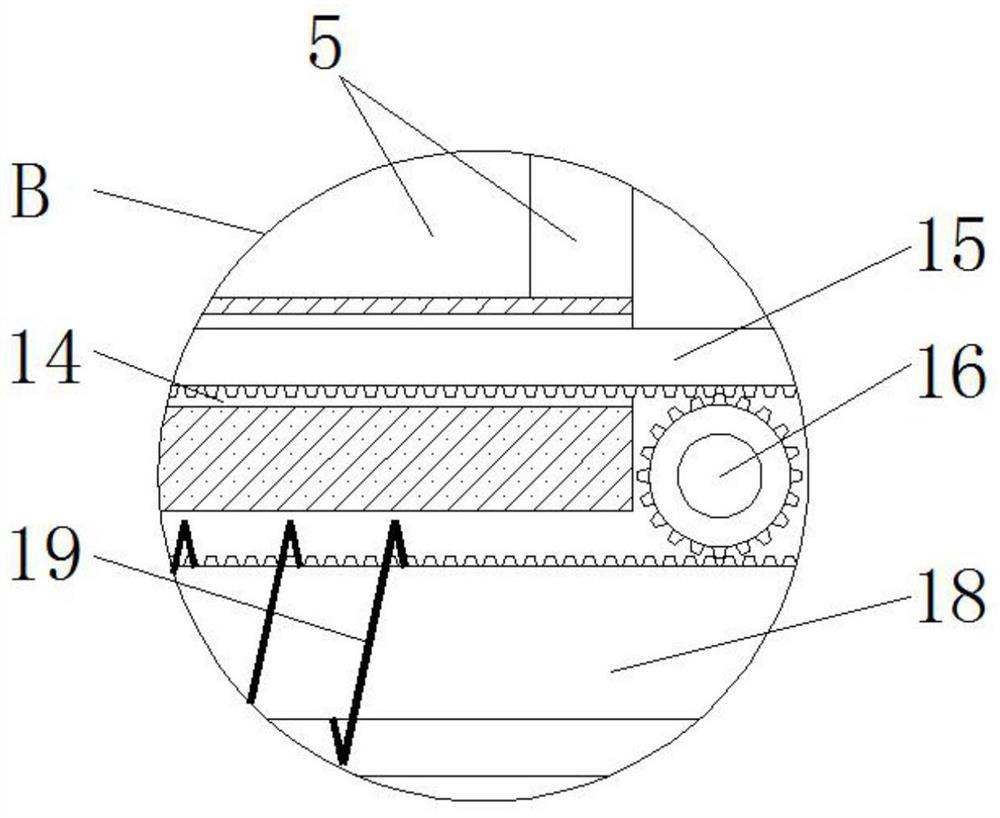

Fixation equipment convenient to screening for Huangkui tea processing

PendingCN112273448AImprove the quality of finishingEasy to filterSievingPre-extraction tea treatmentDrive motorEngineering

The invention discloses fixation equipment convenient to screening for Huangkui tea processing. The equipment comprises a device main body, a driving motor and a double-head motor, a blanking openingis fixedly connected to the upper surface of the device main body, the driving motor is fixedly mounted on the upper surface of the device main body, a discharging opening is formed in one side of thelower end of the device main body, a heating barrel and a material collecting block are installed in the device body, meanwhile, the upper end of the heating barrel is connected with the upper end ofthe device main body, the lower end of the driving motor is connected with an output shaft, and the outer surface of the output shaft is connected with a first connecting gear and a second connectinggear in a sleeved mode. According to the fixation equipment convenient to screening for Huangkui tea processing, a connecting block drives a connecting shaft to rotate, then the connecting shaft drives a screen to move, the connecting block is fixedly connected with the connecting shaft, the length of the screen is equal to that of the material collecting block, screen holes are distributed in the screen at equal intervals, and the screen conveniently screens the Huangkui tea through swinging.

Owner:安徽宏云制茶有限公司

Metallized film vacuum coating machine

InactiveCN106222627AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEngineeringVacuum chamber

The invention discloses a metallized film vacuum coating machine. The metallized film vacuum coating machine comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism. The feeding mechanism, the coating mechanism and the winding mechanism are arranged in the vacuum chamber. The feeding mechanism comprises a first lifting mechanism and a feeding device. A preheating mechanism is arranged between the feeding mechanism and the coating mechanism. A first movable plate assembly adjusting the size of an opening of a first evaporator boat is arranged in the top opening area of the first evaporator boat. A second movable plate assembly adjusting the size of an opening of a second evaporator boat is arranged in the top opening area of the second evaporator boat. A film clamping device is arranged between the feeding mechanism and the coating mechanism. A film clamping device is arranged between the coating mechanism and the winding mechanism. The winding mechanism comprises a fifth lifting mechanism and a winding device. The telescopic end of the fifth lifting mechanism is matched with the winding device and used for driving the winding device to move up and down. The metallized film vacuum coating machine has the advantages that the automation degree is high, material supplementary / material receiving is convenient and in time, preheating is uniform, preheating quantity is adjustable, the metallized film vacuum coating machine is suitable for machining of various models of films, and the coating thickness is adjustable.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

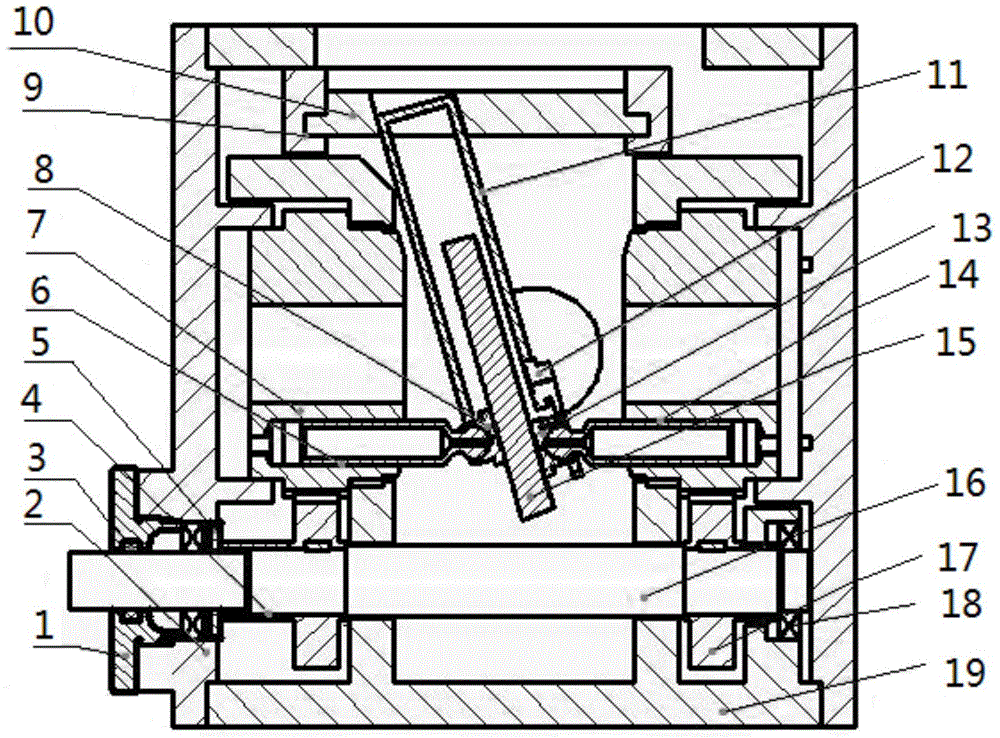

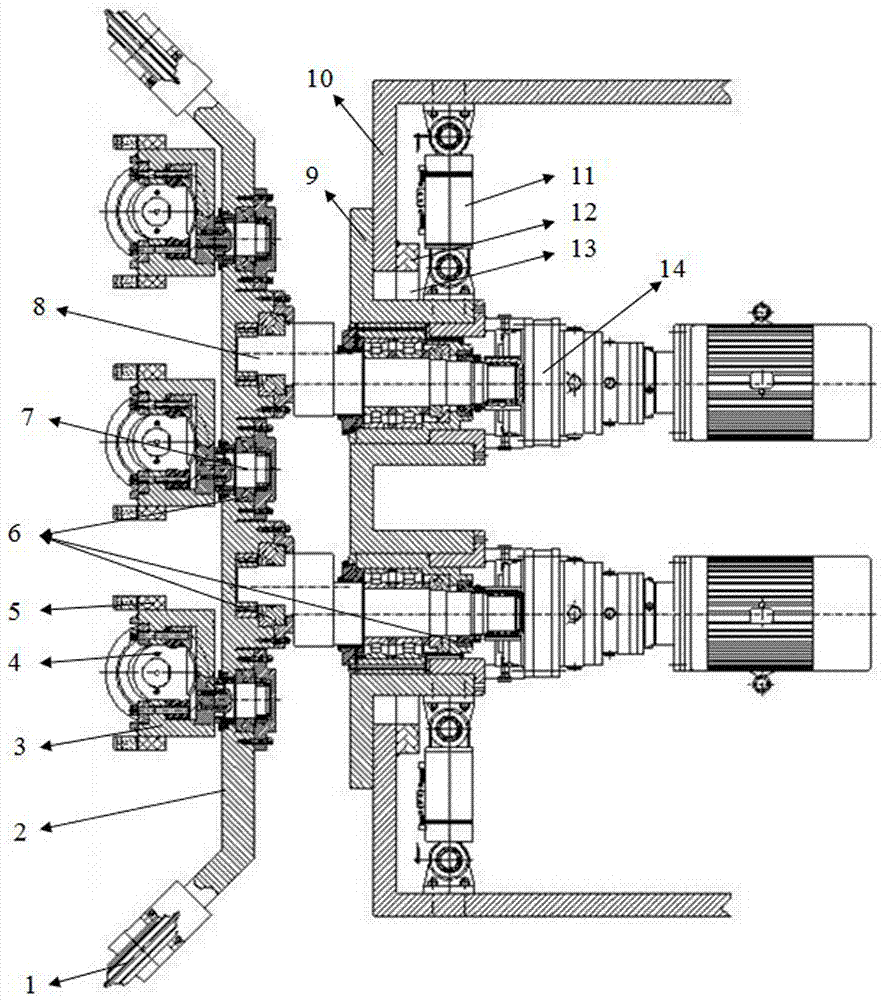

Displacement sensor follower mechanism for testing the thickness of the oil film on the auxiliary shoe

ActiveCN104197879BConsistent trajectoryThe installation position does not changeMeasurement devicesContinuous measurementCylinder block

The follower mechanism of the displacement sensor for testing the thickness of the oil film on the pair of slide shoes includes a housing and an end cover of the housing. The main shaft is set in the housing through bearings. The main shaft is equipped with a pinion for input power, a left gear and a right gear for output power. ;The plunger hole of the cylinder body is provided with a test plunger and a return spring; the axis lines of the test plunger and the auxiliary test plunger are on the same straight line, and the test slide shoe and the auxiliary test slide shoe are respectively attached to the two sides of the swash plate ; The swash plate is installed on the housing through a semicircular bearing; the support frame is slidably installed in the chute on the vertically slidable sliding bracket, and the support frame is sleeved on the outside of the swash plate; the sensor Both the mounting plate and the auxiliary test shoe are fixed to the support frame. The invention can continuously measure the thickness of the auxiliary oil film of the sliding shoe under the condition of simulating the real motion state of the sliding shoe of the swash plate type axial plunger pump.

Owner:ZHEJIANG UNIV

A method for controlling a fan wall and the fan wall

ActiveCN109630447BConsistent trajectoryReduce mutual interferenceEngine controlPump controlAir volumeControl manner

The invention provides a method for controlling a fan wall, which includes the following steps: S1. The control host collects the wind pressure at the tuyere of any fan through a wind pressure sensor, and compares it with the atmospheric pressure to obtain the first pressure difference ΔP1=P 风口 -P 大气压 ; S2, the control host obtains the second pressure difference ΔP2=(Q / (n×k))^2 through calculation, wherein Q is the air volume of the fan set, n is the number of fans in the fan wall, and k is the attribute coefficient of the fan itself; S3 , The control host adjusts P by controlling the fan speed 风口 , so that all fan speeds are consistent and maintain ΔP1 = ΔP2. The control method of the present invention controls the fan by controlling the torque, so that all the fans can run stably together, and the mutual interference among the fans is reduced.

Owner:ZHEJIANG MINGZHEN ELECTRIC&ELECTRONICS CO LTD +1

An automatic clamping bending die

ActiveCN111530992BConsistent trajectoryAvoid skewMetal-working feeding devicesPositioning devicesReducerIndustrial engineering

Owner:台州市森博五金有限公司

Intelligent chair with knee joint health care function

PendingCN113662384AConsistent trajectoryStoolsAdjustable chairsPhysical medicine and rehabilitationEngineering

The invention discloses an intelligent chair with a knee joint health care function. The chair comprises chair legs, a chair face and a chair back, wherein a supporting frame is arranged below the chair face, a power device is arranged on the supporting frame, two movable plates used for supporting the shanks are movably arranged on the front portion of the chair face, and the power device is connected with a linkage mechanism capable of driving the two movable plates to move front and back in a crossed mode. According to the intelligent chair, a driving mechanism is driven by the power device arranged below the chair surface, the driving mechanism can drive the two movable plates to crosswise move back and forth, the two movable plates respectively correspond to the two shanks of a user, and the movable plates can make the shanks make a posture when the user walks under the driving of the driving mechanism; however, the shanks and the knee joints do not have any load and do not need to exert force, the health care effect can be achieved on the knee joints, and particularly the health care effect is very good when the knee joints are used for health care after long-term exercise.

Owner:袁道有

An Eccentric Hob Translating Cutter for Rectangular Cutting Section of Hard Rock

ActiveCN106285709BSolve the problem of blind excavationConsistent trajectoryTunnelsBlind zoneEngineering

The invention provides an eccentric hob horizontal-moving cutterhead used for a hard rock rectangular cutting section. The application of an eccentric multi-shaft hob cutterhead in the prior art to hard rock stratums is achieved. The eccentric hob horizontal-moving cutterhead comprises a cutterhead body, hobs and a driving system. The cutterhead body is driven by the driving system and is a spoke type rectangular cutterhead body; the hobs comprise positive hobs which are mounted on positive hob holders, and the positive hob holders are connected with hob holder rotating shafts into a whole in a fastened mode through bolts; and the hob holder rotating shafts are connected to the cutterhead body through bearings, and the center of each hob holder and the center of the corresponding hob holder rotating shaft are eccentric. The eccentric hob horizontal-moving cutterhead is driven by multiple eccentric driving shafts to make horizontal-connecting-rod movement, and thus the abrasion loss of the hobs is not affected by mounting positions; the positive hobs are eccentrically arranged and have the characteristics that the hobs can horizontally move along with the cutterhead and automatically rotate, and the problem that excavation dead zones exist when hobs and other crushing type tools are used for excavation in an eccentric multi-shaft movement mode is solved; and the cutterhead can conduct excavation in a multi-cutterhead combined mode, and can adapt to special-shaped excavated faces with different sizes.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com